Multi-hole forming machine for section tube and using method thereof

A special-shaped pipe and hole forming machine technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of large clamping project, unfavorable pipe clamping, and low efficiency, and achieve good hole quality and convenient Replacement, the effect that the operation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

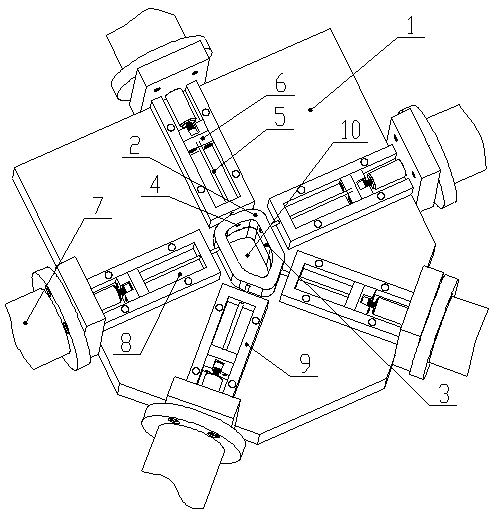

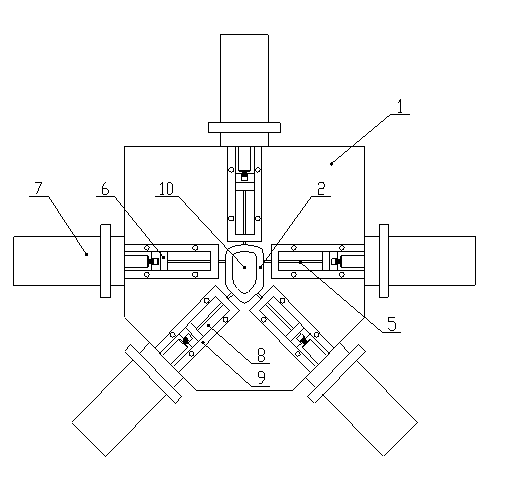

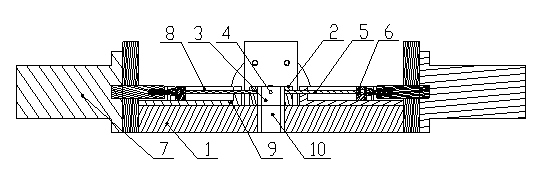

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

[0015] Referring to the legend, a special-shaped tube multi-hole forming machine, including a working platform 1, is characterized in that: the middle part of the working platform is provided with a raised part 2 for close cooperation with the inner peripheral wall of the special-shaped tube, so that the special-shaped tube can be erected stably on the On the working platform; the middle part of the raised part is provided with a hollow part 3 so that the surrounding wall thickness of the raised part is equal; A punch 5 for forming a hole is arranged on the outer peripheral side of the through hole on the axis of the through hole.

[0016] The punch is connected with the air cylinder or hydraulic cylinder 7 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com