Pressure-sensitive adhesive film for laser beam cutting applications

A pressure-sensitive adhesive, pressure-sensitive adhesive layer technology, applied in film/sheet adhesives, applications, laser welding equipment, etc., can solve problems such as laser cutting without processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

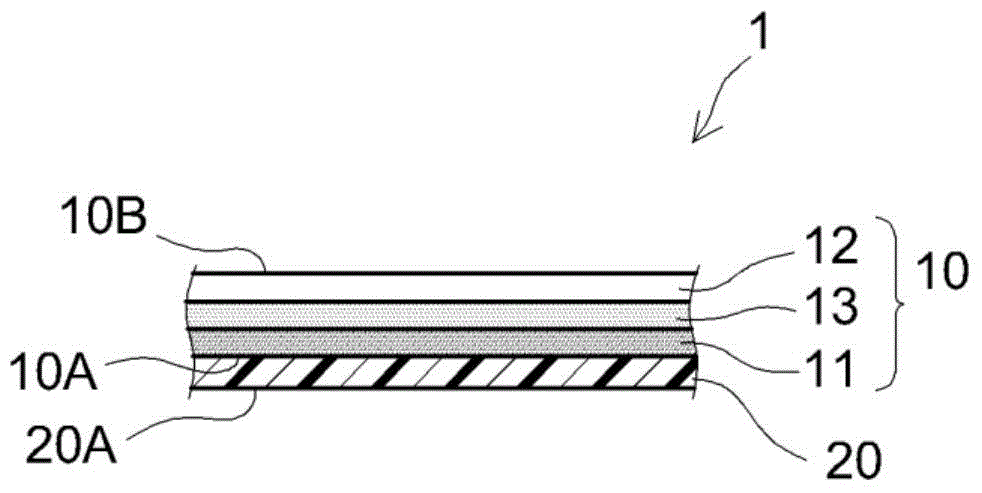

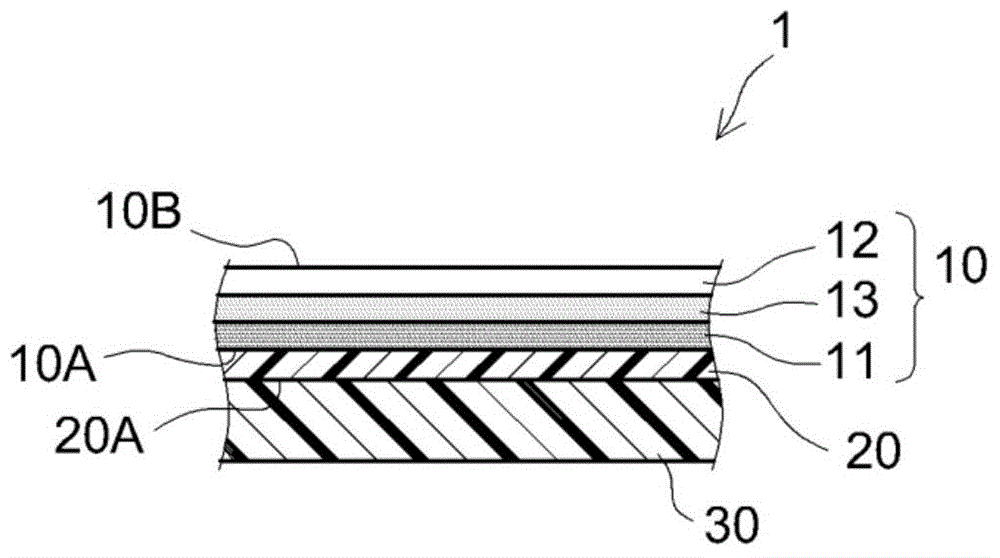

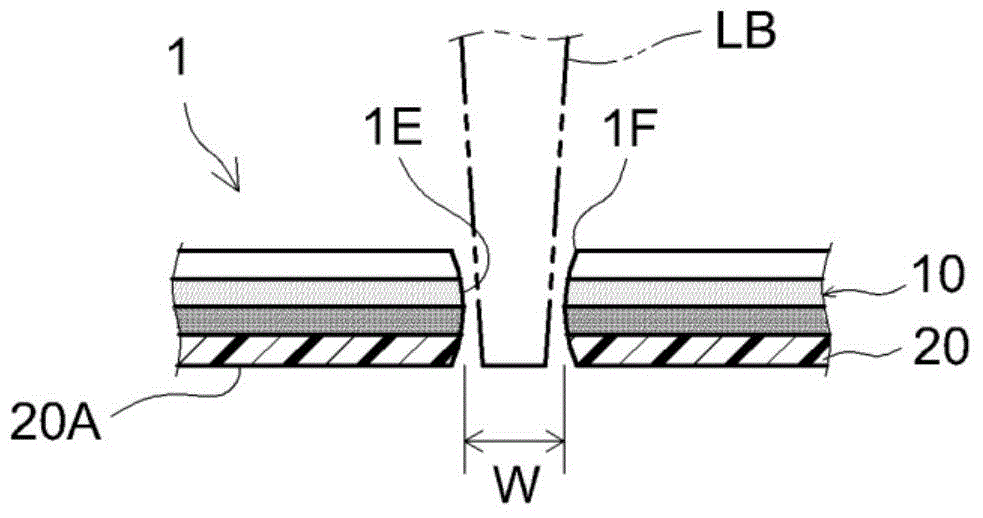

[0062] Make the following with figure 1 A PSA film 1 of the same configuration is shown. Specifically, the materials shown in Table 1 were coextruded at a die temperature of 165° C. using a 3-layer coextrusion film blower (inflation method) to produce a three-layer resin film 10 having a total thickness of 75 μm. Table 1 shows the respective compositions and thicknesses of the first layer 12 , the second layer 13 , and the third layer 11 constituting the resin film 10 .

[0063] The abbreviations found in Tables 1 and 2 are explained as follows:

[0064] PO: polyolefin

[0065] PE: Polyethylene

[0066] WHA: made of 60% by weight of titanium dioxide (TiO 2 ) and polyolefin (PO) carrier material white masterbatch

[0067] ABSA: Absorbent masterbatch comprising the commercially available absorbent material BASFLumogen IR1050 and a polyolefin (PO) carrier material.

[0068] ABSB: Absorbent masterbatch comprising commercially available absorbent material LMPE6550 (Polyone) a...

Embodiment 2

[0077] A resin film according to Example 2 was fabricated in the same manner as in Example 1, except that the composition was changed as shown in Table 1 to increase the content of polyolefin while reducing the amount of absorbent material ABSA. Using the produced resin film, an entirely white PSA film according to Example 2 was obtained in the same manner as in Example 1.

Embodiment 3 and 4

[0079] Resin films according to Examples 3 and 4 were produced in the same manner as in Example 1 except that the thickness of the film layer was changed as shown in Table 1. Using these produced resin films, PSA films which were all white according to Examples 3 and 4 were obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com