Rolling device for plastic thin film

A technology of winding device and plastic film, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of easy generation of static electricity, influence of winding flatness, easy occurrence of adhesion, etc., and achieve high efficiency of static electricity removal , cooling fast, avoiding the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

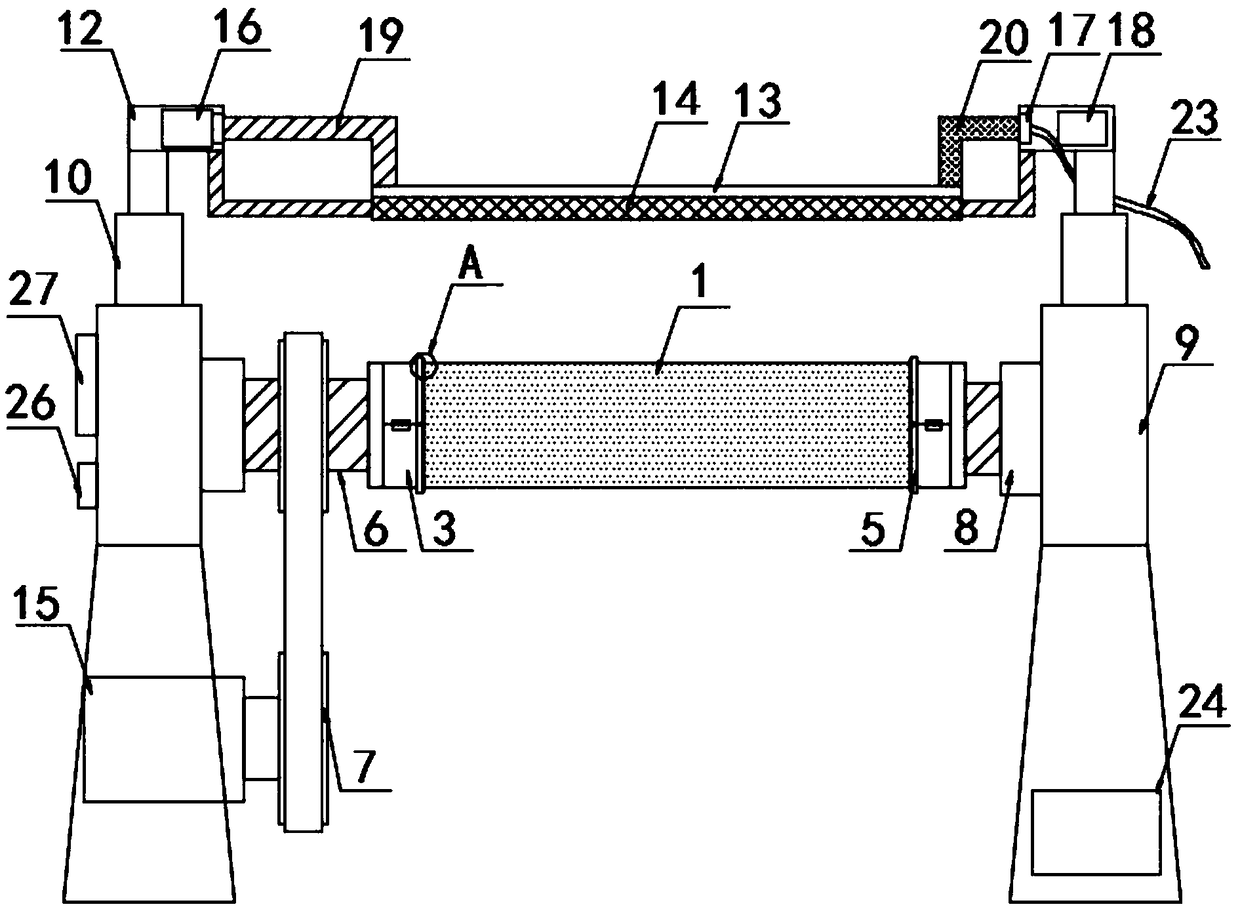

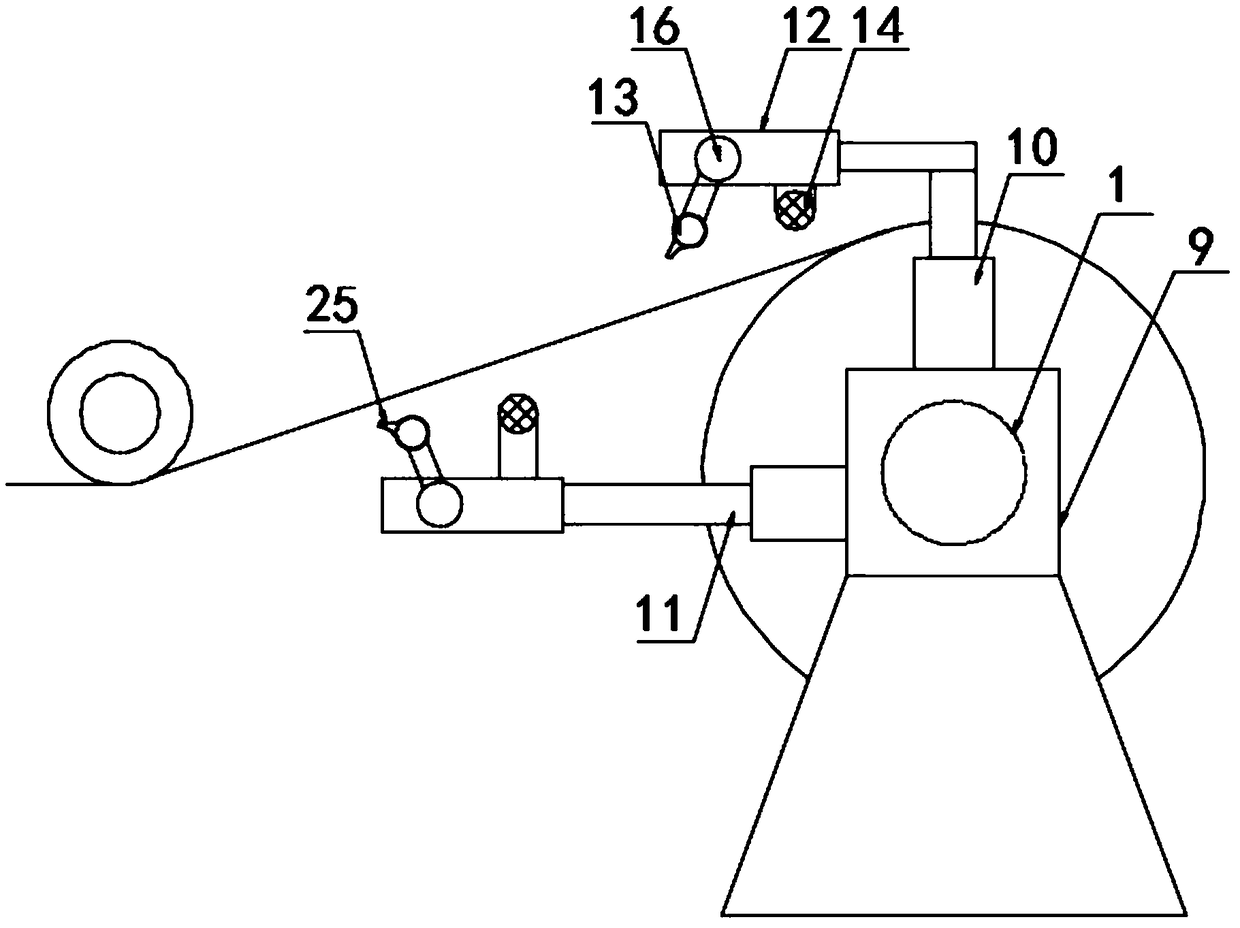

[0026] according to Figure 1-2 The shown winding device for plastic film includes a reel 1 with clamping plates 2 on both ends of the reel 1, a fixing seat 3 on the outside of the clamping plate 2 and an inside of the fixing seat 3 A card slot 4 is provided, the outer wall of the fixed seat 3 near the end of the reel 1 is provided with a ball plate 5, the outer side of the fixed seat 3 is fixedly provided with a rotating shaft 6, and the bottom of the rotating shaft 6 on one side of the fixed seat 3 is provided The driving mechanism 7 includes a driving wheel and a driven wheel, the driven wheel is fixedly sleeved on the rotating shaft 6, and one end of the driving wheel is provided with a servo motor 15 which is connected to one side of the reel 1 The supporting table 9 is fixedly connected, the end of the rotating shaft 6 is provided with a bearing 8, the outer side of the bearing 8 is provided with a supporting table 9, the top of the supporting table 9 is fixed with a firs...

Embodiment 2

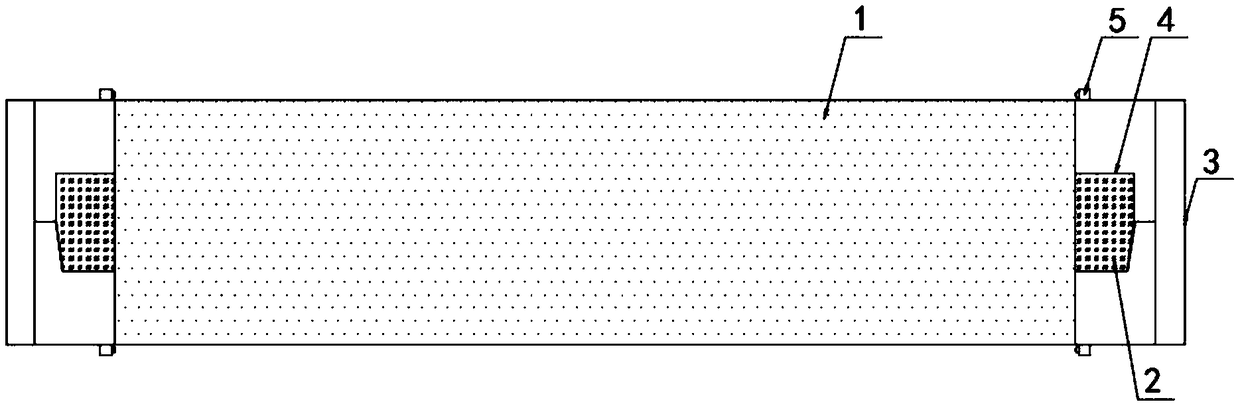

[0029] according to image 3 A winding device for plastic film is shown. The clamping plate 2 includes a semicircular plate 21 and a sinking plate 22. The sinking plate 22 is arranged at the bottom of the semicircular plate 21. The cross section of the sinking plate 22 is It is set as a right-angle trapezoid and the longitudinal section is set as an isosceles trapezoid to facilitate the sinking plate 22 to quickly snap into the lower slot. The slot 4 includes an upper slot and a lower slot. The upper slot is arranged on the upper plate 31 , The lower clamping slot is arranged on the lower buckle plate 32, the semicircular plate 21 is matched with the upper clamping groove, the arrangement of the semicircular plate 21 is convenient for the upper pressing plate 31 and the lower buckle plate 32 to buckle smoothly, the sinking plate 22 Cooperating with the lower card slot, the inner wall of the card slot 4 is provided with a rubber pad to prevent the card board 2 from wearing and sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com