Patents

Literature

108results about How to "Keep closed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

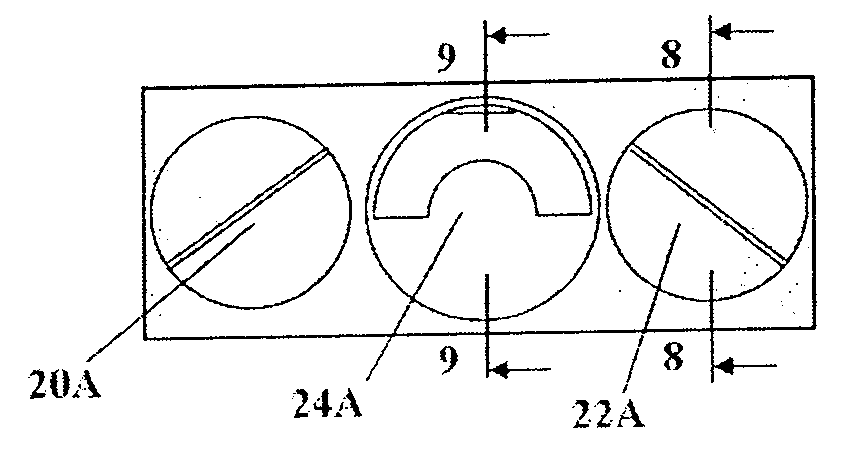

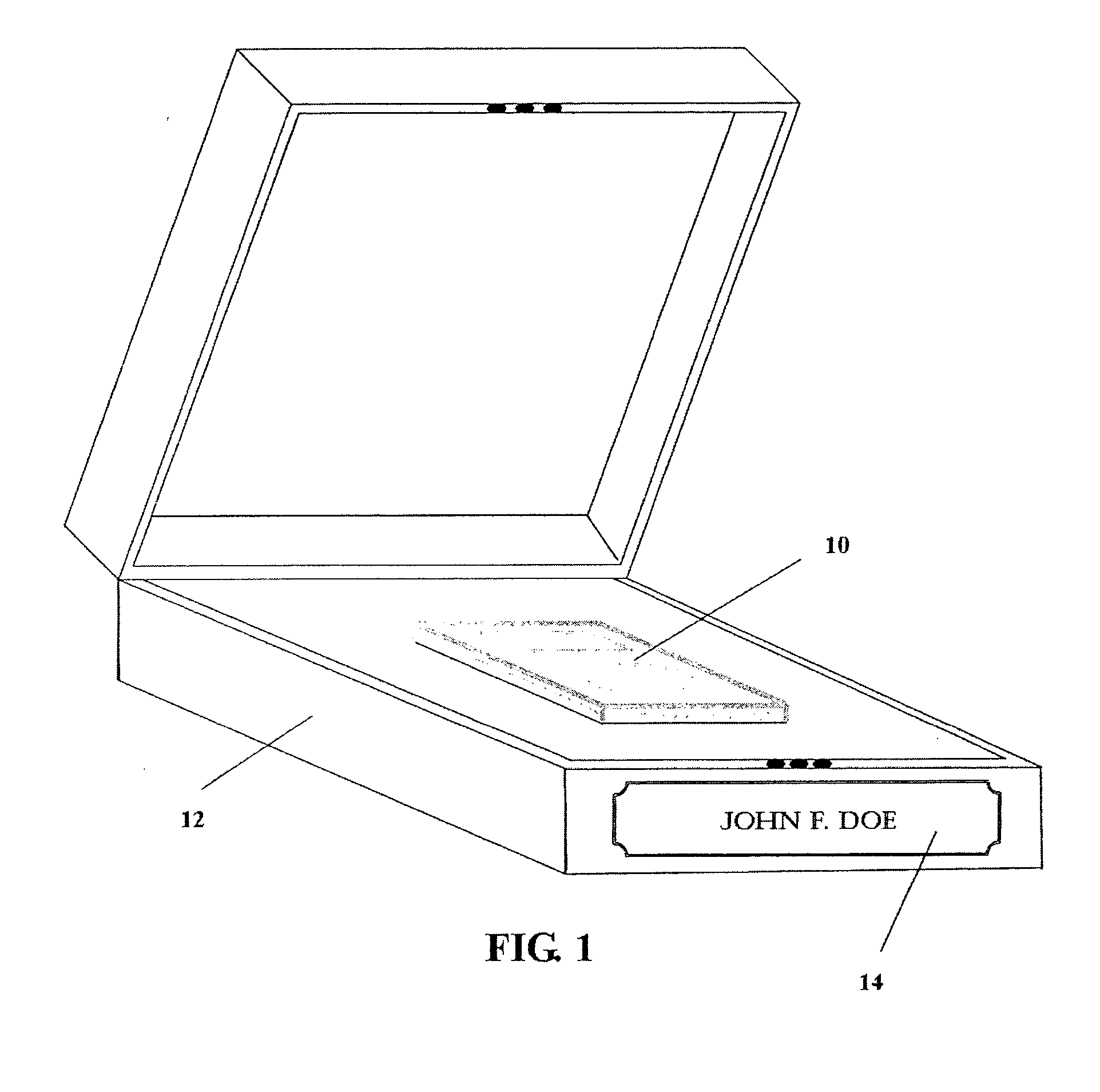

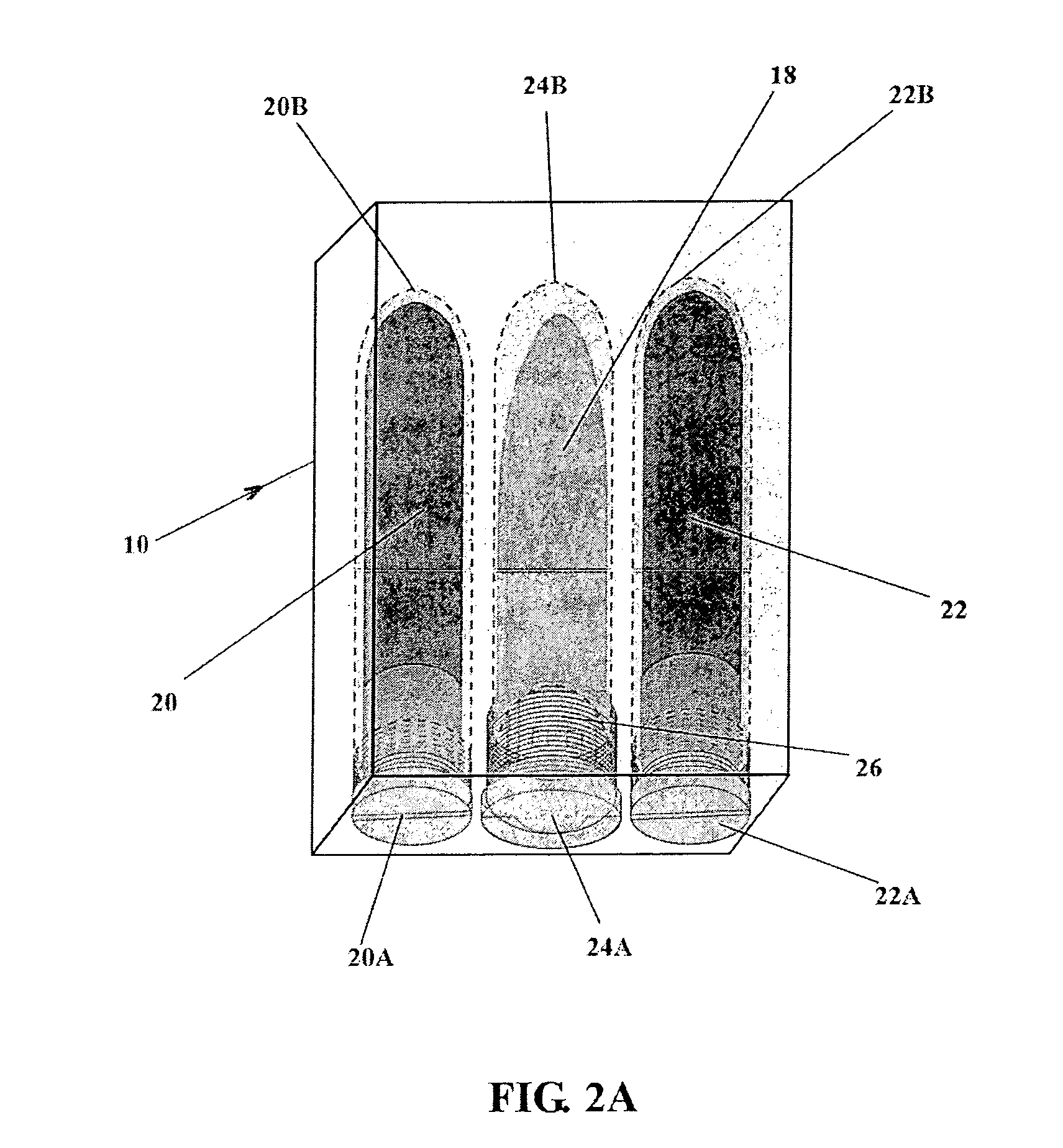

Portable grave time capsule

InactiveUS20050005409A1Reduce financial burdenMaintaining a sense of connectionUrnsCoffinsDigitizationComputer science

A method of burial includes collecting and containing physical remains including cremated ashes and non-cremated DNA material of a deceased person, collecting in a memory device digitized data on the biographical and medical history of the deceased person, providing a sealable time capsule to contain the physical remains and the digitized data, and providing a communication terminal on the time capsule for accessing, uploading and downloading the digitized data.

Owner:ELNATAN GIL

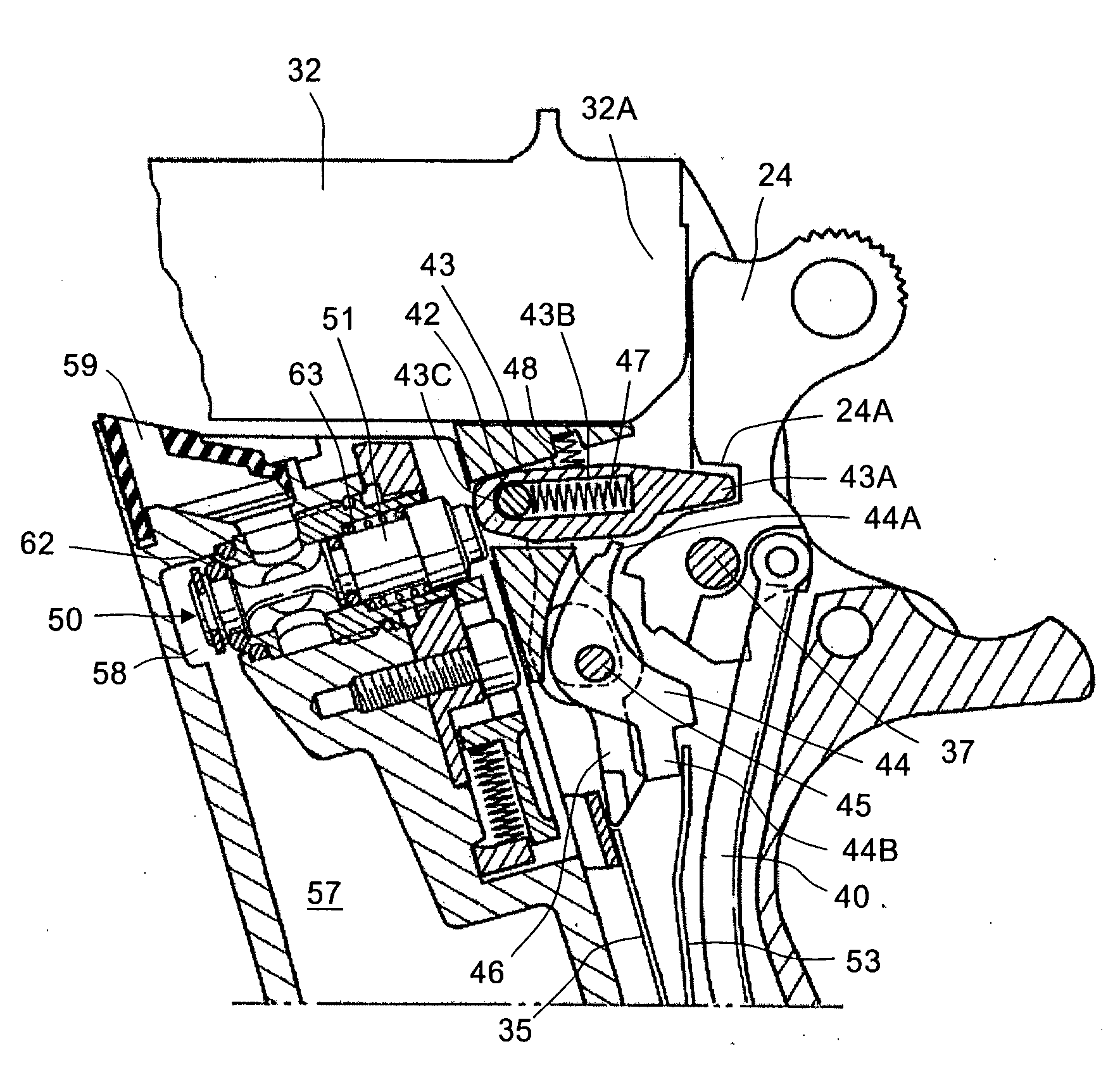

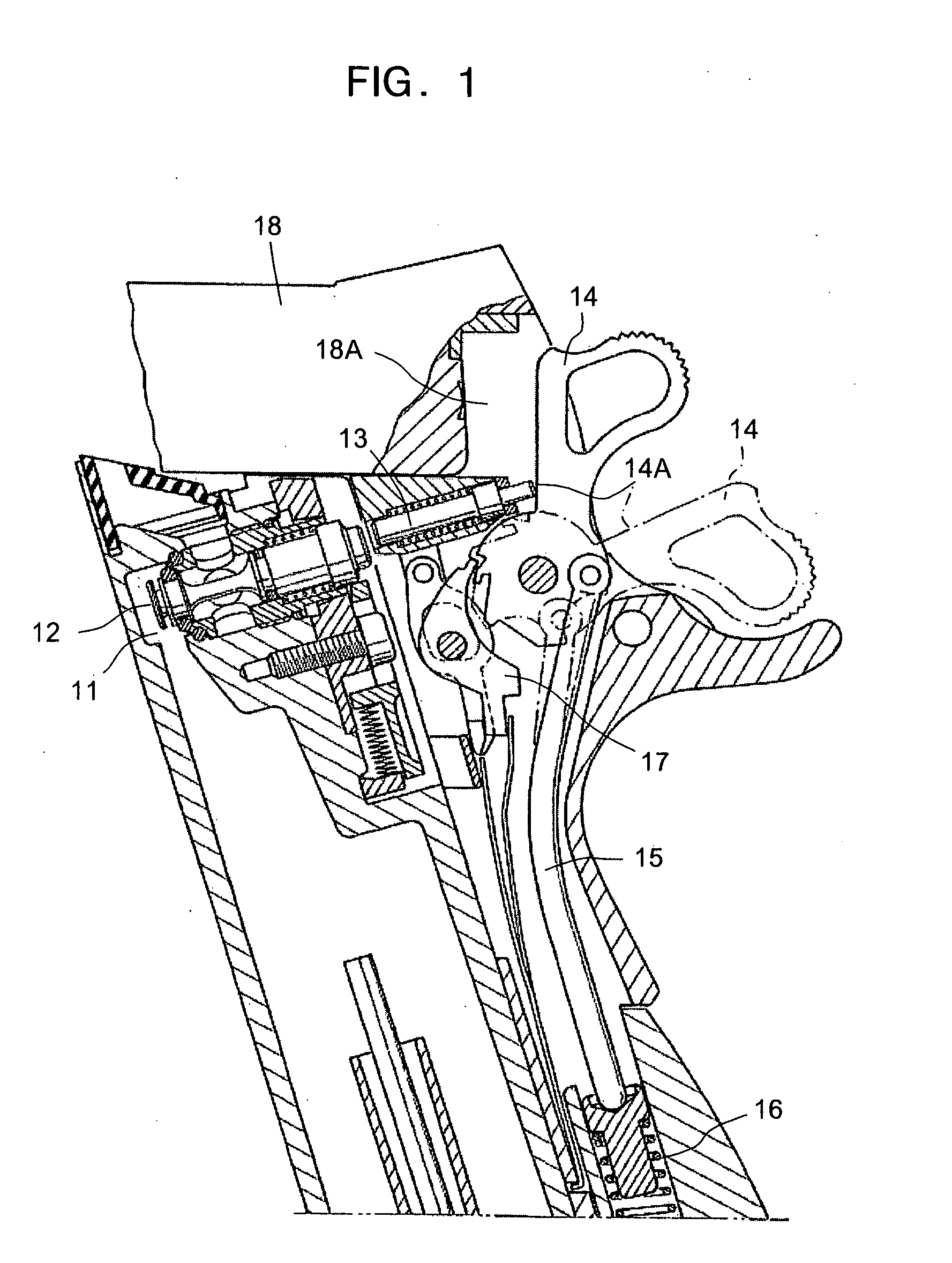

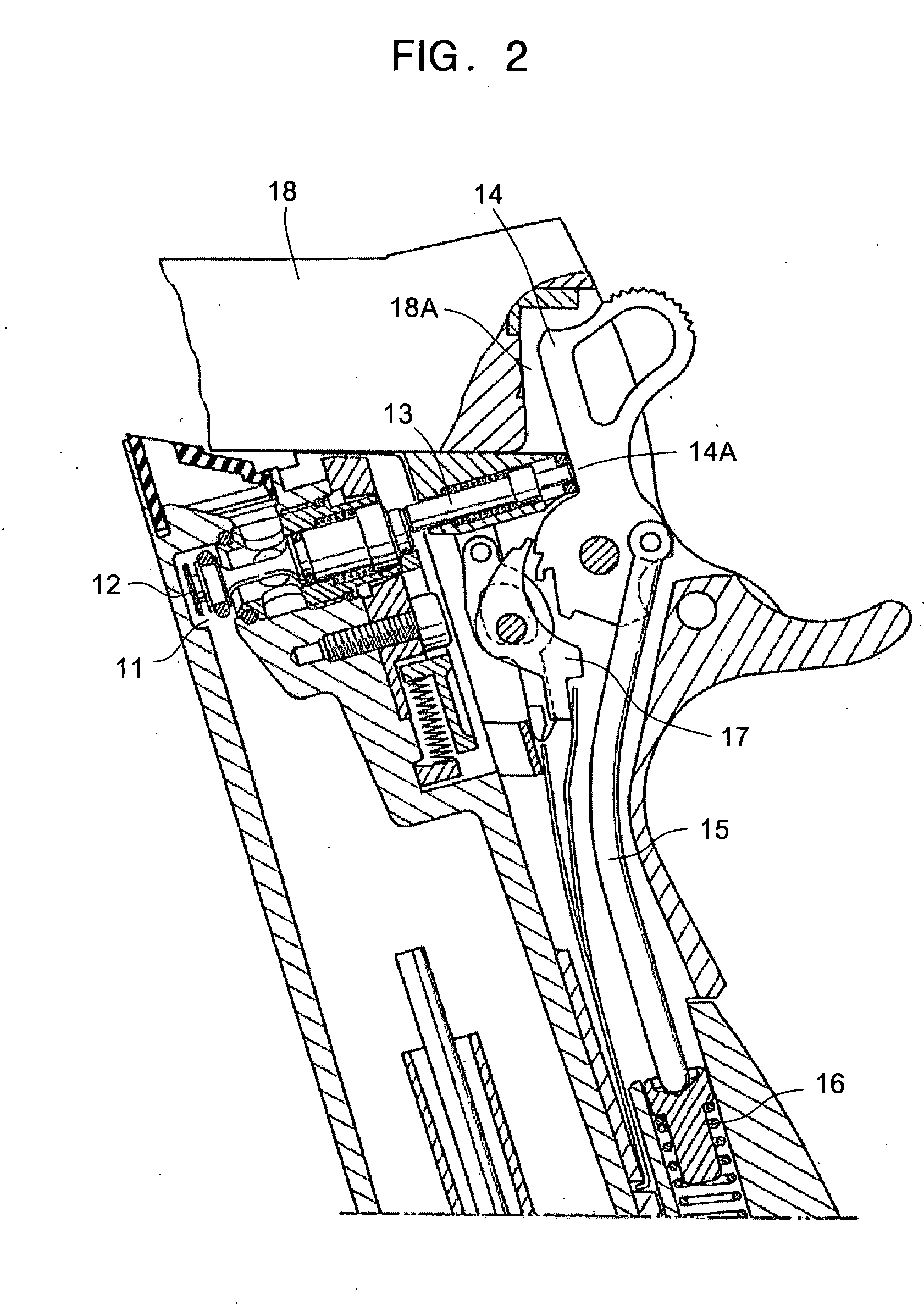

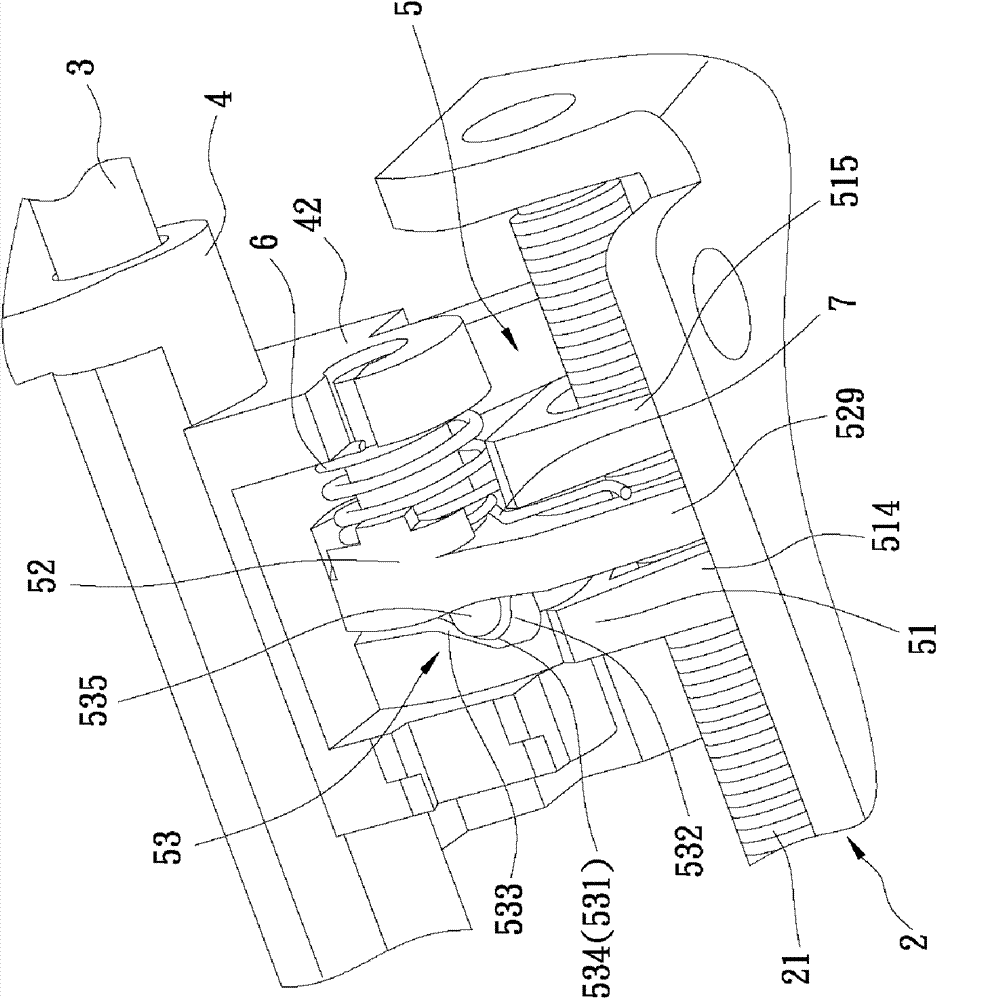

Gas supplying mechanism in a gas powered toy gun

InactiveUS20050011508A1Avoid disadvantagesUndesirable operationSafety arrangementCompressed gas gunsLow speedEngineering

A gas supplying mechanism in a gas powered toy gun comprises a gas passage for supplying gas to be used for shooting a sham bullet put in a bullet holding chamber, a movable valve for controlling the gas passage to be open for supplying the gas and closed for ceasing to supply the gas selectively, a hammer operative selectively to rotate at high speed to a first position from a second position in response to a triggering operation performed for shooting the sham bullet and to rotate at low speed to the first position from the second position independently of the triggering operation, a positioning member provided to come into contact with the hammer put in the first position for positioning the same, and a movable linking member for moving in a first manner corresponding to the high speed rotation of the hammer to push the movable valve to move for shifting the gas passage to be open when the hammer rotates at the high speed and for moving in a second manner corresponding to the low speed rotation of the hammer to cause the movable valve to keep the gas passage closed without pushing the movable valve to move when the hammer rotates at the low speed.

Owner:WESTERN ARMS

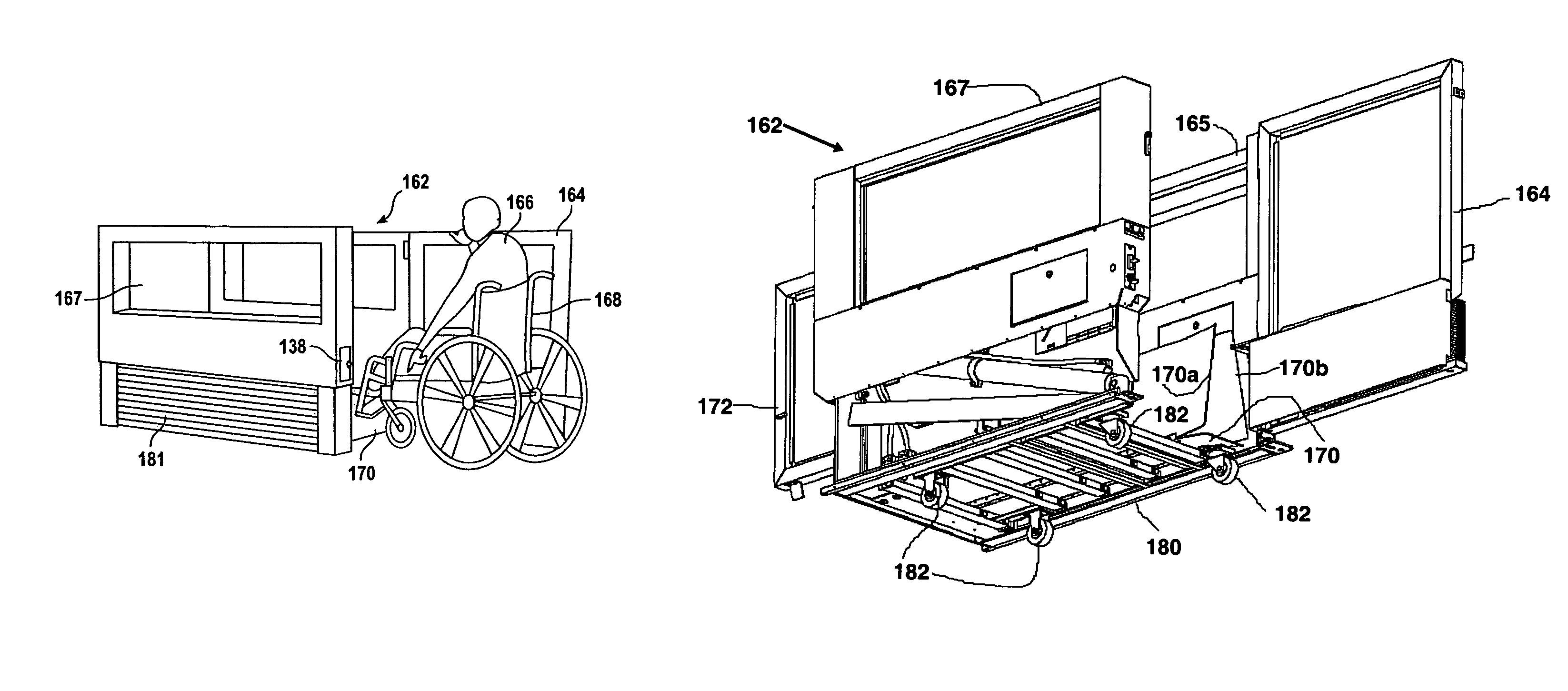

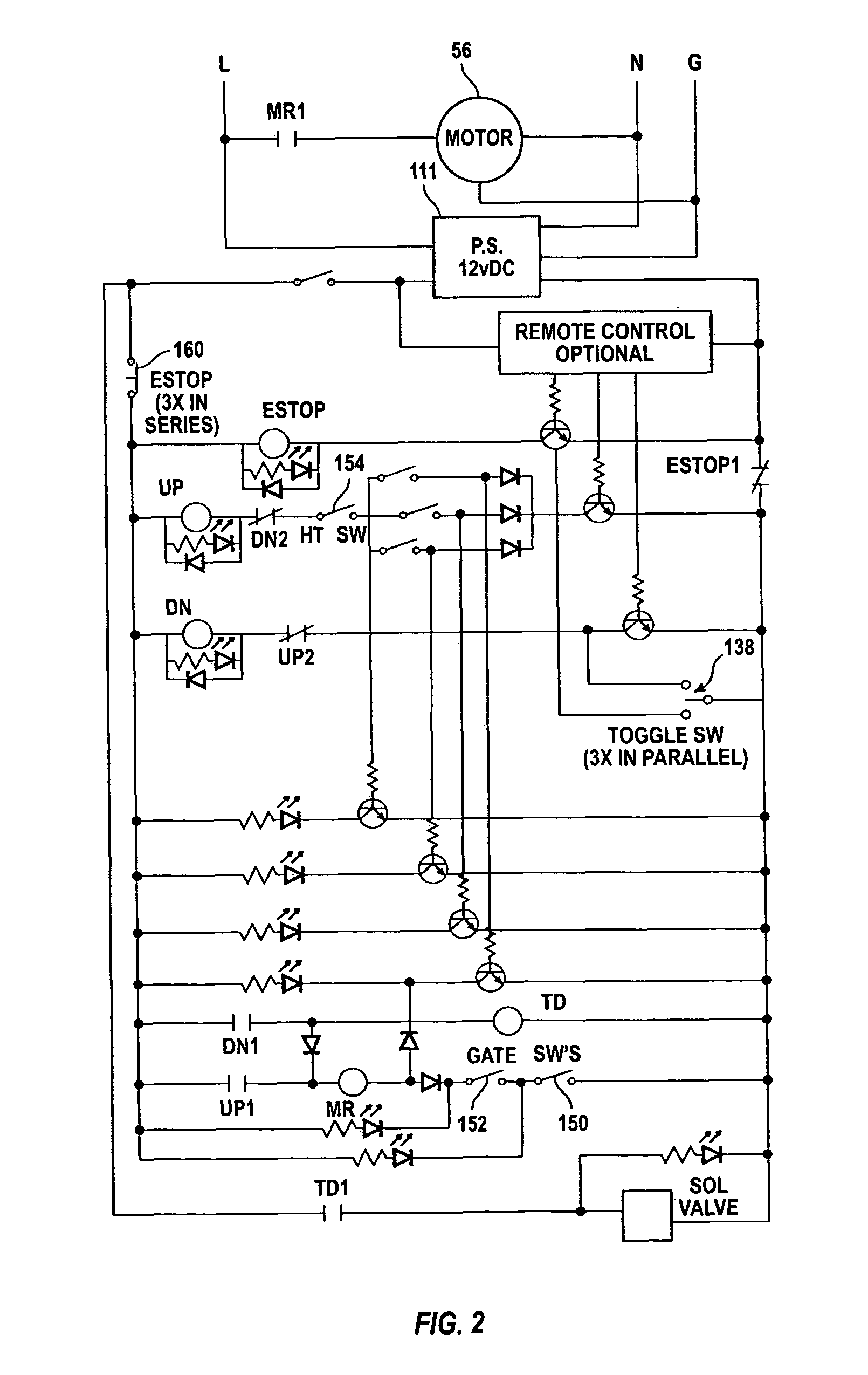

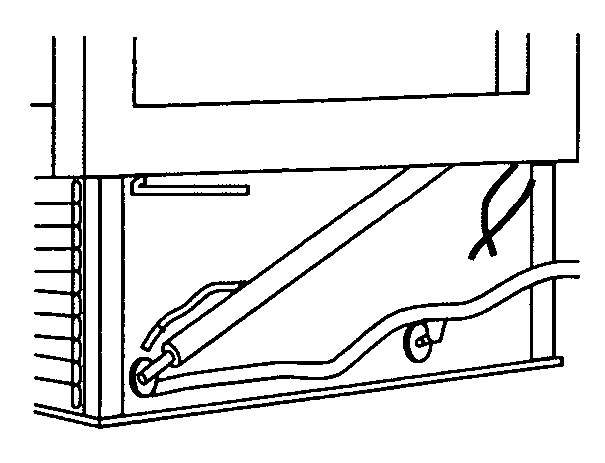

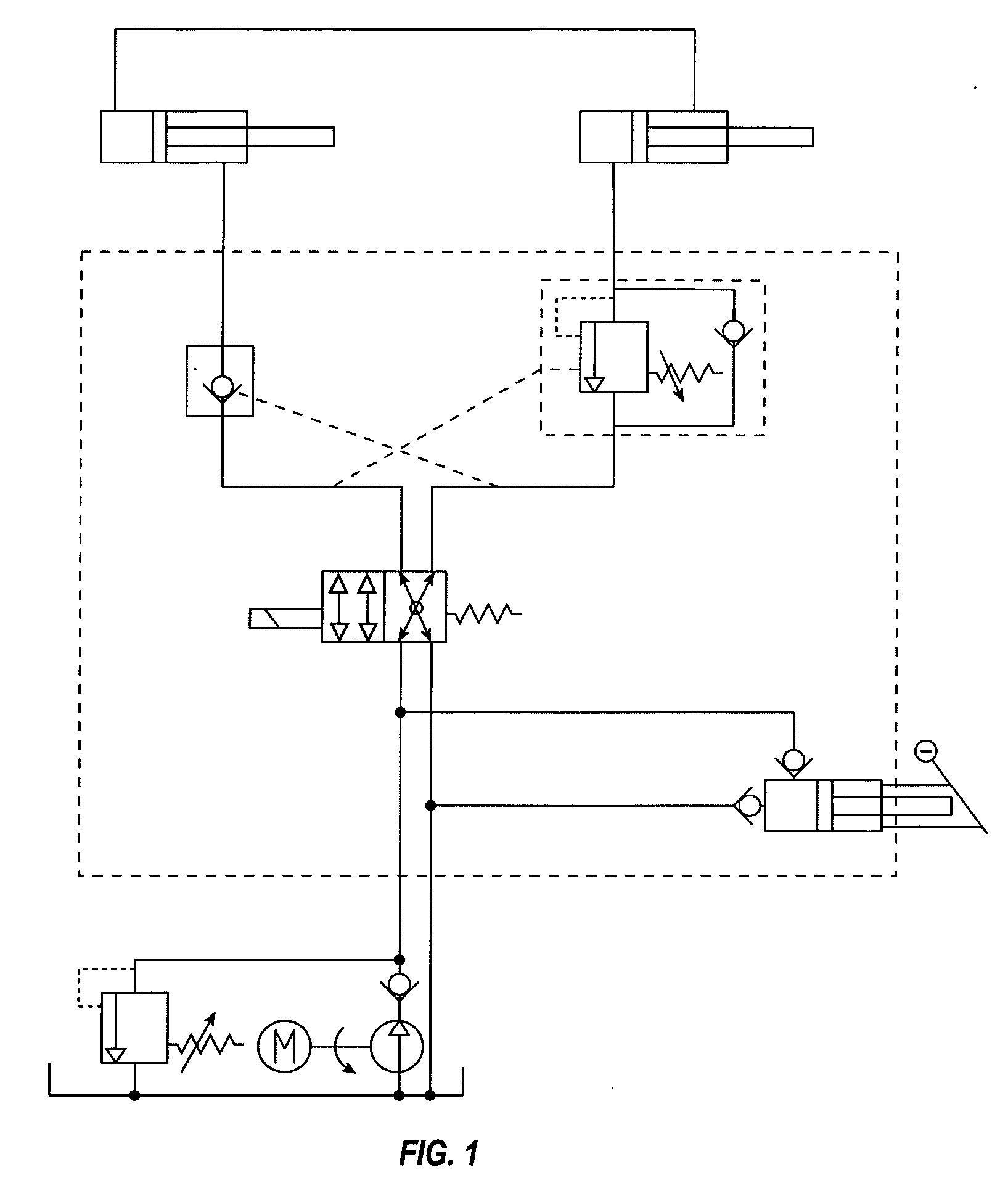

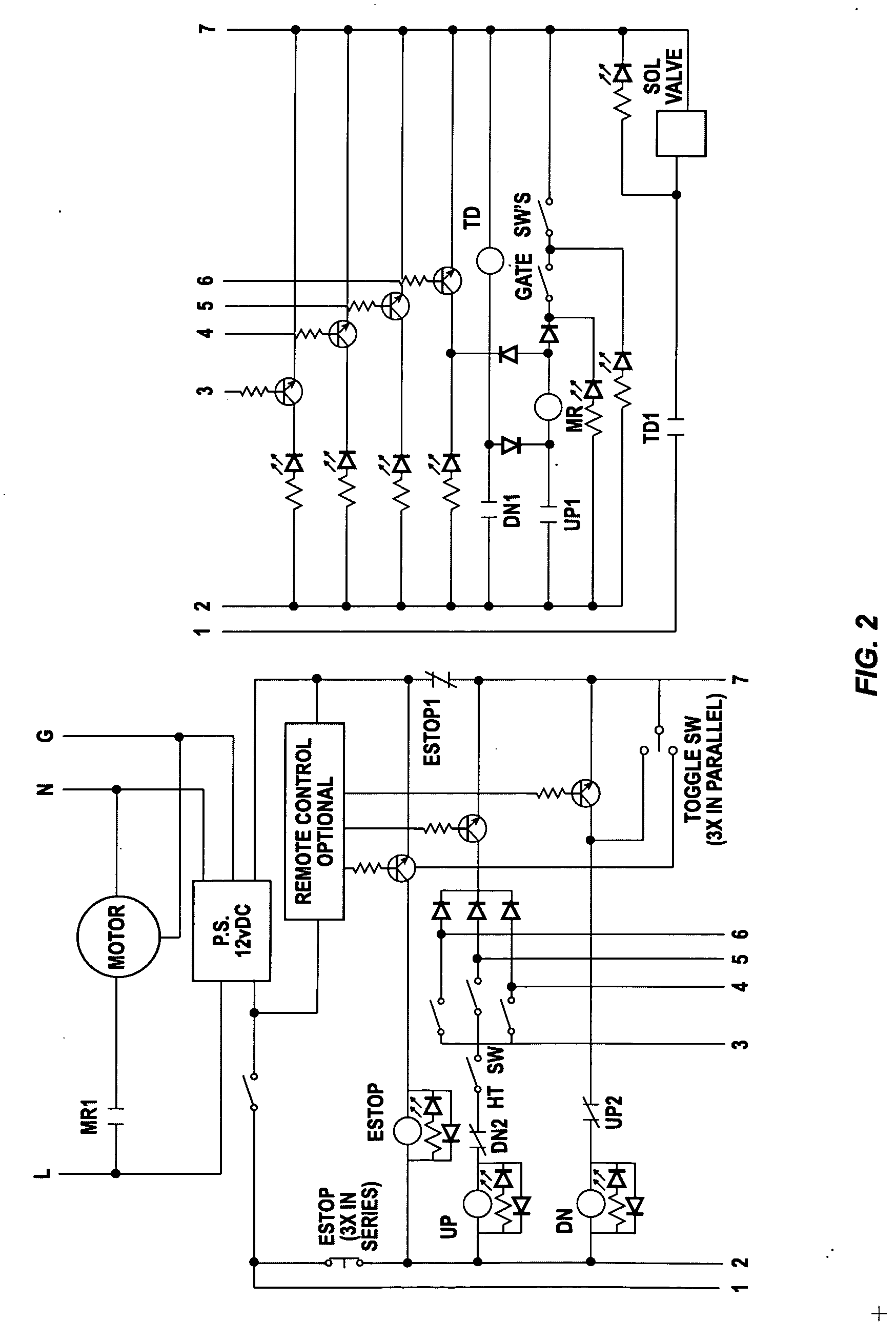

Portable wheel chair lift

Owner:AGM CONTAINER CONTROLS

Portable wheel chair lift

ActiveUS20060182570A1Prevents further operationLittle or no useRefuse receptaclesLifting framesWheelchairChair lifts

Owner:AGM CONTAINER CONTROLS

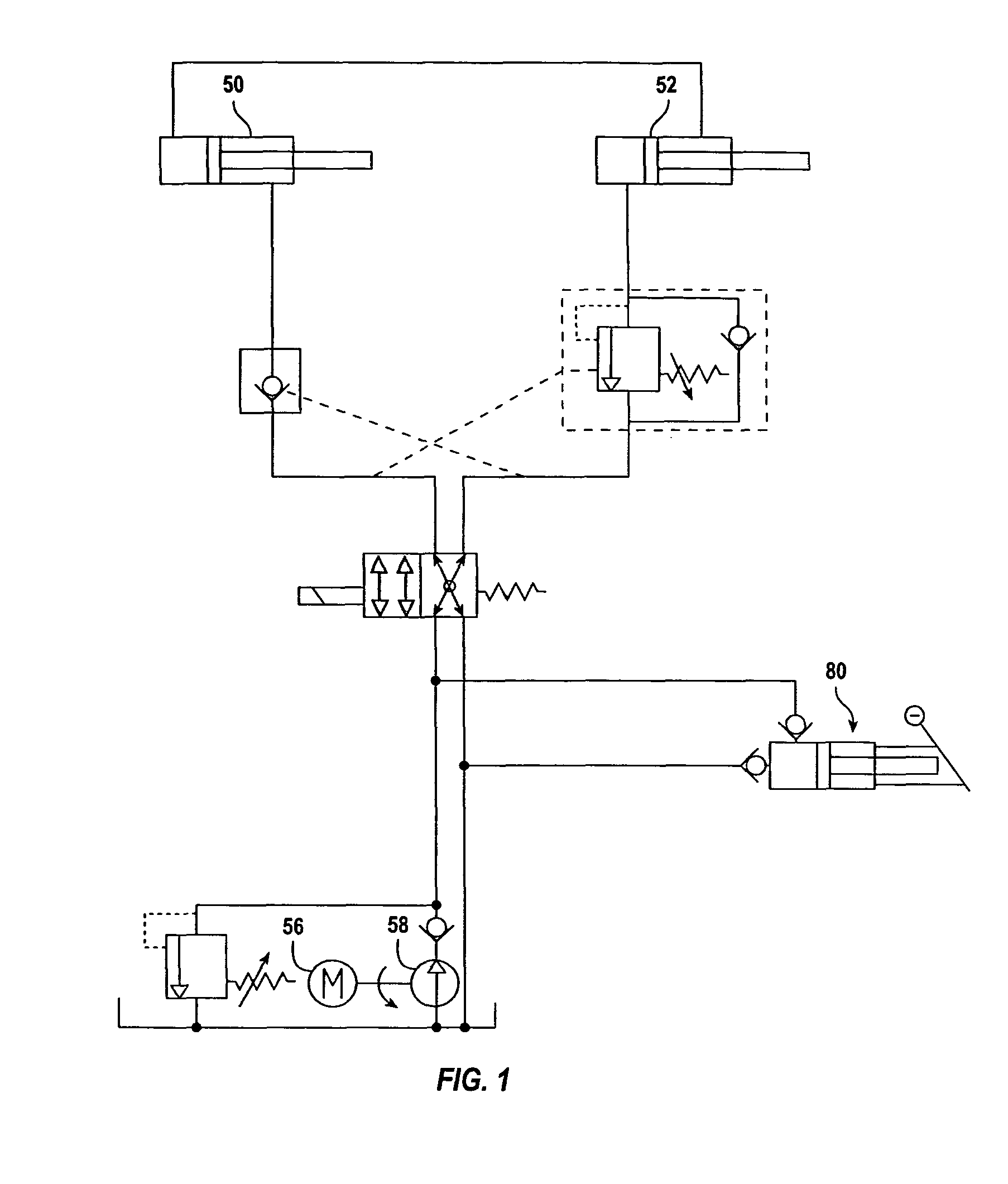

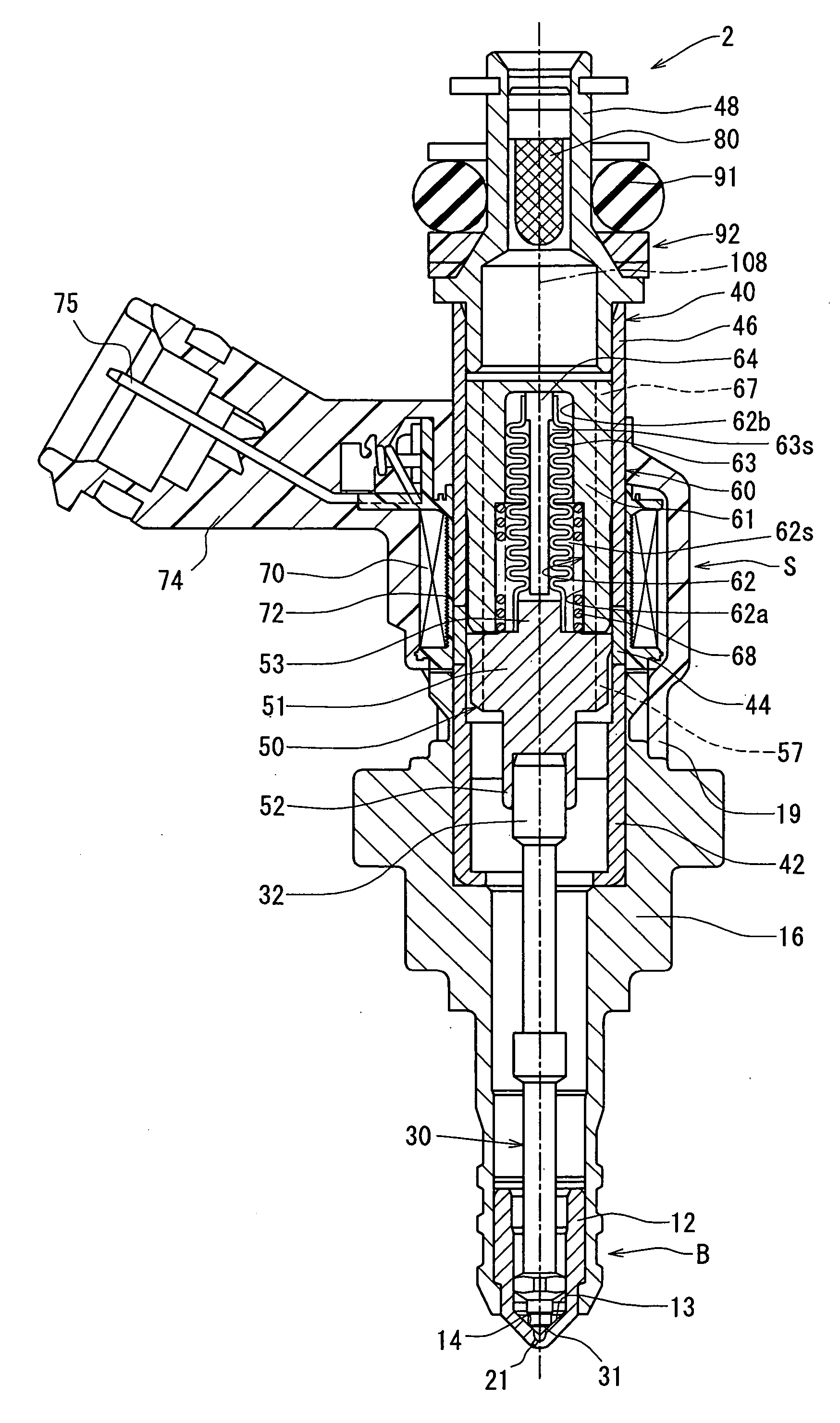

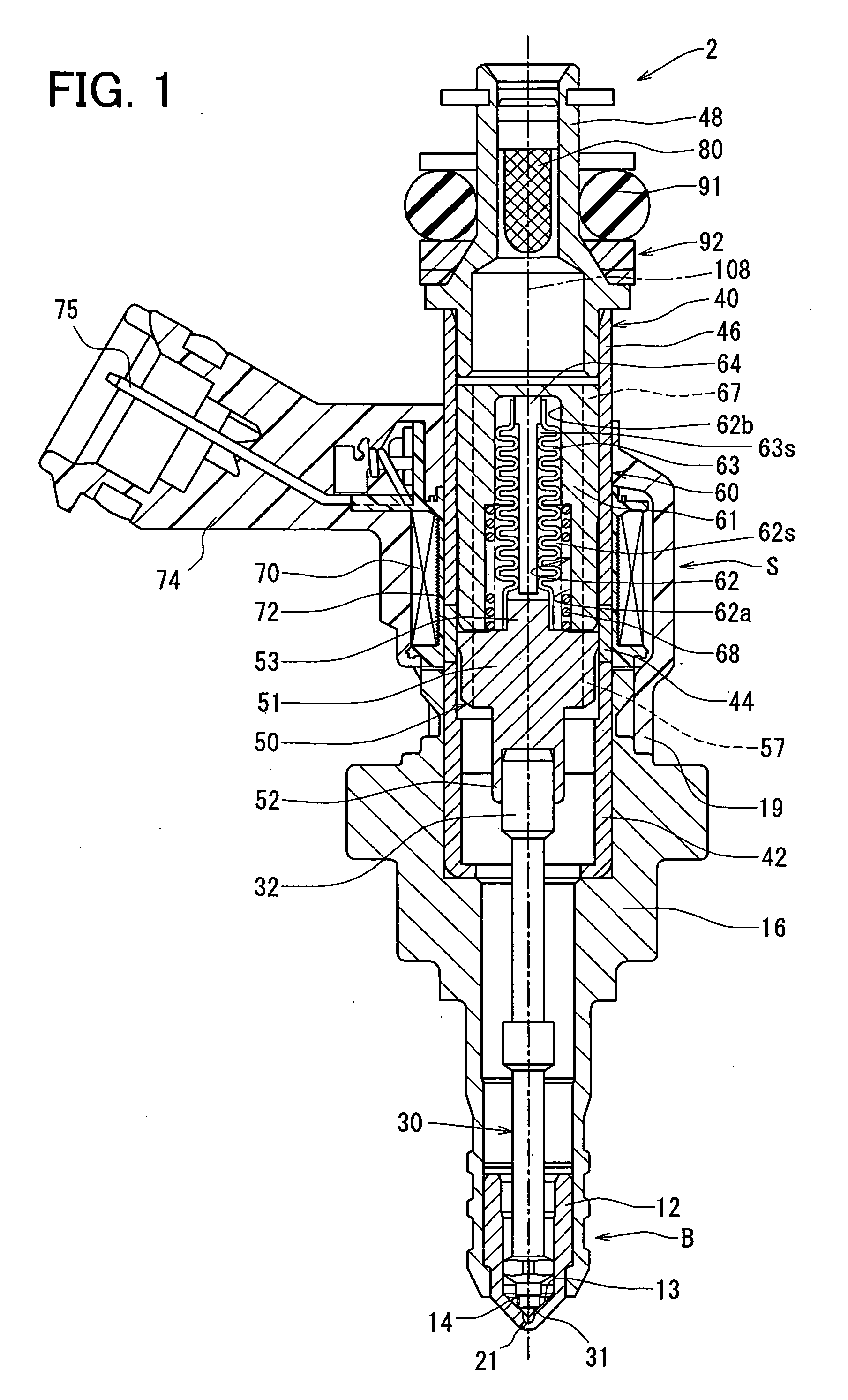

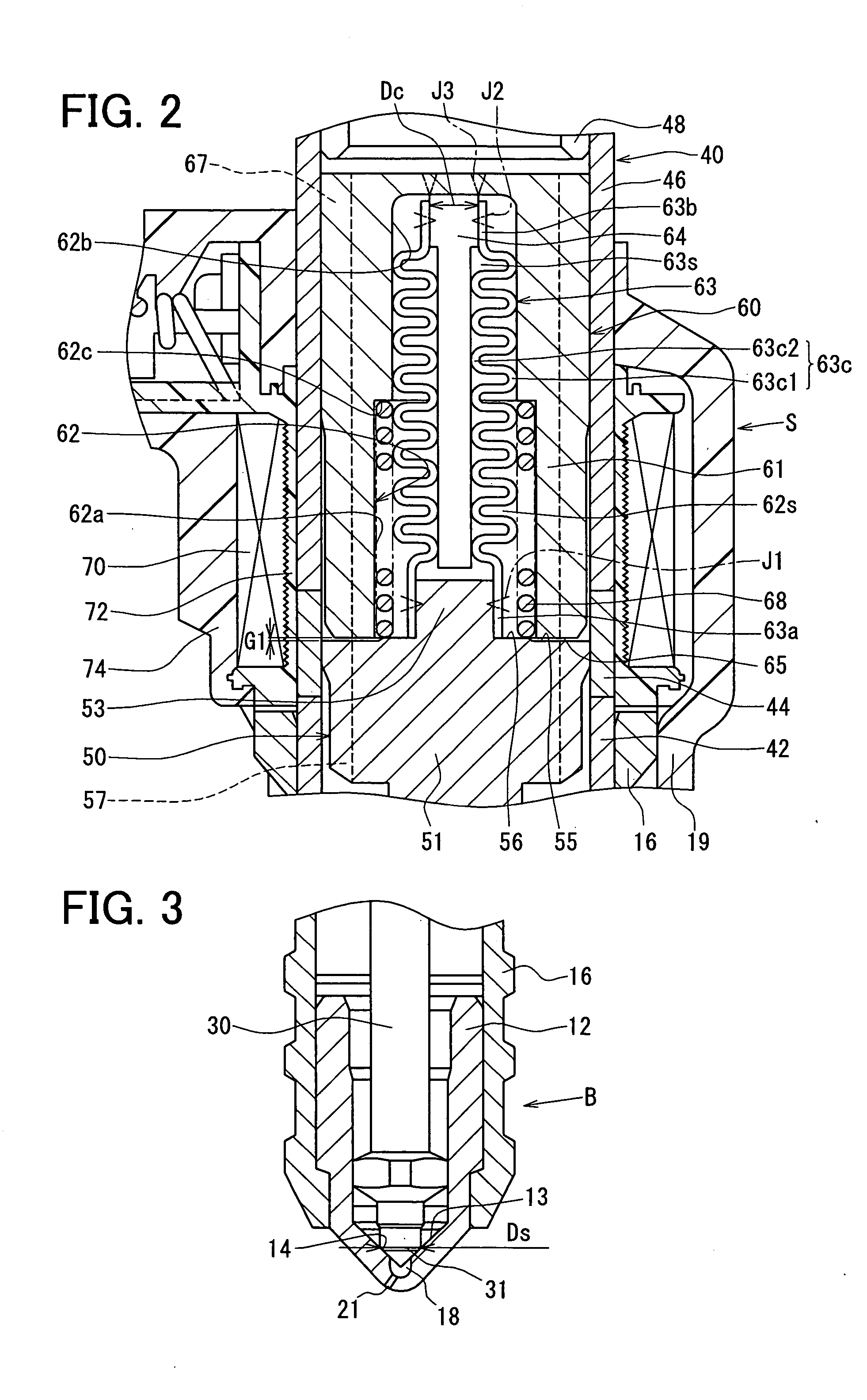

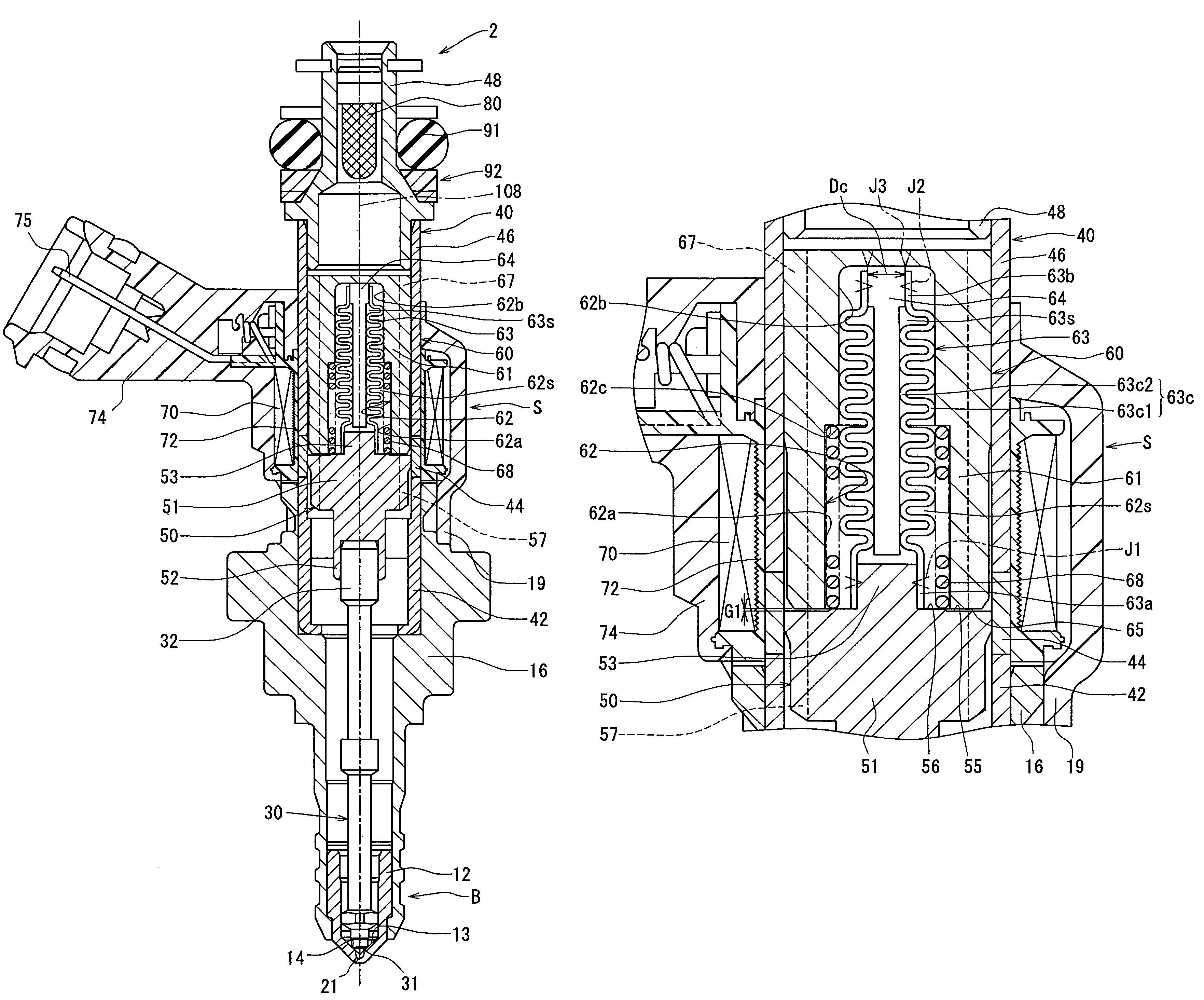

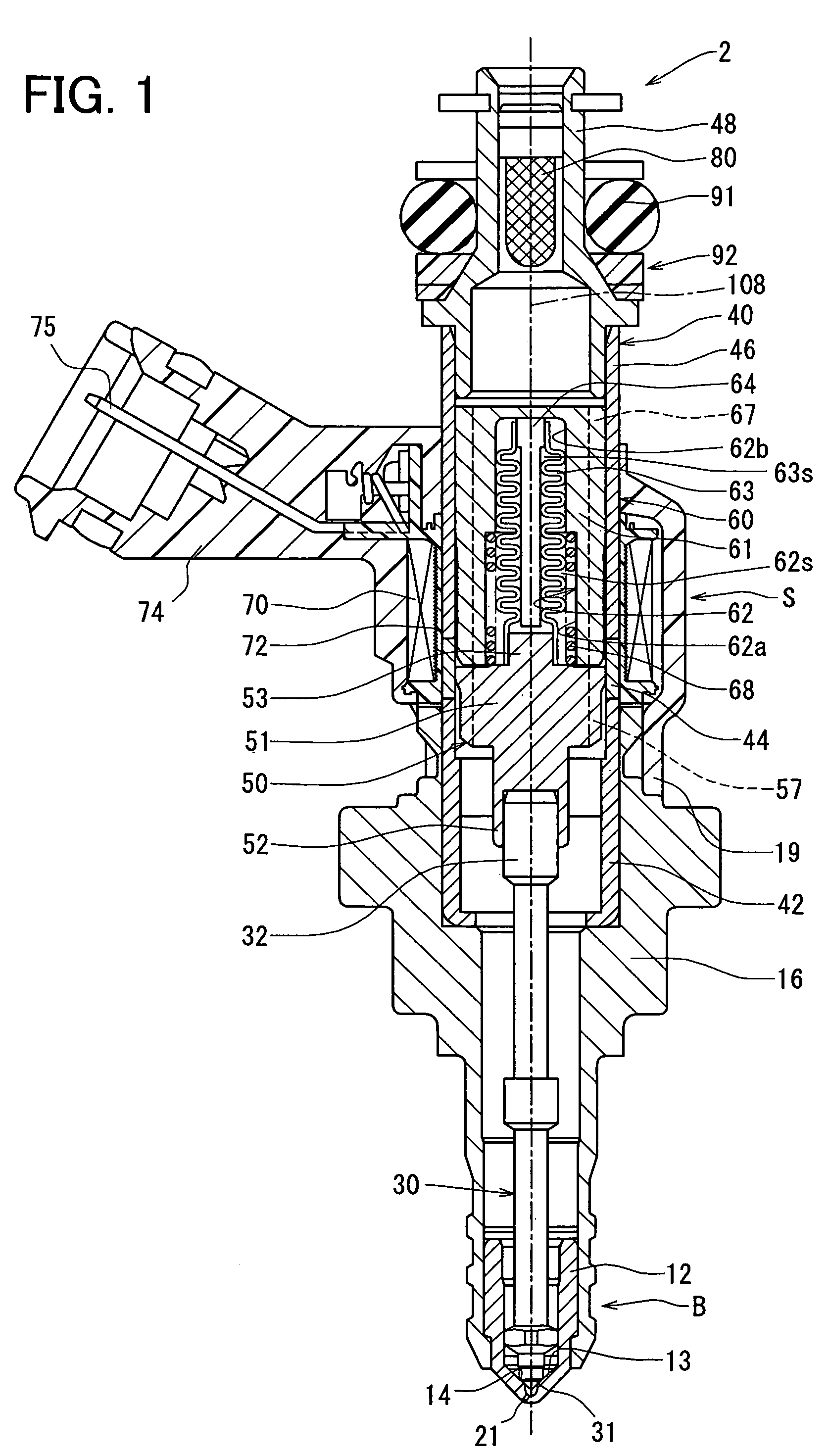

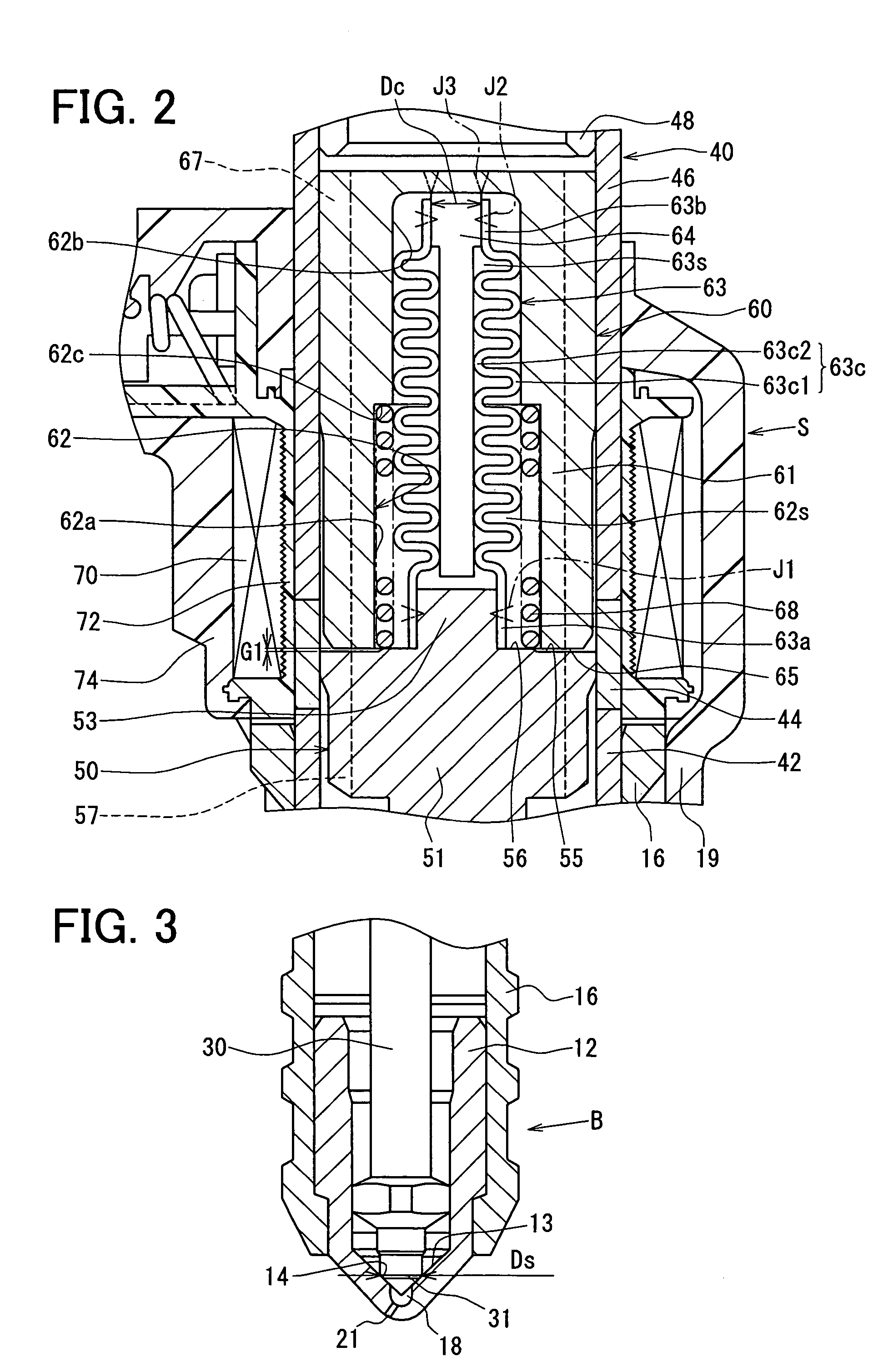

Fuel injection valve

InactiveUS20060283988A1Lessen influenceReduce forceOperating means/releasing devices for valvesSpray nozzlesEngineeringFuel injection

A fuel injection valve includes a valve body having a valve seat, a valve element adapted to sit on and leave a valve seat, a nozzle hole for the injection of fuel, and an electromagnetic drive section. A holding member surrounds and holds, on one end side thereof, at least a partial area of an opposite-to-nozzle-hole-side end face portion of the valve element. The holding member surrounds and holds, on an opposite end side thereof, a predetermined surface area of a constant position holding portion without being influenced by the pressure of fuel flowing through a fuel passage of the valve body and irrespective of movement of the valve element. An internal area of the holding member is shut off so as not to be influenced by the pressure of fuel present around the internal area.

Owner:DENSO CORP

Fuel injection valve

InactiveUS7458531B2Reduce forceKeep closedOperating means/releasing devices for valvesSpray nozzlesEngineeringElectromagnetic drive

A fuel injection valve includes a valve body having a valve seat, a valve element adapted to sit on and leave a valve seat, a nozzle hole for the injection of fuel, and an electromagnetic drive section. A holding member surrounds and holds, on one end side thereof, at least a partial area of an opposite-to-nozzle-hole-side end face portion of the valve element. The holding member surrounds and holds, on an opposite end side thereof, a predetermined surface area of a constant position holding portion without being influenced by the pressure of fuel flowing through a fuel passage of the valve body and irrespective of movement of the valve element. An internal area of the holding member is shut off so as not to be influenced by the pressure of fuel present around the internal area.

Owner:DENSO CORP

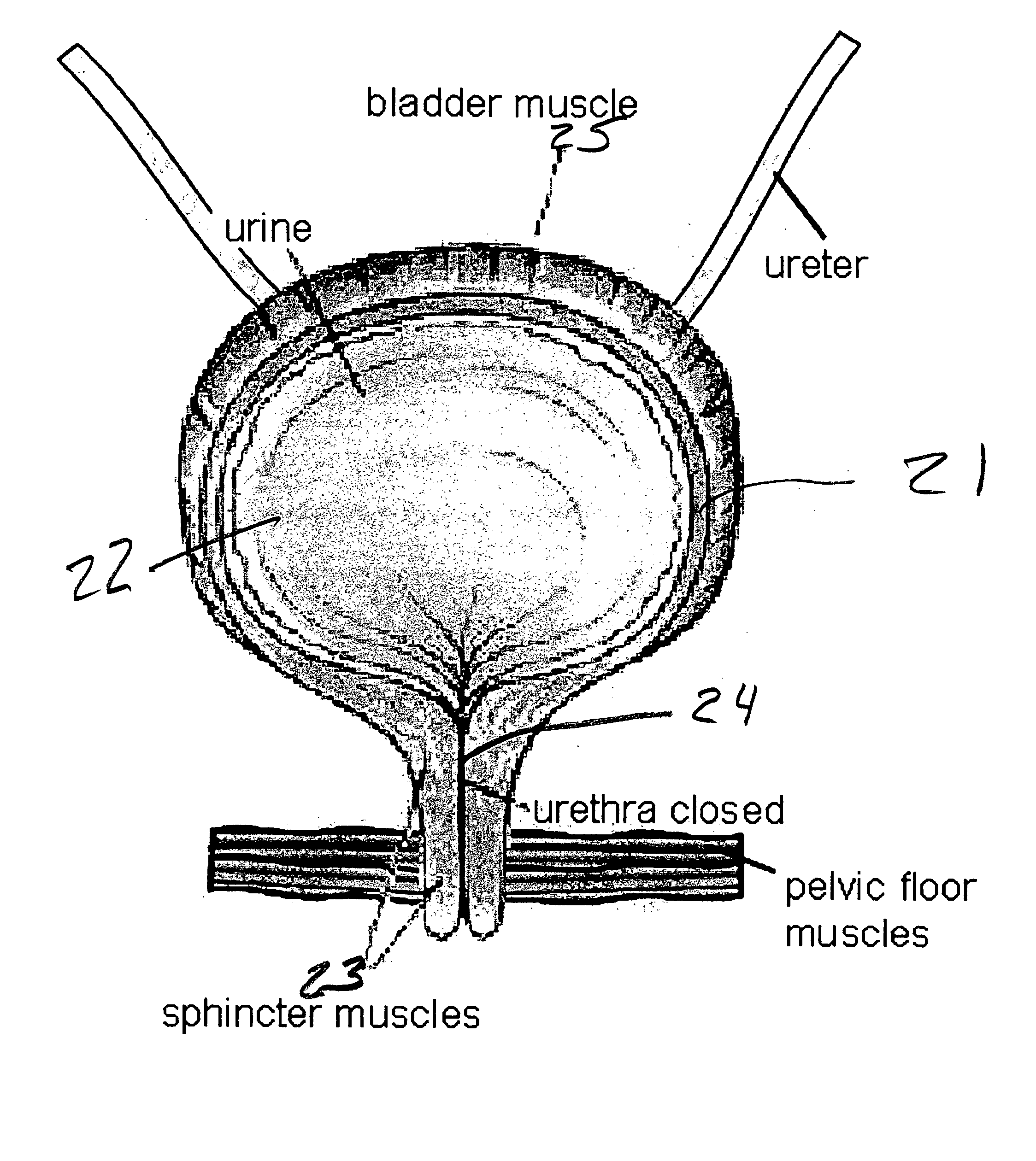

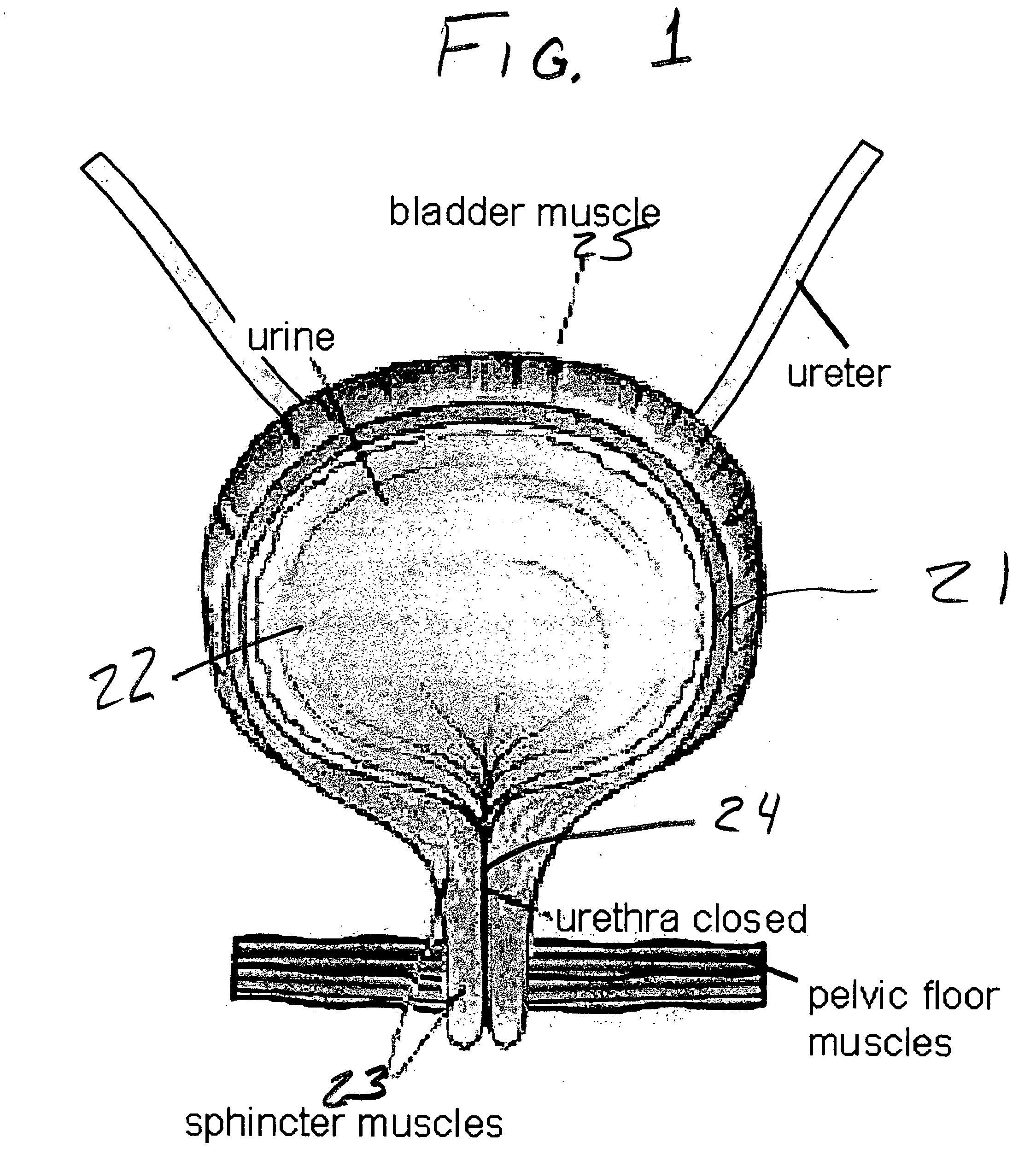

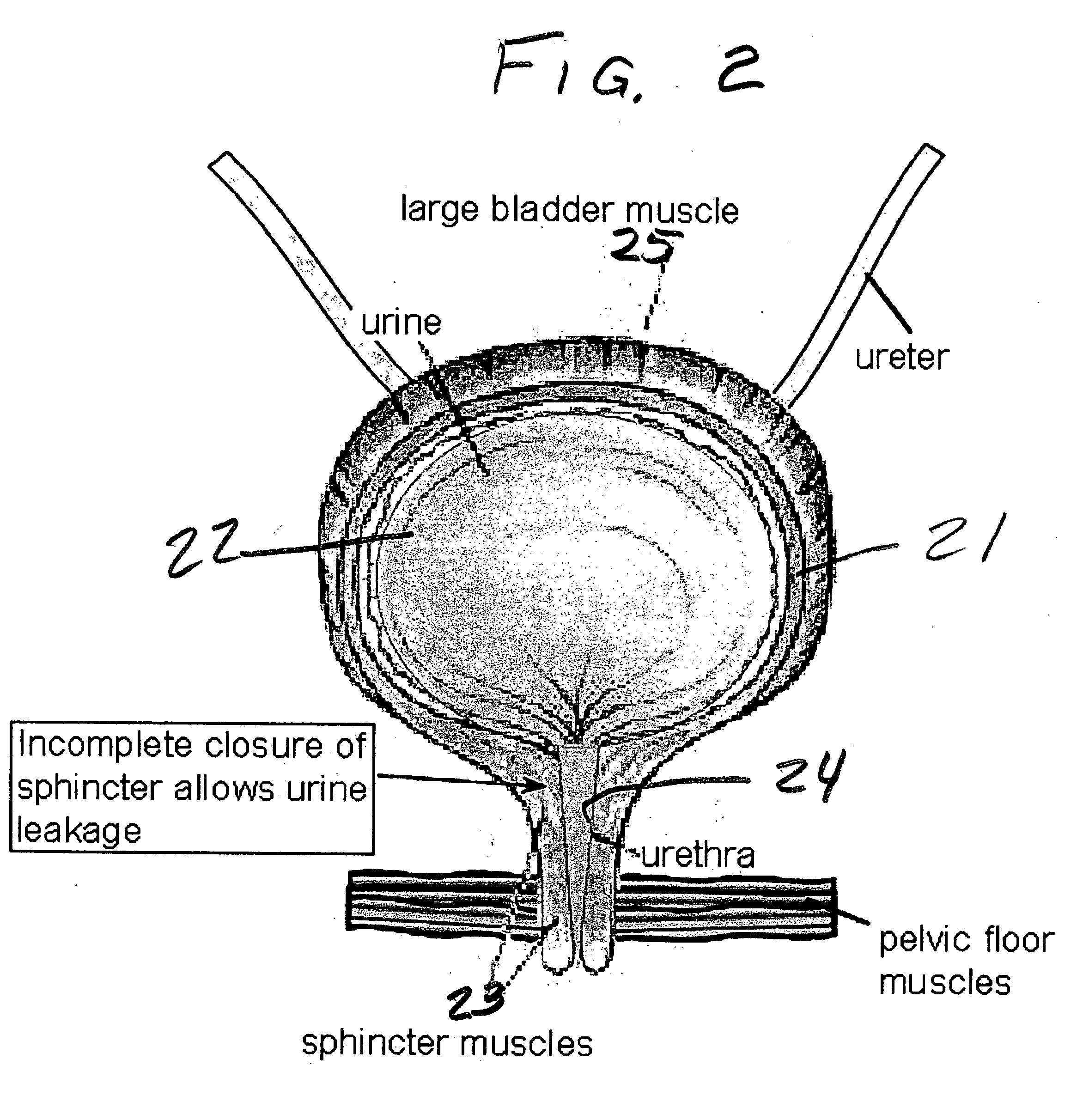

Incontinence therapy

ActiveUS20050075533A1Keep closedGood effectAnti-incontinence devicesSurgerySphincterInternal urethral orifice

Urinary incontinence such as stress incontinence, is alleviated in a mammal, in particular a human being, especially a woman, by correcting the internal urethral orifice and the urethra with an elastic form stable material. Such a material preferably a curable elastomer-precursor composition is injected in the body tissue surrounding the urethra, thereby correcting internal urethral orifice and the urethra substantially to its original shape, allowing the sphincter to act in a controllable way.

Owner:NOES BEHEER

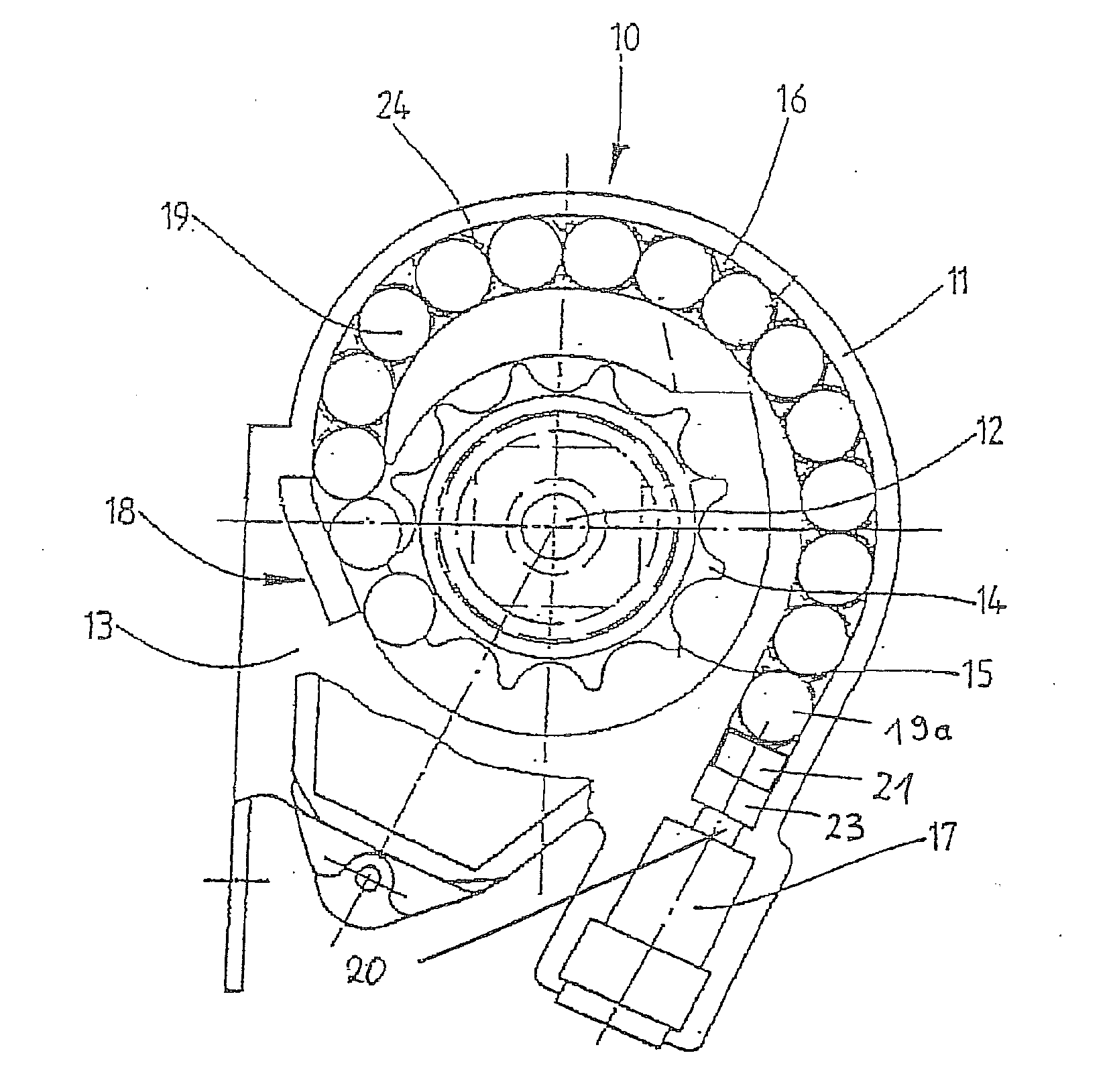

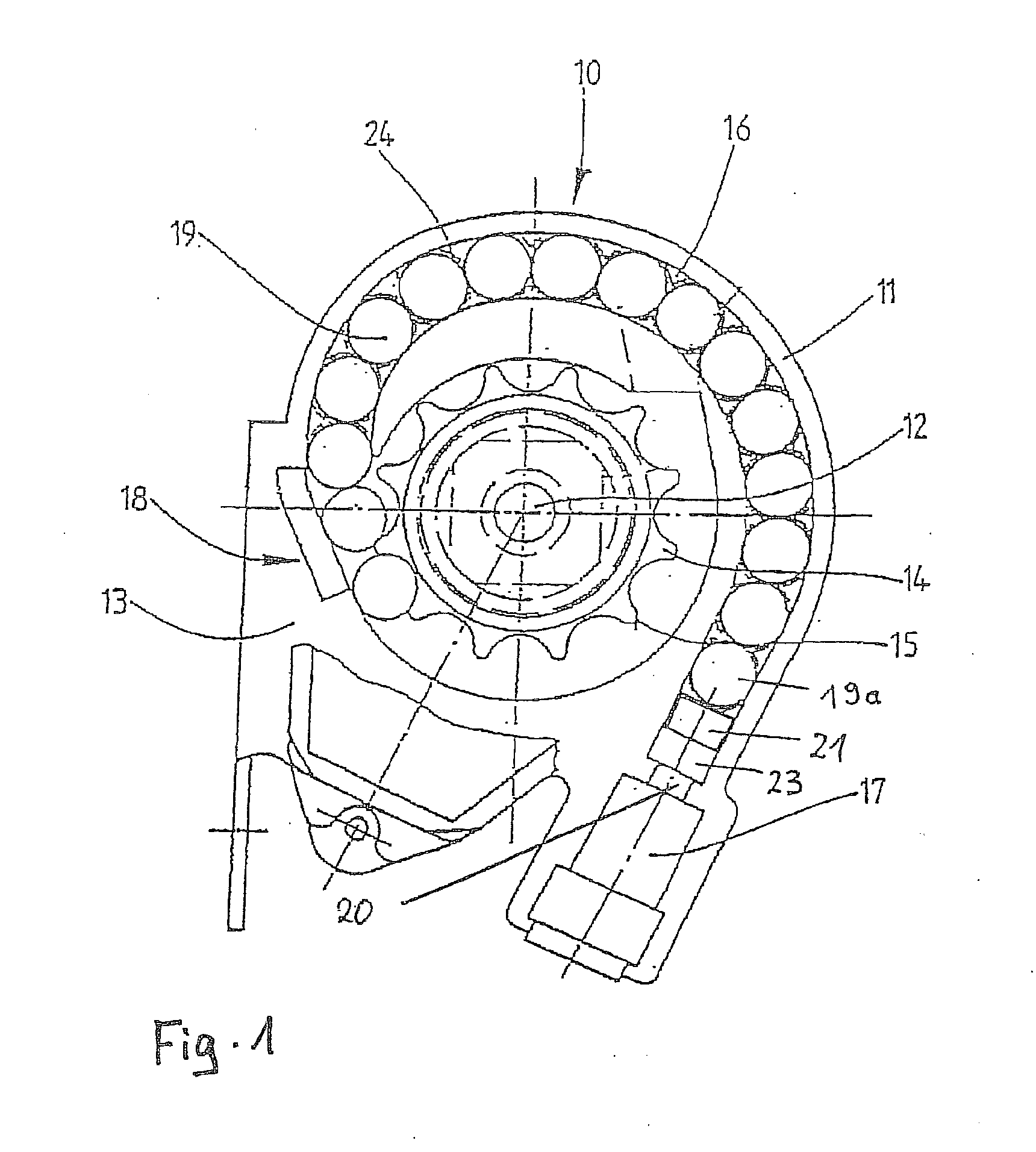

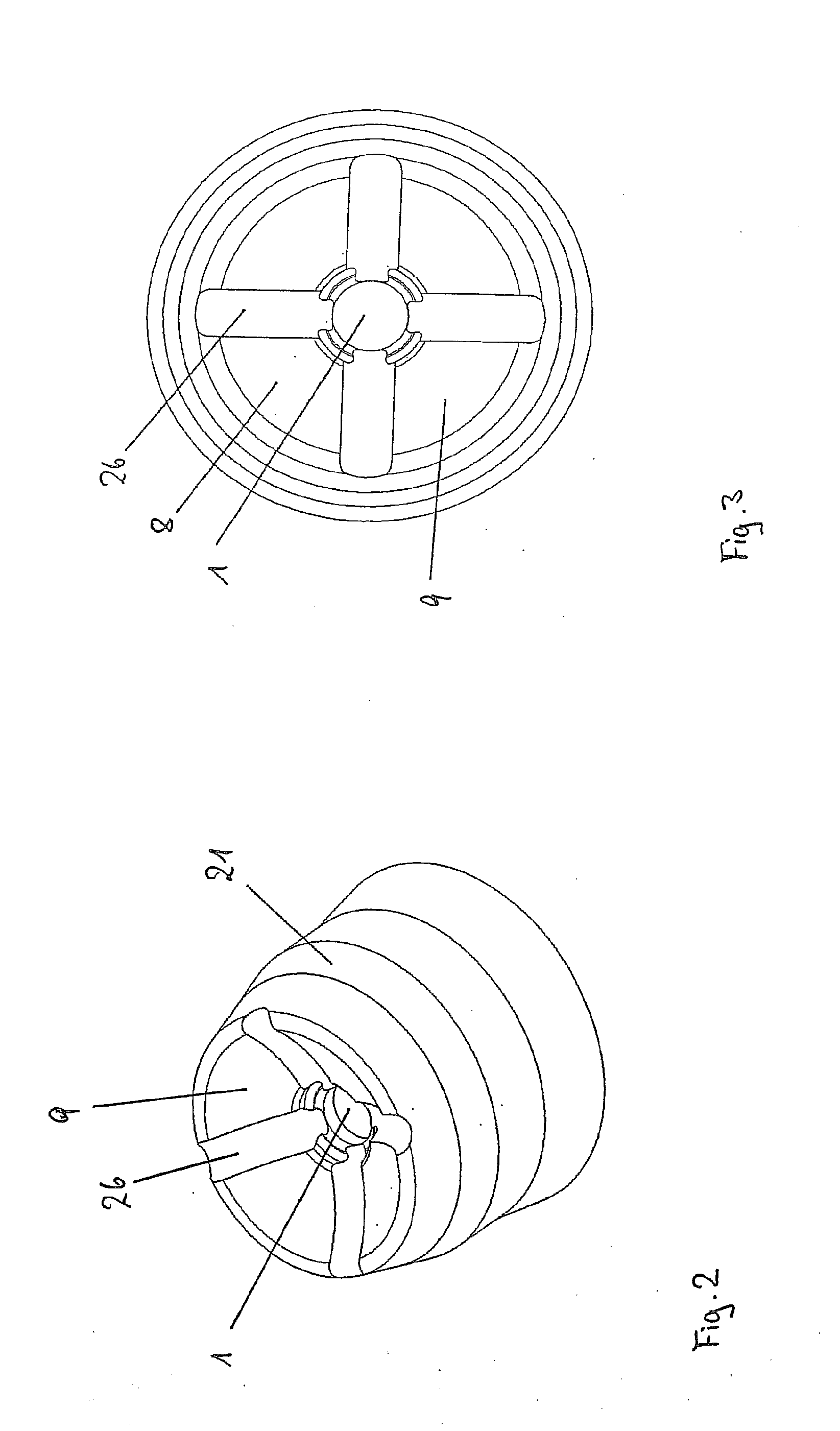

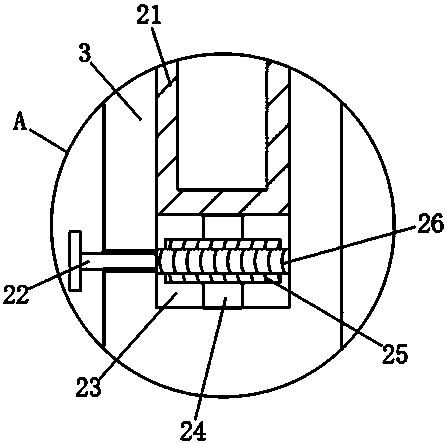

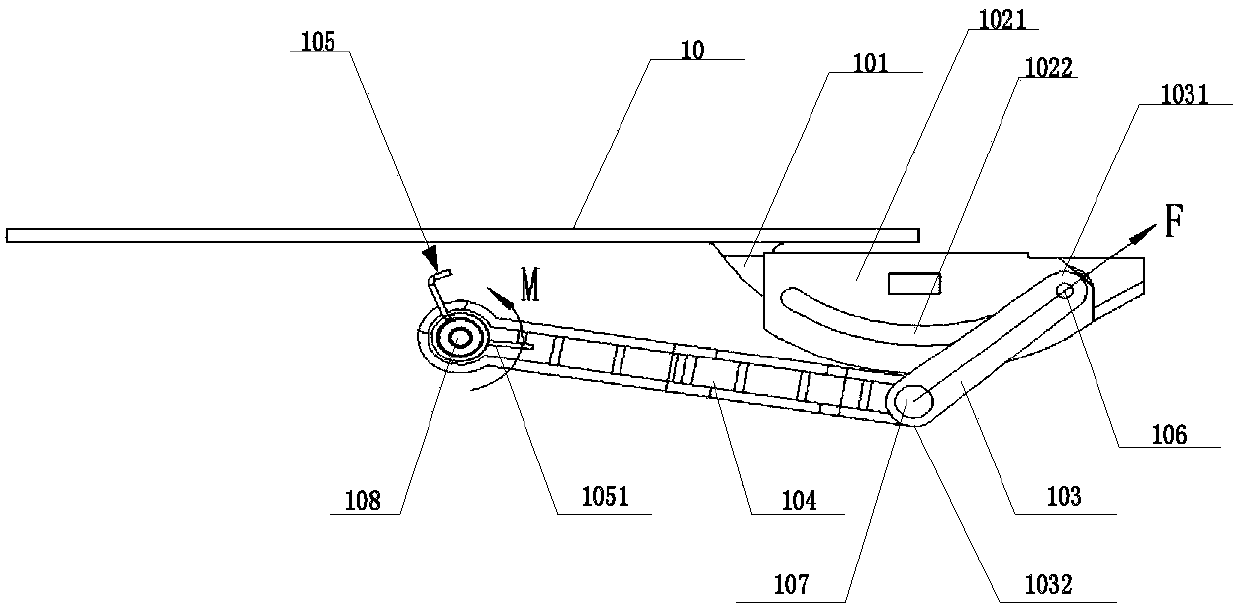

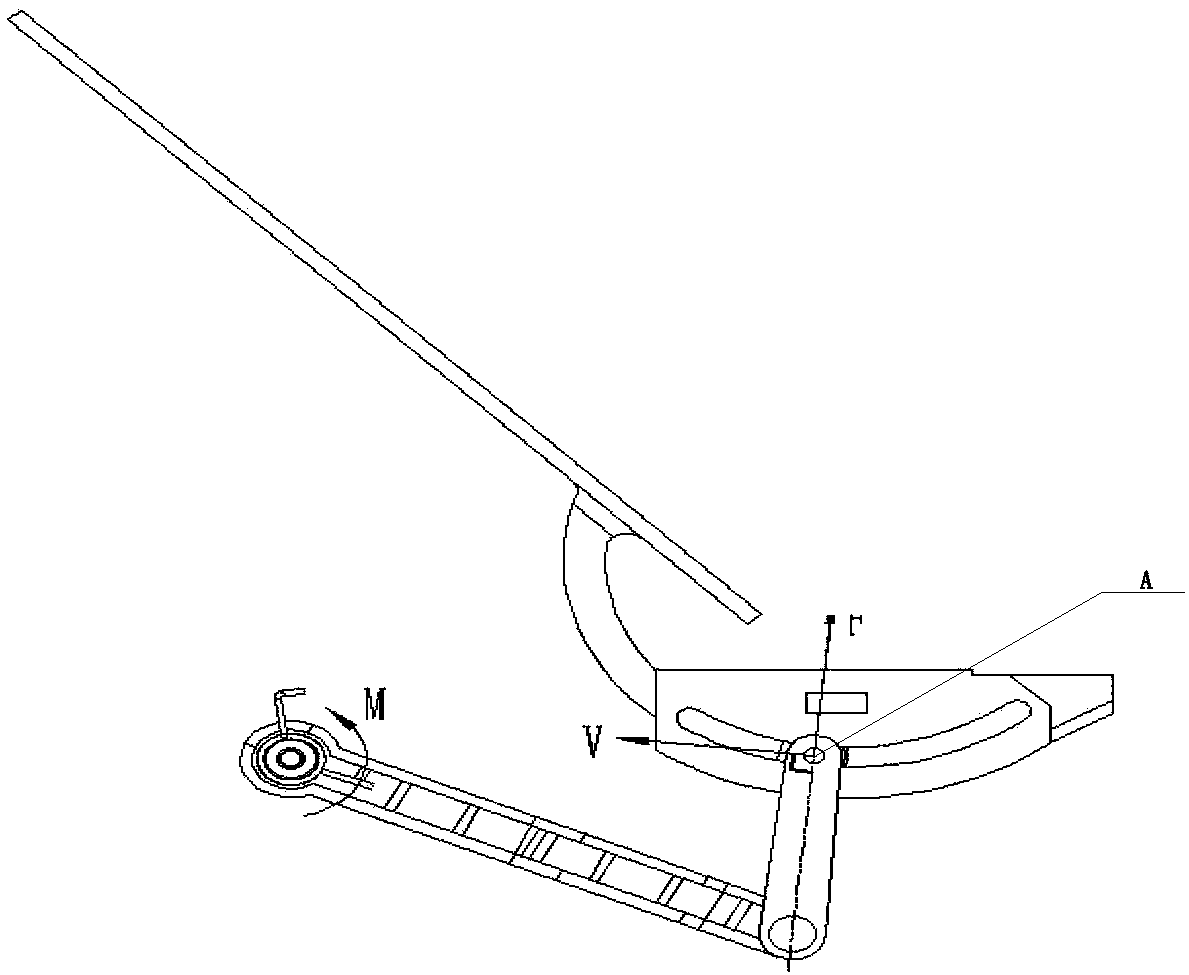

Pretensioning Device for a Safety Belt

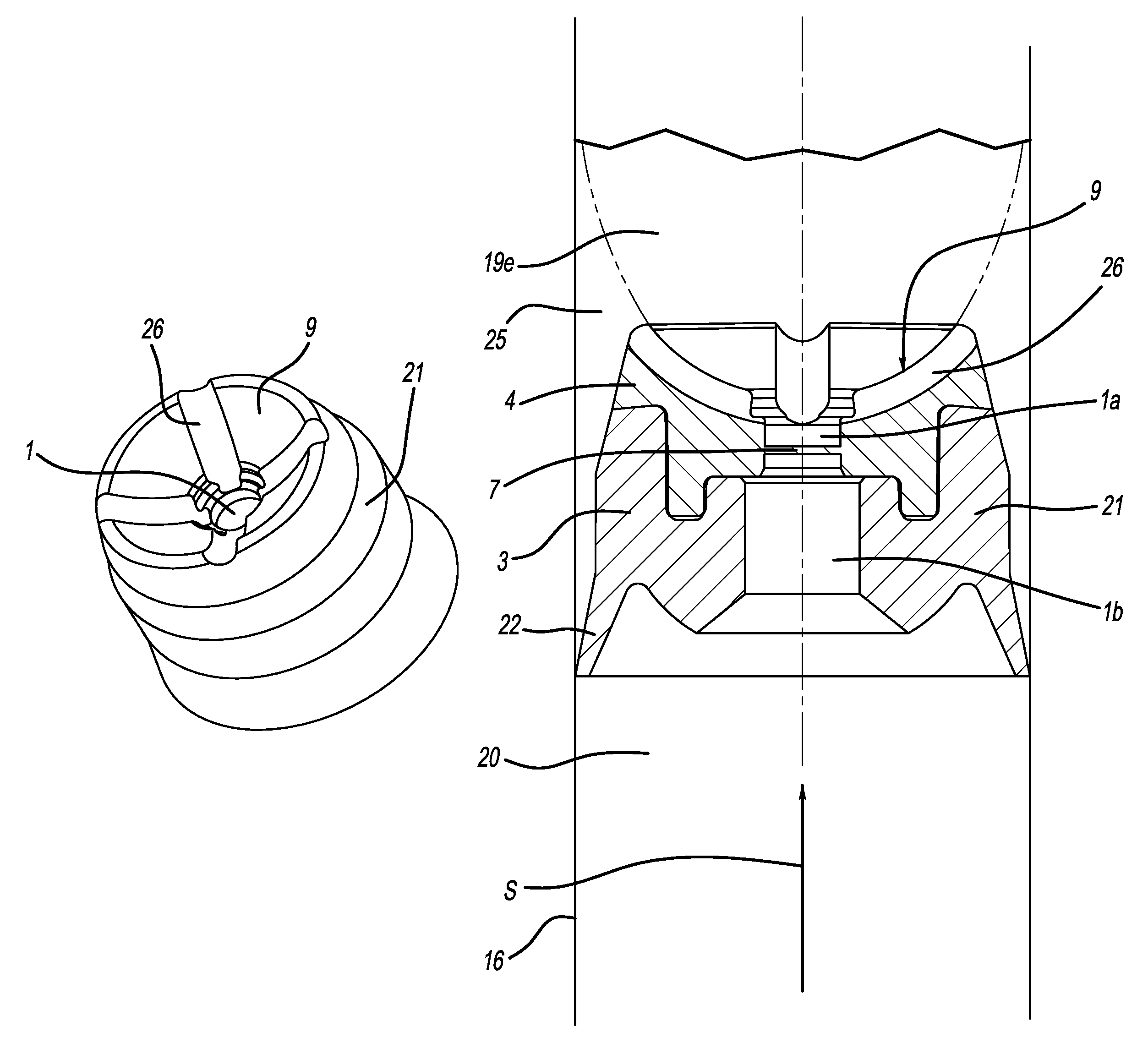

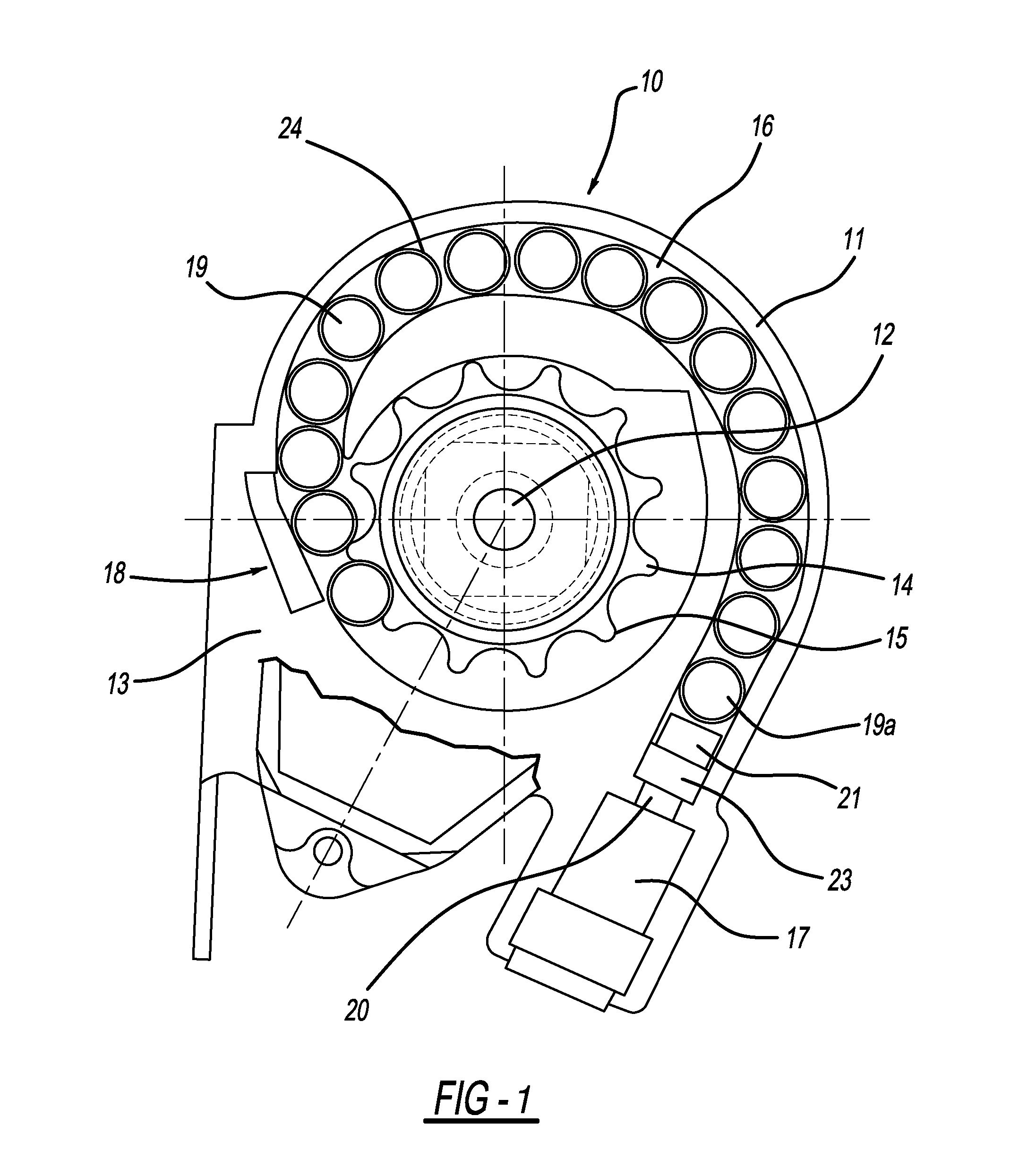

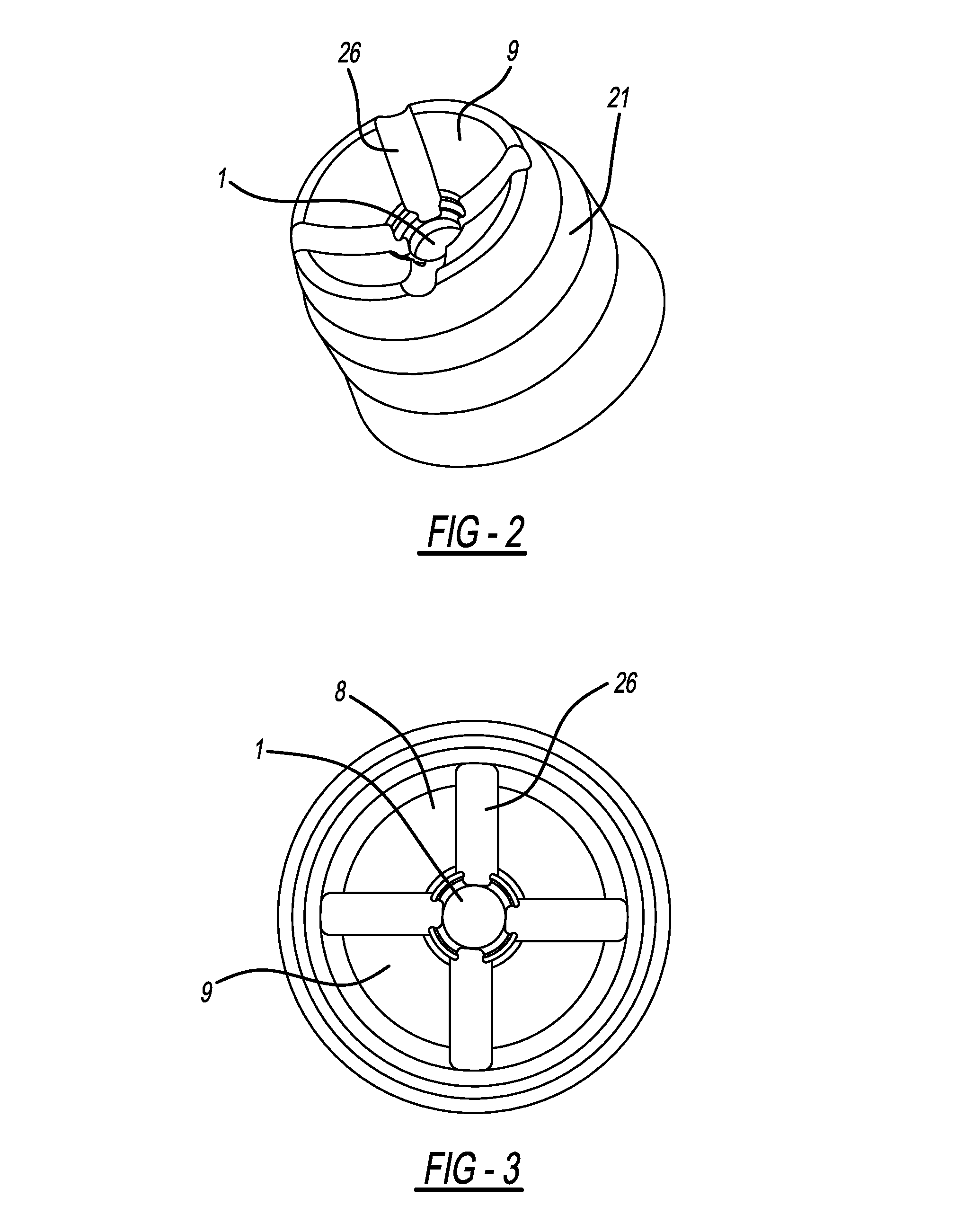

A pretensioning device (10) for a safety belt, of a motor vehicle, having a gas generator (17), a piston (21) guided in a tube (16), which closes a pressure area (20) in the tube (16) that is pressurized by the gas generator (17) whereupon the piston (21) is able to move in a pretensioning movement which is able to be conveyed to the safety belt by means of an inertia body (19a) resting on a front face (9) of the piston (21). The piston (21) forms a pass-through opening (1) releasable upon exceeding of a predetermined pressure and a recess (26) is provided in the front face (9) with an inertia body (19a) resting thereon, so that a flow connection is created from the pass-through opening (1) to the area (25) located behind the piston (21) in the direction of the pretensioning movement (S).

Owner:AUTOLIV DEV AB

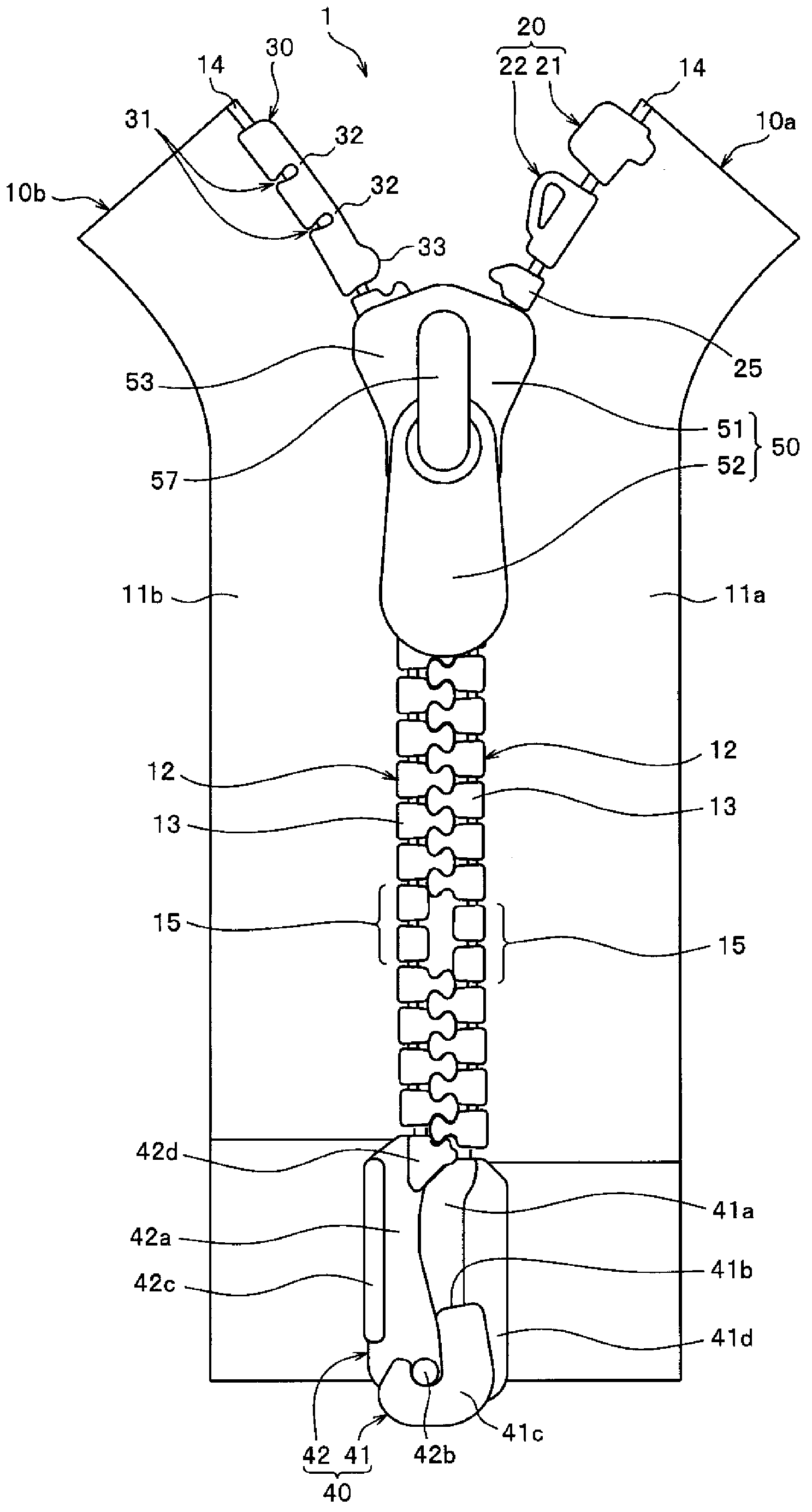

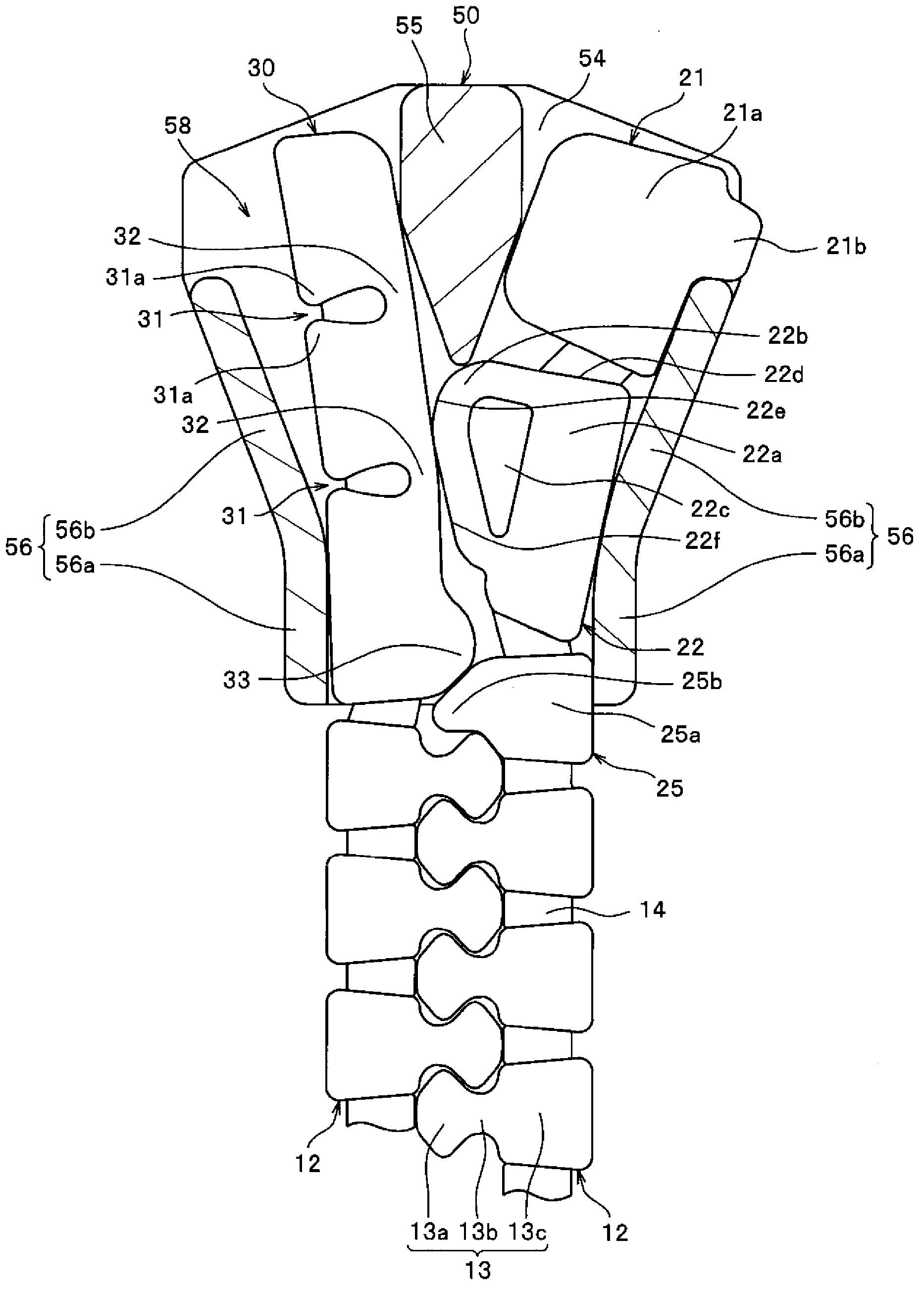

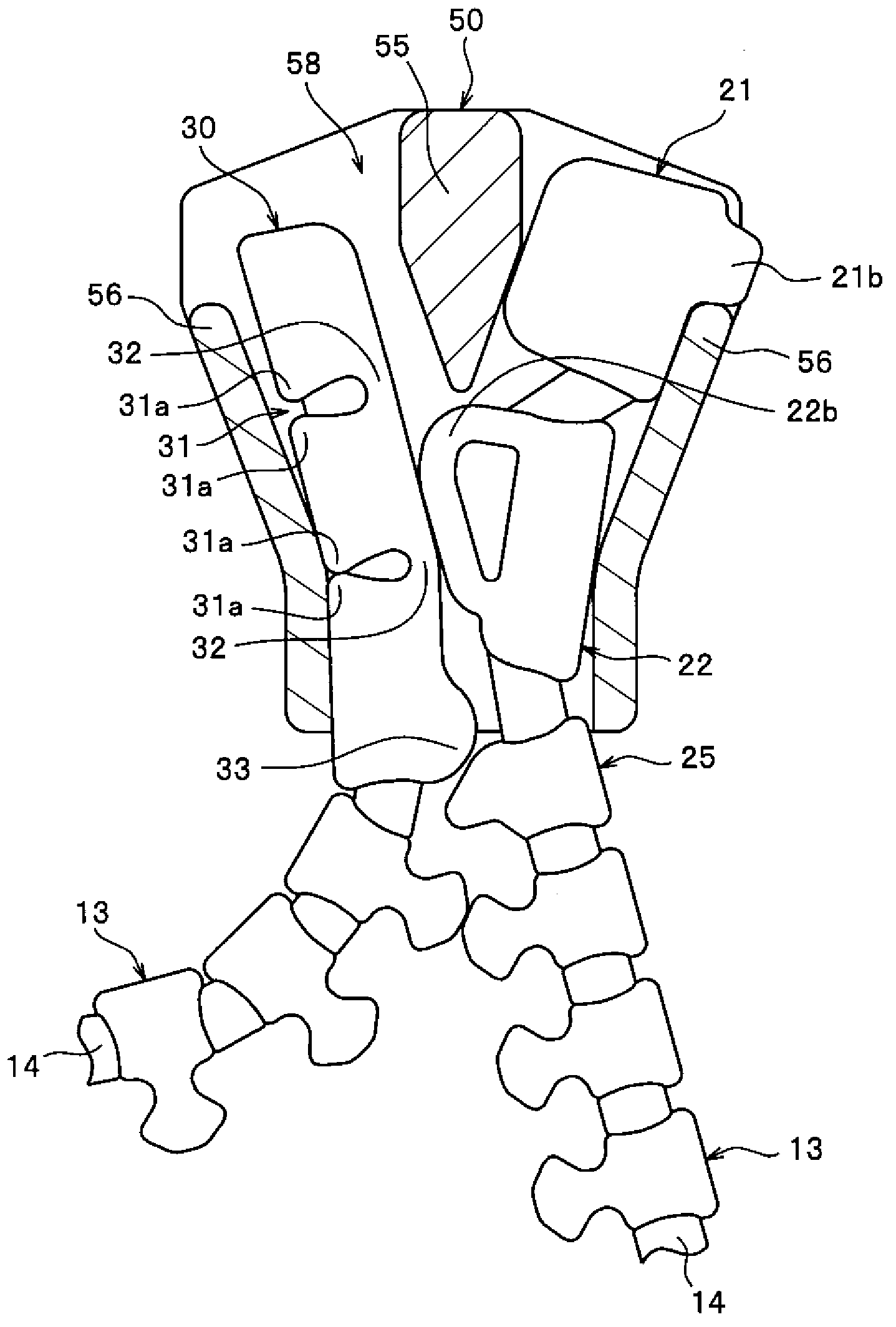

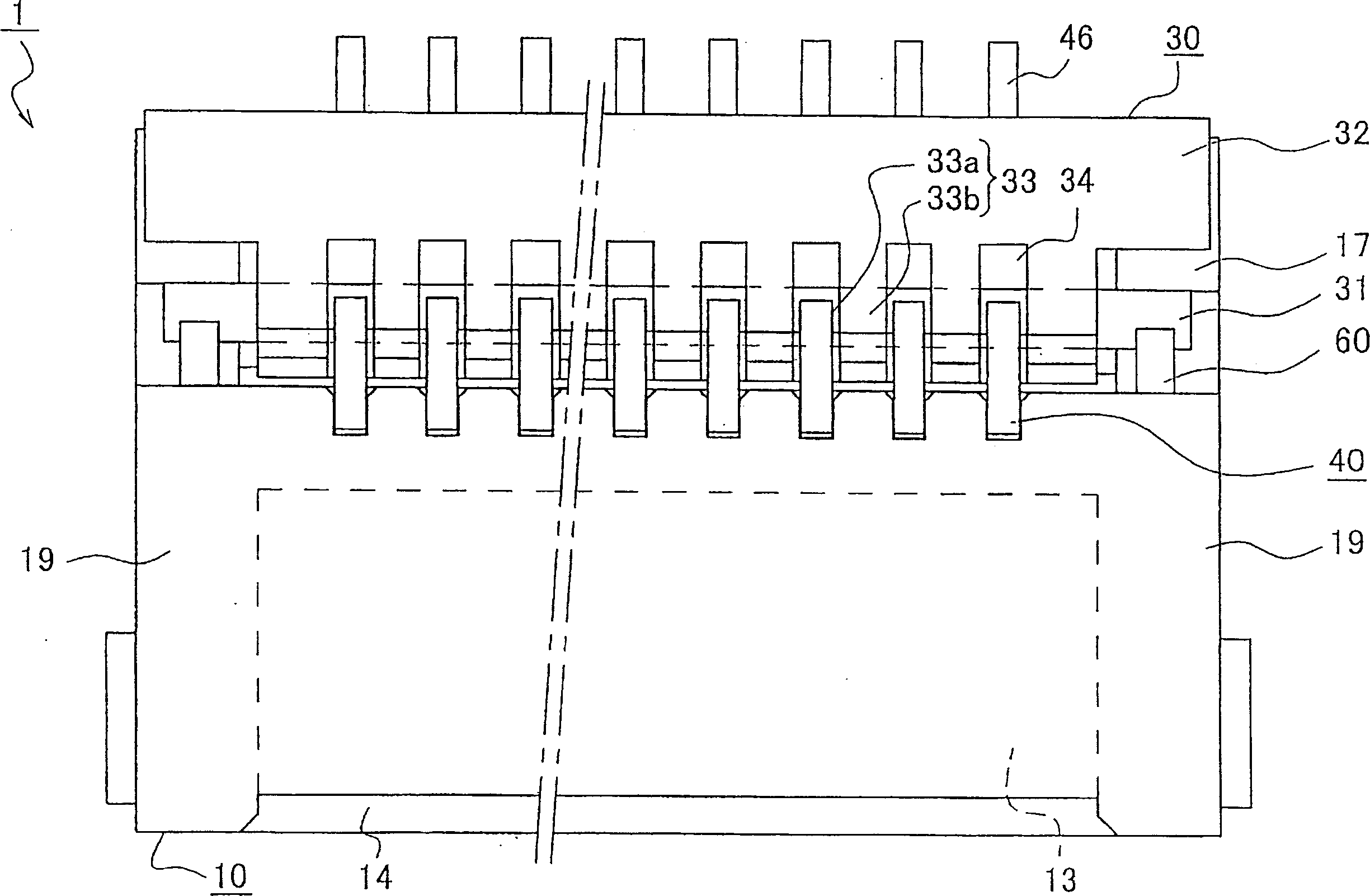

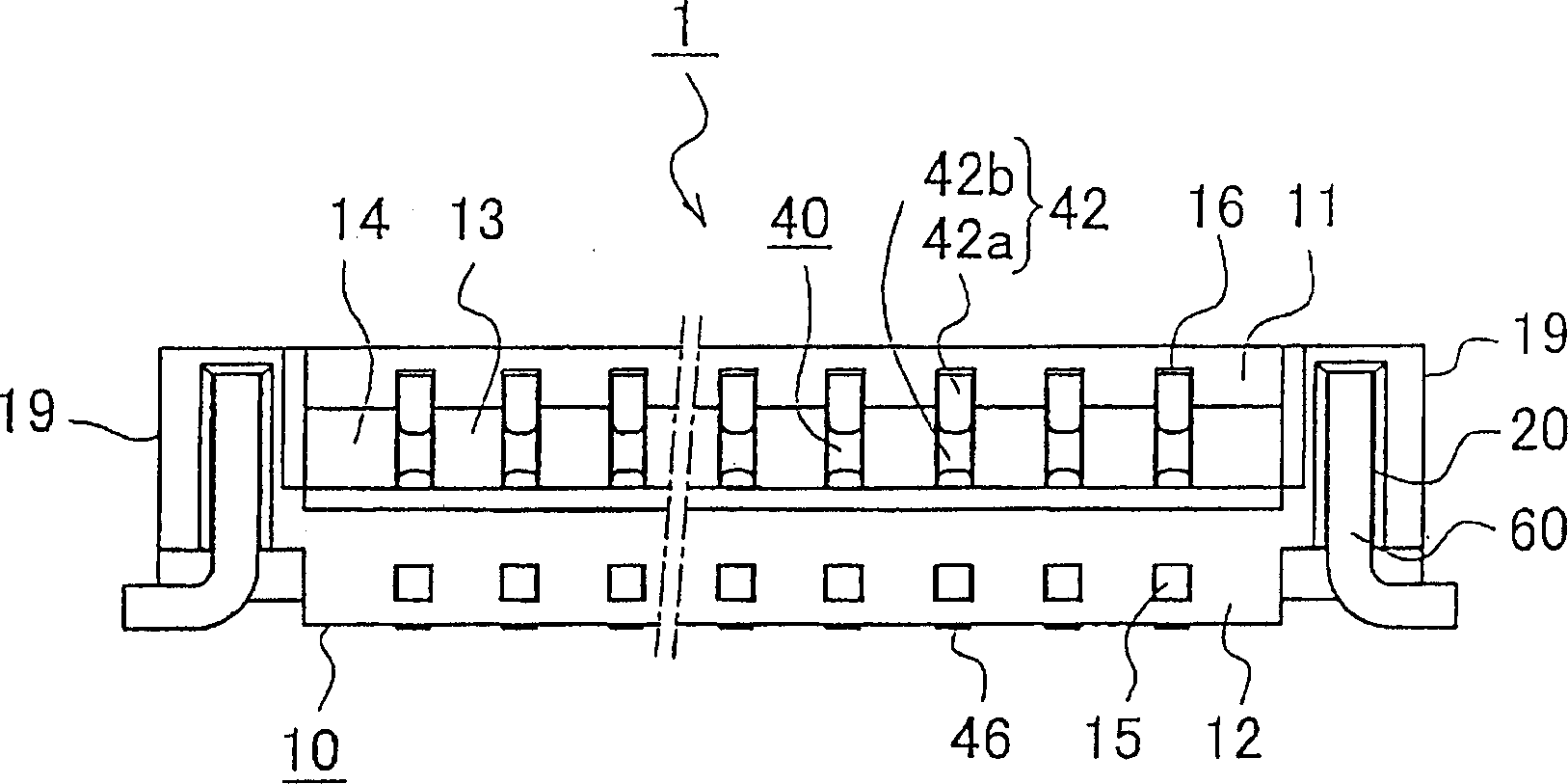

Slide fastener

In this slide fastener (1, 80), a fragile section (15, 86) is provided to an element row (12), and it is possible to detach the element row (12) in an engaged state from the fragile section (15, 86) and to separate first and second fastener stringers (10a, 10b). Lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) are arranged on the second fastener stringer (10b). The lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) have a larger thickness, for preventing lateral withdrawal, than the spacing of a tape insertion and passage gap of a slider (50). The lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) have at least one small-width section (32, 71b, 72b, 72d, 73b, 74b) at a portion provided with a thickness for preventing lateral withdrawal. Even when the slide fastener (1, 80) receives a lateral pulling force, the lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) are thereby held in the slider (50), and a closed state can be maintained. It is also possible, when the element row (12) is detached from the fragile section (15, 86), to pull out the lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) from the slider (50) in a smooth manner.

Owner:YKK CORP

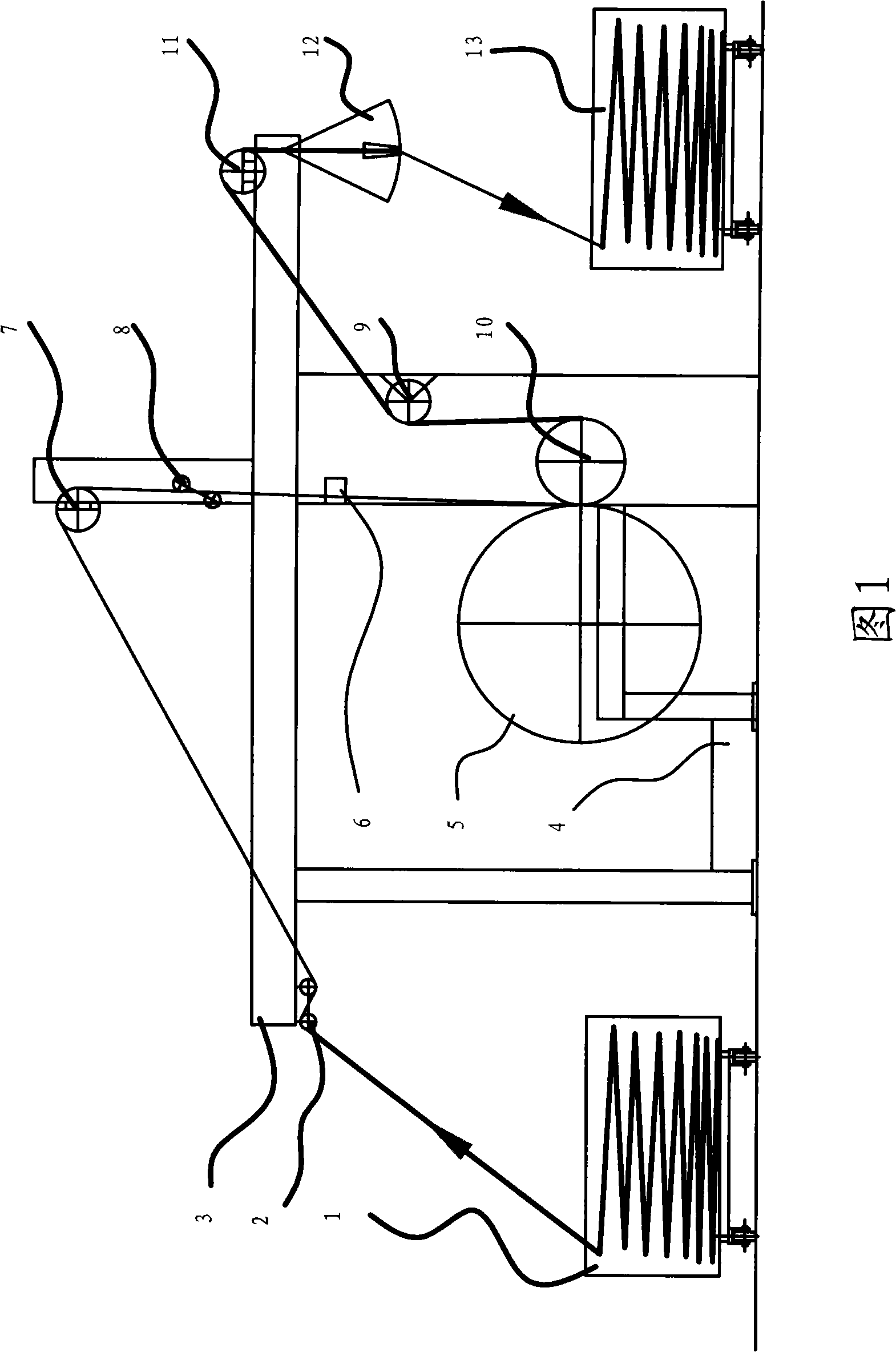

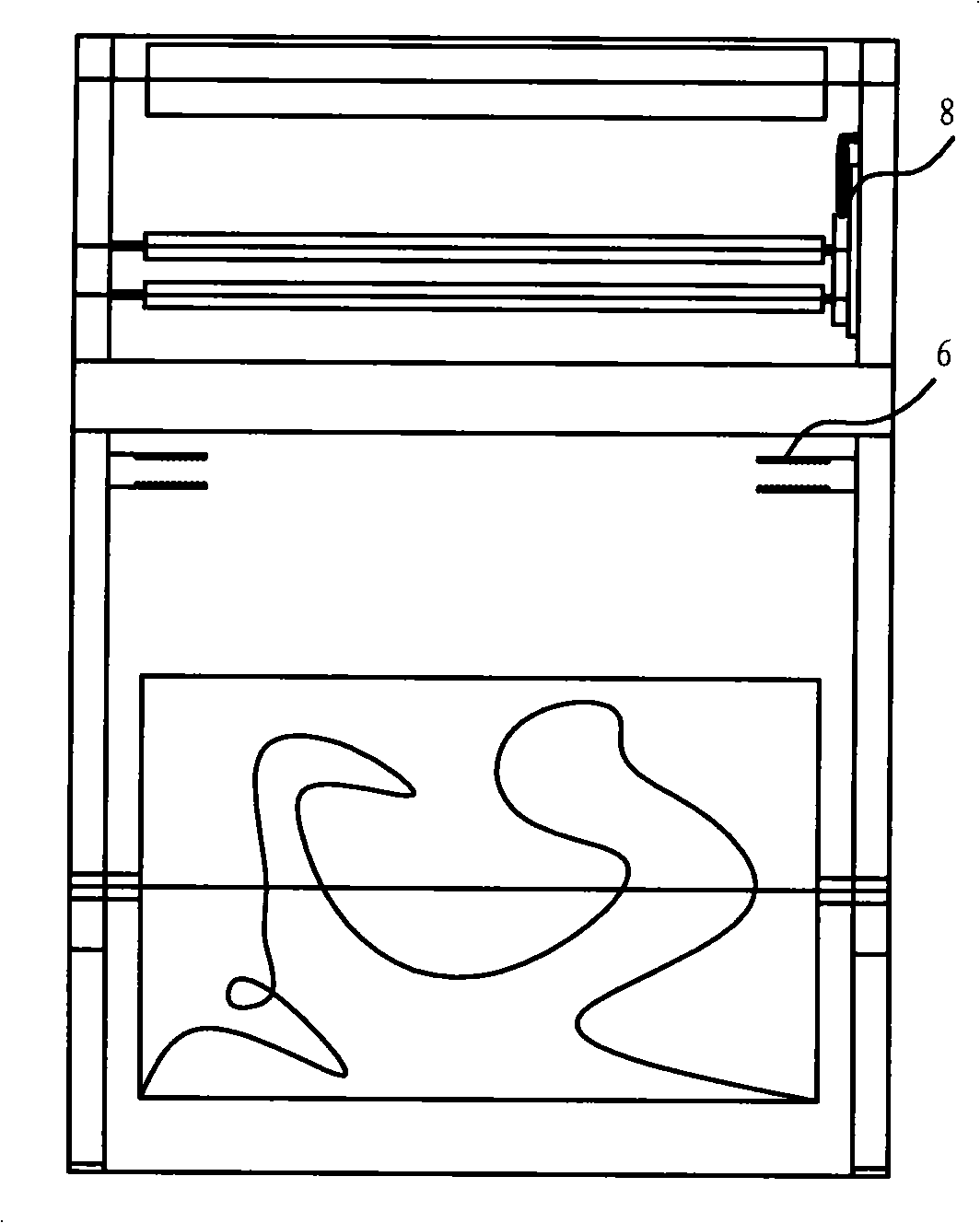

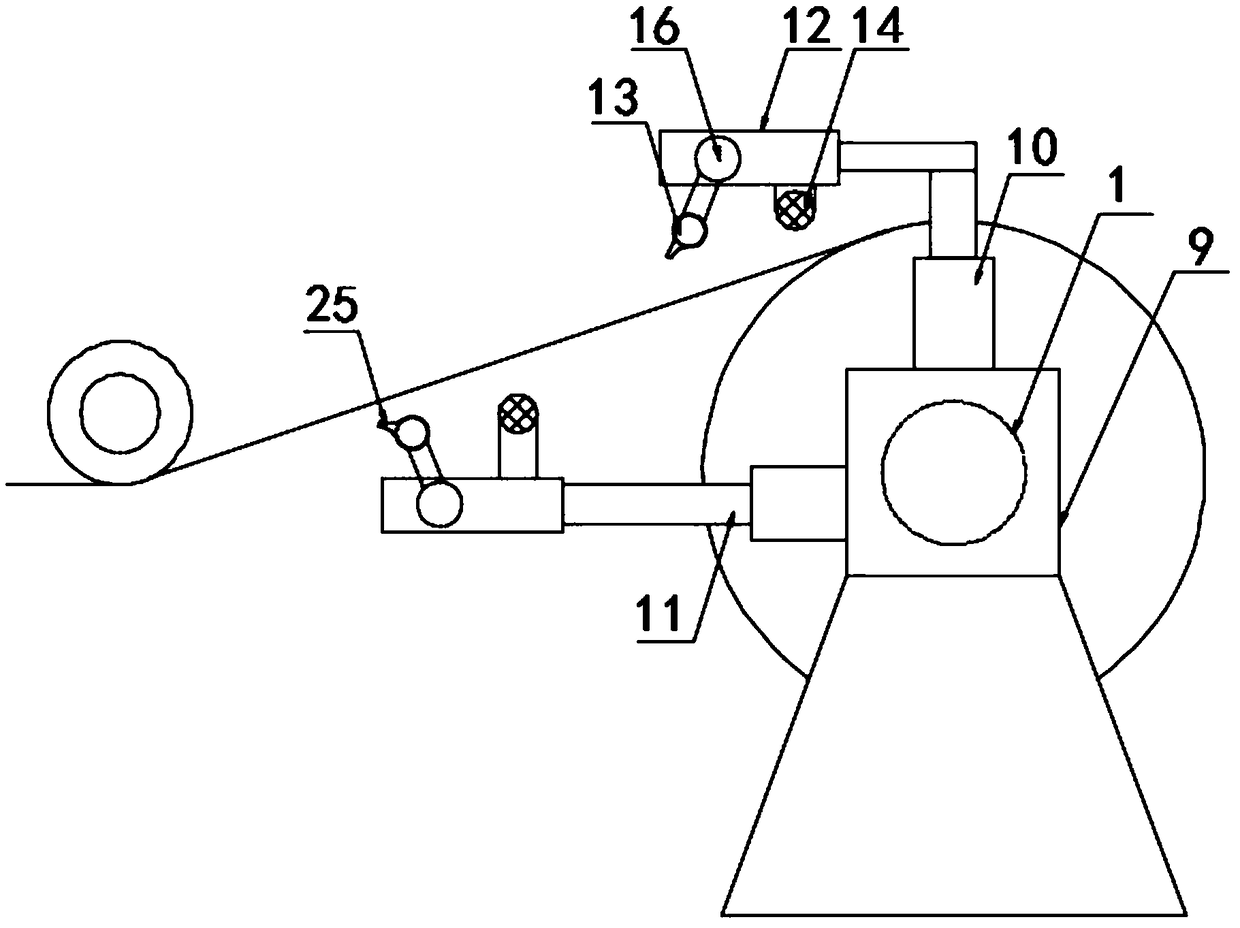

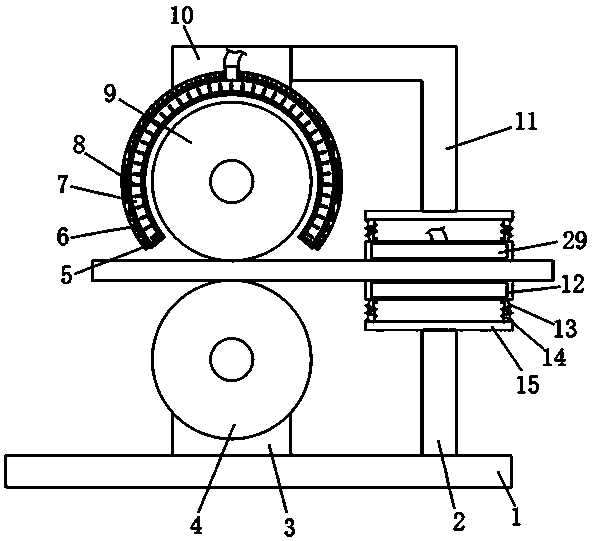

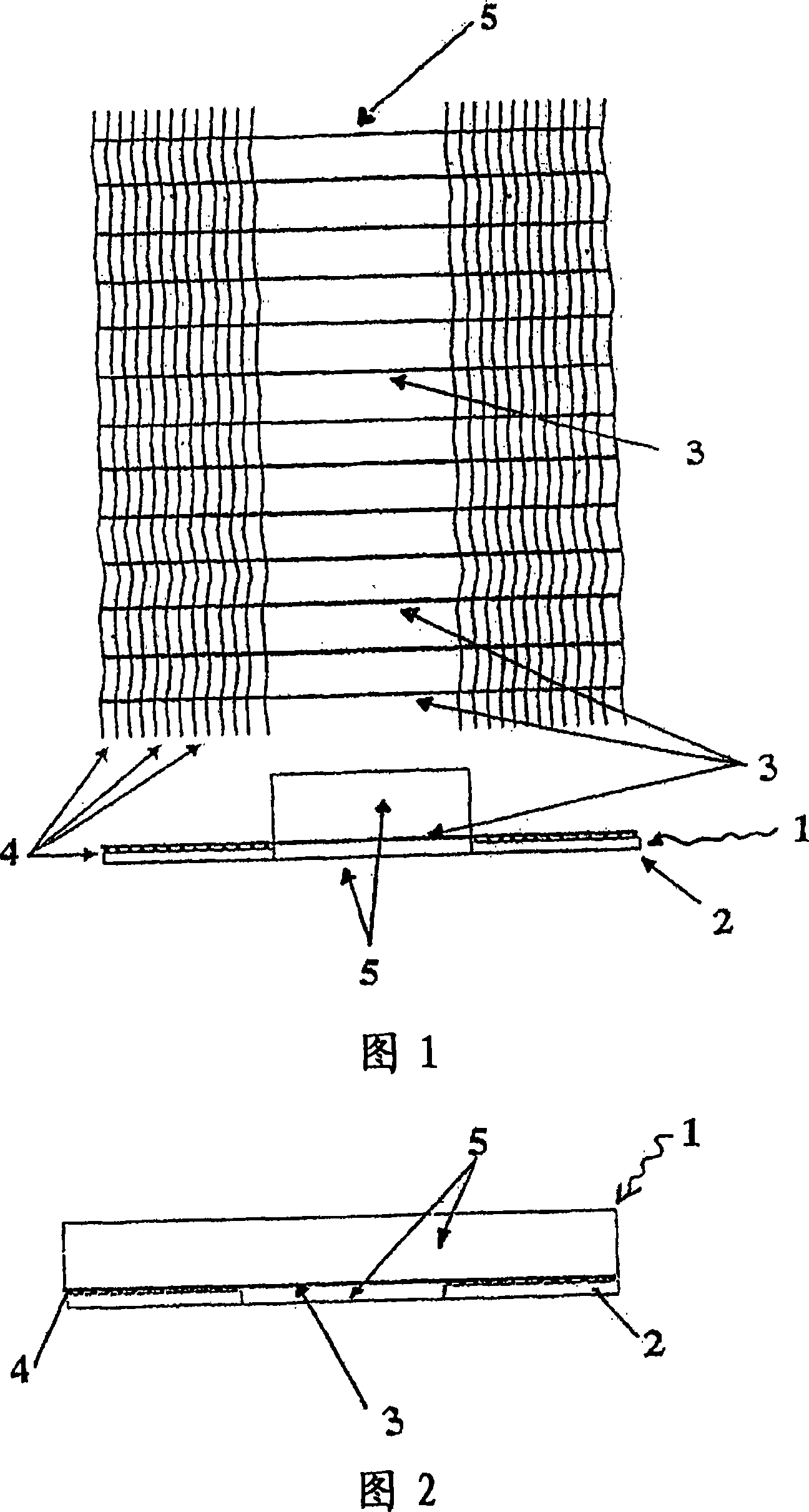

Printing and embossing machine and printing and embossing method thereof

ActiveCN101311402AKeep closedNo longitudinal deformationPattern makingWebs handlingBlanketElectric heating

The invention relates to a production method of fabric and production equipment thereof, in particular to an embossed printing machine for manufacturing embossed printing blankets with an automatic centering device and an embossed printing method thereof. Aiming at the existing electric heating printing machine, the technical improvement of the invention realizes grey cloth always to keep superposing with the center of a design plate in the advancing process, reduces the design difference and edge press leakage and improves the certified product rate. The main content of the invention is that the embossed printing machine comprises a cloth feeding machine, a frame, an embossed die roller, a draw-out roller and a cloth accepting cart. The embossed printing machine further comprises a cloth feeding tension adjusting device, an electronic automatic tracking centering device and a draw-out cooling device.

Owner:ZHEJIANG TRUELOVE GROUP

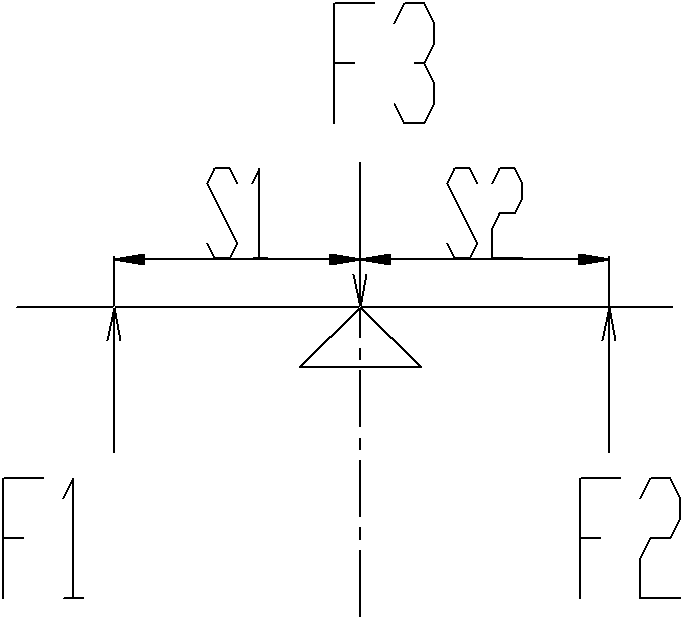

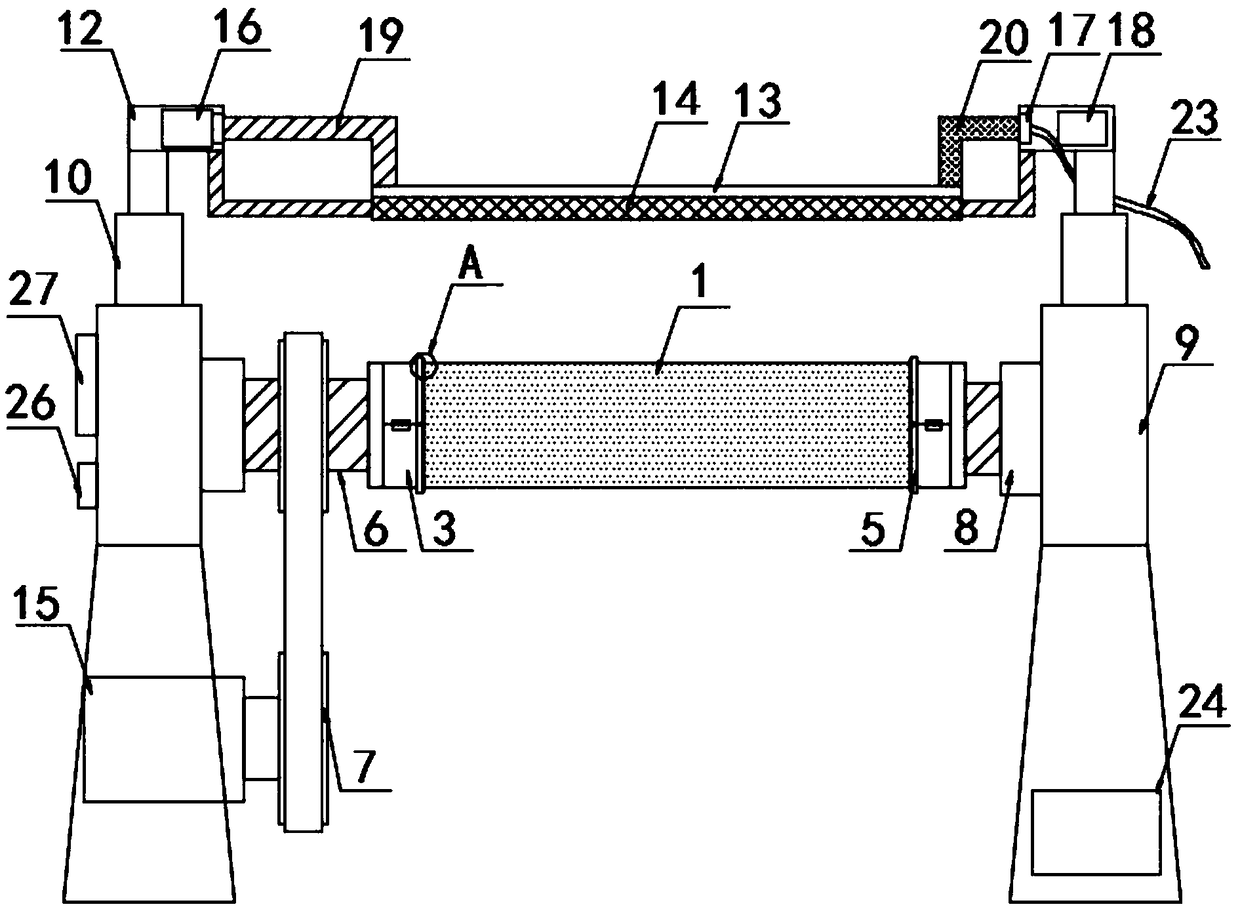

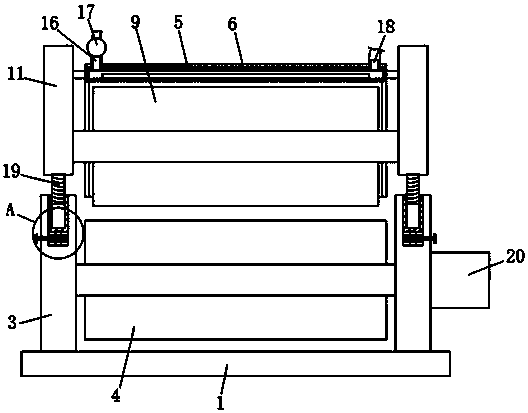

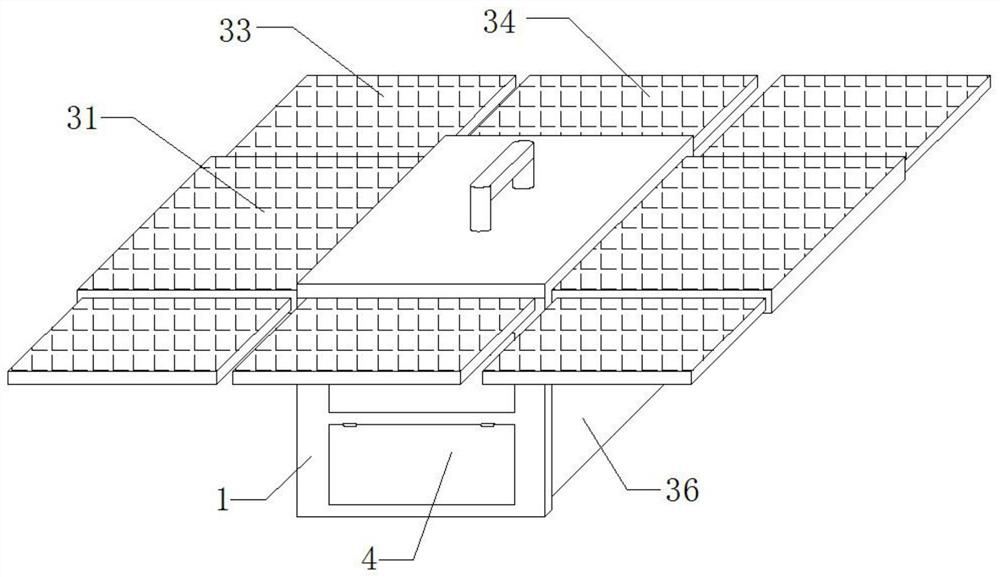

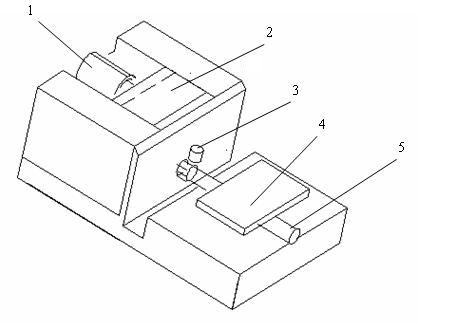

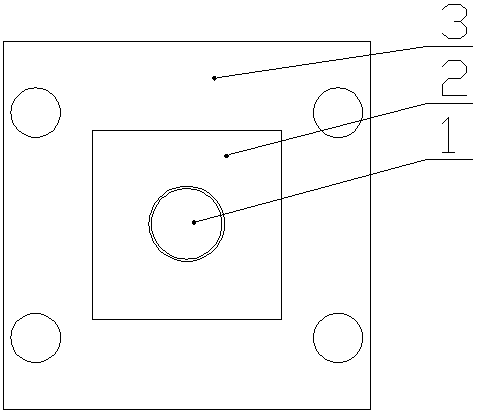

Pressure plate clamping mechanism

ActiveCN102756293AIncrease practical rangeEnsure reasonable balancePositioning apparatusMetal-working holdersEngineering

The invention discloses a pressure plate clamping mechanism. The pressure plate clamping mechanism comprises a pressure plate and a force application rod penetrating the pressure plate, one end of the pressure plate is supported on a cushion block, the other end of the pressure plate is used for compressing a workpiece, the cushion block comprises a support part and an abdication part, the top surface of the support part is in contact with the pressure plate, the abdication part is provided with an abdication hole for enabling the force application rod to penetrate, and a gap is arranged between the top surface of the abdication part and the pressure plate. The pressure plate clamping mechanism disclosed by the invention can achieve the purpose of expanding the range of applications of ordinary clamping by reducing the spatial size of the cushion block. The force at the fulcrum of the cushion block can be balanced at the lower part of the whole cushion block by ingenious force conversion. Simultaneously, the pressure plate clamping mechanism can ensue that the force at the fulcrum can be close to the workpiece as far as possible and ensure the reasonable equilibrium of a lever. Compared with the ordinary clamping, the stress situation of theoretical calculation is the same. The pressure plate clamping mechanism disclosed by the invention has the characteristics of simple and compact structure, and stability and reliability in operation.

Owner:华域视觉科技(长沙)有限公司

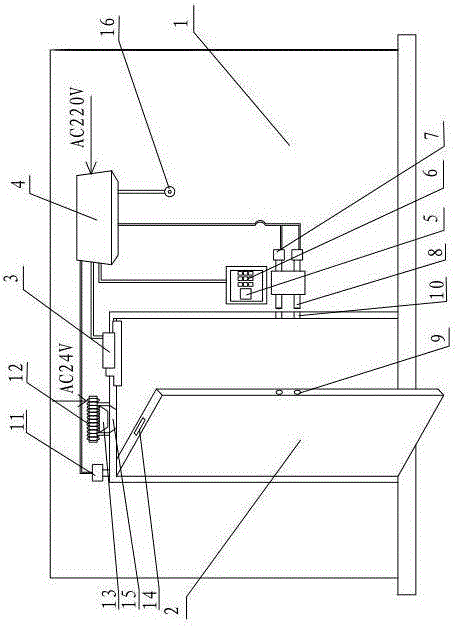

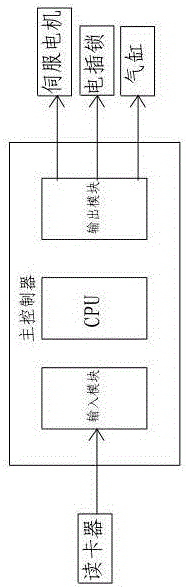

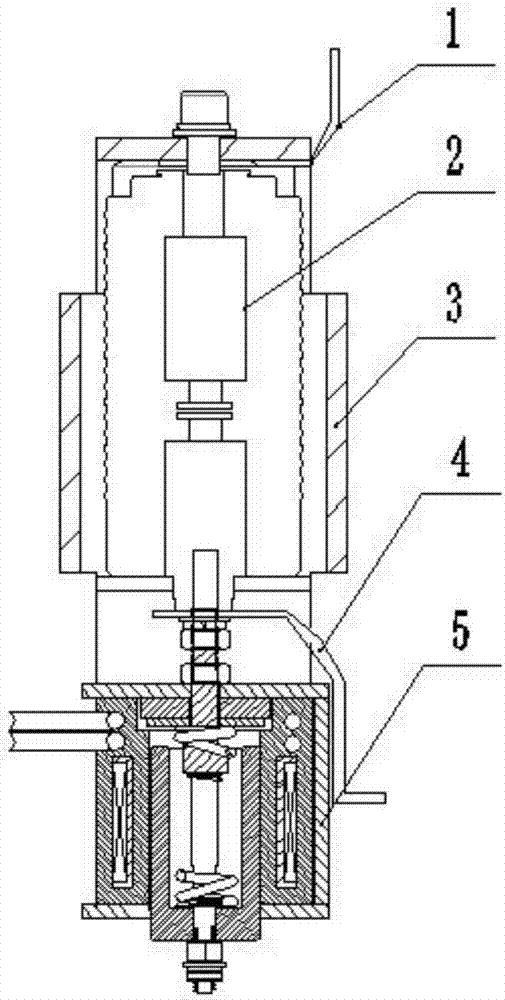

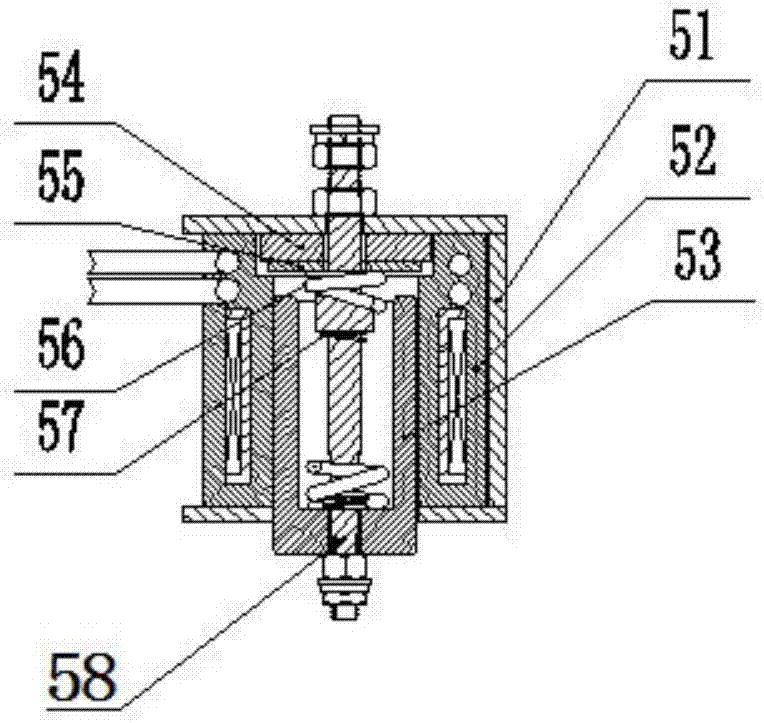

Intelligent antitheft electrical metering box

ActiveCN105021859AGood anti-theft effectPrevent Electricity StealingTime integral measurementElectricityEngineering

The invention discloses an intelligent antitheft electrical metering box, and relates to electric power system protection tool technology field. The metering box comprises a casing and a casing door; the casing door is closed by aid of an electrical mortise lock; a main controller, an input apparatus and an output apparatus are set on the casing; the main controller comprises a CPU processor connecting the input module and the output module; the input apparatus comprises a card reader; the card reader has a reading area and a digital area; the output apparatus comprises an electrical mortise lock and a cylinder lock; the cylinder lock comprises a cylinder; the cylinder is connected with a locking bar; a lockhole is set on the casing door; a rod-passing aperture is set on the doorframe of the casing door; the output module is connected with the electrical mortise lock and the cylinder respectively; the output apparatus also comprises a servo motor for driving the door shaft of the casing door rotate; the output module is connected with the servo motor; and a power-off locking apparatus is set on the casing. The metering box can prevent electricity stealing effectively and avoids illegal behavior of electricity stealing.

Owner:STATE GRID CORP OF CHINA +3

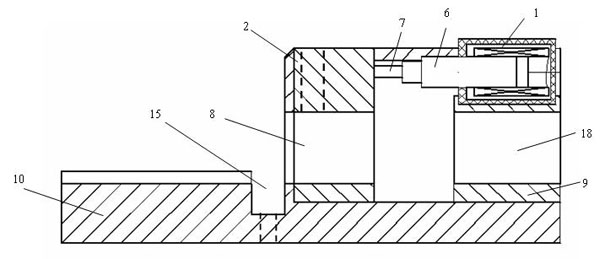

Embedded vacuum contactor

InactiveCN107331572AReduce volumePrevention and control of power failureHigh-tension/heavy-dress switchesAir-break switchesEpoxyElectricity

The invention relates to the electrical technical field, and especially relates to an embedded vacuum contactor with a small size; the embedded vacuum contactor comprises a vacuum bubble and an electromagnetic mechanism; the vacuum bubble top is connected with an upper soft connection, and arranged on the vacuum bubble mounting rack; the electromagnetic mechanism comprises an insulation coil, and a permanent magnet, a movable core and a movable rod arranged in the insulation coil; the movable rod penetrates the movable core and the permanent magnet, and is connected with the vacuum bubble bottom through a lower soft connection; the movable core comprises an opening spring and a closing spring arranged from top to bottom in sequence; the opening spring and the closing spring are respectively sleeved on the movable rod; an external magnetic steel housing is arranged outside the insulation coil. The electromagnetic mechanism and the vacuum bubble of the embedded high voltage contactor are directly connected, thus greatly reducing the vacuum contactor volume; the coil is casted by an epoxy resin, and the outgoing line outputs the high voltage cable connection manipulation electricity, thus isolating low voltage manipulation electricity from a high voltage environment; the permanent magnet can be attached to the movable core once closed, thus keeping the closing state, and preventing tripping caused by manipulation electricity drop out.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG

Pretensioning device for a safety belt

ActiveUS8684413B2Reduce pressure areaReduce pressureBelt retractorsSafety beltsEngineeringBelt safety

A pretensioning device (10) for a safety belt, of a motor vehicle, having a gas generator (17), a piston (21) guided in a tube (16), which closes a pressure area (20) in the tube (16) that is pressurized by the gas generator (17) whereupon the piston (21) is able to move in a pretensioning movement which is able to be conveyed to the safety belt by means of an inertia body (19a) resting on a front face (9) of the piston (21). The piston (21) forms a pass-through opening (1) releasable upon exceeding of a predetermined pressure and a recess (26) is provided in the front face (9) with an inertia body (19a) resting thereon, so that a flow connection is created from the pass-through opening (1) to the area (25) located behind the piston (21) in the direction of the pretensioning movement (S).

Owner:AUTOLIV DEV AB

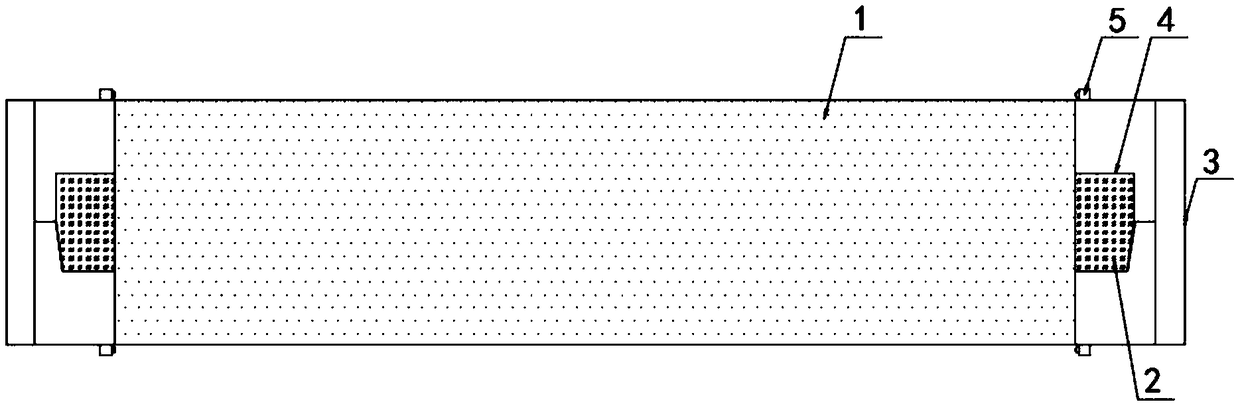

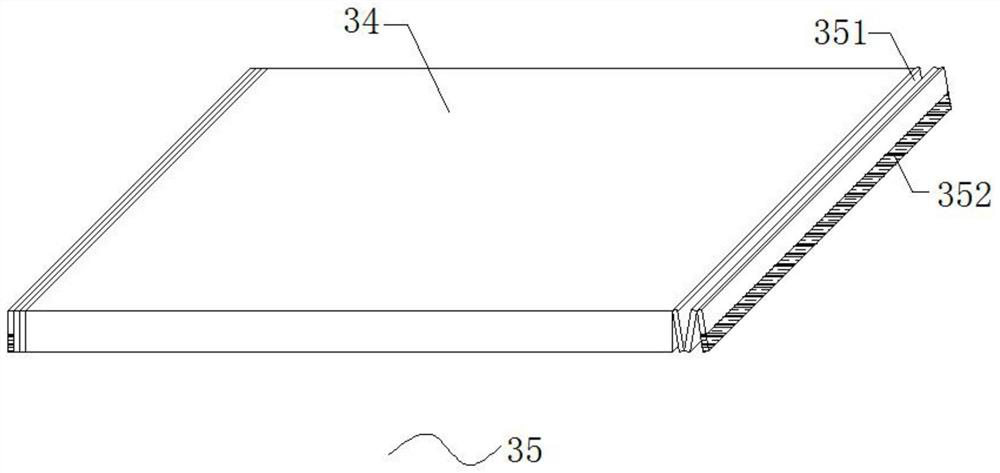

Rolling device for plastic thin film

The invention discloses a rolling device for a plastic thin film. The rolling device comprises a rolling cylinder. Clamping plates are arranged at the two ends of the rolling cylinder. Fixing bases are arranged on the outer sides of the clamping plates. A clamping groove is formed in each fixing base. A ball plate is arranged on the outer wall of the end portion, close to the rolling cylinder, ofeach fixing base. A rotating shaft is fixedly arranged on the outer side of each fixing base. A drive mechanism is arranged on the bottom of the rotating shaft on one side of each fixing base. A bearing is arranged on the end portion of each rotating shaft. A supporting table is arranged on the outer side of each bearing. A first air cylinder is fixedly arranged on the top of each supporting table. A second air cylinder is fixedly arranged on the front side of each supporting table. A control box is fixedly arranged on the end portion of each first air cylinder, and a control box is fixedly arranged on the end portion of each second air cylinder. A cold air pipe and an ion stick are arranged on the inner side of each control box. According to the rolling device, a forward and backward motor drives the cold air pipes to rotate, the cold air pipes and the plastic thin film are adjusted to be arranged in an acute angle manner, the large area of the plastic thin film is cooled through wind, adhesion caused after rolling is avoided, in additional, the ion sticks can remove static electricity on the plastic thin film, and the influence on rolling and caused adhesion are avoided.

Owner:周玉兰

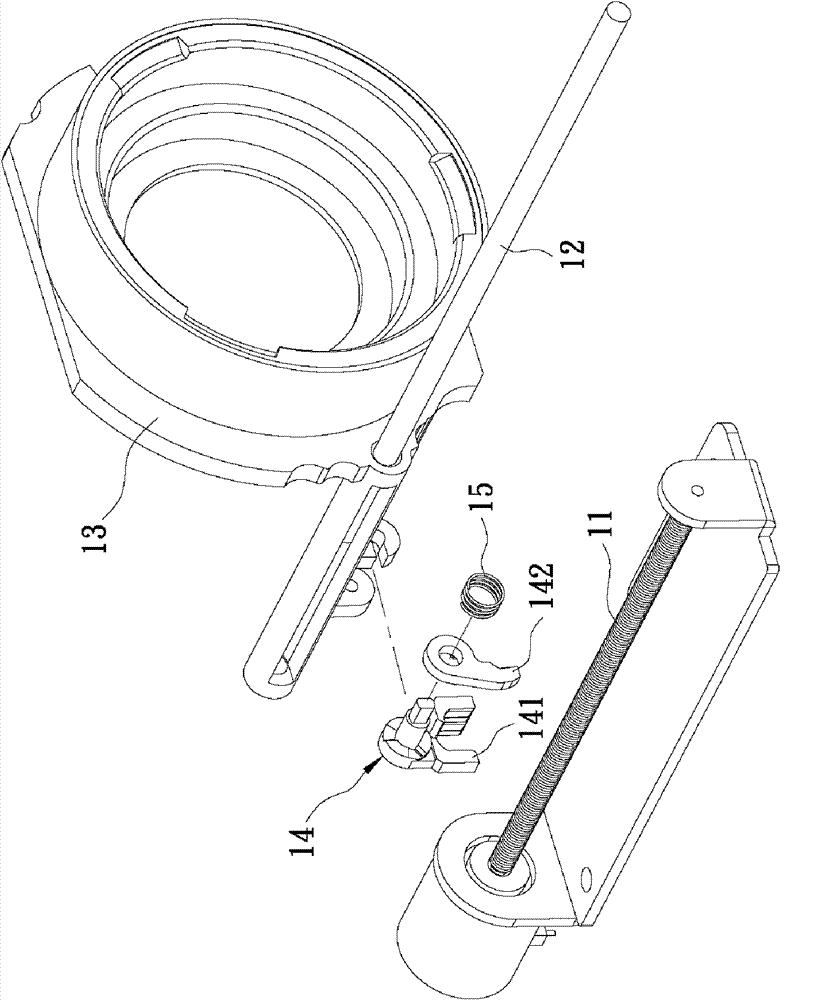

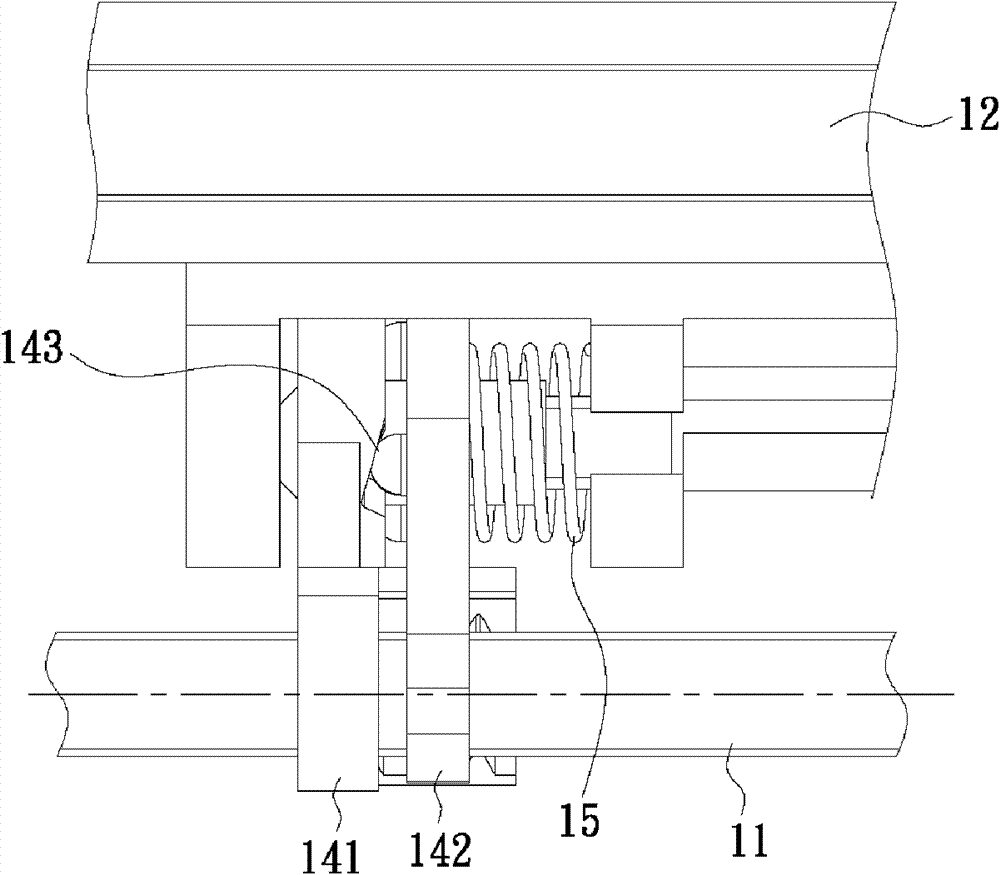

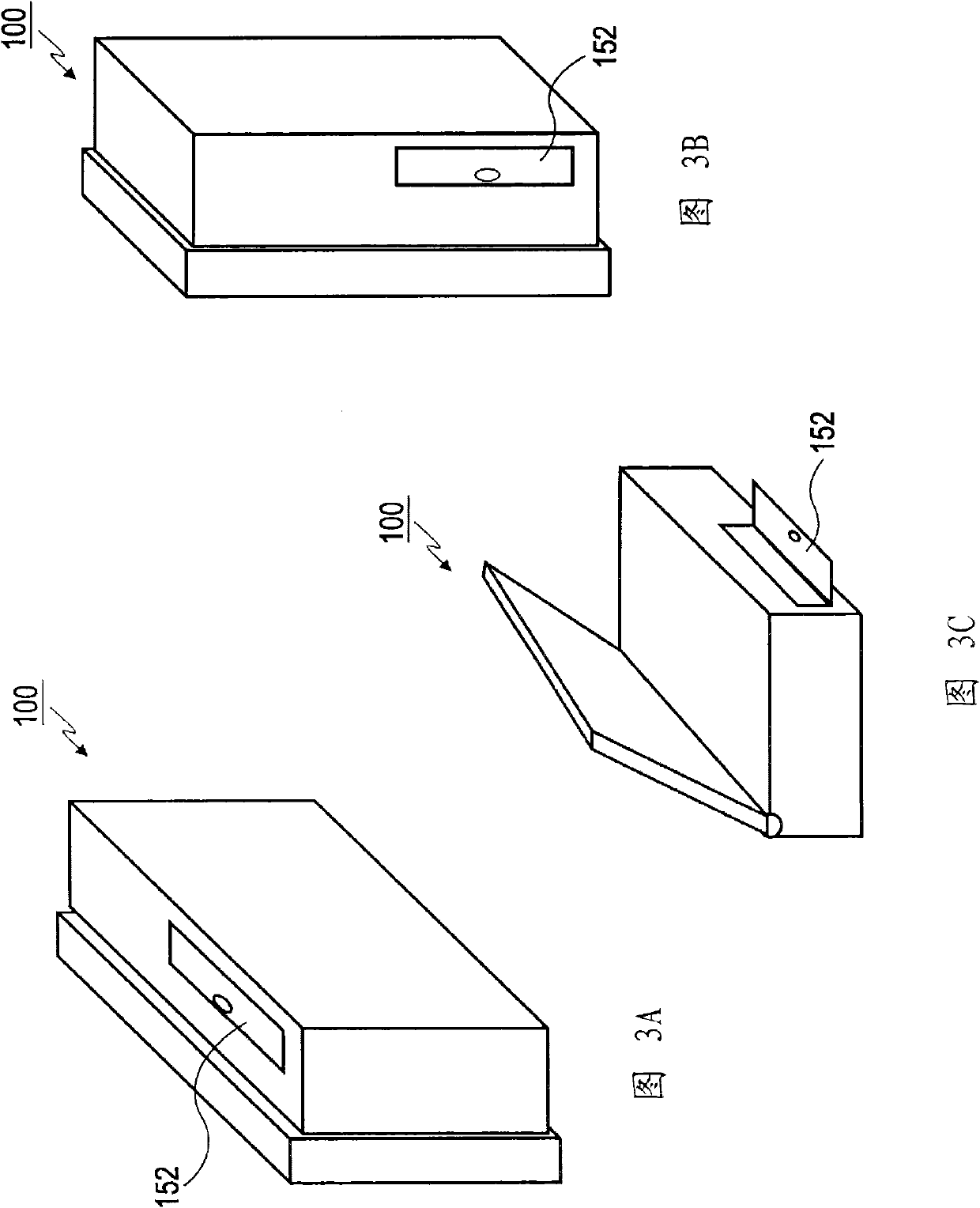

Transmission device for optical equipment

The invention relates to a transmission device for optical equipment, which comprises a drive unit, a guide part, a frame sleeved on the guide part, a clamping jaw unit, a first elastic part and a second elastic part. The drive unit comprises a screw rod. The clamping jaw unit comprises a main clamping jaw and an assistant clamping jaw and is connected with the frame. The first elastic part is arranged on the frame and constantly keeps the main clamping jaw and the assistant clamping jaw to be close with each other so as to be tightly meshed with the screw rod. The second elastic part is arranged on the clamping jaw unit and constantly keeps the frame to push against the guide part. According to the transmission device, the screw rod is driven to rotate by the drive unit so as to drive the clamping jaw unit to lead the optical device on the frame to traverse the guide part; and the frame constantly pushes against the guide part, so that, the frame does not cause shake to result in deviation in optical imaging when being in movement.

Owner:ASIA OPTICAL CO INC

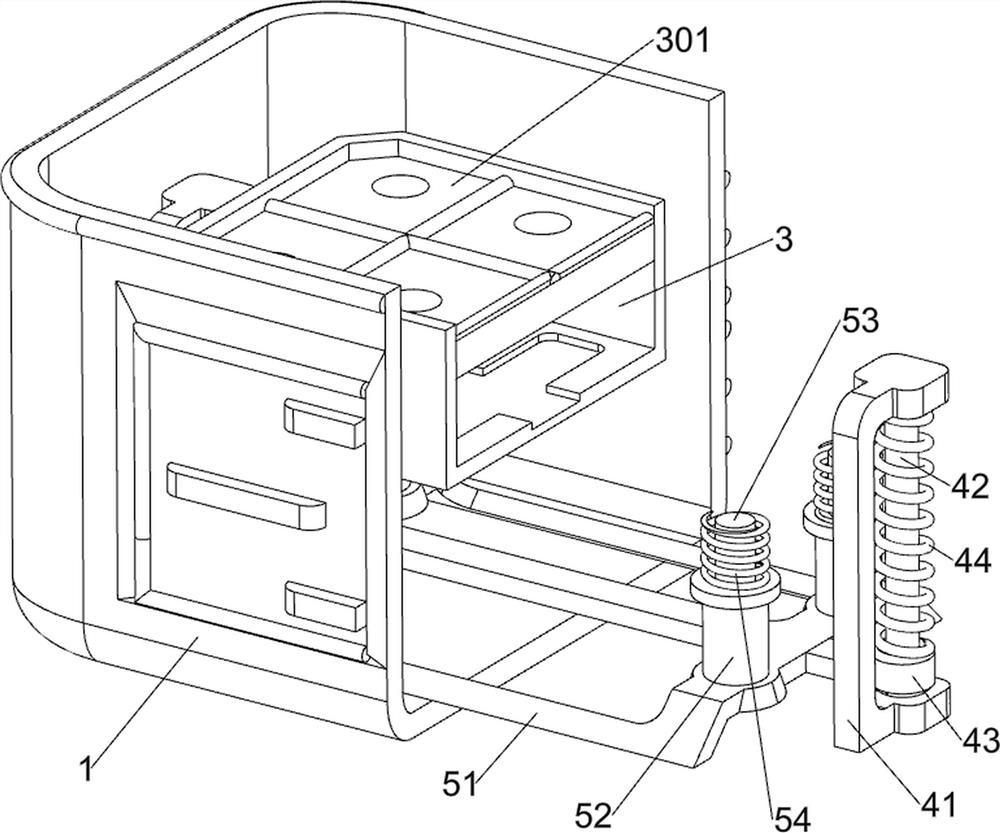

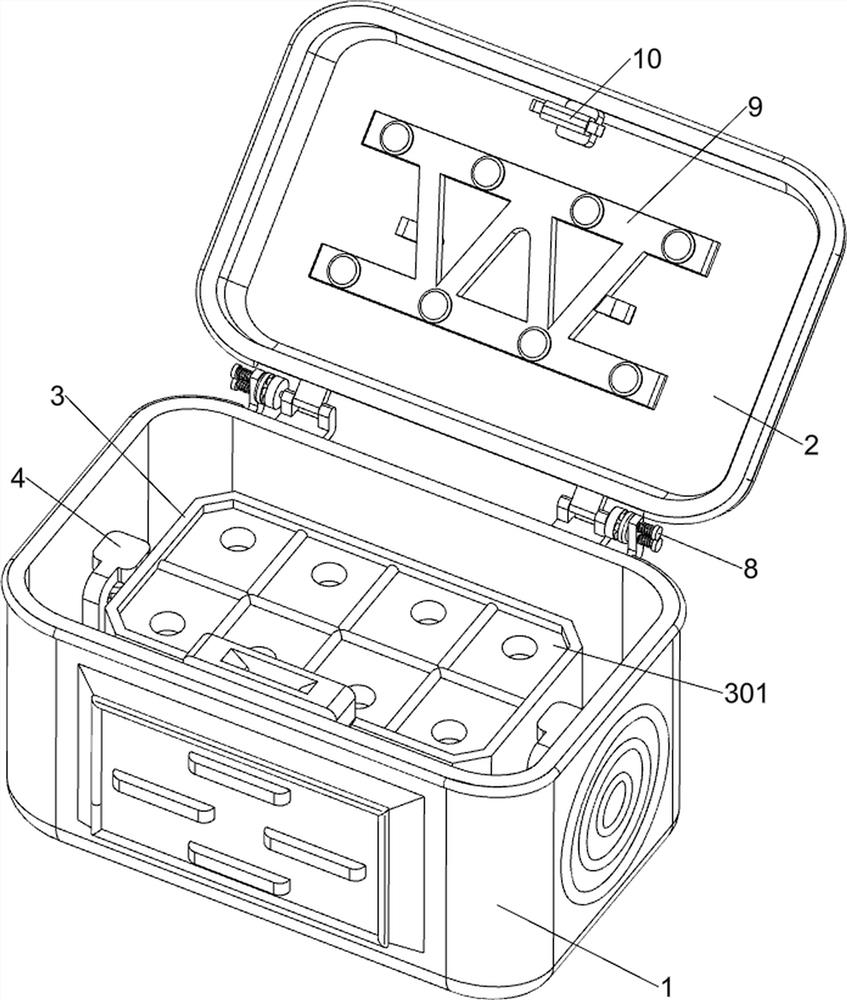

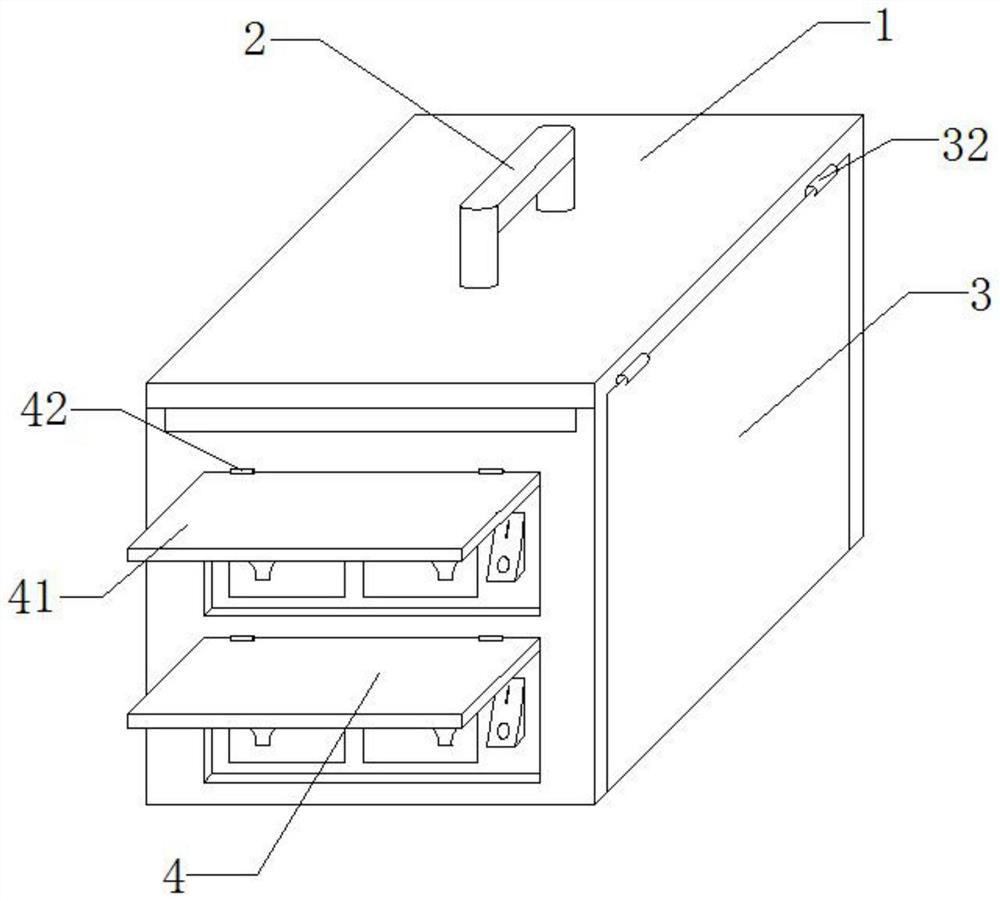

Breast surgery biopsy sample storage box

PendingCN113349840AAvoid shakingKeep closedSurgical needlesVaccination/ovulation diagnosticsSurgery.breastTest tube

The invention discloses a breast surgery biopsy sample storage box, which comprises a box body and the like, wherein, a cover plate is rotatably connected to the rear side of the upper part of the box body, an installation mechanism is arranged at the lower part in the box body, a damping mechanism is arranged on the installation mechanism, a placing frame is arranged on the damping mechanism, and a first protective cotton plate is connected to the upper part of the inner side of the placing frame. The breast surgery biopsy sample storage box disclosed by the invention has the advantages that the cover plate is rotatably positioned, biopsy sample test tubes are automatically pressed and fixed, random shaking of the test tubes is avoided, and the cover plate is conveniently fixed to keep the box body closed.

Owner:郭军峰

Embossing machine with heating function

The invention discloses an embossing machine with a heating function. The embossing machine comprises a base plate, two installing columns are symmetrically and fixedly connected to the upper end of the base plate, a driving roller is arranged between the two installing columns, a driving motor is fixedly connected to the side wall of one installing column and is in transmission connection with the driving roller, a U-shaped support with a downward opening is jointly arranged above the two installing columns, installing grooves are formed in the upper ends of the two installing columns, distance adjusting mechanisms are arranged in the two installing grooves, the two distance adjusting mechanisms are both connected to the lower end of the U-shaped support, and a hot pressing roller is arranged on the inner side of the U-shaped support. The embossing machine is provided with a heat absorbing mechanism and a heat releasing mechanism, heat emitted by the hot pressing roller during heatingcan be absorbed and can be released through the heat releasing mechanism, a material to be subjected to embossing can be preheated, the hot pressing effect is improved, heat can be sufficiently used,heat losses are reduced, and energy consumption can be further reduced.

Owner:YANCHENGSHI YUZHENG PRECISION MACHINE

Emergency power supply

InactiveCN112186875AImprove battery lifeEasy to assemble and disassembleBatteries circuit arrangementsCasings/cabinets/drawers detailsStructural engineeringMechanical engineering

The invention provides an emergency power supply which comprises a shell, a handle, a solar charging mechanism and a power supply connecting mechanism are sequentially arranged on the shell, the handle is fixedly installed in the middle of the outer surface of the upper end of the shell, and the power supply connecting mechanism is arranged on the outer surface of the front end of the shell. The solar charging mechanism comprises a first solar panel, a first hinge, a second solar panel, a third solar panel, a flashing board connecting mechanism, a first clamping groove, a heat dissipation mechanism, a second clamping groove and a supporting block, the first clamping groove is formed in the two sides of the shell, and the first solar panel is installed in the first clamping groove in a clamped mode; and the emergency power supply is convenient to charge when being used outdoors, the cruising ability is improved, the solar panel can form a flashing board to prevent the use from being influenced by rainy days, the heat dissipation effect is better, the plug is fixed and is not easy to fall off after being inserted, the jacks are closed for protection when not used, and insects are prevented from entering and damaging.

Owner:郭娅

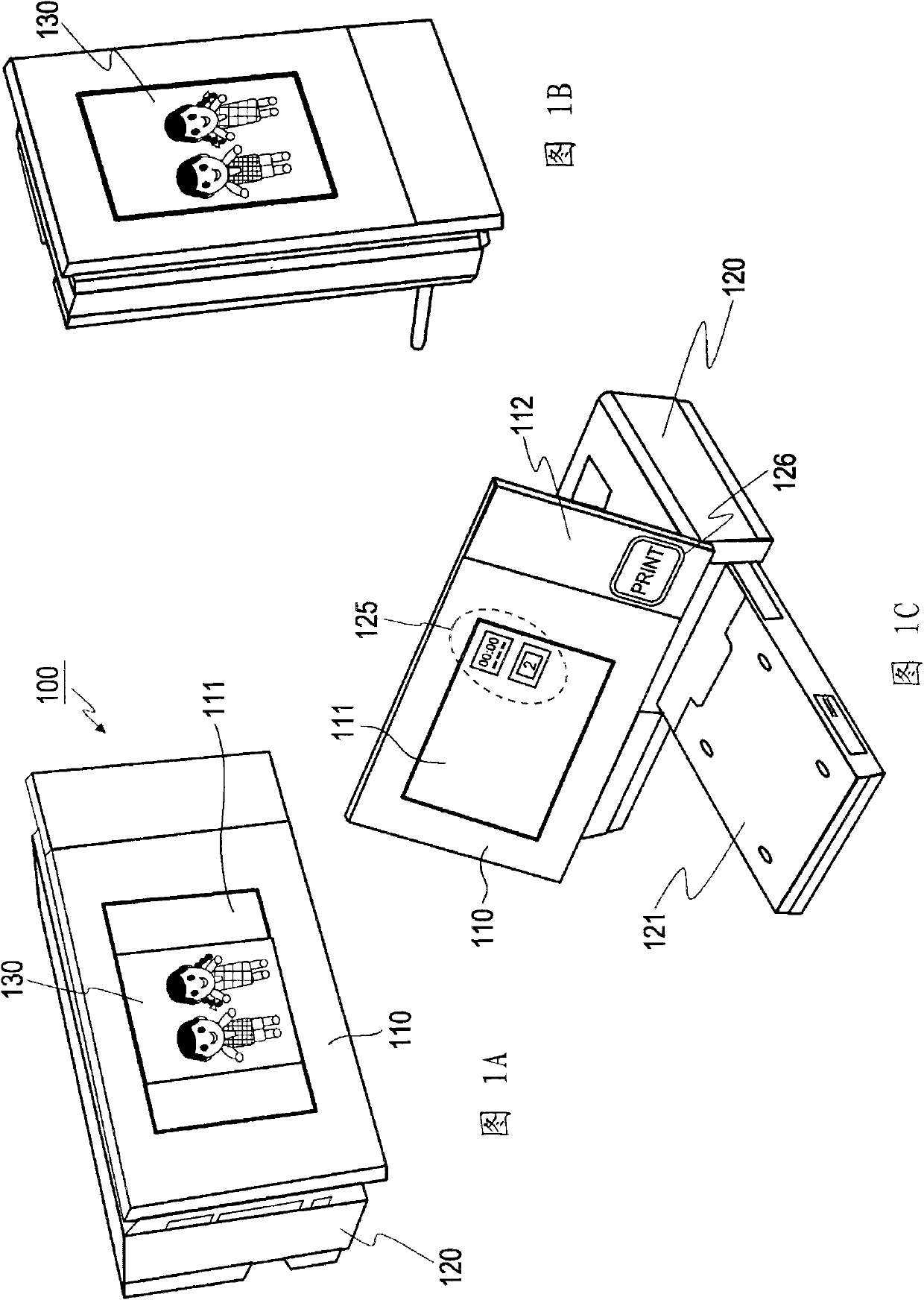

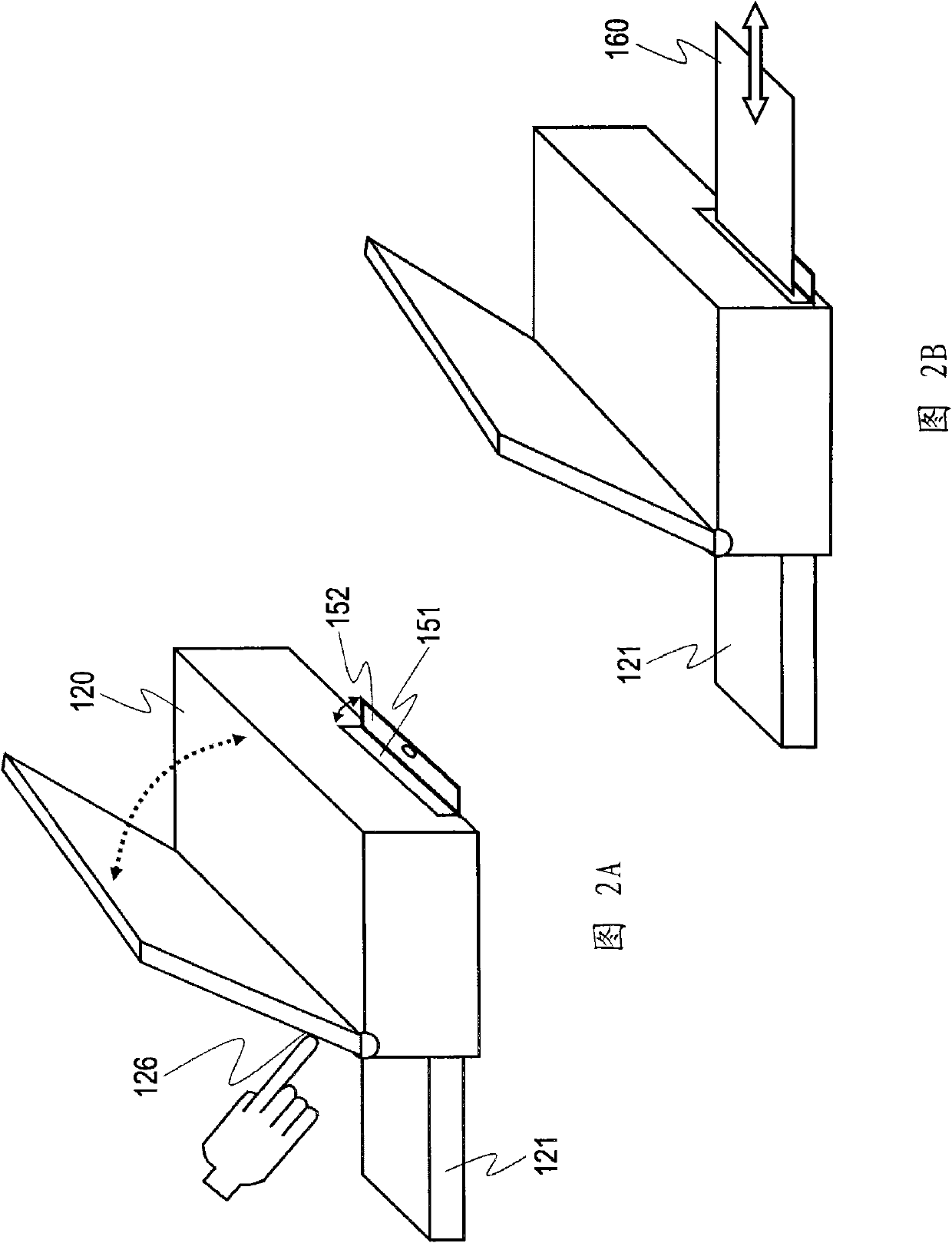

Information processing apparatus

InactiveCN101991311AAvoid enteringKeep closedPicture framesDomestic mirrorsInformation processingLocking mechanism

Owner:SONY CORP

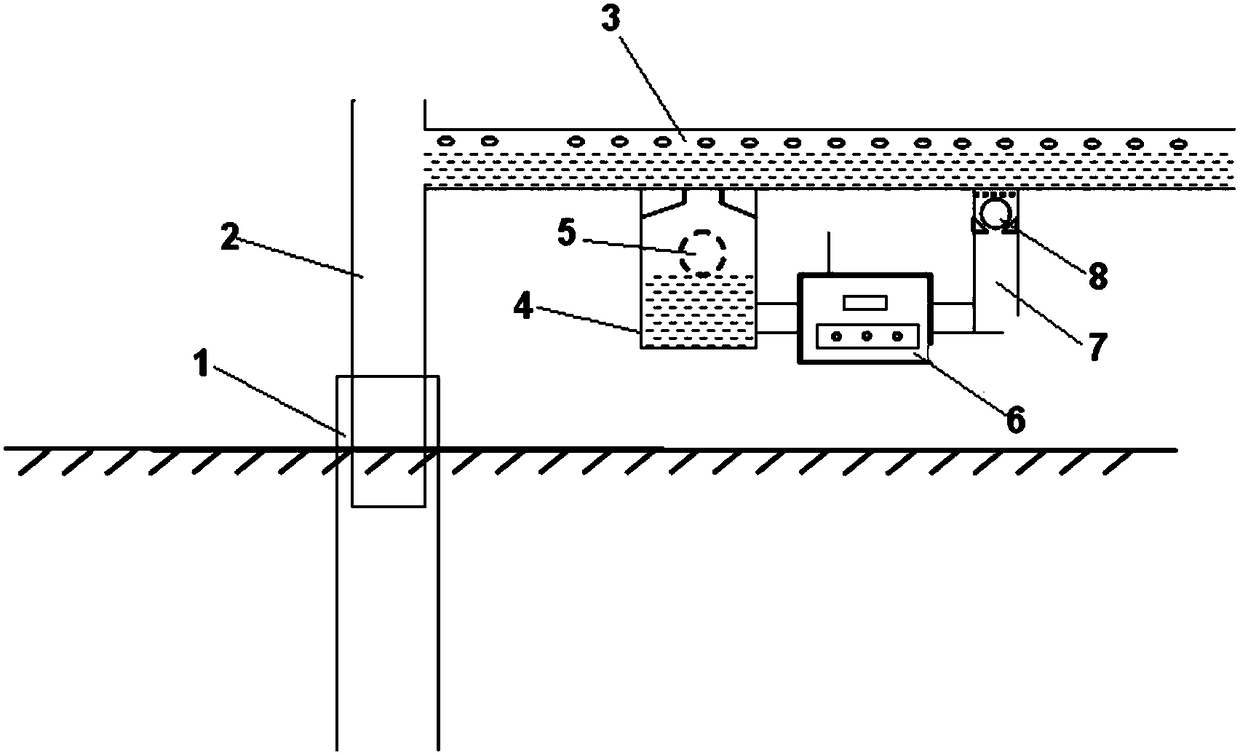

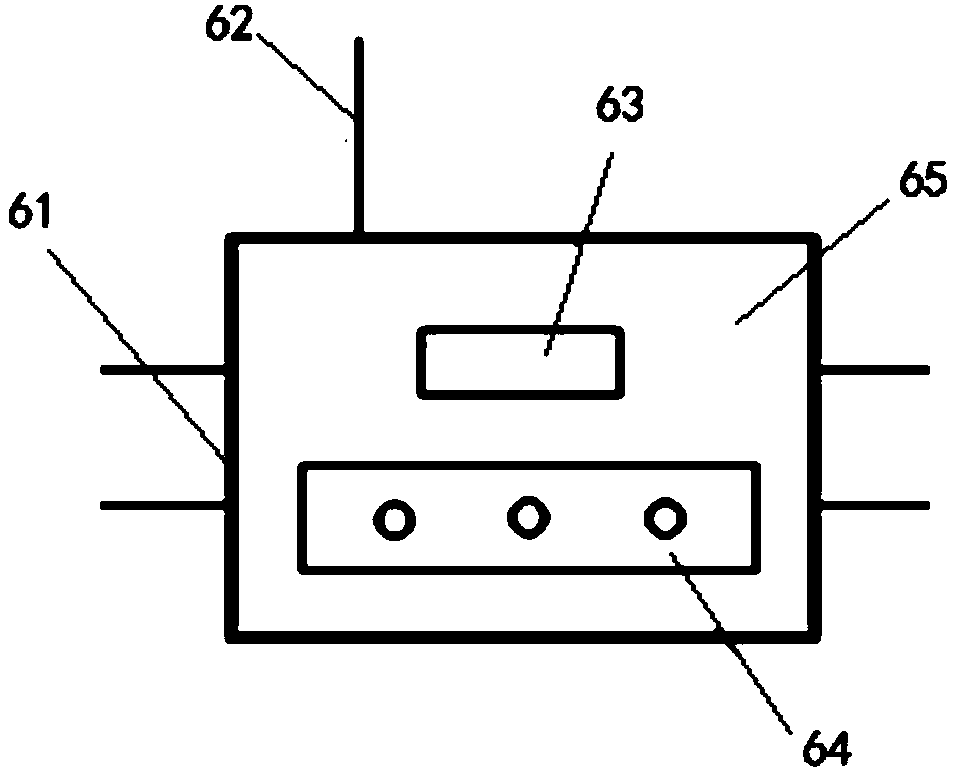

Oil well wellhead water content automatic test device and test method thereof

PendingCN108562723ATimely detection of fluctuations in productionSolve the problem that the water content data can only be obtained during transportation to the central laboratory for testing and other processesMaterial testing goodsMeasuring instrumentOil field

The invention discloses an oil well wellhead water content automatic test device and a test method thereof. By means of the method, the water content of an oil-water mixture can be conveniently and rapidly measured at a wellhead to achieve fine monitoring of yield fluctuation of oil wells of an oil field and rapid monitoring of the water content of the oil wells. The device comprises an oil storage box, a floating ball plug, a water content measuring instrument, a back flowing tube and a one-way valve; the oil storage box is communicated with an oil well oil delivery manifold through a formedliquid inlet, and the oil storage box is located below the oil well oil delivery manifold; the input end of the water content measuring instrument is communicated with the oil storage box, and the output end is connected with the back flowing tube; a power device is arranged in the water content measuring instrument, and the power device is used for delivering the liquid in an oil storage tank tothe oil well oil delivery manifold through the back flowing tube; the floating ball plug is arranged in the oil storage box, and the density of the floating ball plug is smaller than oil; the one-wayvalve is arranged between the back flowing tube and the oil well oil delivery manifold, and the back flowing tube is communicated with the oil well oil delivery manifold in one direction from the backflowing tube to the oil well oil delivery manifold by means of the one-way valve.

Owner:PETROCHINA CO LTD

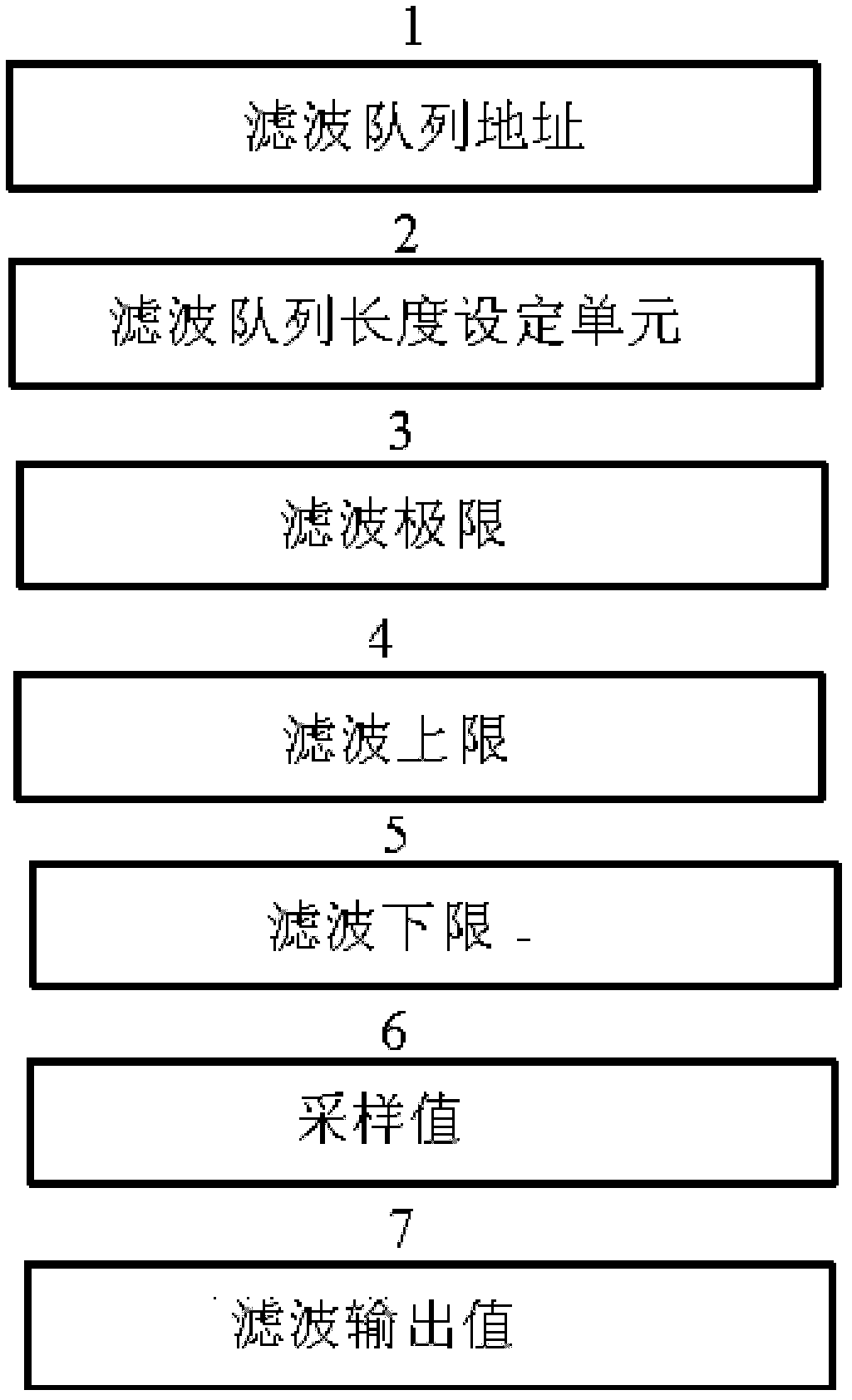

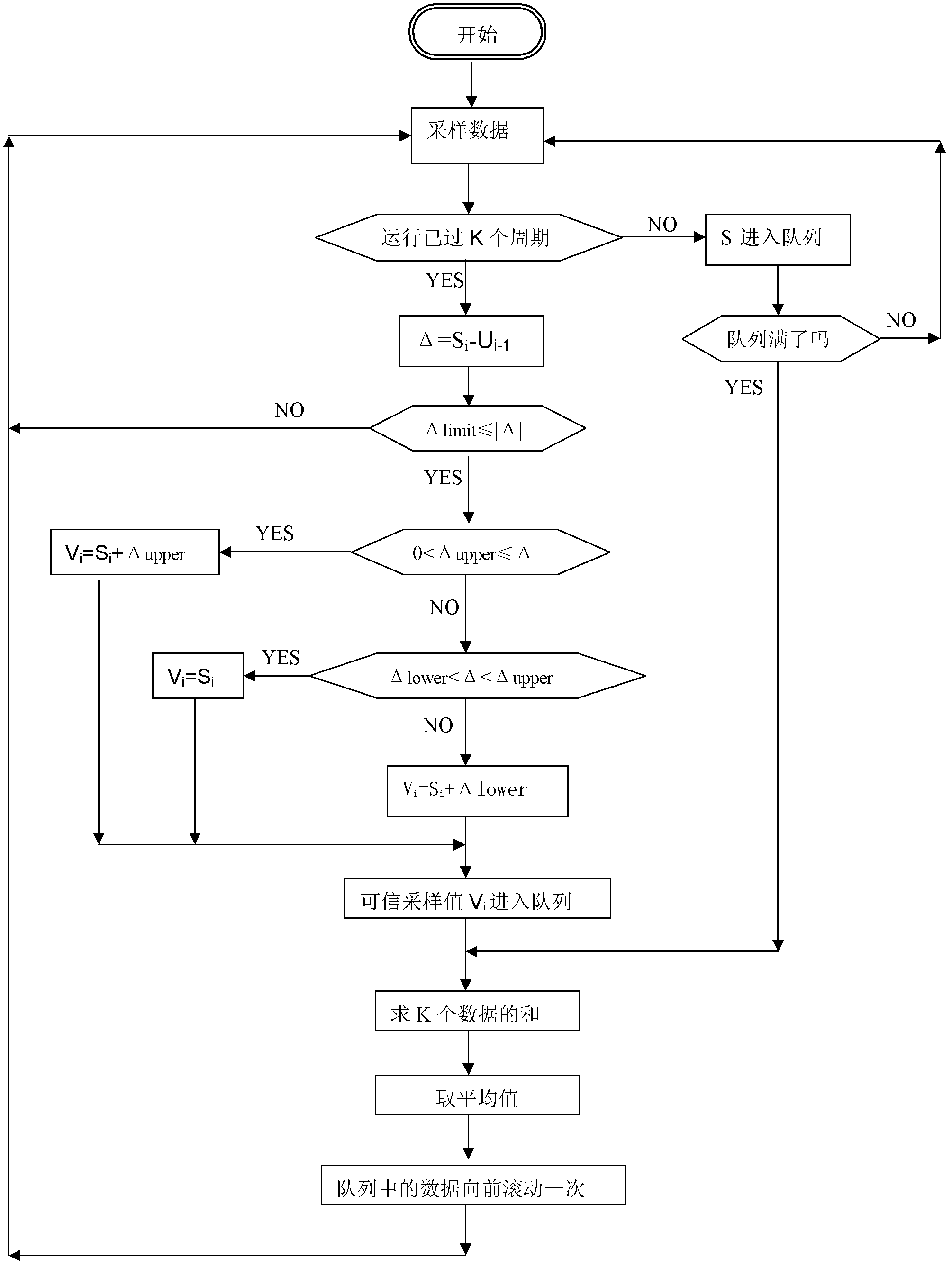

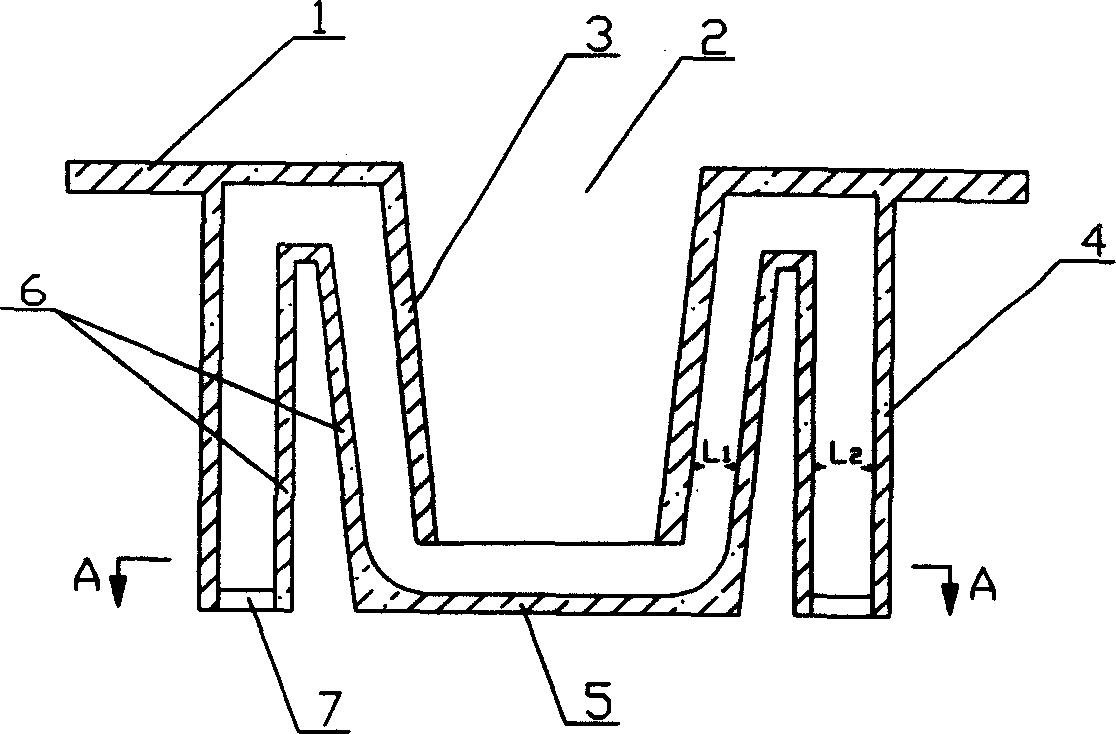

Method for post-processing measured data by using scrolling smoothing filtering

ActiveCN102571032AEasy to changeEliminate fluctuation errorsDigital technique networkDigital filterComputer science

The invention discloses a method for post-processing measured data by using scrolling smoothing filtering. The method is independent of hardware and high in reliability, and filtering characteristics are conveniently modified. The technical scheme comprises the following steps of: setting a scrolling smoothing digital software filter for post-processing a fuel quantity signal, wherein a filtering queue address (1), a filtering queue length setting unit (2), a filtering limit (3), an upper filtering limit (4), a lower filtering limit (5), a sampled value (6) and a filtering output value (7) are set in the digital software filter; refusing obviously false data by utilizing Deltalimit; performing reliability analysis on sampled data by utilizing Deltaupper and Deltalower; and performing queue filling, and performing averaging for K times. The scrolling smoothing filter for post-processing the fuel quantity signal is implemented by a software algorithm, and the fuel quantity signal is smoothed by a digital filtering method, so that fuel level fluctuation errors are eliminated, and the shortcomings of fuel quantity measurement errors caused by maneuver flight are overcome.

Owner:四川泛华航空仪表电器有限公司

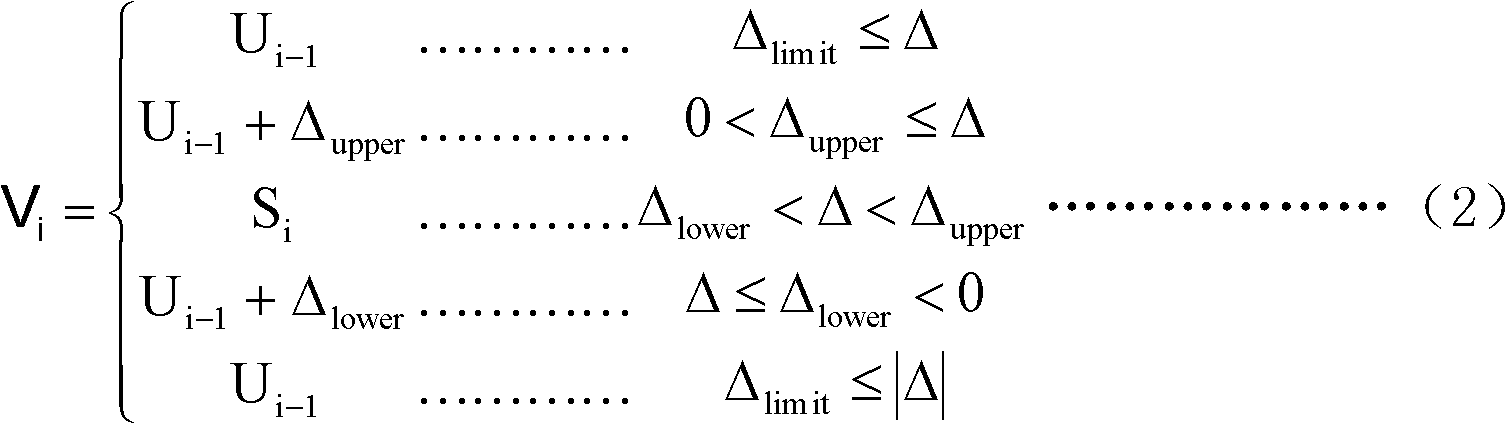

Permanent-magnet type electricity loss brake electricity-saving control device

InactiveCN101169165AKeep closedAutomatically adjust working voltageProgramme-controlled manipulatorBrake actuating mechanismsField-effect transistorEnergy conservation

A power saving control device for a permanent-magnet safe brake relates to the technical field of energy conservation and heat-production reducing of permanent-magnet brakes. The invention aims at solving the problem that the prior permanent-magnet safe brake when working after turned on can consume much power (energy), most of which is transformed into heat, quickly raising the surface temperature of the brake. The output end of a PWM duty ratio adjustment controller connects with one input end of the permanent-magnet safe brake via a first operational-amplifier comparer U1, a two-way and-gate comparer U2, a triode B1 and a field-effect transistor B2; the other input end of the permanent-magnet safe brake connects with the input end of the PWM duty ratio adjustment controller via a voltage amplifier U3 and a second operational-amplifier comparer U4; the PWM duty ratio adjustment controller is provided with an electromotor controlling an enabling input end. The invention can automatically adjust the working voltage of the brake according to the distance between the magnet of the permanent-magnet safe brake and a keeper, thereby reducing the power consumption to about 75 percent of the previous amount.

Owner:HARBIN INST OF TECH

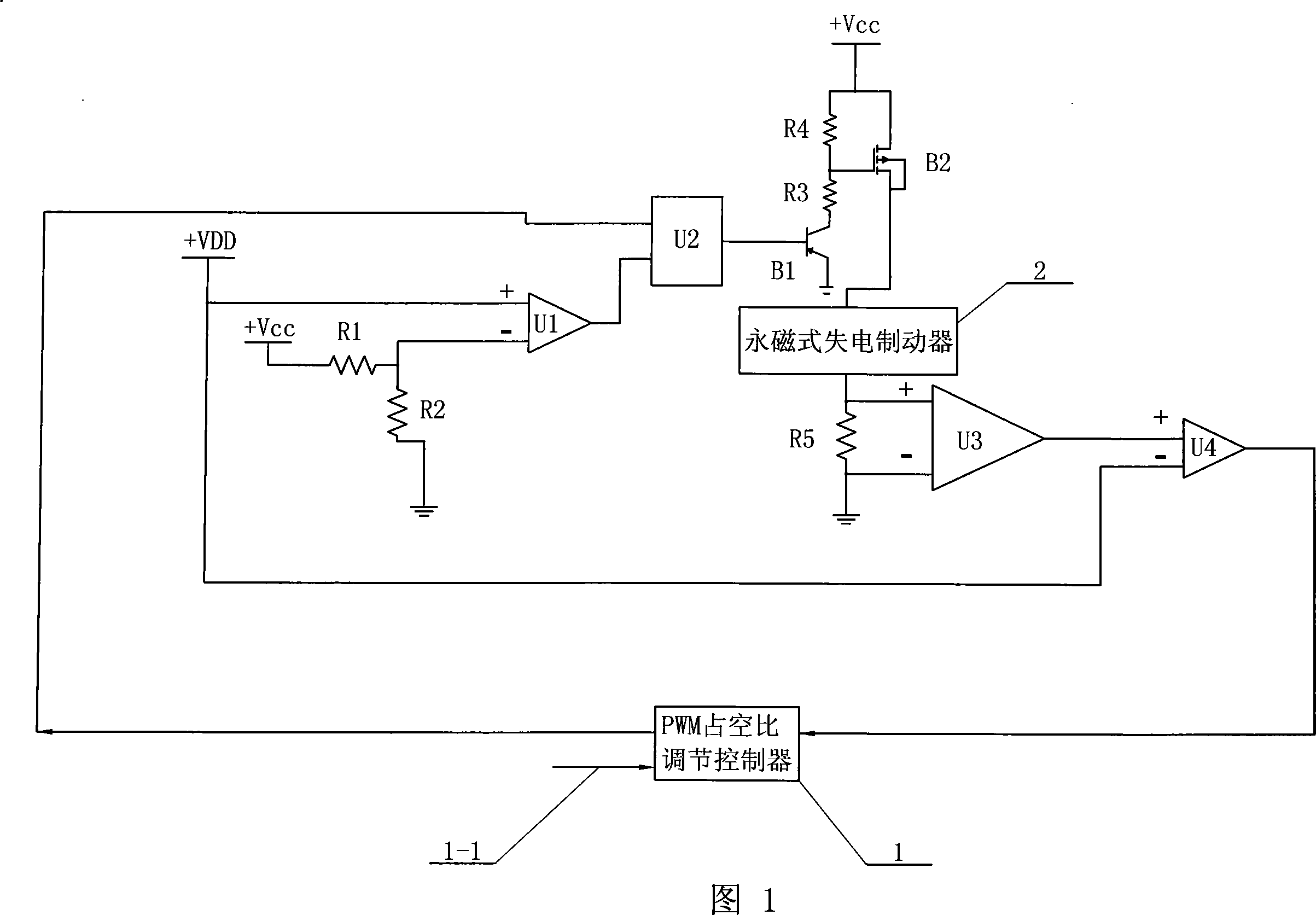

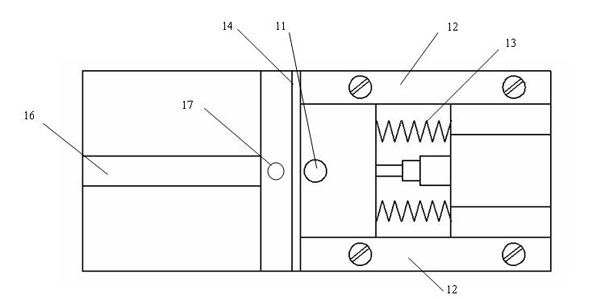

Connector

InactiveCN1856910AAchieve compactnessKeep closedTwo-part coupling devicesFour or more pole connectionsCamMechanical engineering

A connector having a substantially box-like housing having an insertion opening into which an FPC is inserted, a two-forked contact placed inside the housing, and a lever provided so as to face the insertion opening of the housing and pivotably held by the housing. The two-forked contact has a base section held by the housing, an upper arm and a lower arm that extend from the base section toward the insertion opening, and two-forked engagement arms extending from the base section in the opposite direction to the insertion opening. The lever has a grip section, a rotating shaft provided on the grip section and held by the housing, and a first plate cam provided on the rotating shaft and engaging the engaging arm. When the grip section is opened, the first plate cam widens the interval between the two-forked engagement arms, widening the interval between the upper arm and the lower arm of the two-forked contact.

Owner:JST MFG CO LTD

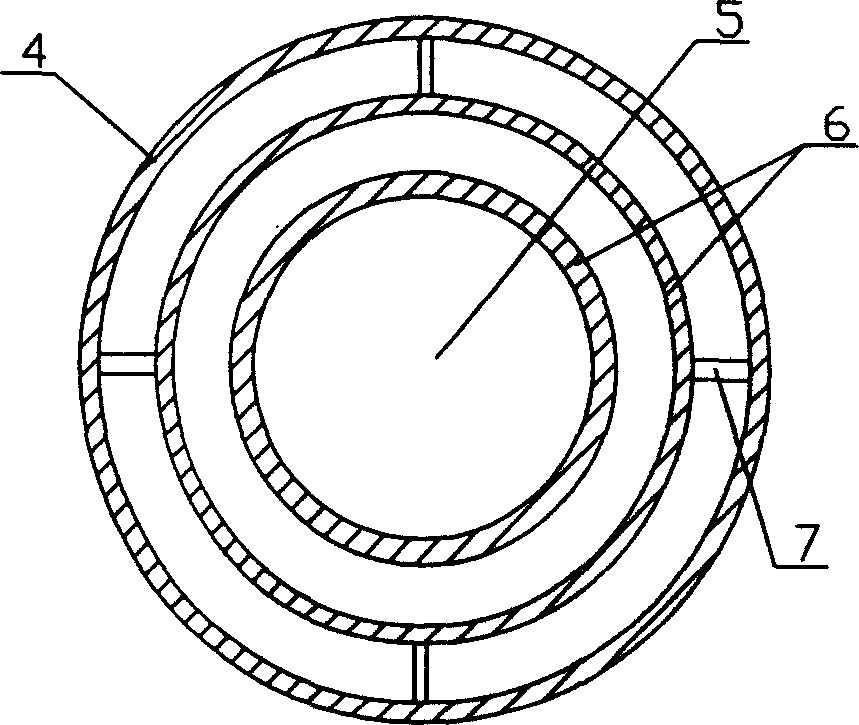

M-shape water seal floor drain

The M-shaped water seal floor drain includes top board with water inlet, water inlet barrel around the water inlet and below the top board and water outlet barrel around the water inlet barrel, as well as cup with cup bottom and cup wall inserted into the interval between the water inlet barrel and the water outlet barrel. There are interval between the top of the cup wall and the bottom of the top board, and interval between the bottom of the water inlet barrel and the bottom of the cup. The top board of the water seal floor drain may be closed to ground to avoid bad smell to overflow through peripheral of the floor drain, resulting in high deodorizing effect. The water seal floor drain has M-shaped cross section, deep sealing water and excellent sealing effect.

Owner:WUHAN UNIV OF TECH

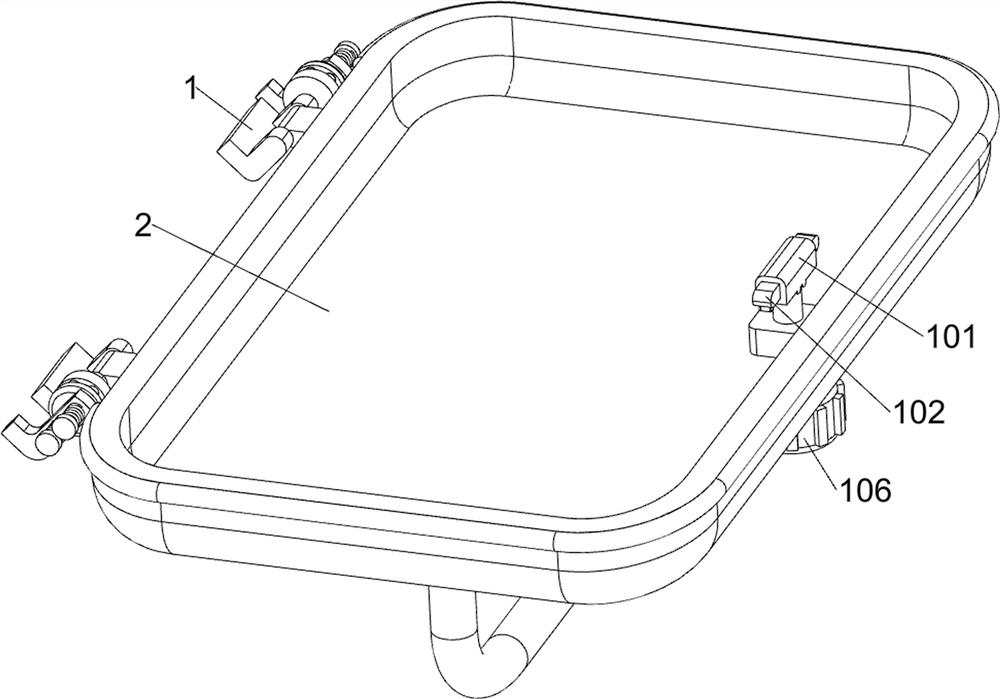

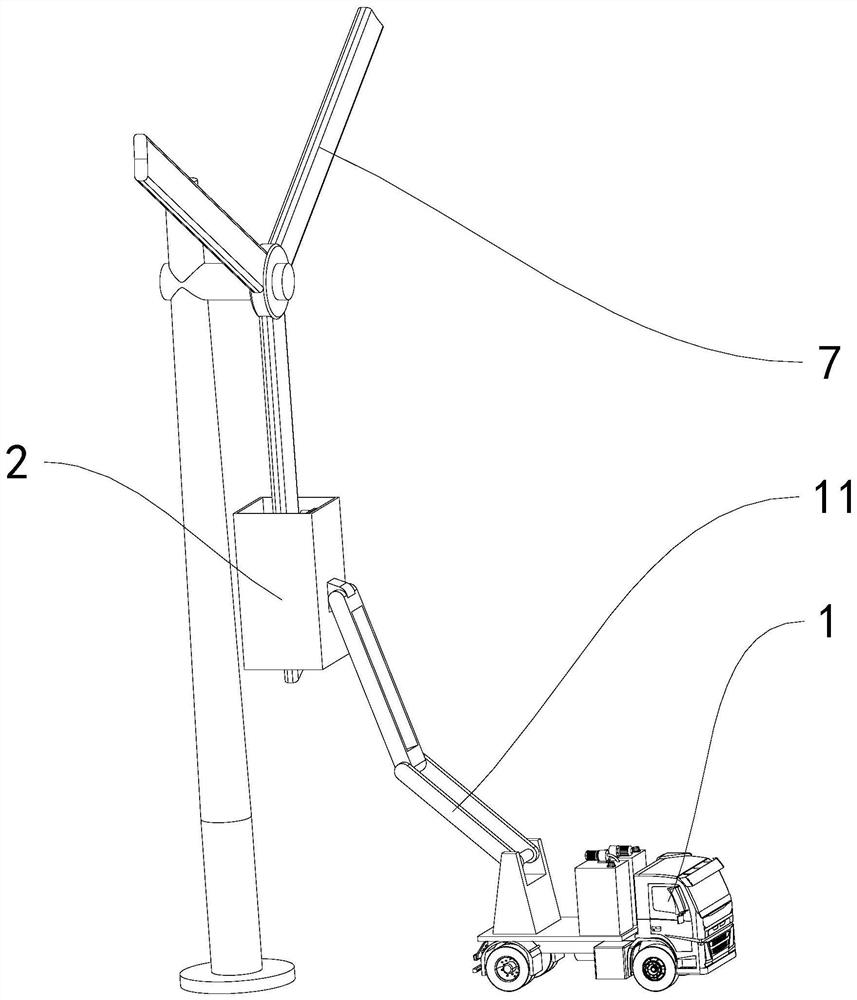

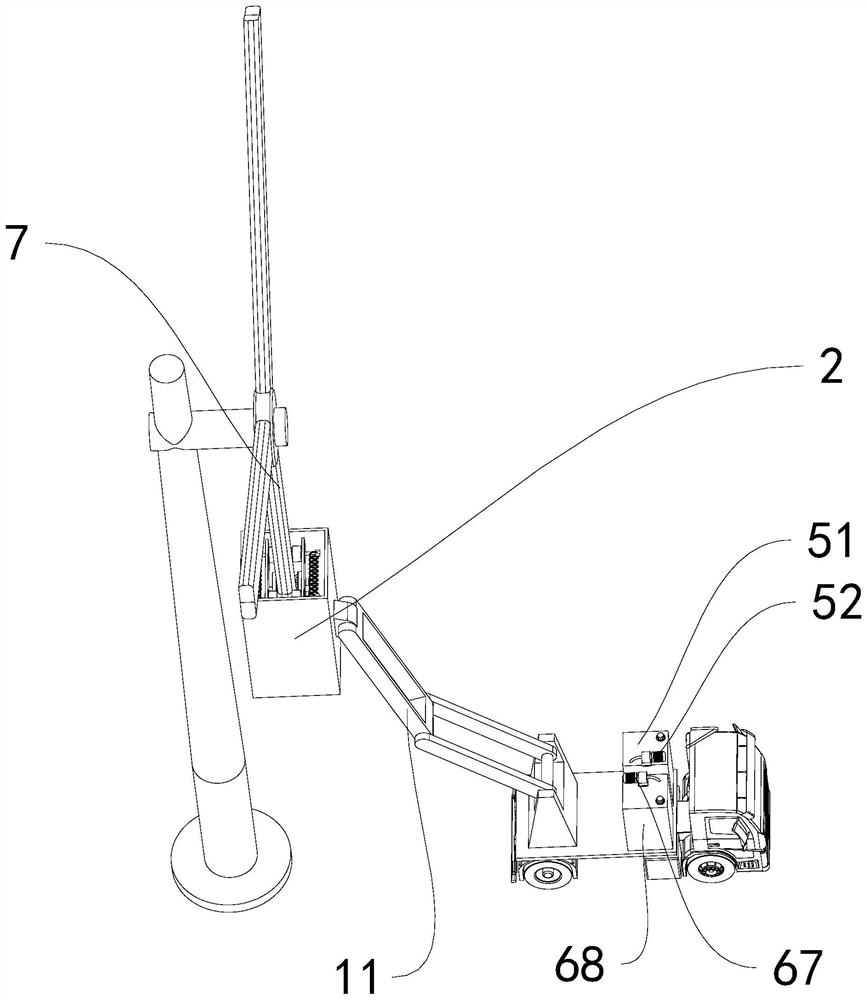

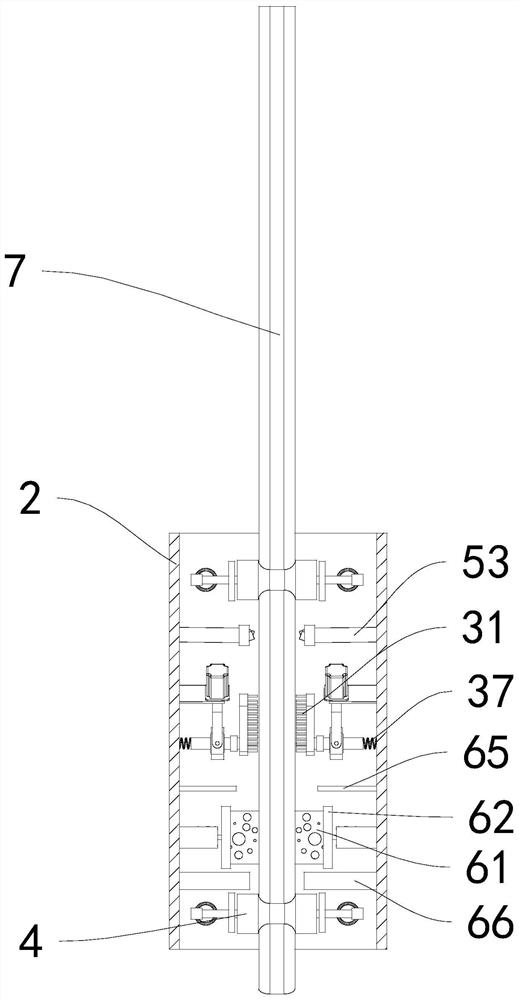

Cleaning system for large power generation fan blades

ActiveCN112958521AEasy to cleanKeep closedCleaning using toolsWind energy generationTruckEngineering

The invention discloses a cleaning system for large power generation fan blades, and belongs to the technical field of wind power generation blade cleaning. The cleaning system for the large power generation fan blades comprises an overhead working truck, a working box, a scrubbing mechanism, a cleaning liquid loading mechanism, a wiping mechanism and fan blades, wherein an overhead working arm is arranged on the overhead working truck, and the working box is arranged at a movable end of the overhead working arm; the working box is of a hollow structure, a locating mechanism, the cleaning liquid loading mechanism, the scrubbing mechanism and the wiping mechanism are all arranged in the working box, the working box is driven by the overhead working arm to move on the fan blades, and the fan blades are located through the locating mechanism; and the cleaning liquid loading mechanism, the scrubbing mechanism and the wiping mechanism can clean the surfaces of the fan blades while the working box moves.

Owner:盐城国丰海上风力发电有限公司

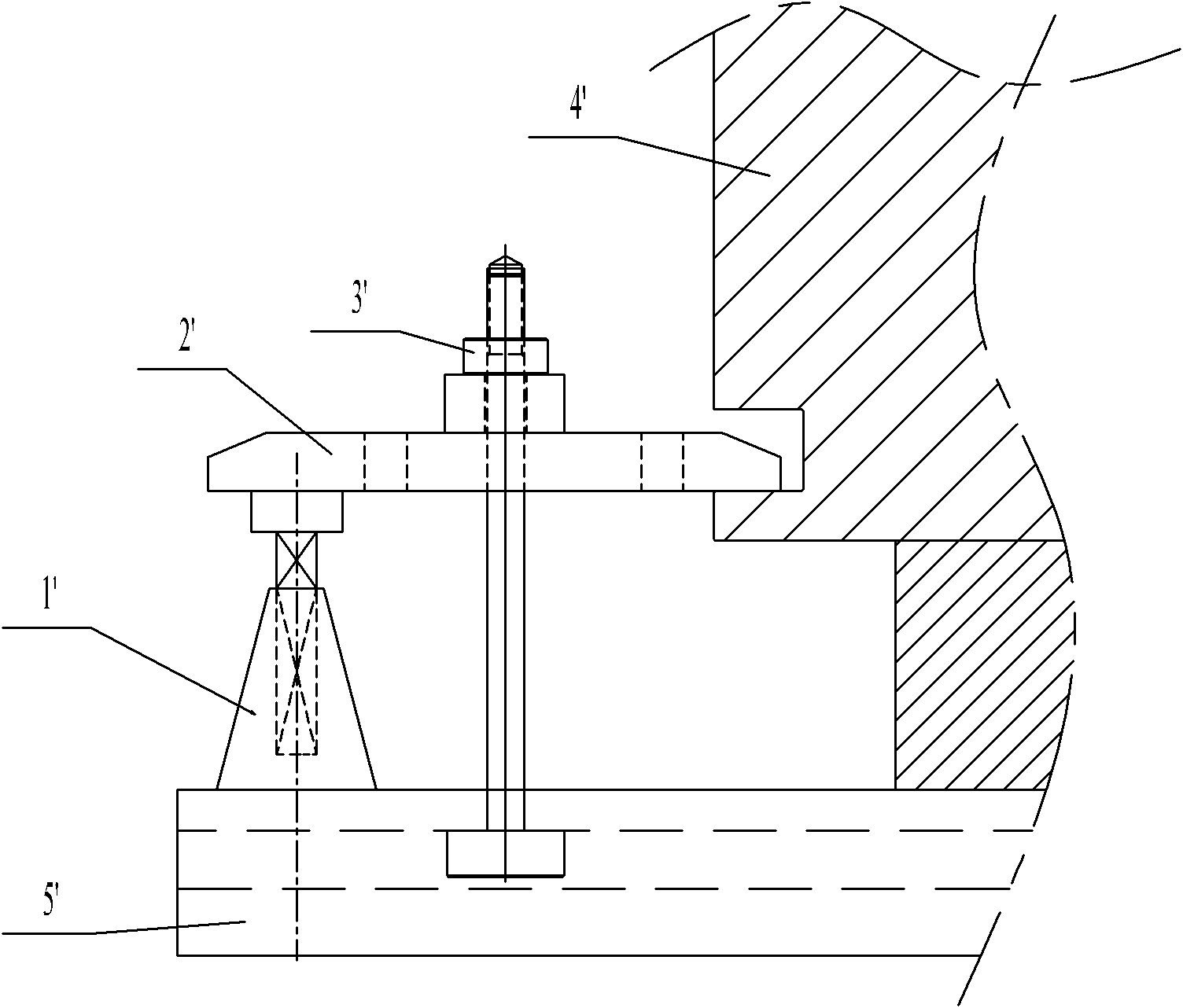

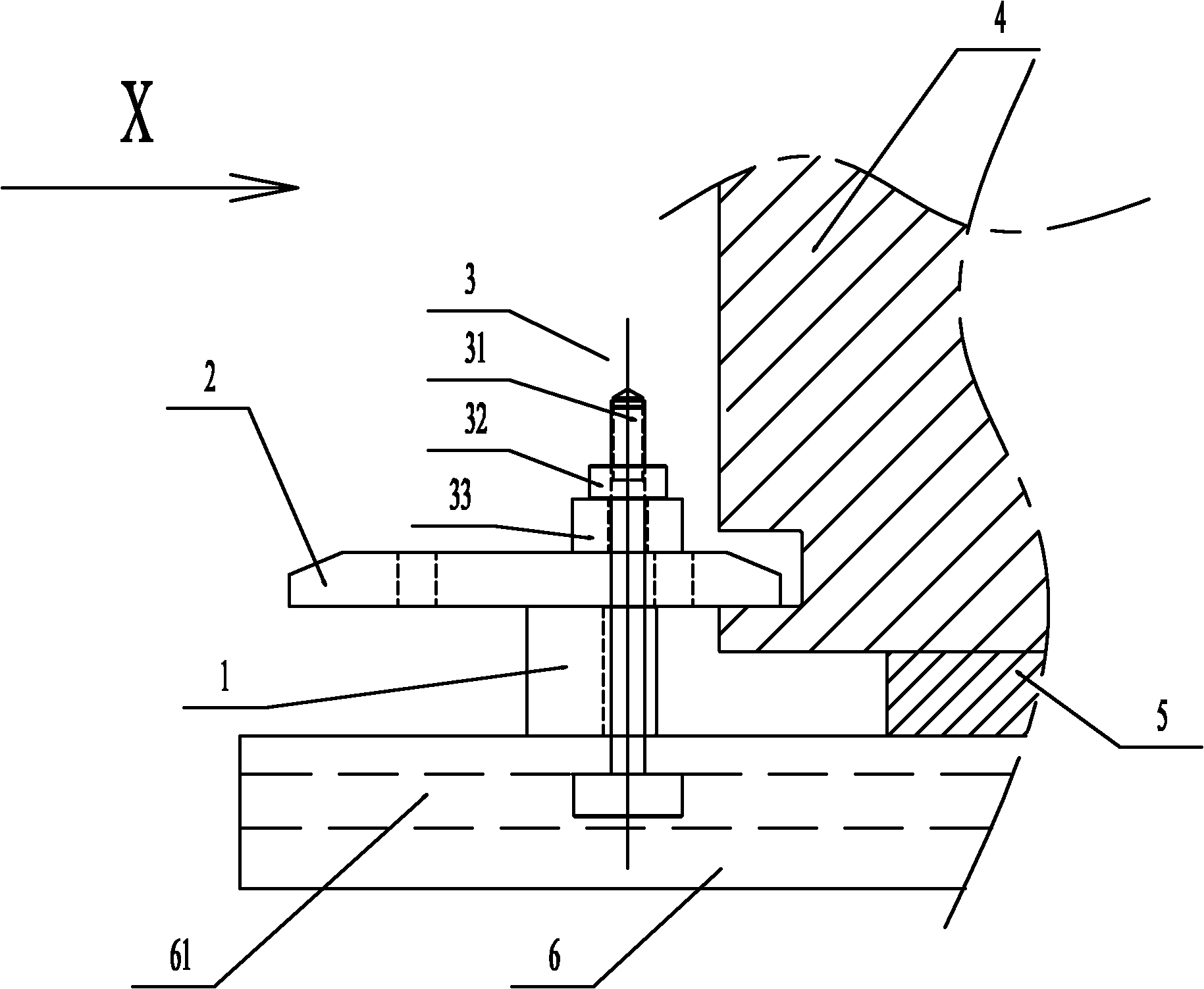

Upsetting plasma arc welding fixture for aluminum-based composite material and arc welding method thereof

InactiveCN102069282AImprove deteriorationHigh tensile strengthPlasma welding apparatusWelding accessoriesHigh energyEngineering

The invention discloses technology for rod melting connection for an aluminum-based composite material, in particular an upsetting plasma arc welding process method for the aluminum-based composite material. High-energy density beams with concentrated arc energy and high straightness and arc penetration serve as a welding heat source, so that the whole connecting time is shortened, the heated area is reduced, heat input is reduced to the greatest degree, and the problem of deterioration of welding seam structures is effectively improved; moreover, after a joint of the aluminum-based composite material is molten, the molten weld metals are extruded by utilizing a pretightening force through a special fixture, the burnt enhanced phase is extruded, the joint is purified, grains of the welding joint are close to base metals and a new phase is not produced, the welding line of a welded joint is saturated, a joint basically consisting of uniform base metals is obtained, and the tensile strength of the welded material is guaranteed to the greatest degree.

Owner:NANJING UNIV OF SCI & TECH

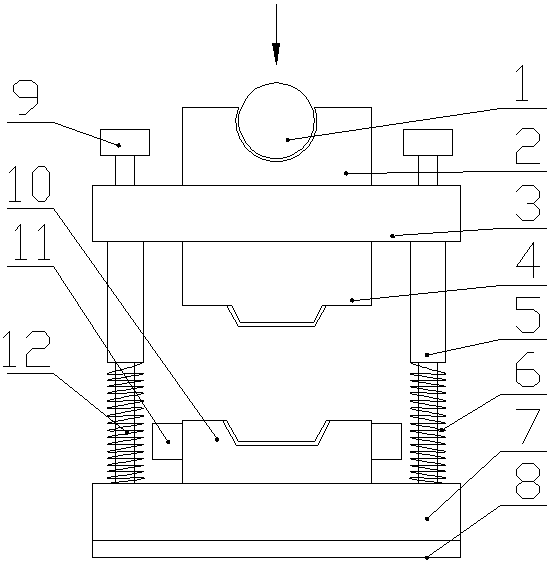

Stamping-resistant automobile die

The invention relates to a stamping-resistant automobile die which comprises an upper die base and a lower die base. A concave die is arranged on the upper end surface of the lower die base; a rubberpressure-resistant layer is arranged on the lower end surface of the lower die base; a stripper plate is arranged on the concave die; guide pillars are arranged on four corners of the lower die base;buffer springs sleeve the guide pillars; guide pillar slots are formed in the upper parts of the guide pillars; limiting blocks are arranged at the top ends of the guide pillars; the upper die base isarranged at the top ends of the guide pillar slots; a convex die corresponding to the concave die is arranged on the lower end surface of the upper die base; a fixed pillar is arranged on the upper end surface of the lower die base; and an equilibrium spheroid is movably arranged in the fixed pillar. The stamping-resistant automobile die provided by the invention has the advantages of simple structure, high accuracy, capability of reducing die damage, durability, uniformity in stressing on the die, and high practicability.

Owner:XUCHANG HUAIHAI MACHINERY MFG

Wound dressing

InactiveCN101014309AKeep closedEliminates the risk of scarringPlastersAdhesive dressingsWound dressingBiomedical engineering

Owner:APIMED MEDICAL HONEY

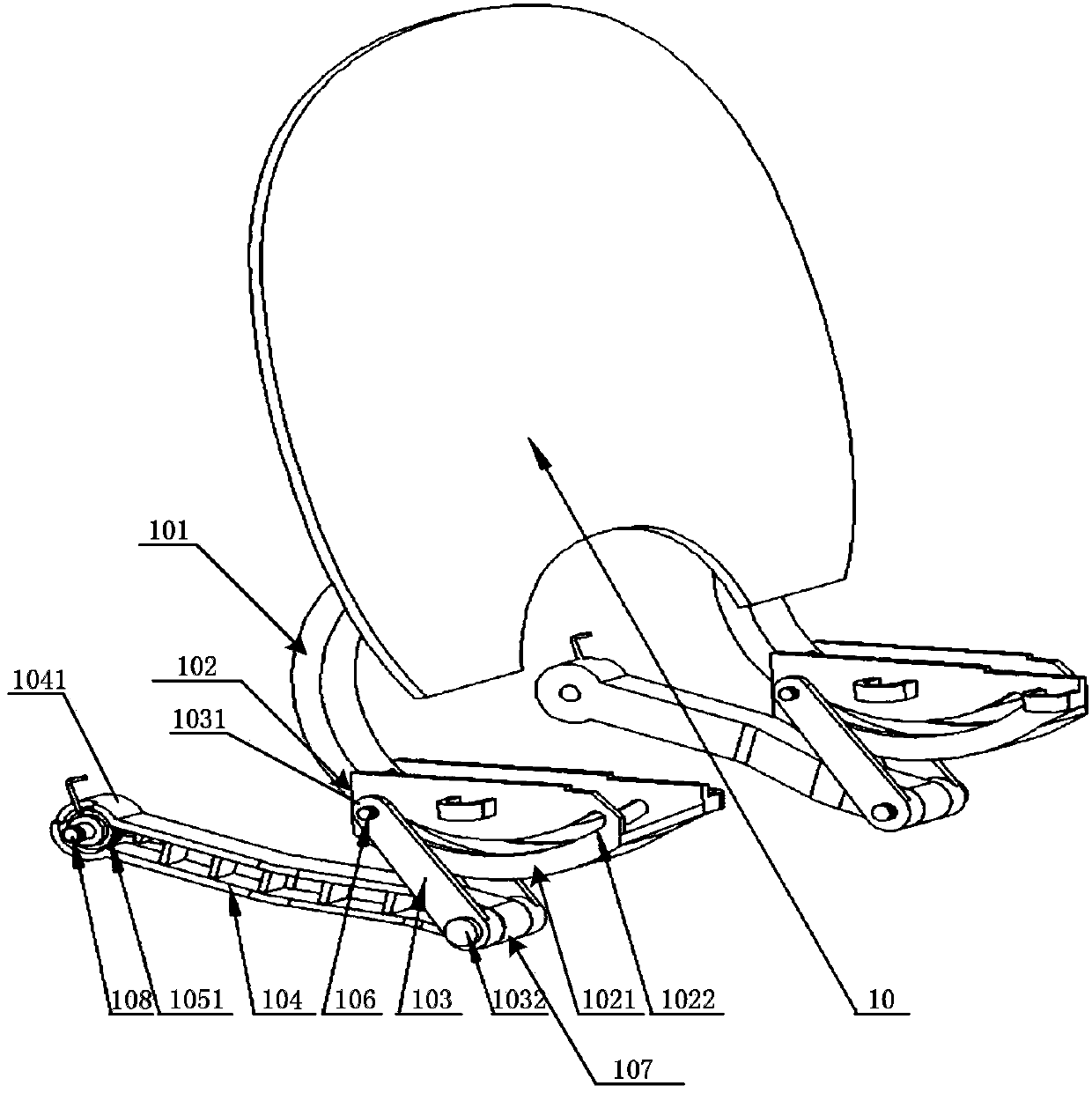

Cover body overturning device, mobile cleaning robot and dust box cover opening-closing method

PendingCN110522366AAvoid the defect of automatic pop-upGuaranteed OnCarpet cleanersFloor cleanersEngineeringBalance point

The invention discloses a cover body overturning device, a mobile cleaning robot and a dust box cover opening-closing method. The cover body overturning device comprises a cover body, a cover body push rod and a force application mechanism, the cover body can turn over between a closing position and an opening position around a fixed axis, the force application mechanism can apply the acting forces on the cover body push rod, and the acting forces are finally applied on the cover body through the cover body push rod. A balance point is arranged in the overturning stroke of the cover body, andwhen the cover body is located at the side, close to the closing position, of the balance point, the acting force applied on the cover body push rod by the force application mechanism enables the cover body to move towards the closing position, and when the cover body is located at the side, close to the opening position, of the balance point, the acting force applied on the cover body push rod bythe force application mechanism enables the cover body to move towards the opening position, so that the cover body keeps a stable opening state in an opening state or keeps a stable closing state ina closing state.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com