Phosphor and method of producing phosphor

A manufacturing method and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of insufficient moisture resistance, and achieve the effect of excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

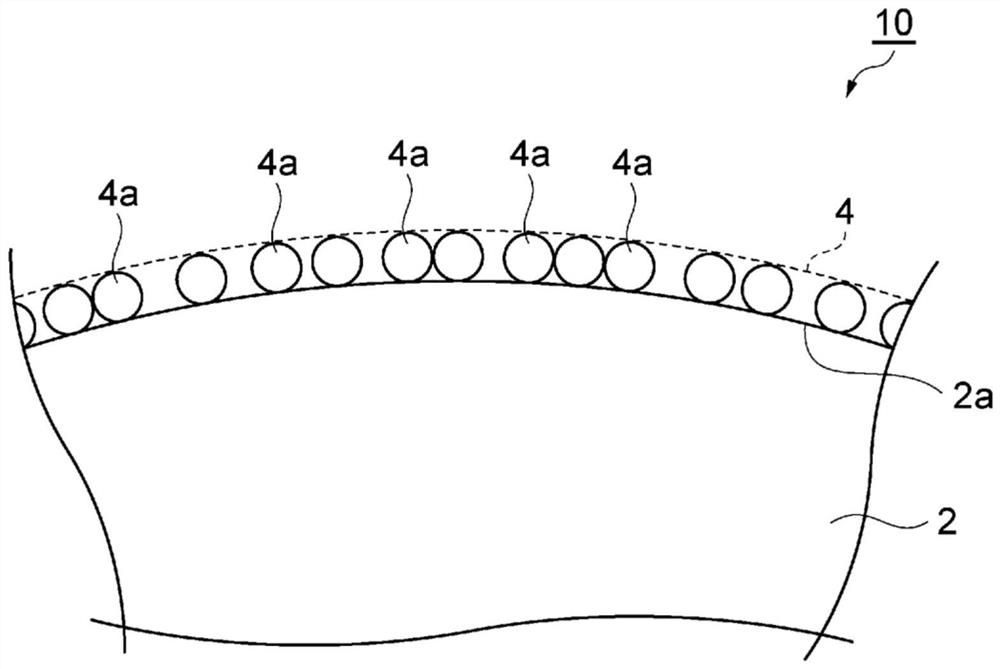

Method used

Image

Examples

Embodiment 1

[0056] [KMF(K 2 MnF 6 ) preparation]

[0057] Weigh 800 mL of hydrofluoric acid (concentration: 40% by mass) in a fluororesin beaker with a capacity of 2000 mL, and dissolve 260.00 g of potassium hydrogen fluoride powder (manufactured by Kanto Chemical Co., Ltd.) and 12.00 g of potassium permanganate powder ( Kanto Chemical Co., Ltd.), thereby preparing a hydrofluoric acid aqueous solution. While stirring the obtained hydrofluoric acid aqueous solution with a magnetic stirrer, 8 mL of a hydrogen peroxide solution (concentration: 30% by mass, manufactured by Kanto Chemical Co., Ltd.) was added dropwise. When the dropwise amount of the hydrogen peroxide solution exceeded a certain amount, yellow powder started to precipitate, and it was confirmed that the color of the solution in the beaker changed from purple.

[0058] Stir the solution for a while after the solution changes color, then stop stirring to allow the precipitated powder to settle. After the powder was precipita...

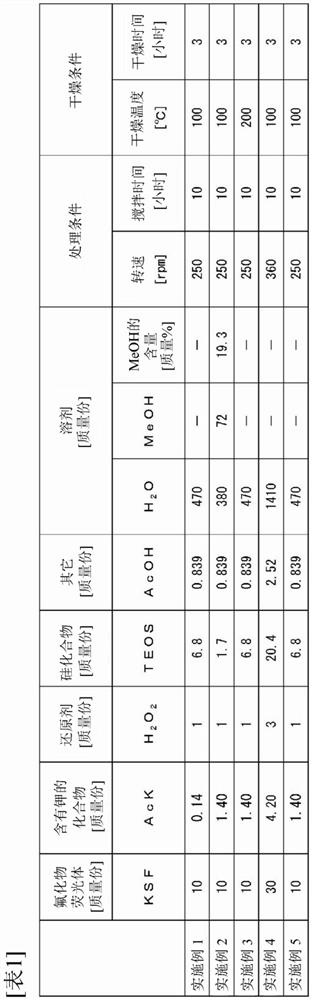

Embodiment 2~5

[0066] Phosphors were obtained in the same manner as in Example 1, except that the compounding ratio of each component, processing conditions, and drying conditions were changed as shown in Table 1.

[0067]

[0068]

[0069] For the phosphors prepared in Examples 1 to 5, surface composition analysis and quantum efficiency were evaluated by X-ray photoelectron spectroscopy as described later. In addition, the same evaluation was performed on KSF prepared in Example 1 before being treated with a solution containing a potassium-containing compound, a manganese reducing agent, and a silicon compound (hereinafter referred to as Comparative Example 1). The results are shown in Table 2.

[0070] [Surface Composition Analysis of Phosphor Surface by X-ray Photoelectron Spectroscopy]

[0071] Using an X-ray photoelectron spectrometer (manufactured by Thermo Fischer Scientific Inc., trade name: K-Alpha system), the ratio of elements present on the surface was measured for each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com