Transmission device for optical equipment

A transmission device and equipment technology, applied in the direction of transmission device, optics, optical components, etc., can solve the problems of affecting imaging and inaccurate travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with accompanying drawings.

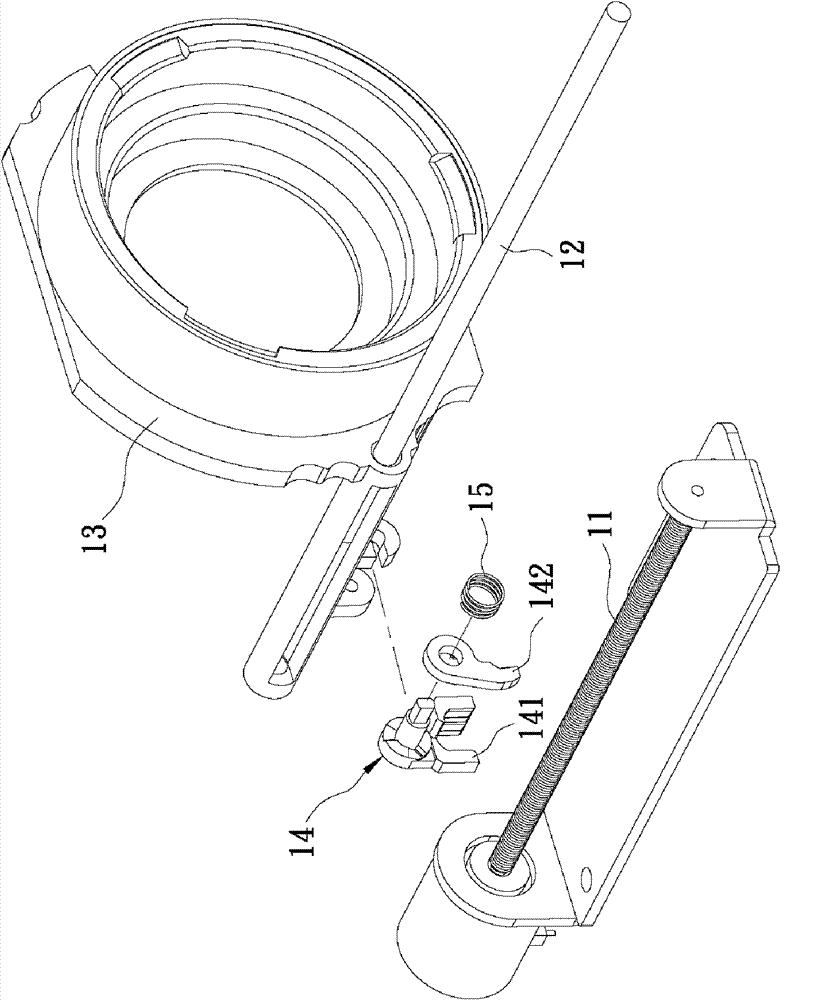

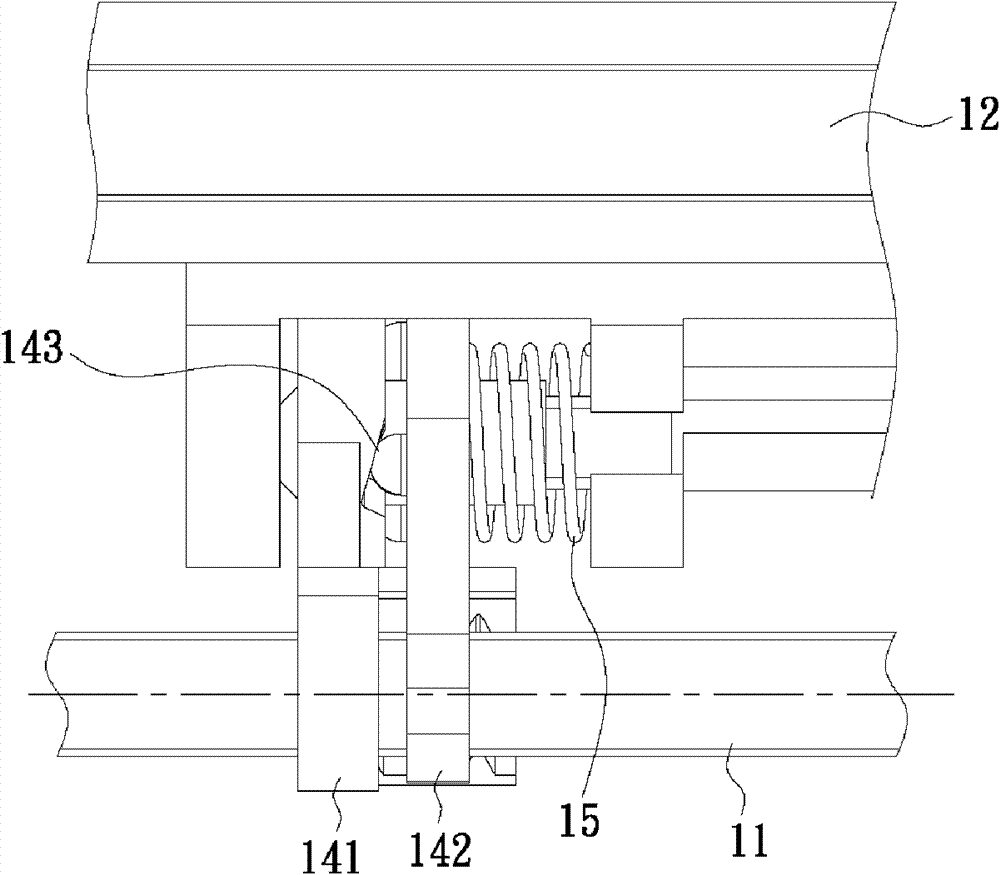

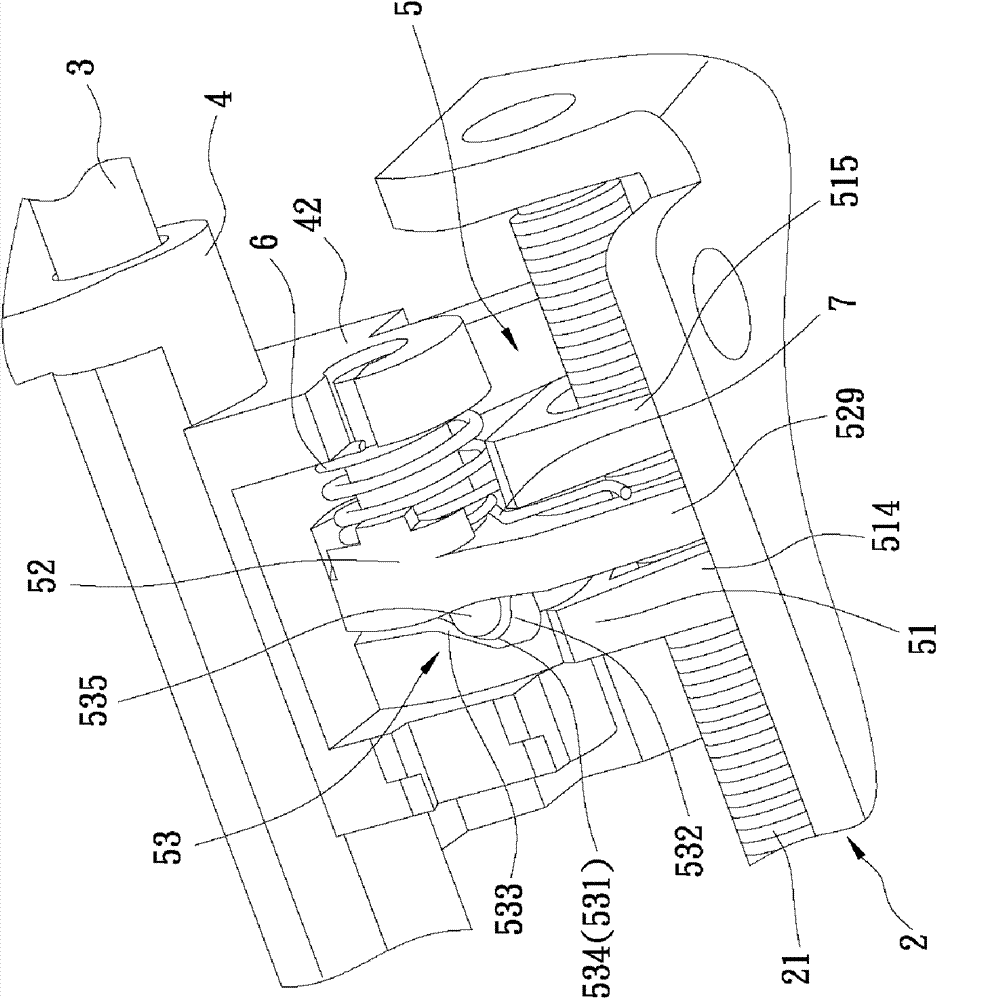

[0015] refer to image 3 , Figure 4 and Figure 5 A preferred embodiment of the transmission device of the optical equipment of the present invention includes a driving unit 2 , a guide member 3 , a frame body 4 , a jaw unit 5 , a first elastic member 6 and a second elastic member 7 .

[0016] The driving unit 2 includes a screw 21 disposed along the axis L, and a driving member 22 for driving the screw 21 to rotate around the axis L. In this embodiment, the driving member 22 can be a motor.

[0017] The guide 3 is arranged parallel to the screw 21 along the direction of the axis L. In this embodiment, the guide 3 is a guide rod.

[0018] The frame body 4 is used to carry optical components and includes a first pivot ear 41 and a second pivot ear 42 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com