Patents

Literature

170results about How to "Increase practical range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

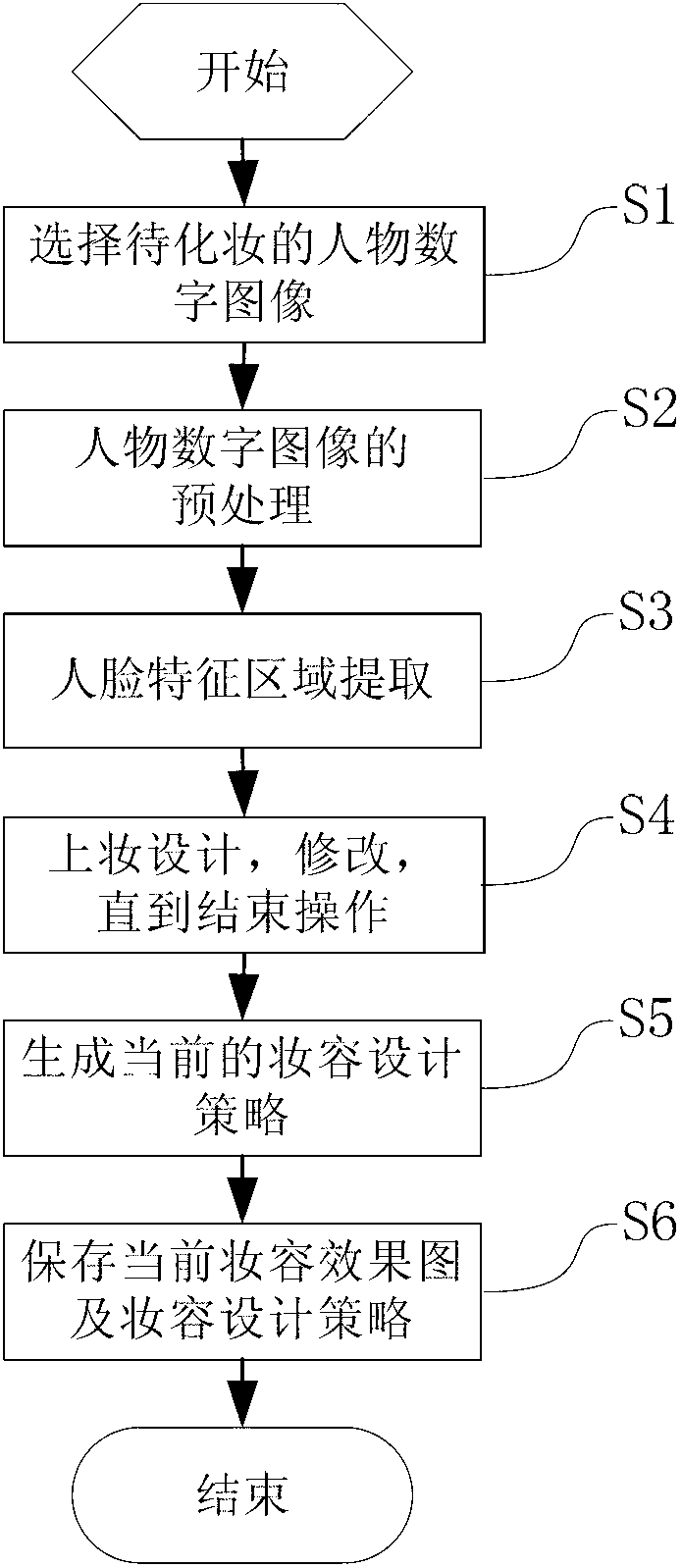

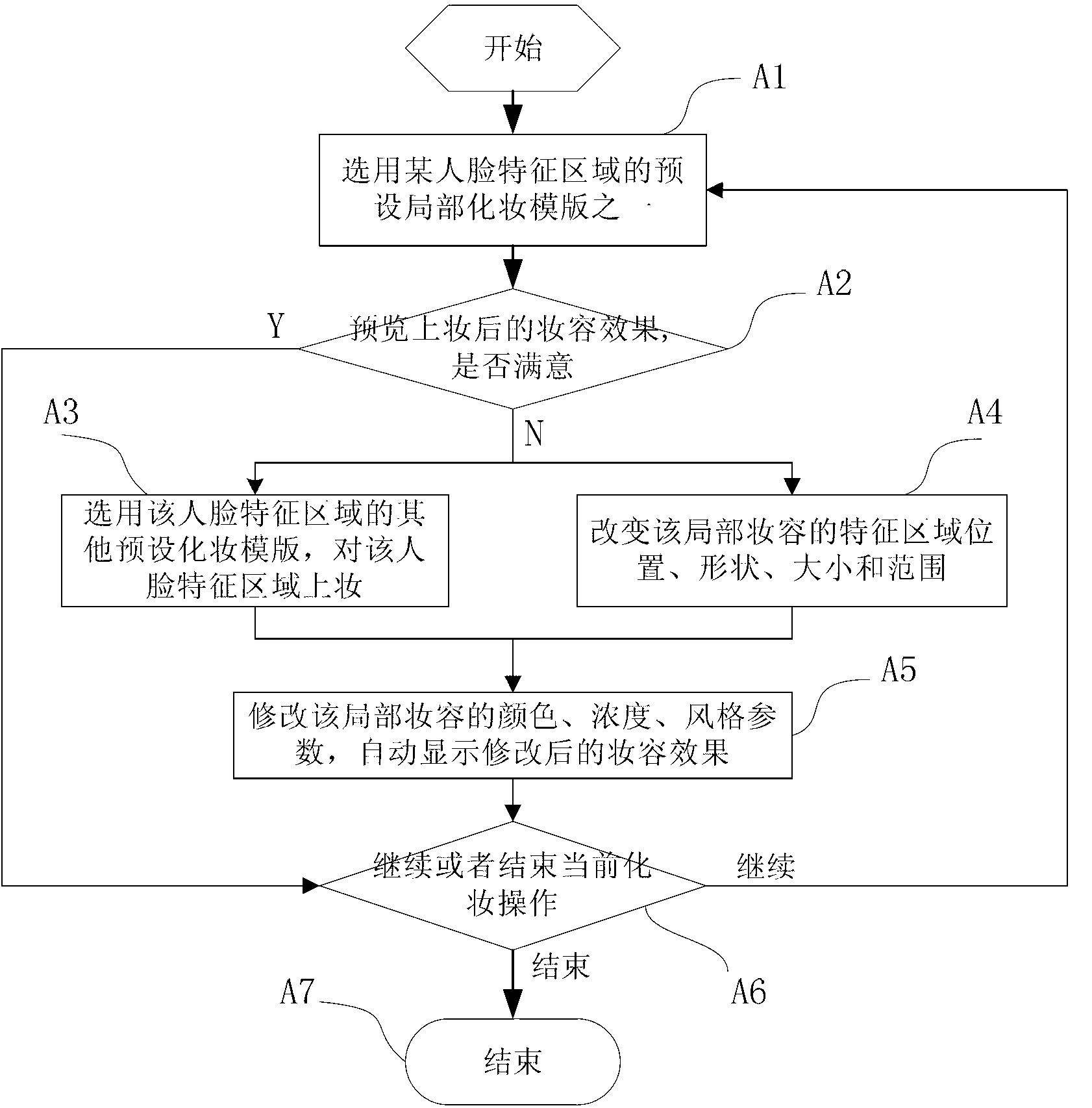

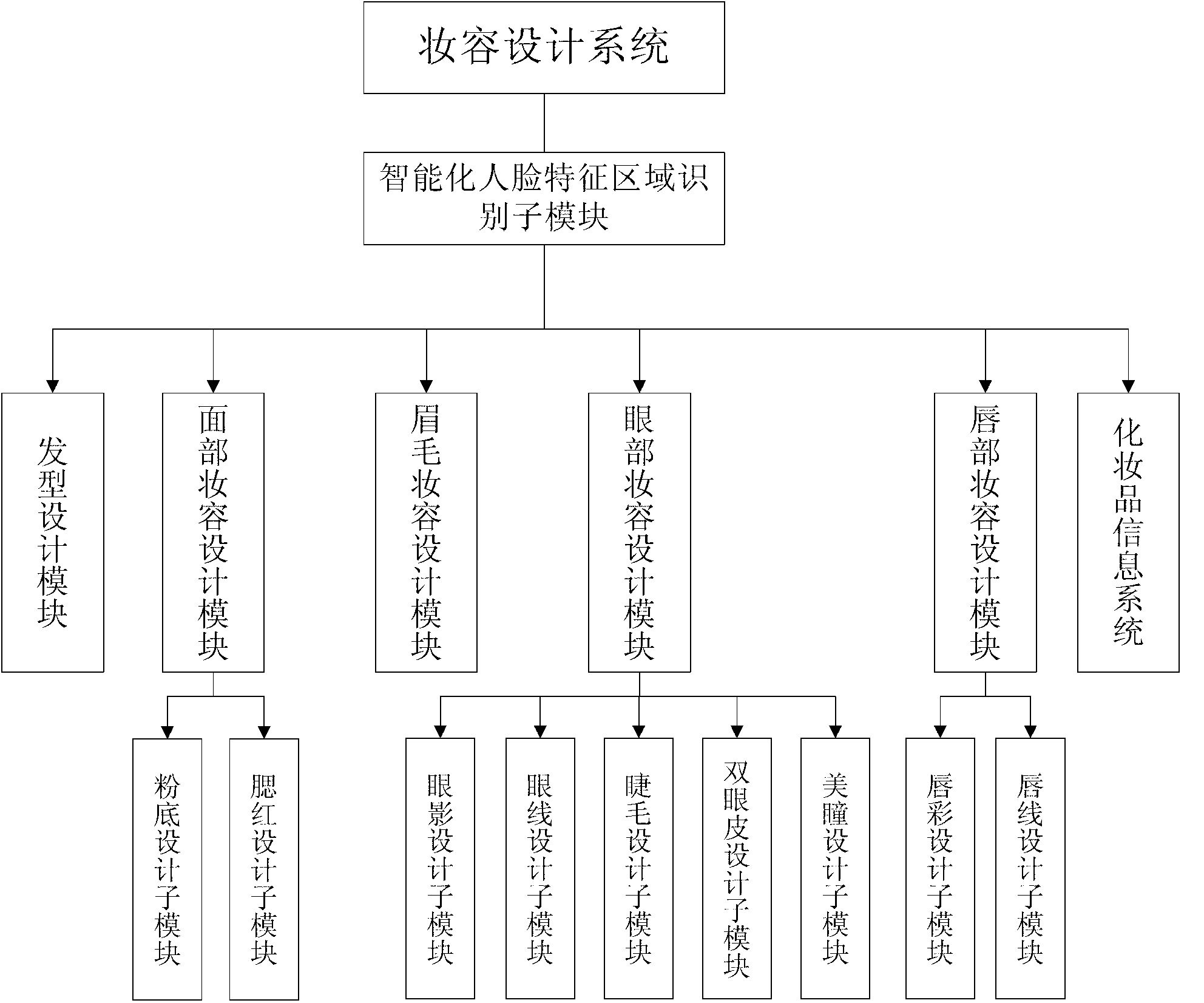

Daily makeup design method and system based on face feature region recognition

InactiveCN102708575AIncrease interest in useEasy to operate2D-image generationPattern recognitionDigital pictures

The invention discloses a daily makeup design method and a system based on face feature region recognition. The method includes inputting a digital picture of a figure obtained through local uploading or shooting of other tools such as a camera; performing processing such as proper tailoring, zoom and rotation on the digital picture; automatically recognizing and extracting a face feature region from the picture; performing makeup operation on the recognized face feature region through a makeup design system; previewing the whole effect after the makeup, performing local adjustment on unsatisfied makeup; prompting parameters of cosmetics used by the makeup to find a corresponding relation of the parameters with real cosmetics when the design is finished; and saving the current makeup effect and makeup strategies. The daily makeup design method and the system have the advantages that the operation is convenient, the practicability is high, the makeup display effect is good, the operational process accords with makeup design mentality of users, the user experience is good, and the design method and the system are worth widely popularizing and using.

Owner:彭强

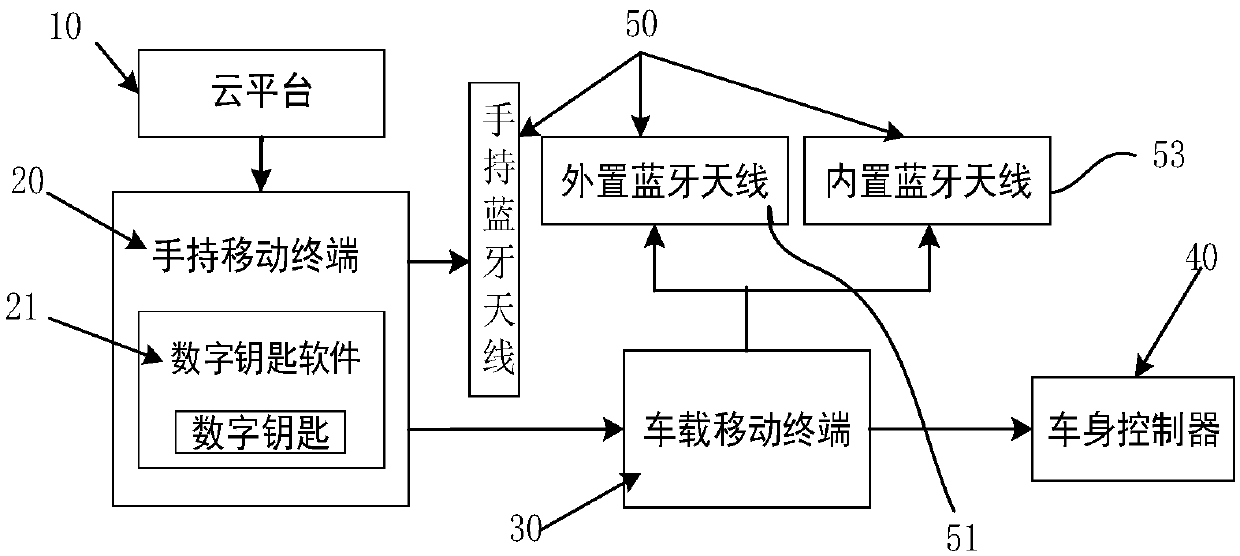

Vehicle sharing system and method based on digital key

InactiveCN109515384AImprove securityImprove experienceAnti-theft devicesIndividual entry/exit registersHand heldComputer terminal

The invention provides a vehicle sharing system and method based on a digital key. The vehicle sharing system and method based on the digital key comprises a cloud platform, a hand-held mobile terminal, a vehicle-mounted mobile terminal, a vehicle body controller and a Bluetooth antenna; the cloud platform is used for issuing the digital key to the hand-held mobile terminal; the hand-held mobile terminal is used for receiving a digital key signal and transmitting the digital key signal to the vehicle-mounted mobile terminal; the Bluetooth antenna comprises an external Bluetooth antenna and aninternal Bluetooth antenna of a vehicle; when judging that the hand-held mobile terminal holds a vehicle control authority, the vehicle-mounted mobile terminal is used for judging a relative distancebetween the hand-held mobile terminal and the vehicle through the strength of signals received by the external Bluetooth antenna and the internal Bluetooth antenna and is used for transmitting a corresponding vehicle body control instruction to the vehicle body controller according to the relative distance to control the vehicle. The invention further provides the vehicle sharing method; and by using internet of vehicles and shared operation, the digital key replaces a traditional mechanical key to realize functions of keyless entry and keyless start.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

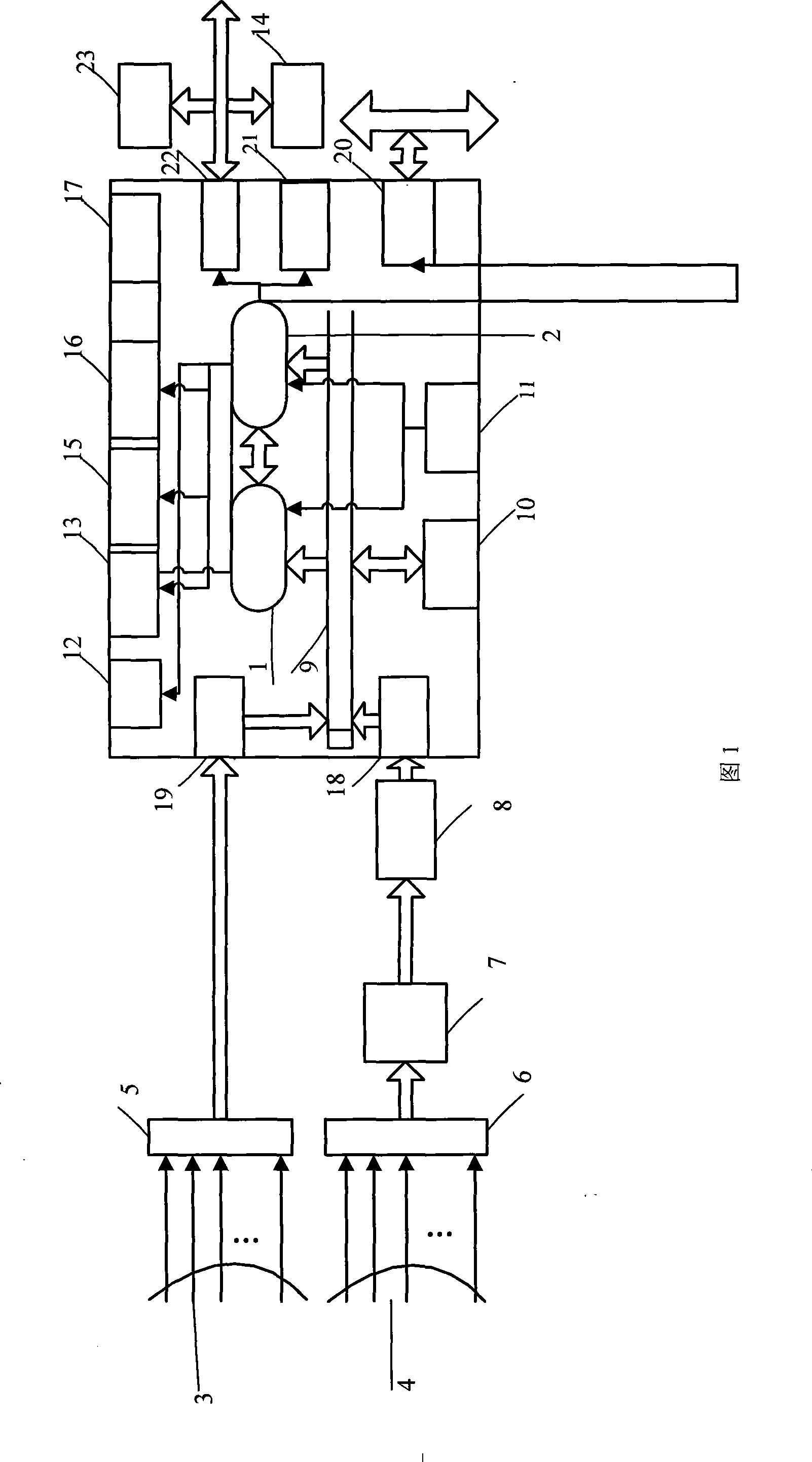

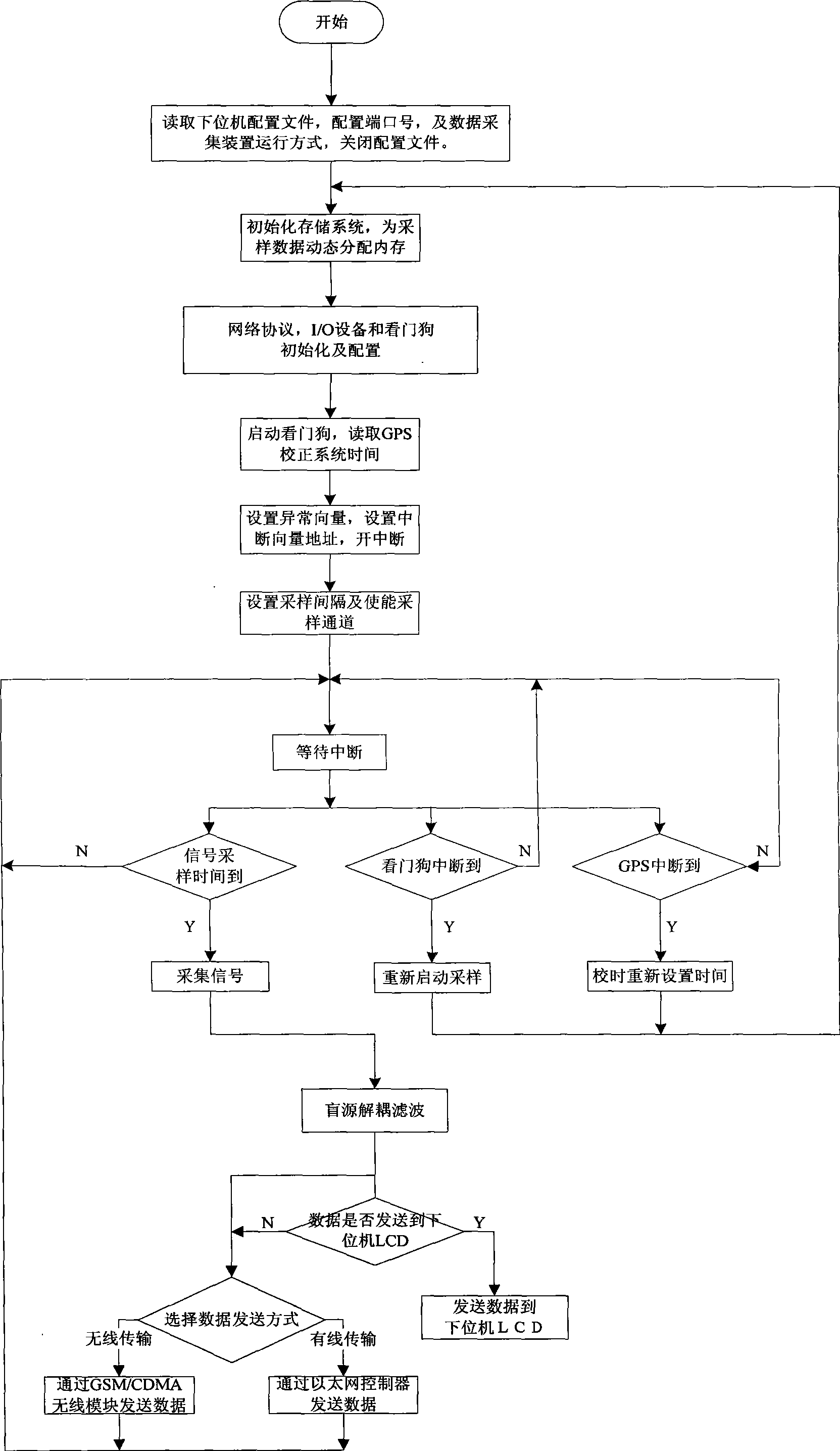

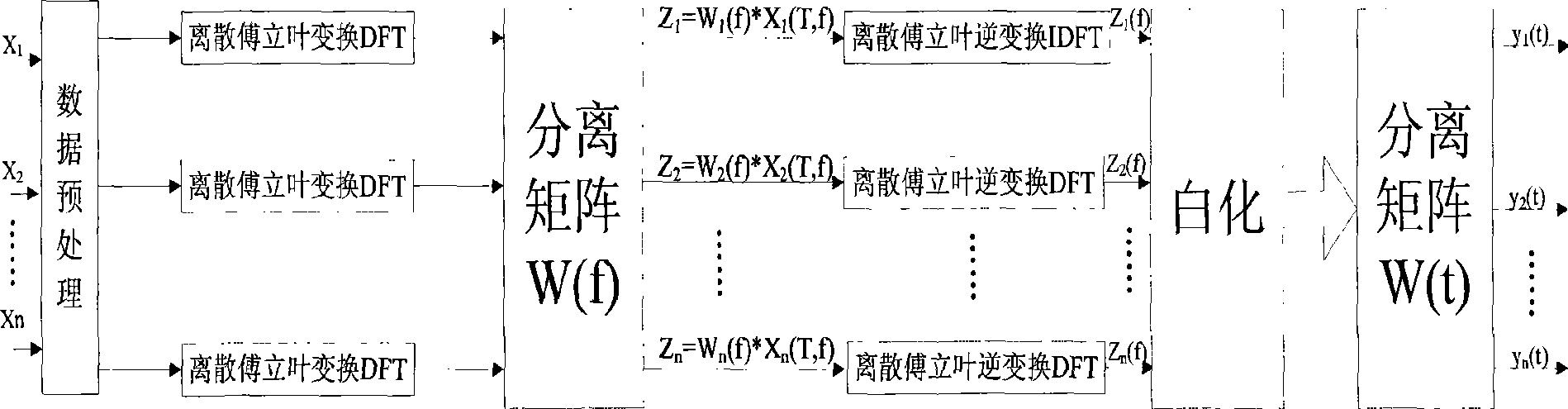

Double-core embedded type networking data collector and blind source separating filtering method

InactiveCN101441456AHigh speedImprove operational efficiencyComputer controlSimulator controlDigital signal processingDual core

The invention relates to a duel-core embedded networking data acquisition device and a filtering method for blind source separation thereof, which belongs to the field of information technology. The duel-core embedded data acquisition device controls a running state of the whole system by using ARM, analyzes and processes the acquired data by using DSP, is communicated with ARM through an HPI interface, can give a play to the advantages of ARM in terms of logic control, also can give a play to the advantages of DSP in terms of digital signal processing. Moreover, the running speed of the system is improved. The device can send data through not only Ethernet, but also a GSM / CDMA module, and is automatically switched to other transmitting modes by an ARM embedded processor, thereby avoiding breakdown of the system and increasing robustness of the system without influencing the normal operation of the system. A second class filtering mode for combining hardware filtering with software filtering based on blind source decoupling is adopted to truly and effectively restore signals and separate the needed source signal.

Owner:NORTHEASTERN UNIV

Cotton and spun silk segment-color yarn and production method thereof

The invention relates to a type of cotton and spun silk segment-color yarn and a production method thereof. The cotton and spun silk segment-color yarn comprises colored decorative yarn and white base yarn, wherein the colored decorative yarn is spun silk yarn, and the white base yarn is pure cotton yarn. The process comprises the following steps that scouring, opening and carding are carried out on spun silk raw materials, then, combing is carried out, four drawing is carried out so that spun silk drawn slivers can be made, the spun silk drawn slivers are cut into spun silk fibers with a fiber cutting-off machine, the average length of the spun silk fibers ranges from 28 mm to 35 mm, dyeing is carried out, and colored spun silk roving is made through roving; cotton fibers is processed through opening picking, carding, combing, drawing and roving to form white cotton roving; in the working procedure of spun yarn, the spun silk serves as the colored decorative yarn, cotton serves as base yarn, and spinning is carried out to form the cotton and spun silk segment-color yarn. By the adoption of the process, resource allocation is fully utilized, the cotton fibers serve as the main body of the yarn, the expensive spun silk is used for forming colored segments, the production of the high value-added cotton and spun silk segment-color yarn is achieved, and the product profit is increased.

Owner:安徽寿县银丰棉业有限责任公司

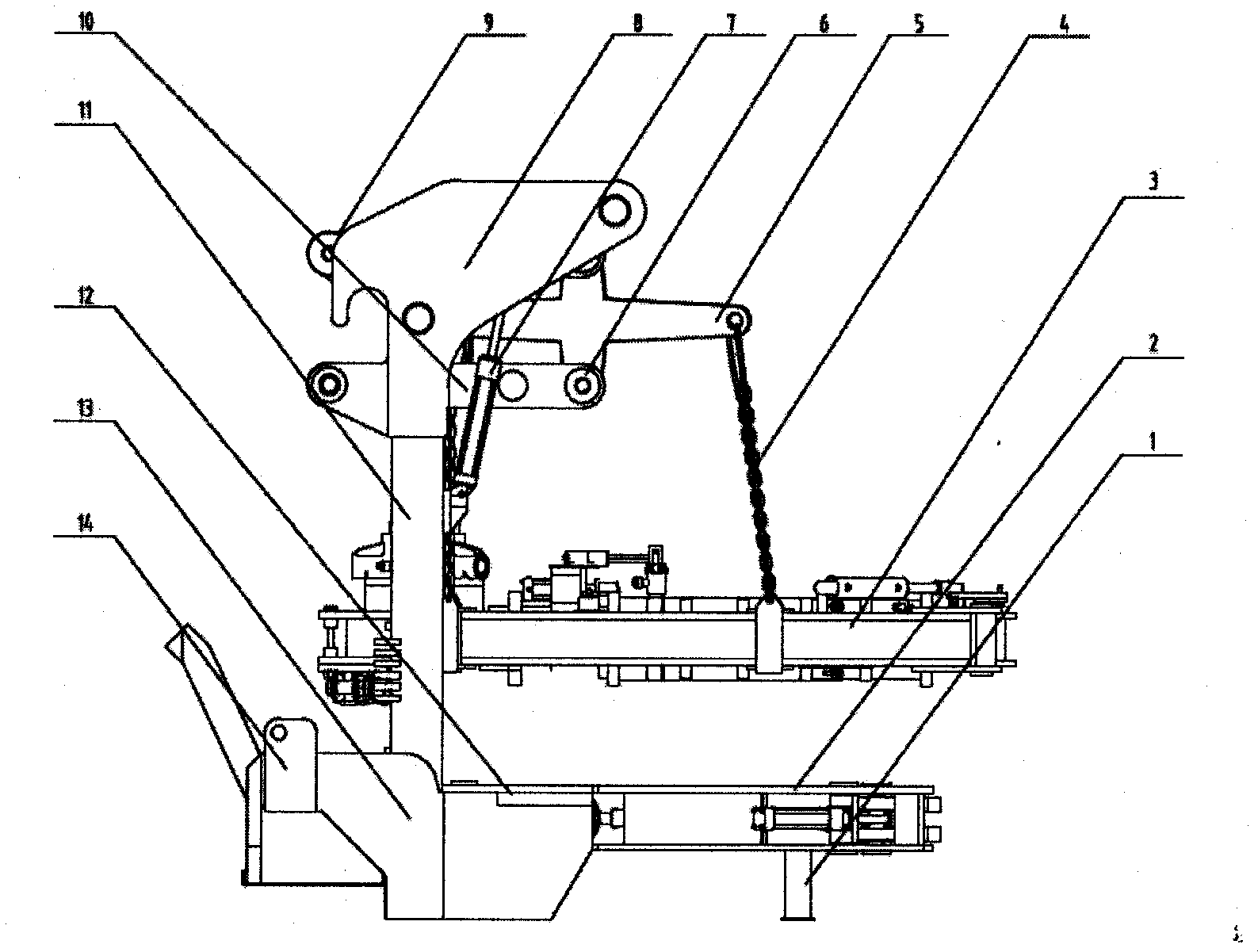

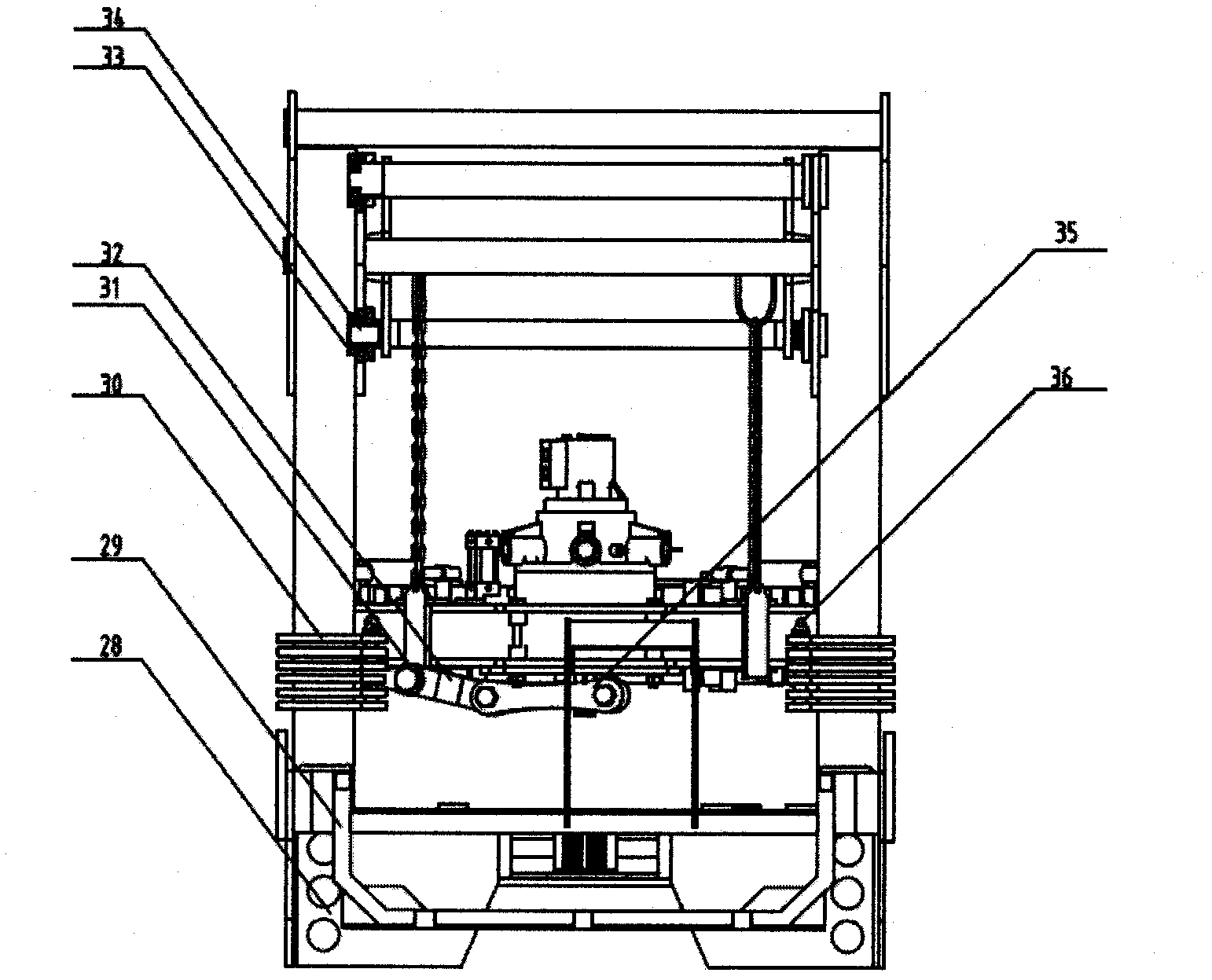

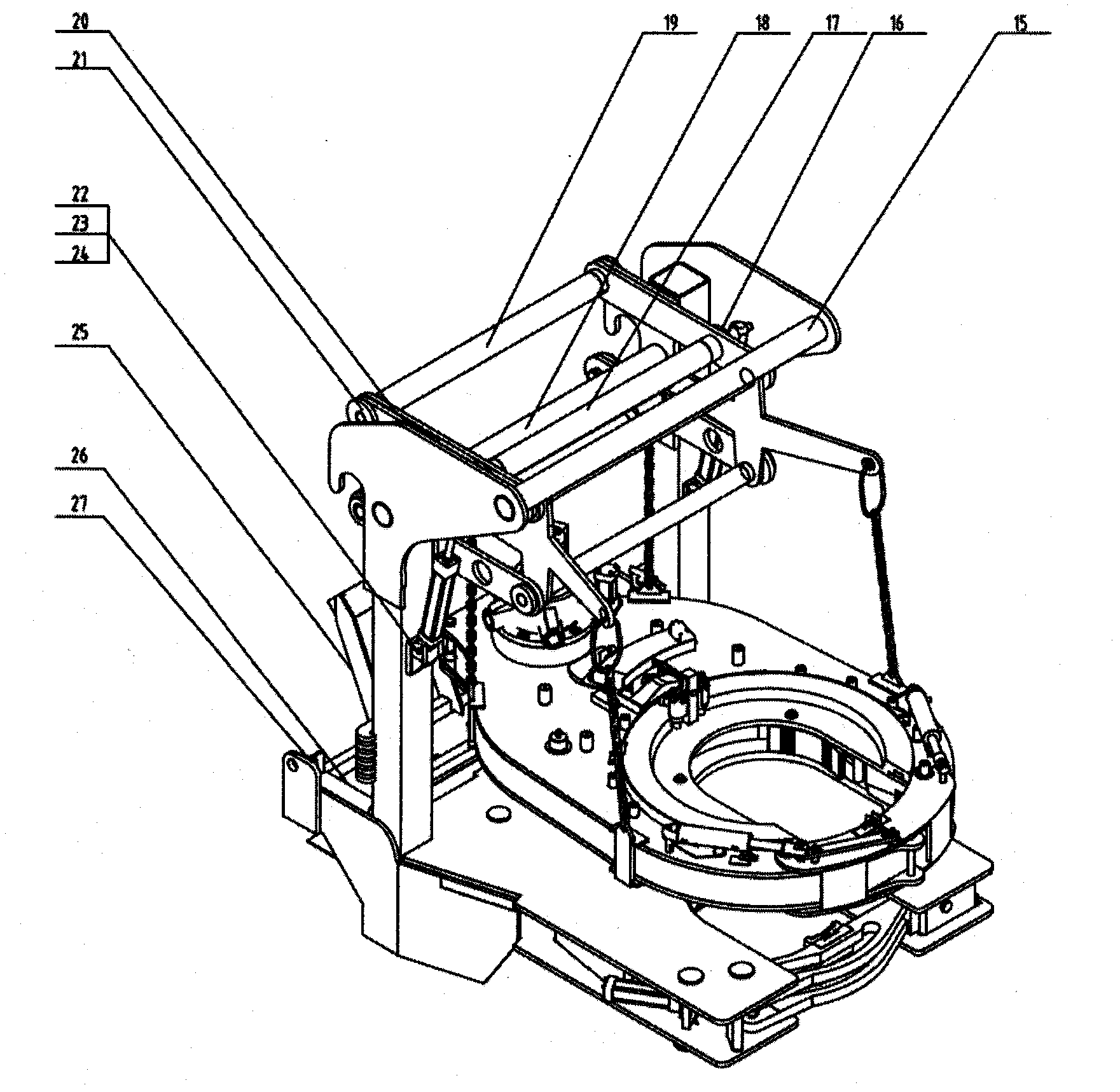

An Intelligent Casing Pliers with Back Tongs

InactiveCN102278083ARealize full automationReduce labor intensityDrilling rodsDrilling casingsEngineeringUltimate tensile strength

The invention provides intelligent casing tongs with back-up tongs, which comprises a main frame, a hanging frame, main tongs and back-up tongs, wherein the main tongs and the back-up tongs are connected on the main frame; the main tongs are suspended on the hanging frame through a chain, which is connected with the main frame; the back-up tongs are welded with the main frame and supported by two feet; the hanging frame is parallelogram-shaped; a rotary torque measuring device is mounted to the main frame; the main tongs achieve the effect of clamping a casing in a claw climbing manner; the back-up tongs are tightly clamped by three claws; and the claws are distributed in a mode of 120 degrees. The purpose of full-range automation of work of casing tongs is achieved, and the labor intensity of workers and accident incidence are reduced. The parallelogram-shaped hanging frame is adopted to ensure horizontal movement of power tongs. The tooth alignment process is centralized by adjusting a support cylinder. The back-up tongs improve the clamping force of the claws by use of a wedging mechanism. The back-up tongs are flexibly connected with the main tongs and can be detached to be used alone. The types of the claws are changed to fit different tube diameters, so as to increase the application range.

Owner:金华萨博思石油机械有限公司

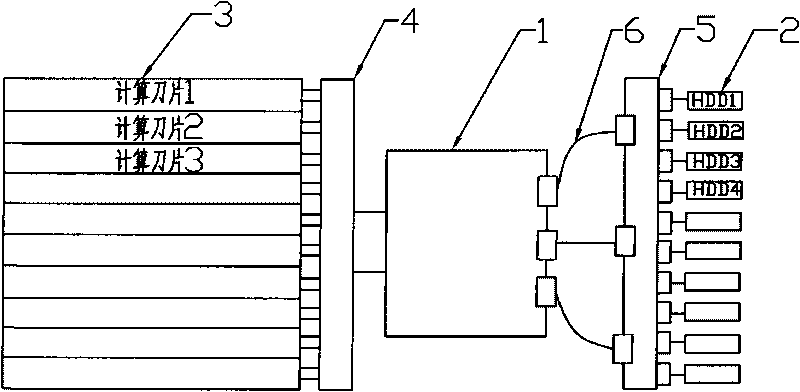

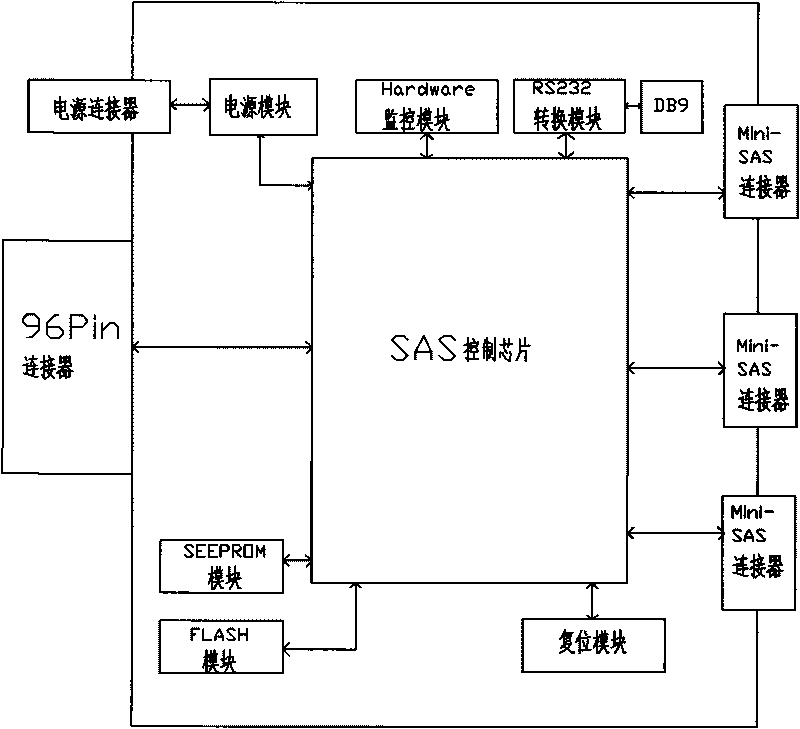

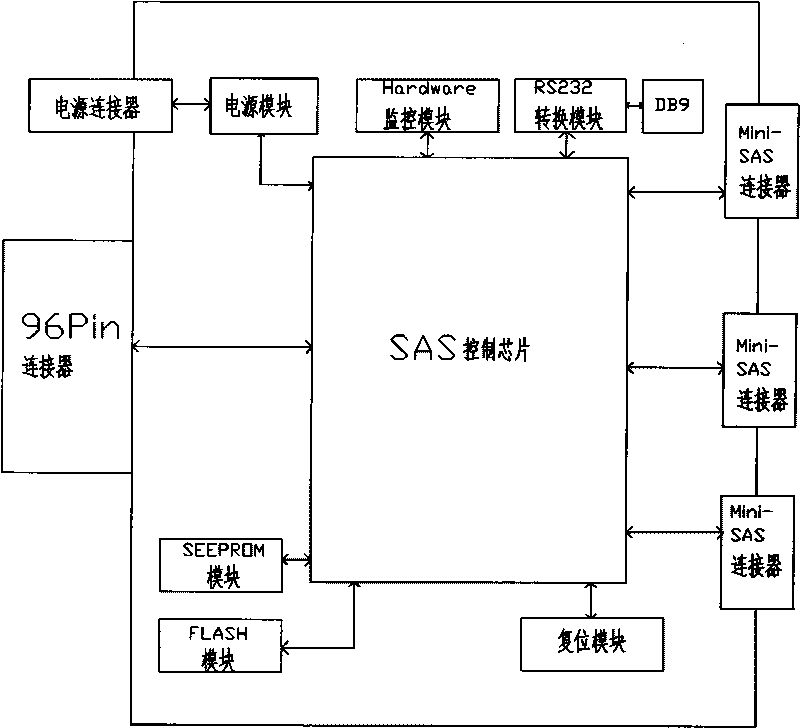

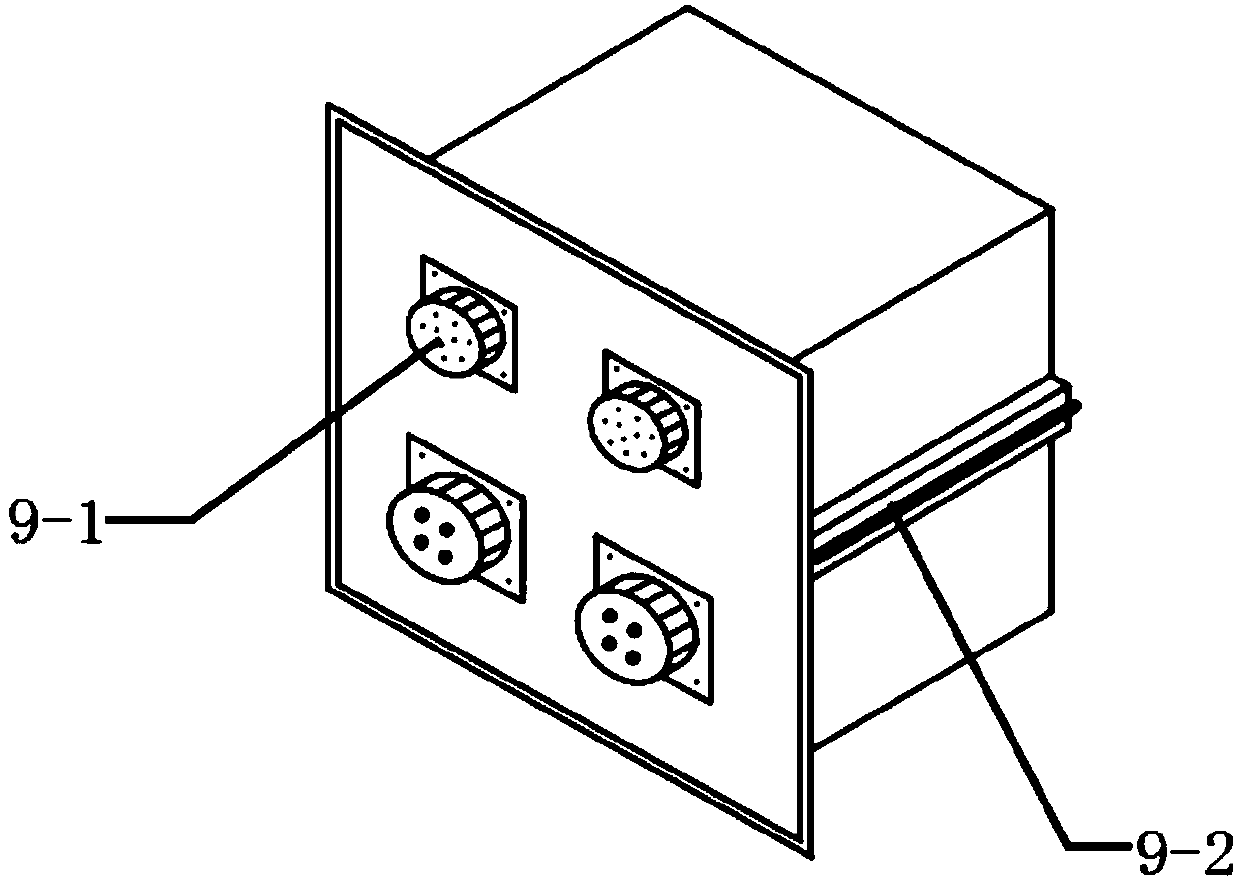

Storage expanding module for blade server

InactiveCN101751229ADoes not affect the spaceDoes not affect densityInput/output to record carriersEmbedded systemBlade server

The invention discloses a storage expanding module for a blade server and particularly relates to a storage expanding module having a sharing function. The transmission signal of the storage expanding module is connected with a blade by a middle plate, and simultaneously the blade and the storage expanding module are powered by the middle plate respectively and the blade and the storage expanding module are not mutually affected. Because the storage expanding module is used as big storage equipment, the storage capacity of the blade server is improved; by using an SAS control chip, the blade and the hard disk are separated, the hard disk can exist without relying on the computing blade, and only the SAS control chip needs to be configured when the storage capacity of the blade needs to be expanded, so that the capacity expansion of the corresponding computing blade can be realized; and the SAS control chip is configured by the CMM, and the configuration mode is flexible and diversified; and simultaneously, both the whole storage module and single hard disk support the hot-plugging, so that the problem of under storage capacity of the conventional blade server is solved, and the future maintenance is quick and convenient.

Owner:DAWNING INFORMATION IND BEIJING

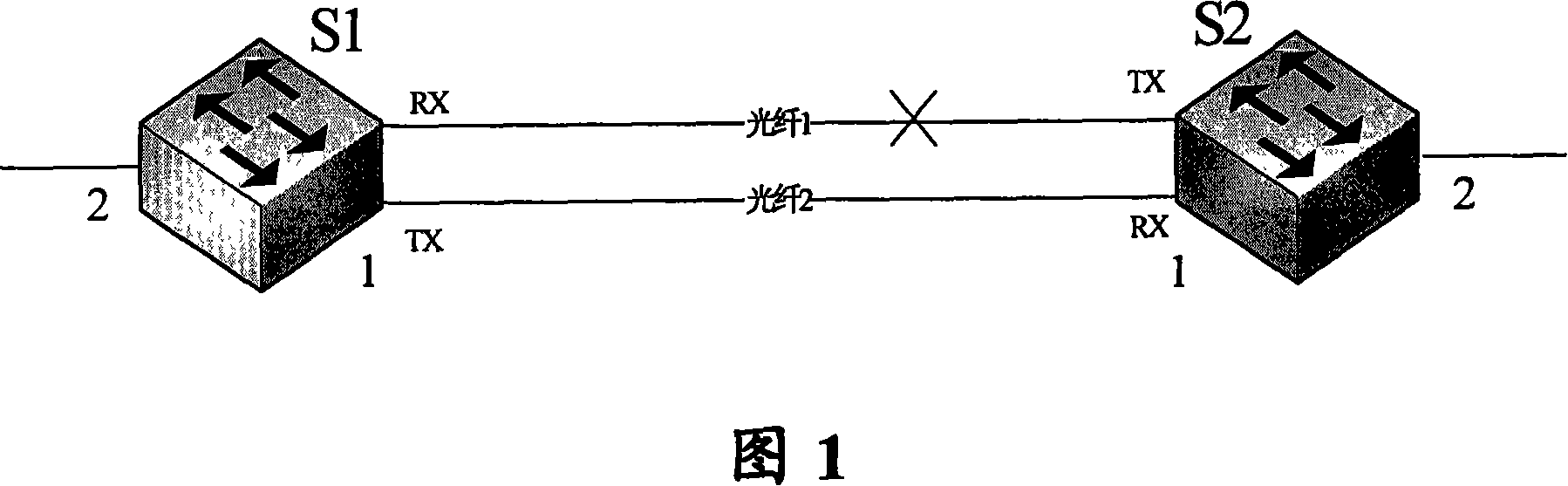

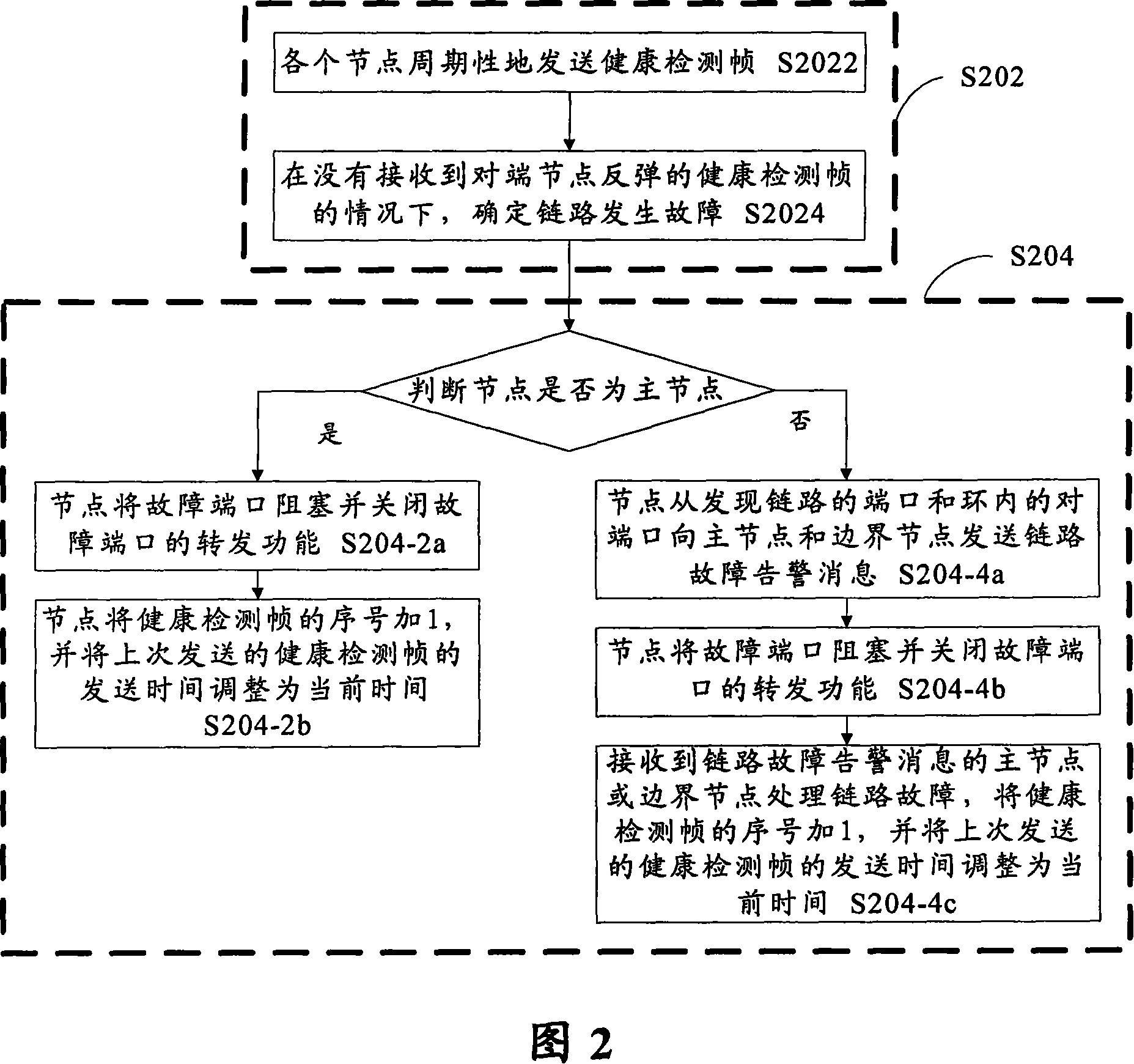

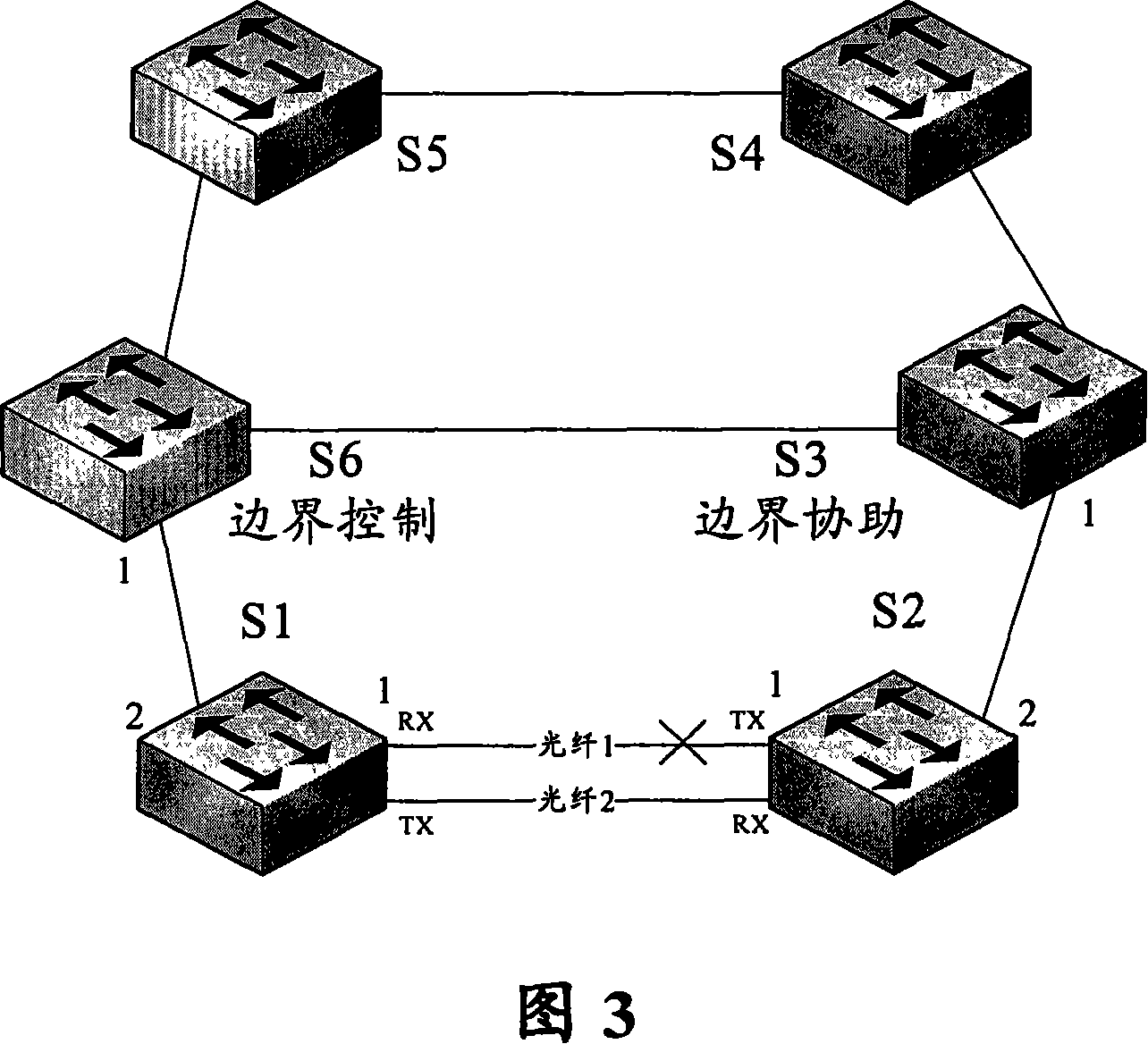

Single optical fiber fault processing method for Ethernet antomatic protection system

InactiveCN101072155AShorten convergence timeImproved resistance to failureFault recovery arrangementsTransmission monitoring/testing/fault-measurement systemsAlarm messageProtection system

The method includes following steps: step S202, each node of Ethernet automatic protection system (EAPS) sends out health detection frame to detect link statute of each protected port; step S204, when link failure or link alarm message is received, main node or boundary node processes link failure, and changes sequence number of health detection frame and sending time. Through bidirectional sending failure alarming frame etc processes, the invention can prevent too long convergence time of EAPS caused by that nodes inside ring couldn't detect link failure quickly when failure of single optical fiber occurs as well as prevents misinterpretation of EAPS caused by that health detection frame passes through another optical fiber.

Owner:ZTE CORP

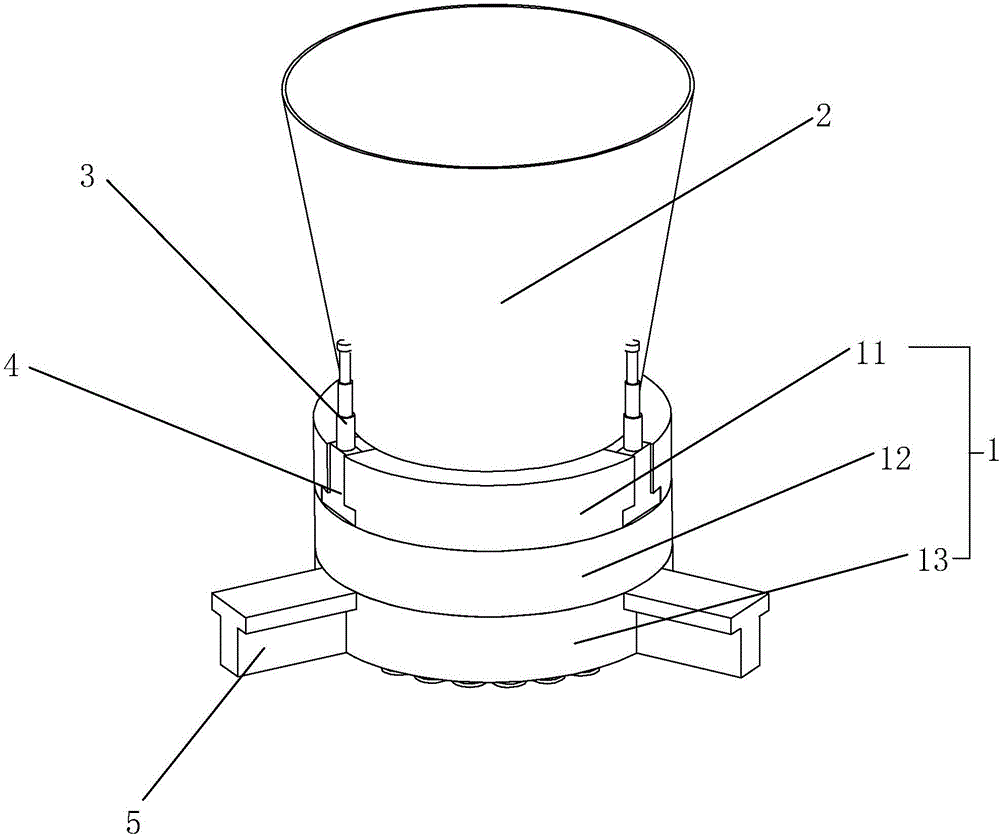

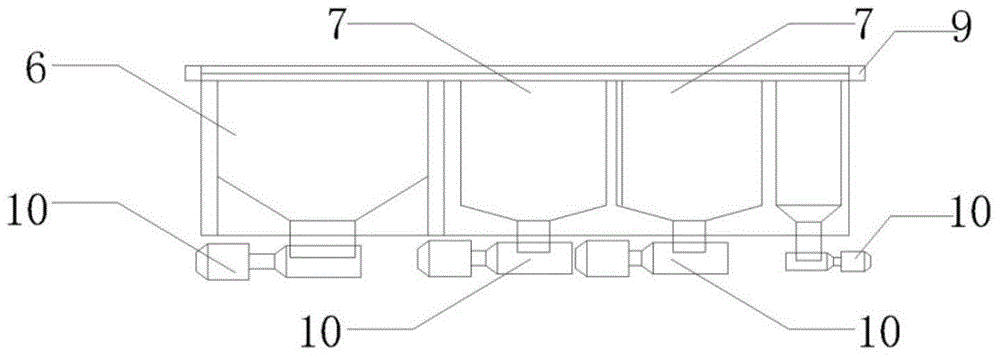

Multifunctional falling prevention bracket

ActiveCN105020553AImprove stabilityIncrease practical rangeWalking sticksStands/trestlesMechanical engineeringFall prevention

Owner:陈锐

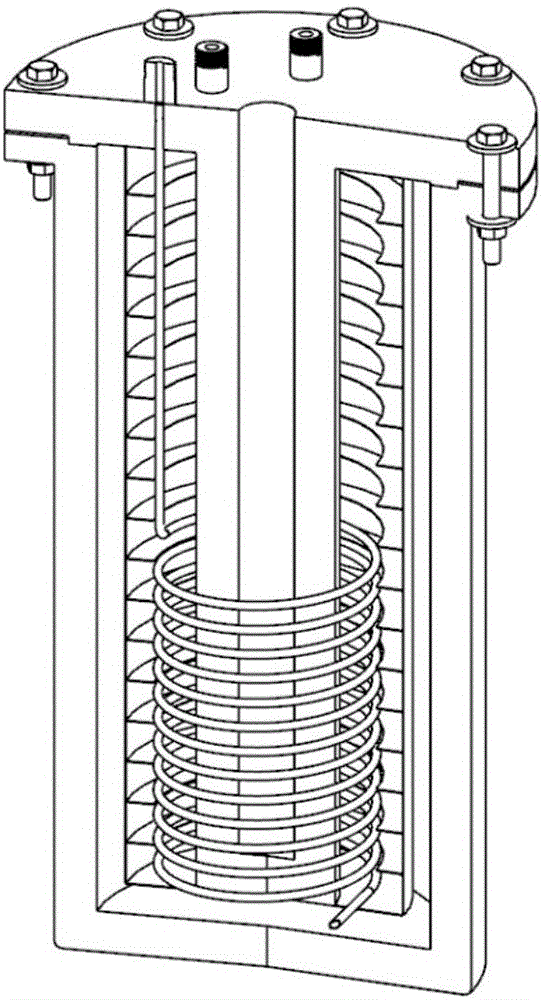

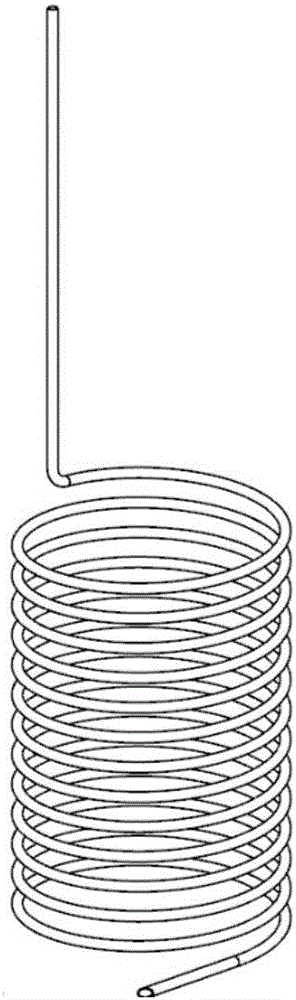

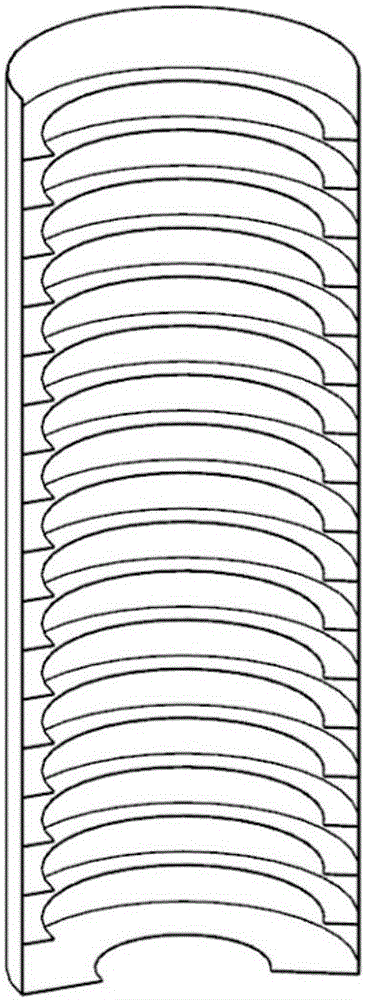

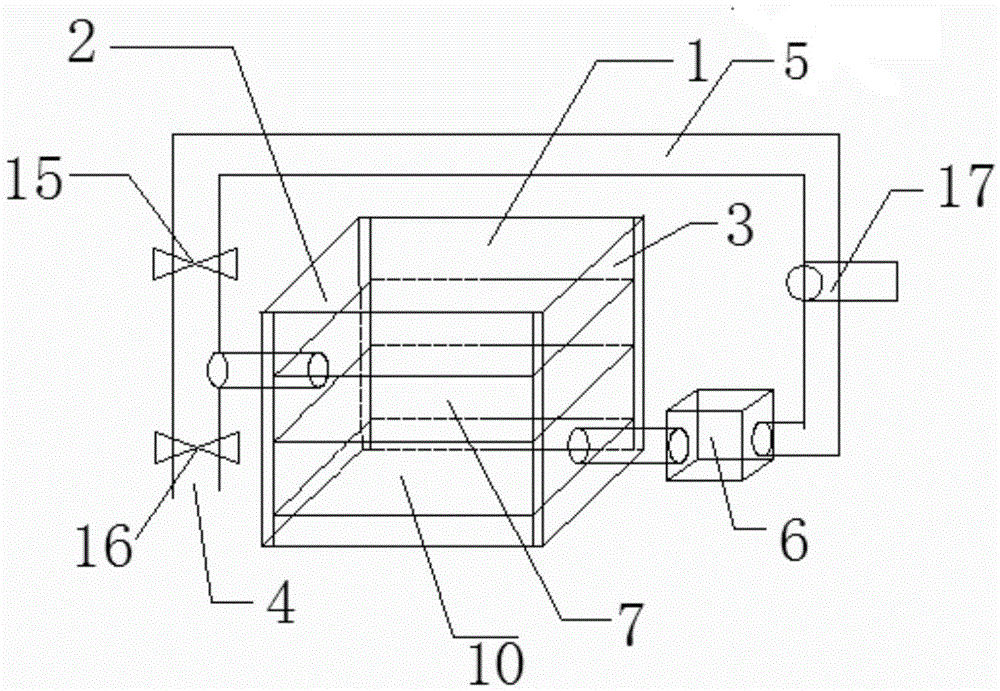

Supercritical fuel oil heating device in supercritical oil bath type

ActiveCN106568101AMeet the experimental needsPrecisely adjustable temperatureLiquid fuel feeder/distributionContinuous combustion chamberHeat fluxFuel oil

The invention discloses a supercritical fuel oil heating device in a supercritical oil bath type. With supercritical oil bath heating and flowing heat exchange in a spiral pipe as a basis, a sleeve type structure is adopted, and supercritical fluid in different temperatures and pressures can be continuously and stably provided for a supercritical jet test of fluid effectively. By means of the supercritical oil bath heating, generation of a coking and cracking reaction in the fuel oil heating process can be effectively avoided, and generation of impurities is inhibited. The spiral pipe is used as a flowing path, and the heat flux and the heat exchange efficiency can be effectively improved, so that the problem that the heating temperature of an existing heater is not uniform can be solved. Two stages of heating manners are integrated, and the heat preserving performance and the heat efficiency of the device are improved. Due to the gas circuit design, zero pressure difference among the spiral pipe, a pre-heating cavity and an oil bath cavity is achieved, the weight and the cost of the device are reduced, and the heat exchange capacity is also improved. The supercritical fuel oil heating device in the supercritical oil bath type is compact in structure and convenient to use, meanwhile, the supercritical fuel oil heating device in the supercritical oil bath type is also applicable to subcritical, transcritical and supercritical tests of gas, liquid and various fluid, and has quite high adaptability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

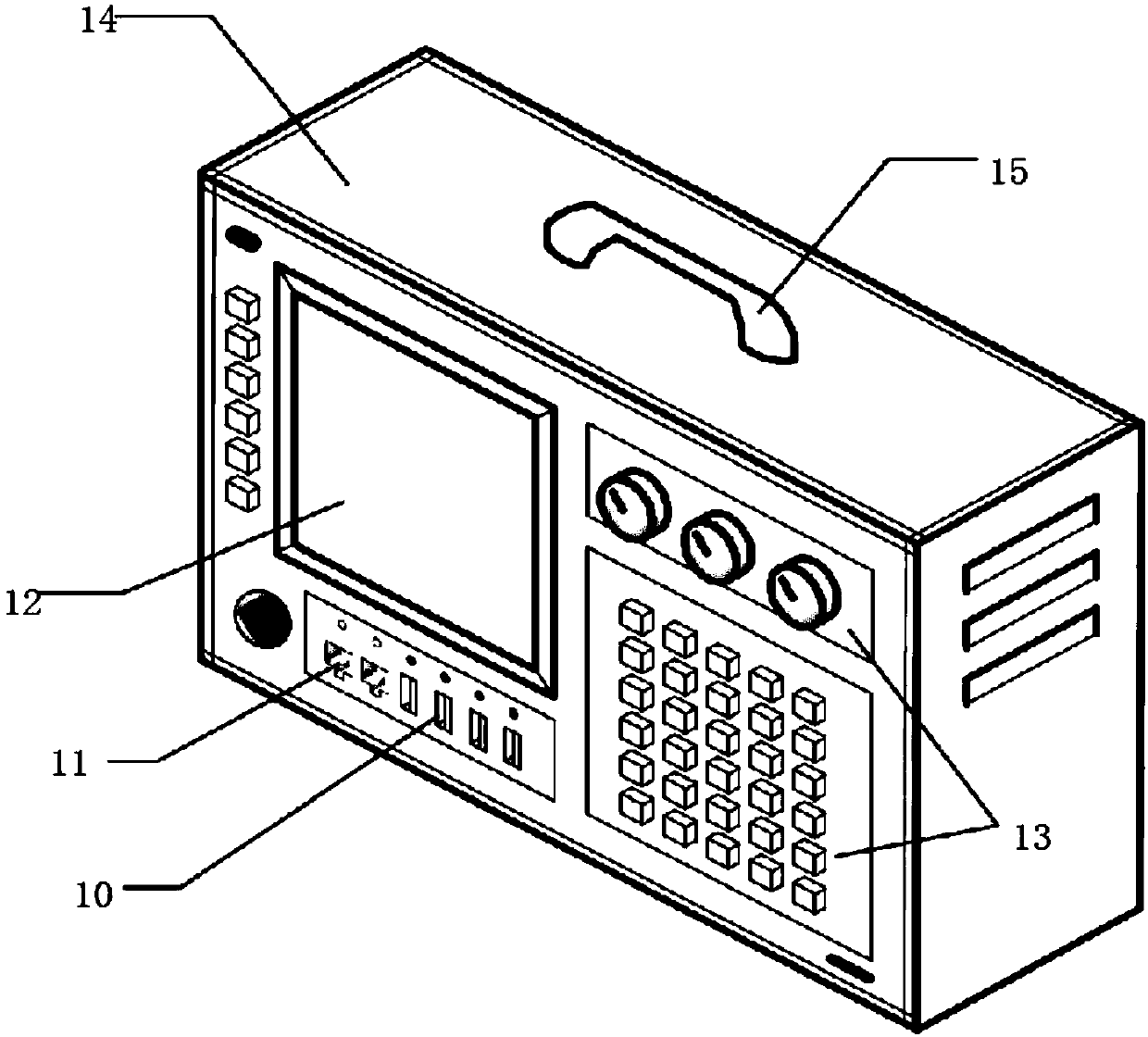

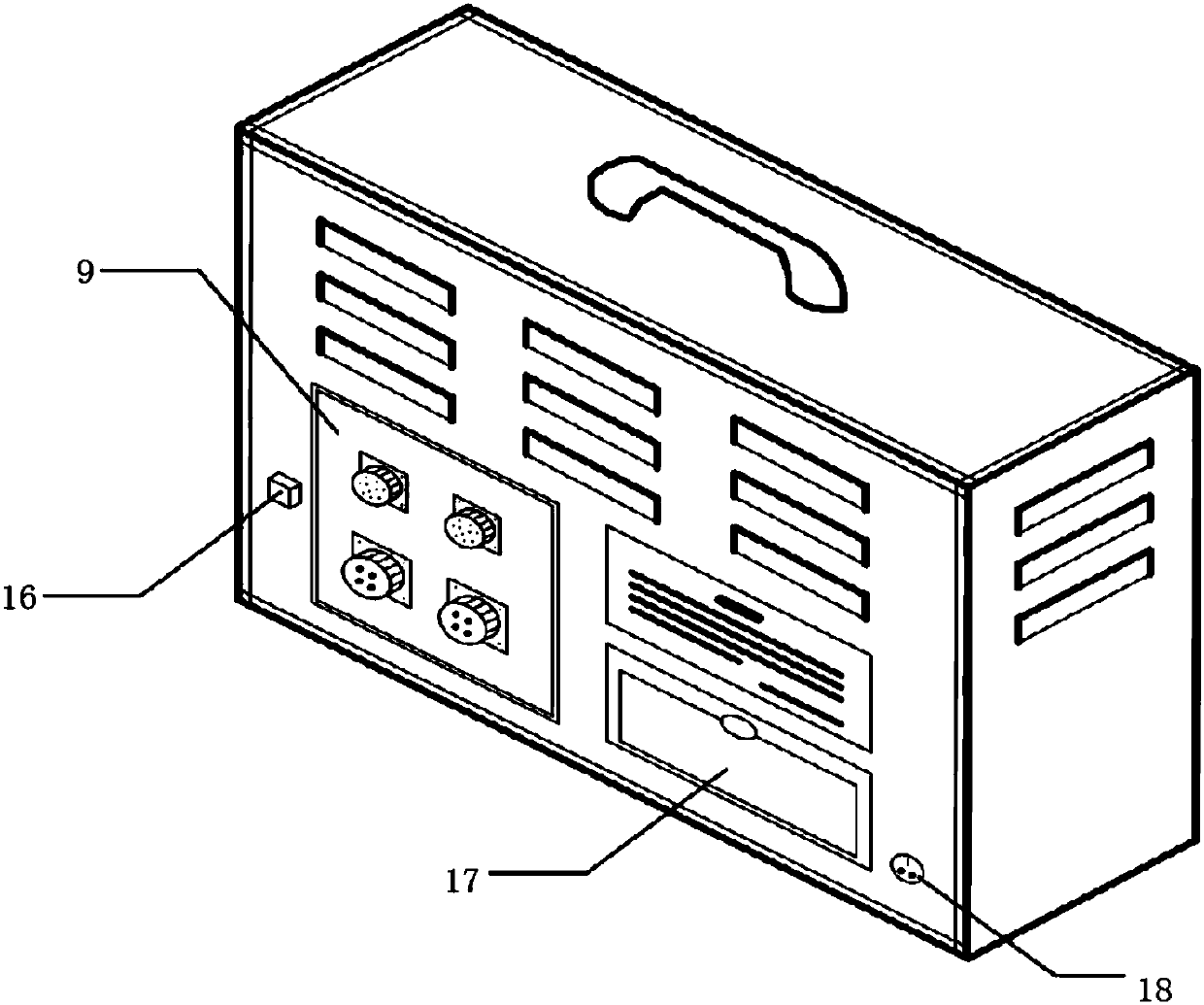

Portable multifunctional aerospace cable detection instrument and method

PendingCN107728007AImprove test efficiencyReduce labor intensityFault location by conductor typesDisplay deviceContinuity test

The invention provides a portable multifunctional aerospace cable detection instrument and method, and belongs to the field of automated instruments. The detection instrument includes external USB interfaces, an Ethernet interface, and a liquid crystal display linked computer; the computer is connected with a digital input / output module, an insulation resistance detection module, a continuity testmodule, a four-wired resistor detection module, a dielectric strength test module and an input equipment through USB interfaces; the digital input / output module, the insulation resistance detection module, the continuity test module, the four-wired resistor detection module and the dielectric strength test module are connected with a test unit adapter through a relay matrix module. The method includes the steps of obtaining the cable test state, the electrical element test state and the calibration state. The automated test process is achieved through computer control, integration of varioustest functions is achieved, the test efficiency is improved, and the labor intensity is reduced. A shell case is designed to be miniaturized, lightweight and portable, a handle is arranged, and the detection instrument is easy to carry.

Owner:航天科工哈尔滨风华有限公司

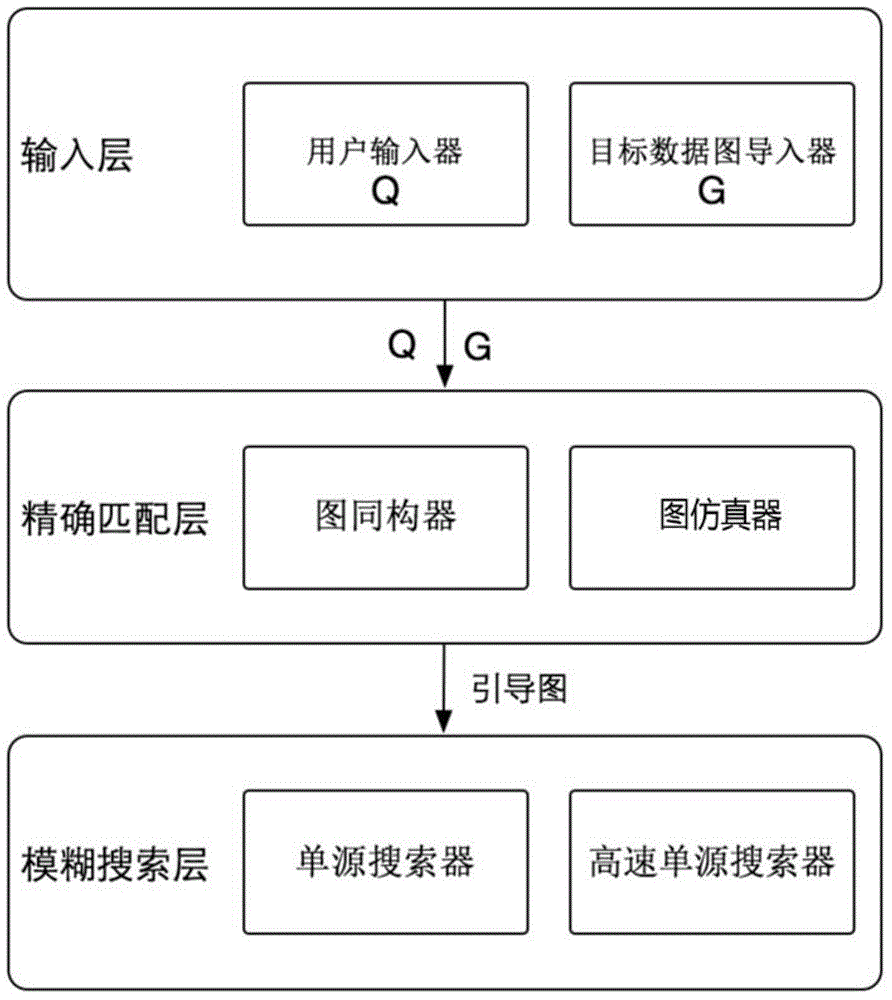

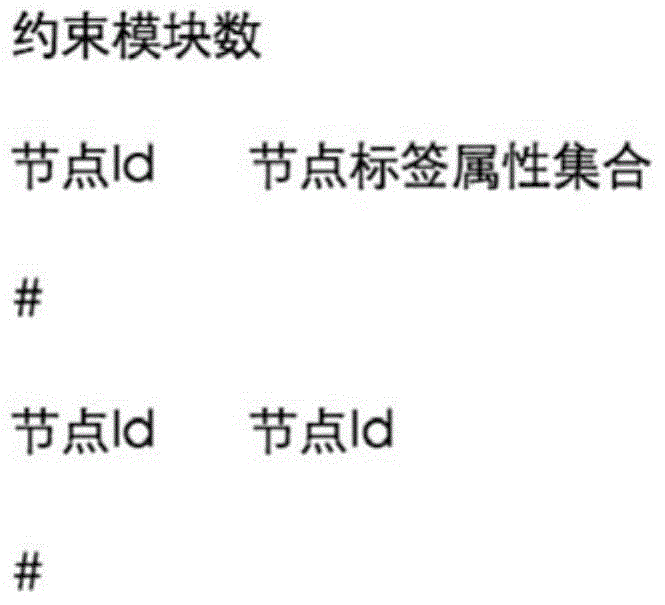

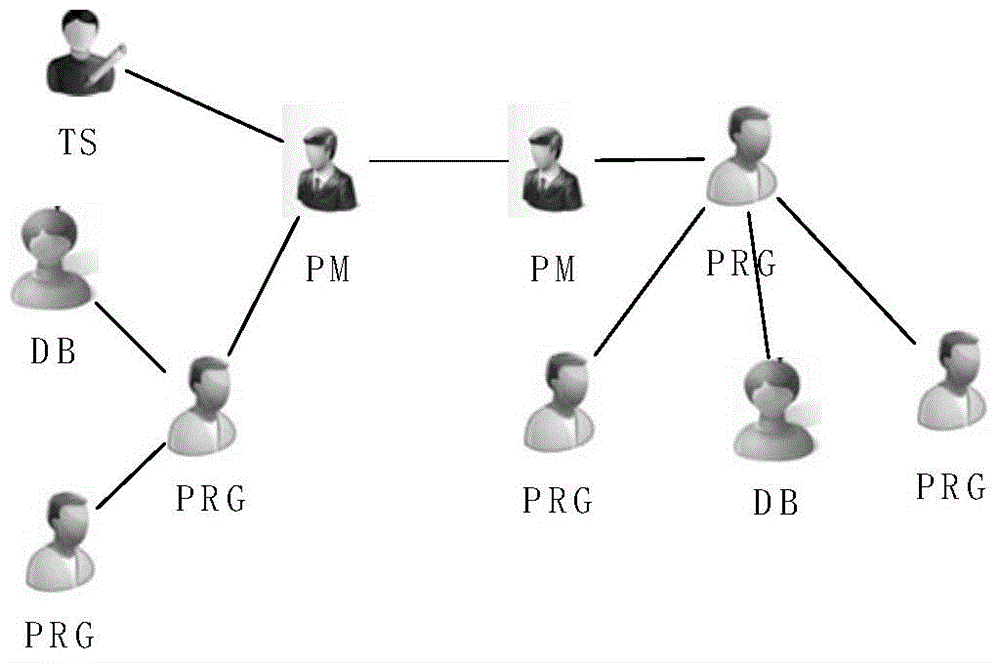

Graph pattern matching method for supporting fuzzy constraint relation

ActiveCN105138601AIncrease practical rangeImprove match qualityStill image data retrievalSpecial data processing applicationsMap matchingFuzzy constraint

The present invention provides a graph pattern matching method for supporting a fuzzy constraint relation, which relates to the technical field of graph information query and is used for solving the problem, in the prior art, of failing to support matching of a fuzzy constraint relation on the basis of meeting all accurate constraints. The method comprises: by means of an input layer, acquiring a query graph Q input by a user and a stored target data graph G, wherein the query graph contains the accurate constraint relation and the fuzzy constraint relation; by means of an accurate matching layer, performing accurate map matching for the accurate constraint relation in the query graph input by the user in the target data graph, and constructing a guide graph with a merging node in the target data graph; and by means of a fuzzy search layer, finding out and outputting K matching graphs that have the best fuzzy constraint matching quality on the basis of meeting all the accurate constraints in the guide graph. The graph pattern matching method for supporting the fuzzy constraint relation is applicable for performing hybrid query supporting the fuzzy constraint relation and the accurate constraint relation in massive target data graphs.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

Flame-retardant environment-friendly material and manufacturing process thereof

The invention relates to an environment-friendly material with flame-retardant effect, which comprises 5-8 parts by mass of plastics, 1-3 parts by mass of kaolin, 0.5-1.5 parts by mass of bamboo powder, 2-4 parts by mass of flame retardants, 0.5-1 parts by mass of chemical additives. When compared with current products, the material of the invention has low cost and good kaolin viscosity, and can substitute 3%-5% of plastics; because of certain flame-retardant effect of kaolin, 3%-5% of flame retardants can be relatively reduced; and thus the cost is reduced, and large industrial demands become possible. The application scope of the new product is improved, and the market share is extended.

Owner:陈姜志 +1

Method for rapidly corroding and patterning indium tin oxide surface by using electrochemical technology

InactiveCN102691093AEasy to operateAccelerated corrosionPhotomechanical apparatusChronoamperometryIndium tin oxide

The invention relates to a method for rapidly corroding and patterning an indium tin oxide (ITO) surface by using an electrochemical technology, belonging to the fields of electrochemistry and micro-nanotechnologies. Aiming at the problem of the traditional ITO-corroding method, the method for rapidly corroding and patterning the indium tin oxide surface by using the electrochemical technology, provided by the invention, comprises the steps as follows: (1) washing the ITO surface; (2) pressing a used photoresist into a protective film on an ITO substrate by using a plastic-envelop machine, directly placing a mask of a used pattern, performing ultraviolet exposure and developing, and forming and washing to form a needed pattern; (3) corroding exposed ITO part of the photoresist on the ITO surface with diluted hydrochloric acid as a corrosive liquid by using cyclic voltammetry or chronoamperometry and the electrochemical technology; and (4) washing an electrochemically corroded ITO glass sheet by using an alkali solution, removing a protective photoresist film; and drying by using N2 to obtain a patterned ITO surface. The method for rapidly corroding and patterning the indium tin oxide surface by using the electrochemical technology has the advantages of simplicity in operation, high speed, good corrosive effect, clearness of borders, low cost and the like.

Owner:HARBIN INST OF TECH

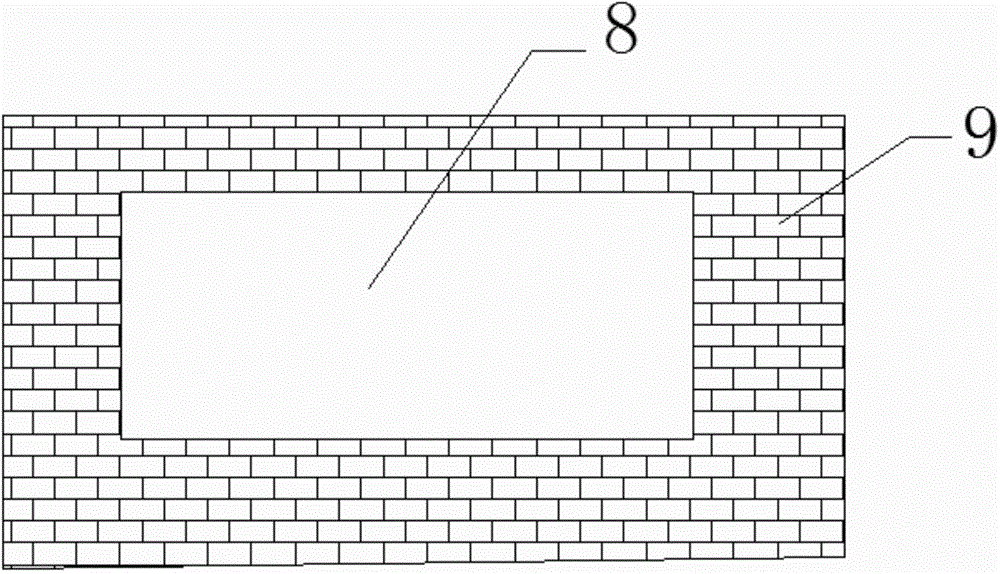

Baking and cooling integrated device for lithium ion battery production

InactiveCN104596209AReduce usageAchieve cycleDrying using combination processesFinal product manufactureBiochemical engineeringNitrogen

The invention provides a baking and cooling integrated device for lithium ion battery production. The baking and cooling integrated device for lithium ion battery production comprises a baking box body. Partition plates and containing plates are arranged in the baking box body. A heating device is arranged on each partition plate. Battery containing racks are arranged on the containing plate. Cold water interlayers are arranged in the battery containing racks. A nitrogen inlet is formed in the upper portion of a left side plate of the baking box body. The nitrogen inlet is communicated with a nitrogen supply pipe through a pipeline. The nitrogen supply pipe is communicated with one end of a nitrogen circulating pipe. A drying box and a circulating pump are arranged on the nitrogen circulating pipe. A nitrogen outlet is formed in the lower portion of a right side plate of the baking box body. The nitrogen outlet is communicated with the other end of the nitrogen circulating pipe. The nitrogen supply pipe is provided with a second valve. A first valve is arranged on the nitrogen circuiting pipe. Each partition plate is provided with a plurality of through holes. By the adoption of the drying and cooling integrated device, the nitrogen consumption is reduced, the drying time is shortened, and the application range is wide.

Owner:百顺松涛(天津)动力电池科技发展有限公司

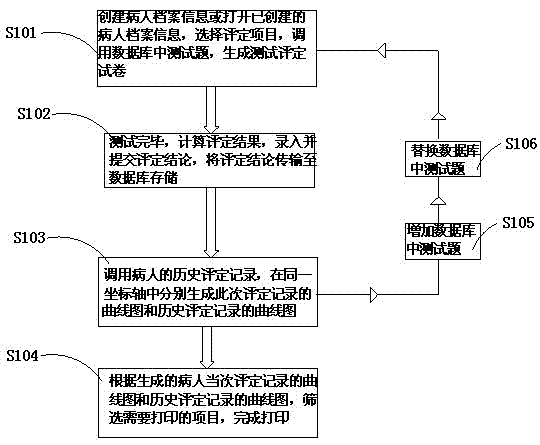

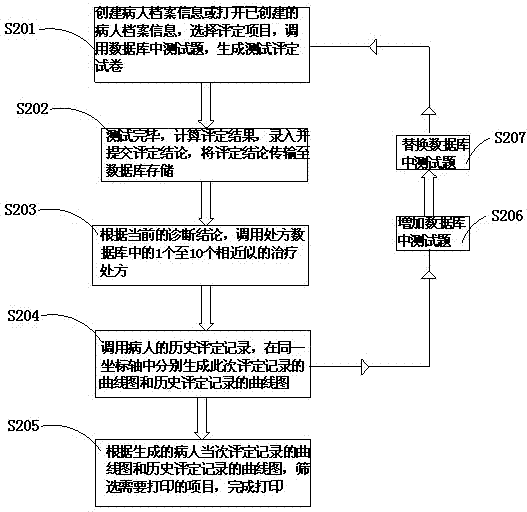

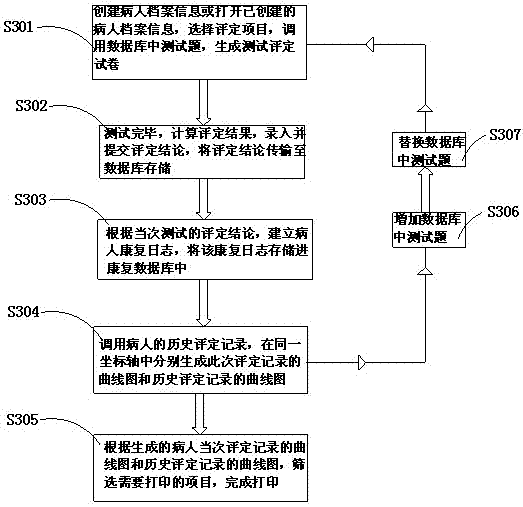

Patient rehabilitation rating scale generation method and system

InactiveCN104281768AReduce workloadImprove assessment work efficiencySpecial data processing applicationsPatient diagnosisTest question

The invention discloses a patient rehabilitation rating scale generation method, which comprises the following steps of creating patient file information or opening the created patient file information, selecting rating items, calling test questions in a database, and generating test rating paper; after the test is completed, calculating rating results, entering and submitting the rating conclusion, and transmitting the rating conclusion to the database to be stored; calling a historical rating record of a patient, and respectively generating a curve graph of the rating record and a curve graph of the historical rating record in the same coordinate axis. The invention also discloses a patient diagnosis and rehabilitation rating scale generation system.

Owner:成都沃瑞特医疗设备有限公司

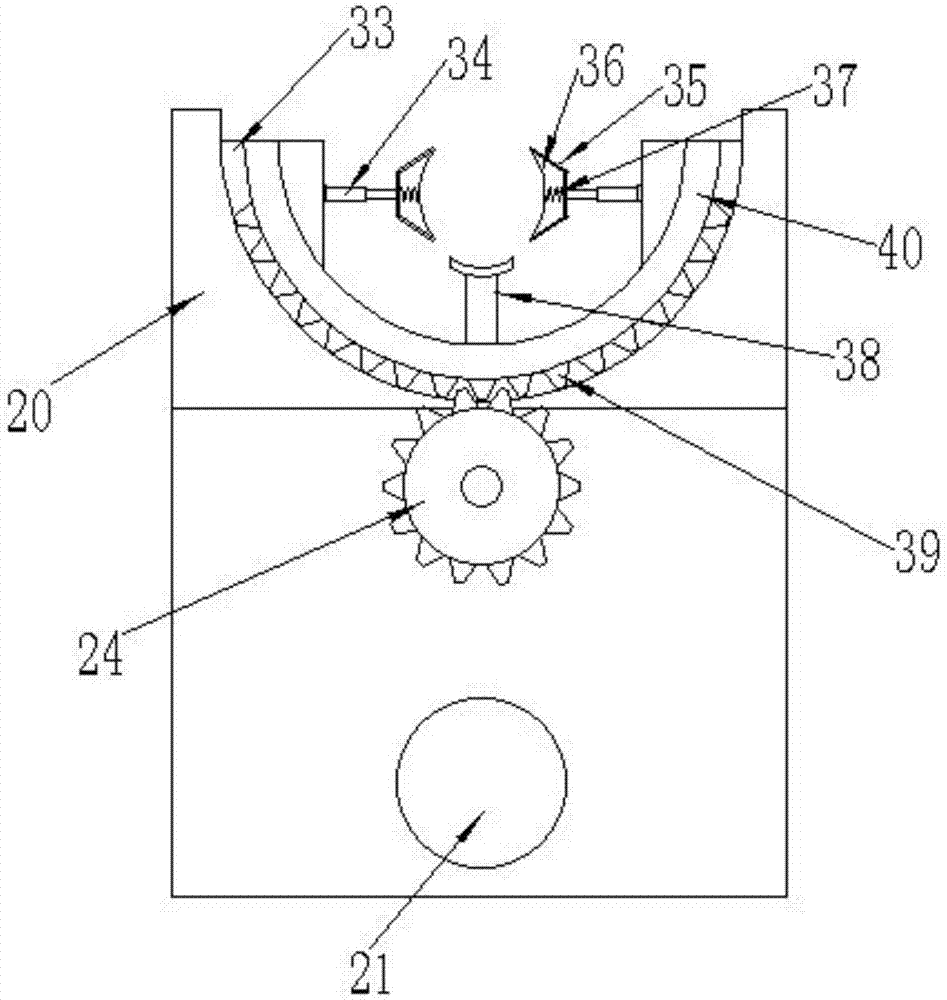

Efficient steel pipe polishing device

InactiveCN107378719AAvoid wear and tearReduce pollutionGrinding carriagesGrinding drivesDual axisMechanical engineering

The invention discloses an efficient steel pipe polishing device which comprises a support, a feeding mechanism, a polishing mechanism, a dust removing mechanism and a transmission chamber. The feeding mechanism comprises a forward and backward rotation motor, a feeding table, a second sliding block, a double-axis motor, a rotating gear and a clamping device. The clamping device comprises a clamping frame, a semicircular-ring-shaped rotating plate A, a semicircular-ring-shaped rotating plate B, an electric telescopic rod, a clamping rod and a supporting table. The dust removing mechanism is arranged on the right side of the feeding mechanism and comprises a suction fan, an electromagnet, a chip feeding pipe and a collecting groove. The polishing mechanism is arranged above the feeding mechanism and comprises a rotating motor B, a rotating wheel A, a second belt, a rotating wheel B, a polishing wheel A and a polishing wheel B. The transmission chamber is arranged on the left side of the polishing mechanism. The efficient steel pipe polishing device is simple in structure and convenient to operate, the polishing efficiency of the steel pipe polishing device is improved, meanwhile, labor force is greatly lowered, and the environment pollution is effectively reduced due to the arranged dust removing device.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

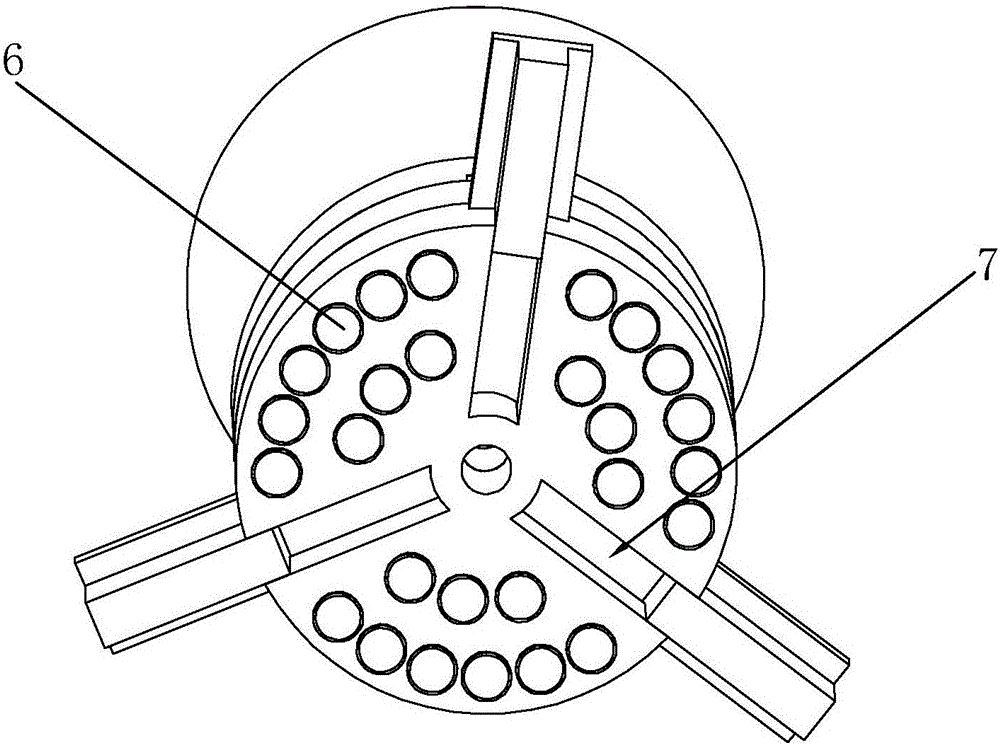

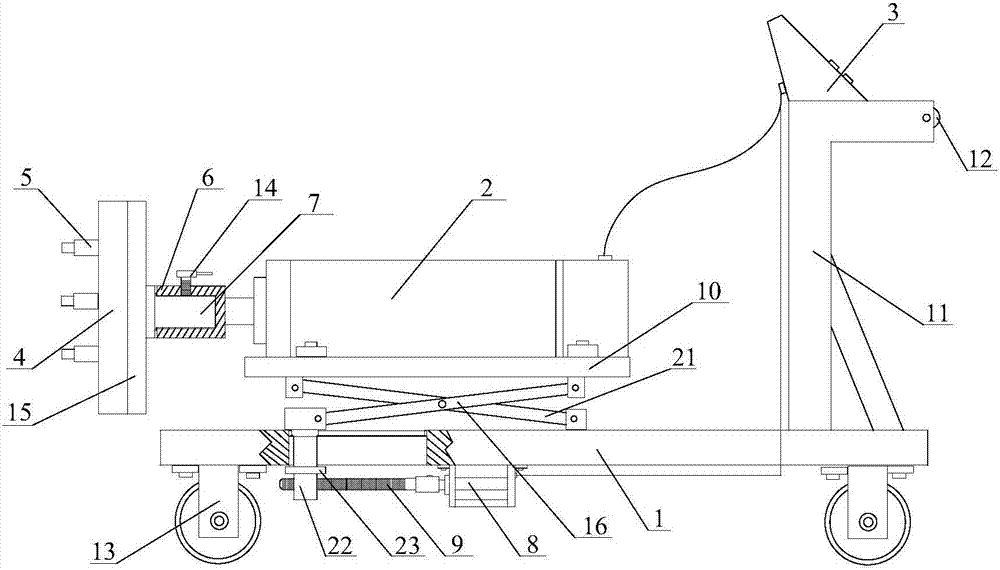

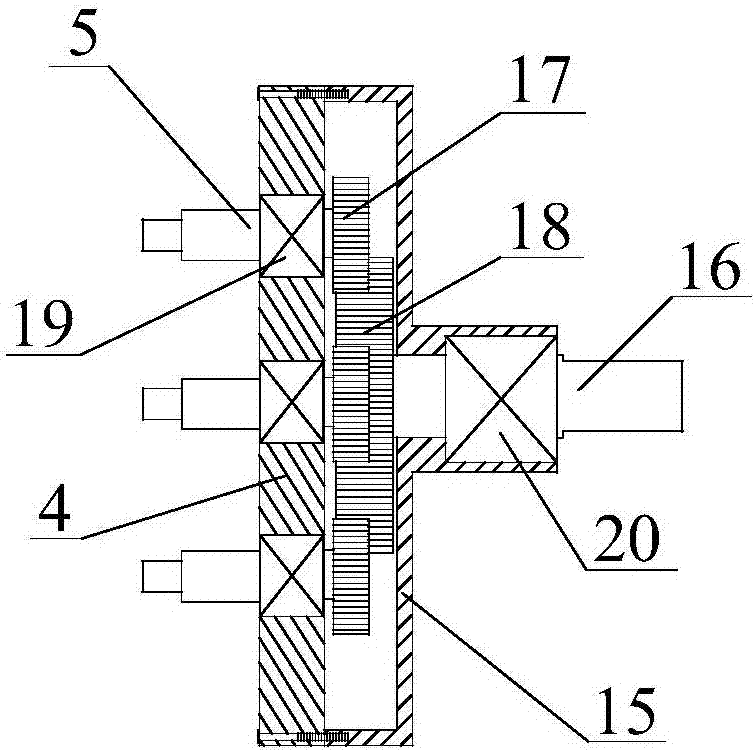

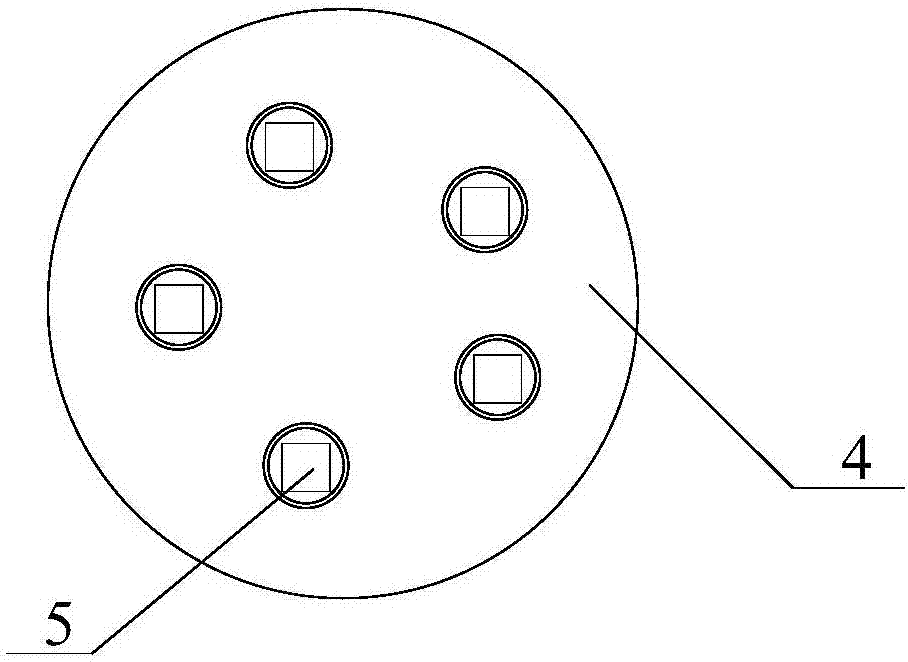

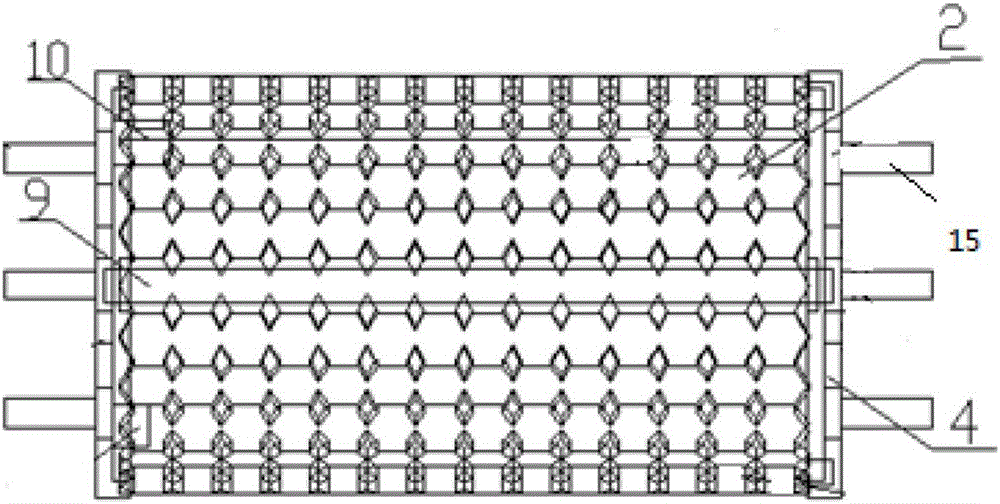

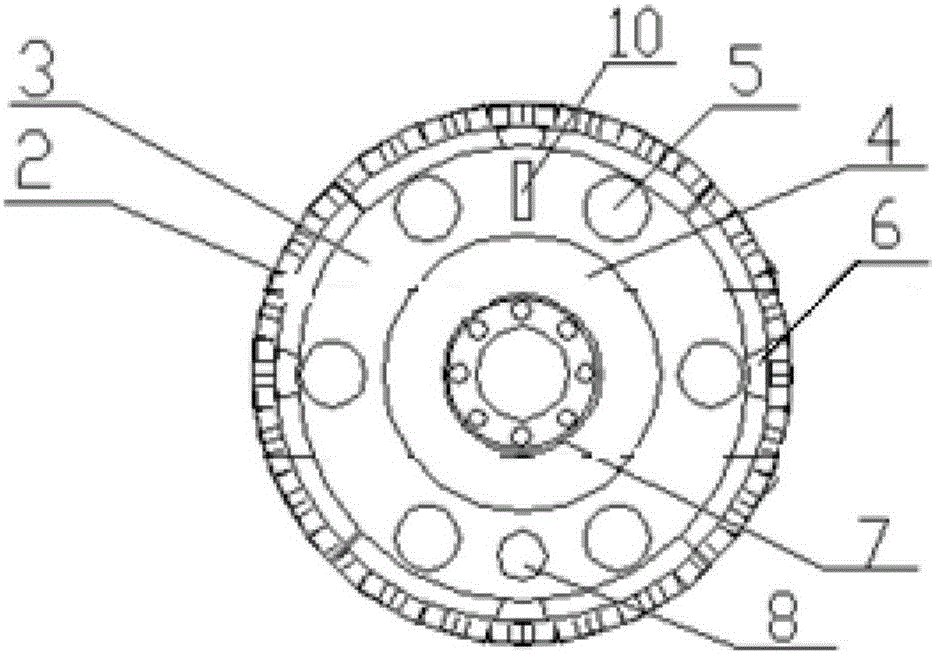

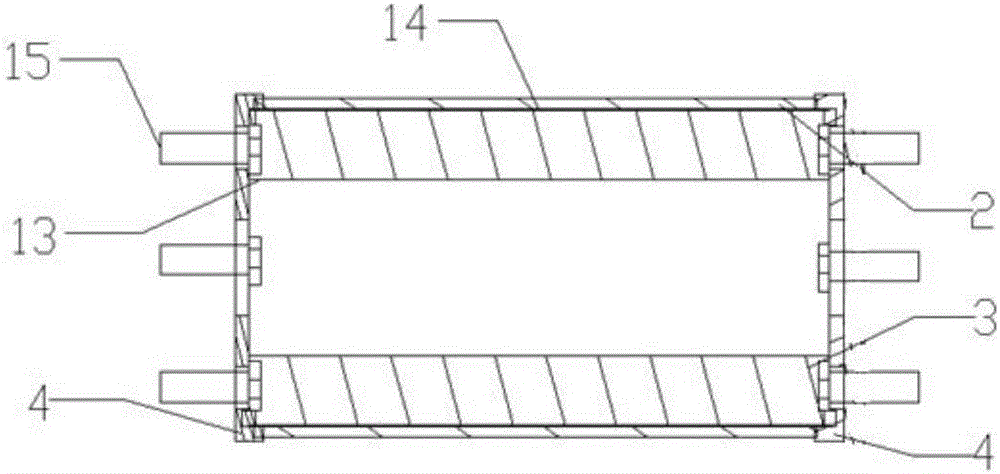

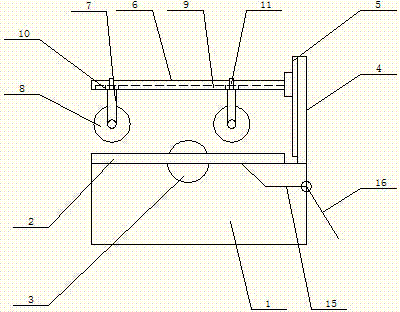

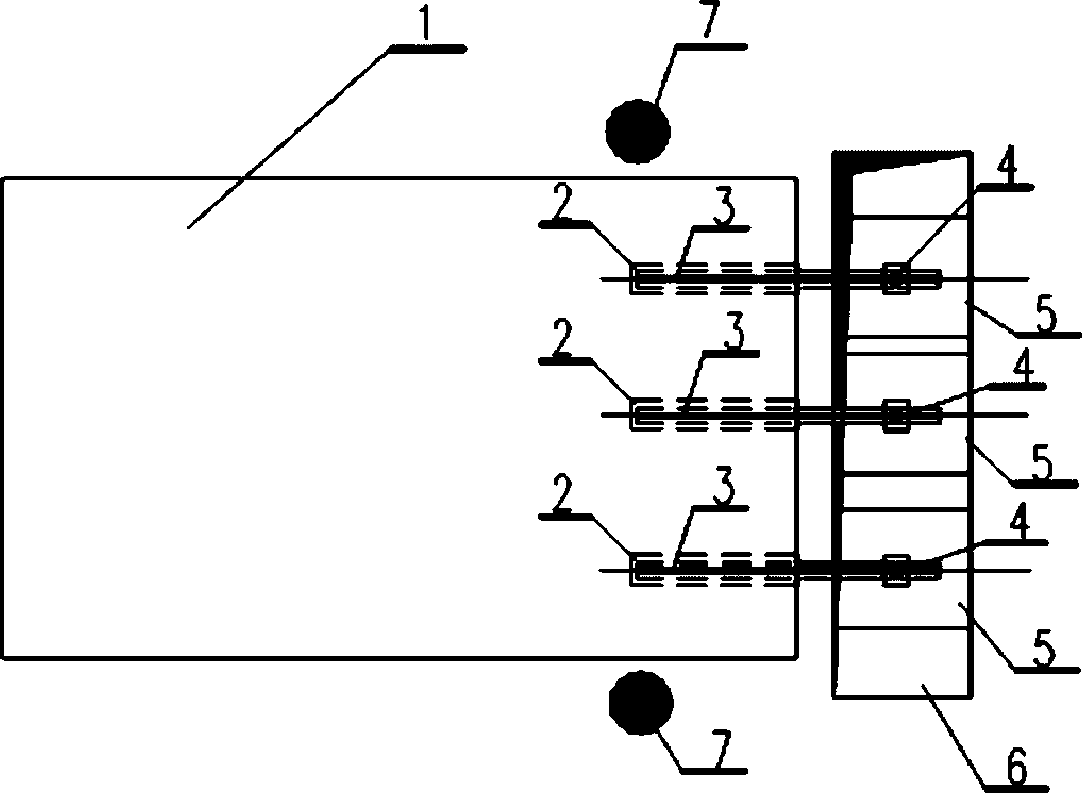

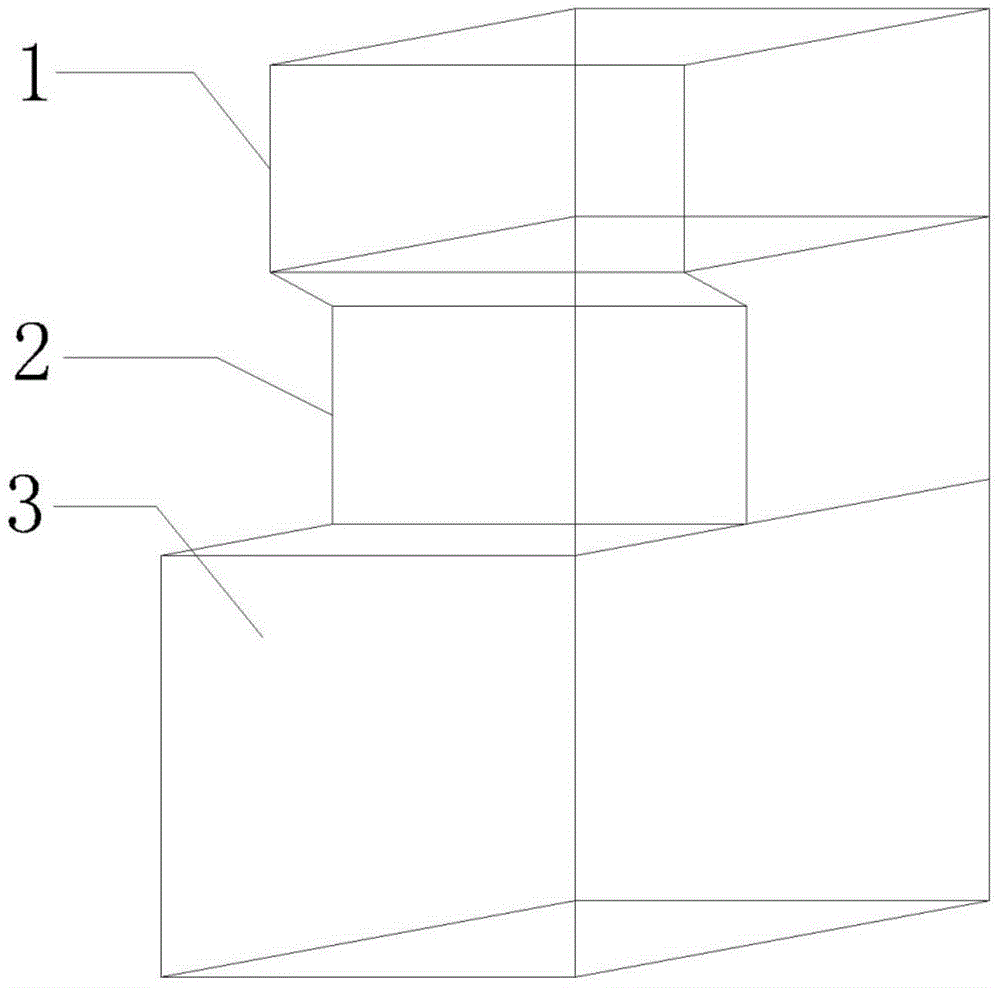

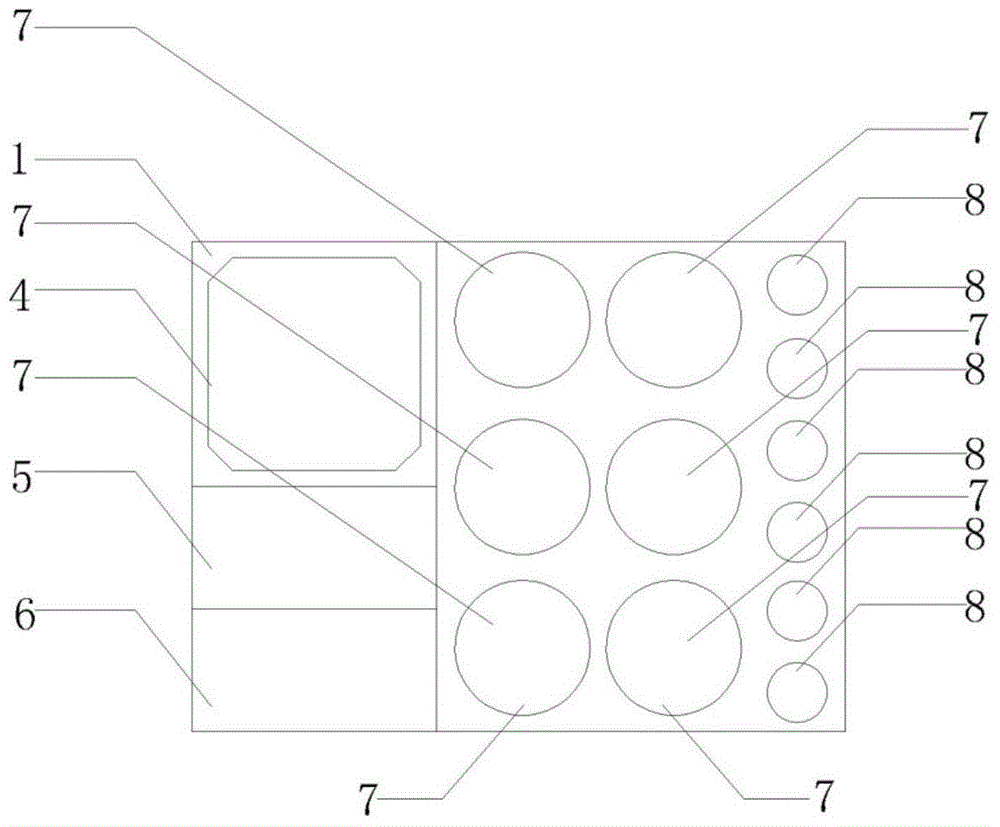

Tire dismounting equipment

InactiveCN107962909AImprove disassembly efficiencyRealize one-time disassemblyWheel mounting apparatusTyre repairingLarge toothEngineering

The invention discloses a tire dismounting device, which is characterized in that it comprises a base (1), a controller (3), and a multi-axis rotating head device; the wind gun (2) is connected with the controller (3). The multi-axis turret device includes a carrier (4), a housing (15), a secondary shaft (5), a small tooth (17), a main shaft (7), and a large tooth (18). The present invention has simple structure and strong practicability. The equipment cooperates with multiple nuts of the tire through a multi-axis turning device, and the multi-axis turning device realizes one-time disassembly of all the nuts of the tire under the action of the jackhammer. Thereby the present invention has improved the efficiency of tire dismounting very well.

Owner:四川新驱科为科技有限公司

Information processing method and electronic device

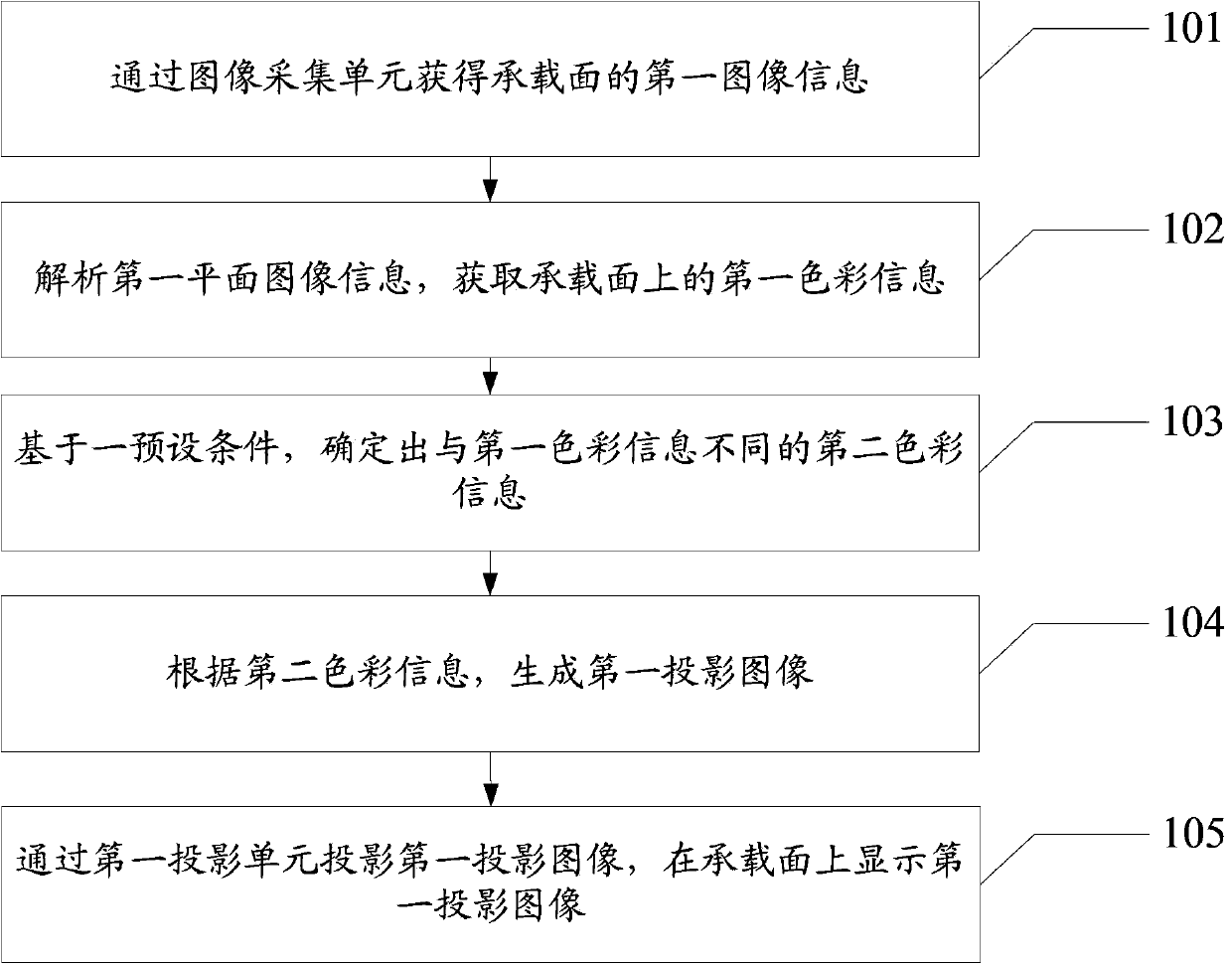

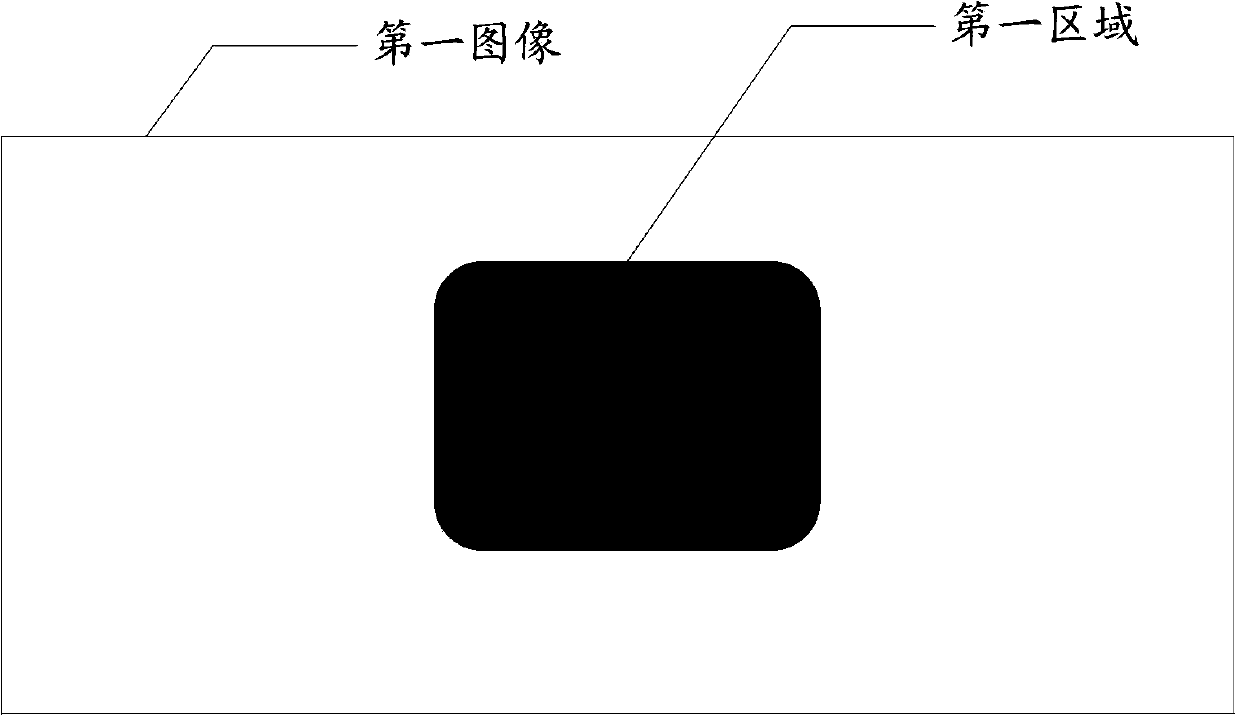

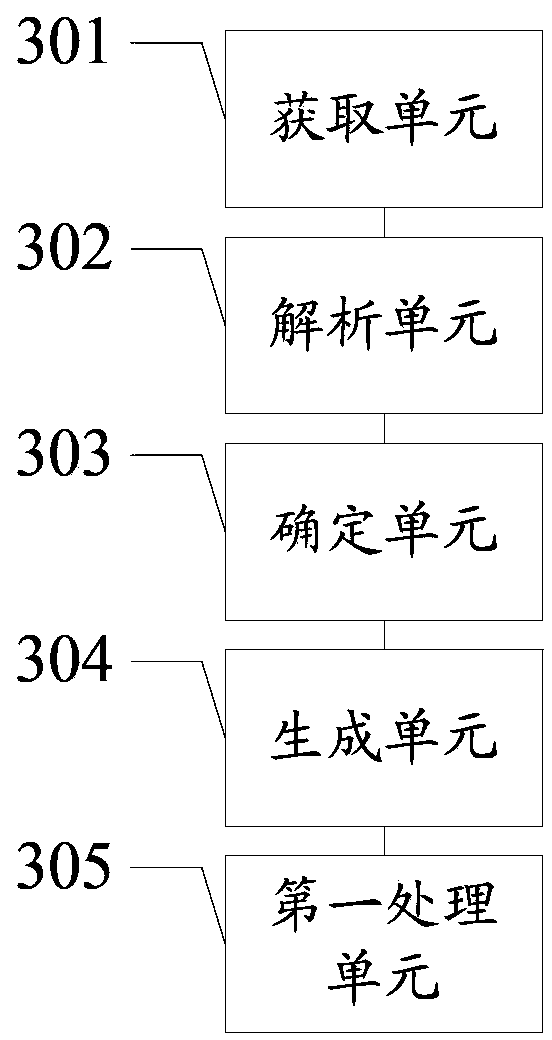

ActiveCN103974045AImplement color adjustmentsImprove the projection effectPicture reproducers using projection devicesInformation processingColored white

The embodiment of the invention provides an information processing method and an electronic device. First image information of a bearing face is obtained through an image collecting unit, first color information on the bearing face is obtained and corresponds to a first color, second color information different from the first color information is determined, a first projection image is generated according to the second color information, projected through a first projection unit, and displayed on the bearing face, a third color of the first projection image is mixed with the first color on the bearing face in an overlapped mode to generate a fourth color, the fourth color is similar to the second color, and the technical problem that in the prior art, when a projection device is used for projection, only a white or similar white projection screen can be used for projection, and projection contents cannot be adjusted according to the color of the projection screen is solved.

Owner:LENOVO (BEIJING) LTD

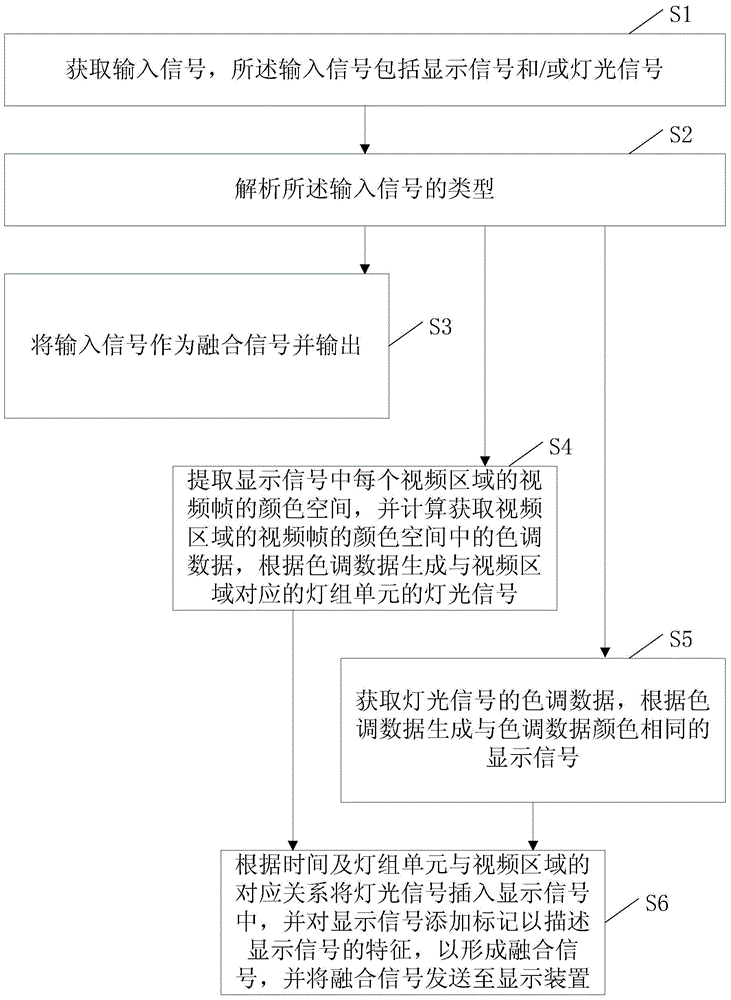

Light and display content fusing method

ActiveCN106341929AEasy to integrateIncrease practical rangeElectrical apparatusStatic indicating devicesColor effectLed array

The invention provides a light and display content fusing method which is applied to a display device. The display device is an integrated screen. The display device comprises a display area and a light area. The light area is illuminated by an LED array which is located behind the display area and surrounds the display area. The method is used for fusing the display content of the display area and the display state of the LED array according to an input signal. The LED array comprises a number of light set units. The display area is divided into a number of video areas according to the number of the light set units, wherein each video area is corresponding to a light set unit. By analyzing the type of the input signal, corresponding light signals and display signals are output according to different input signals, so as to intelligently adjust the display content and the light color effect. Light signals and display signals are well fused to expand the practical range.

Owner:YUTOU TECH HANGZHOU

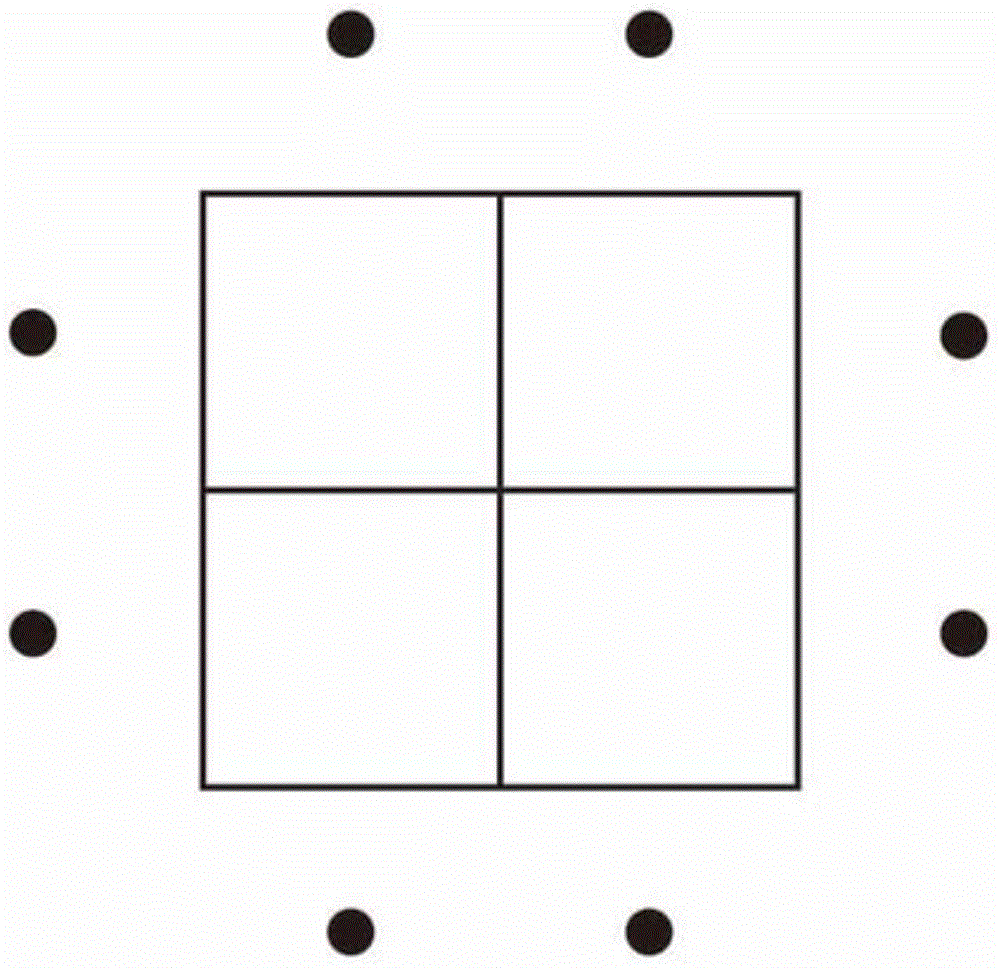

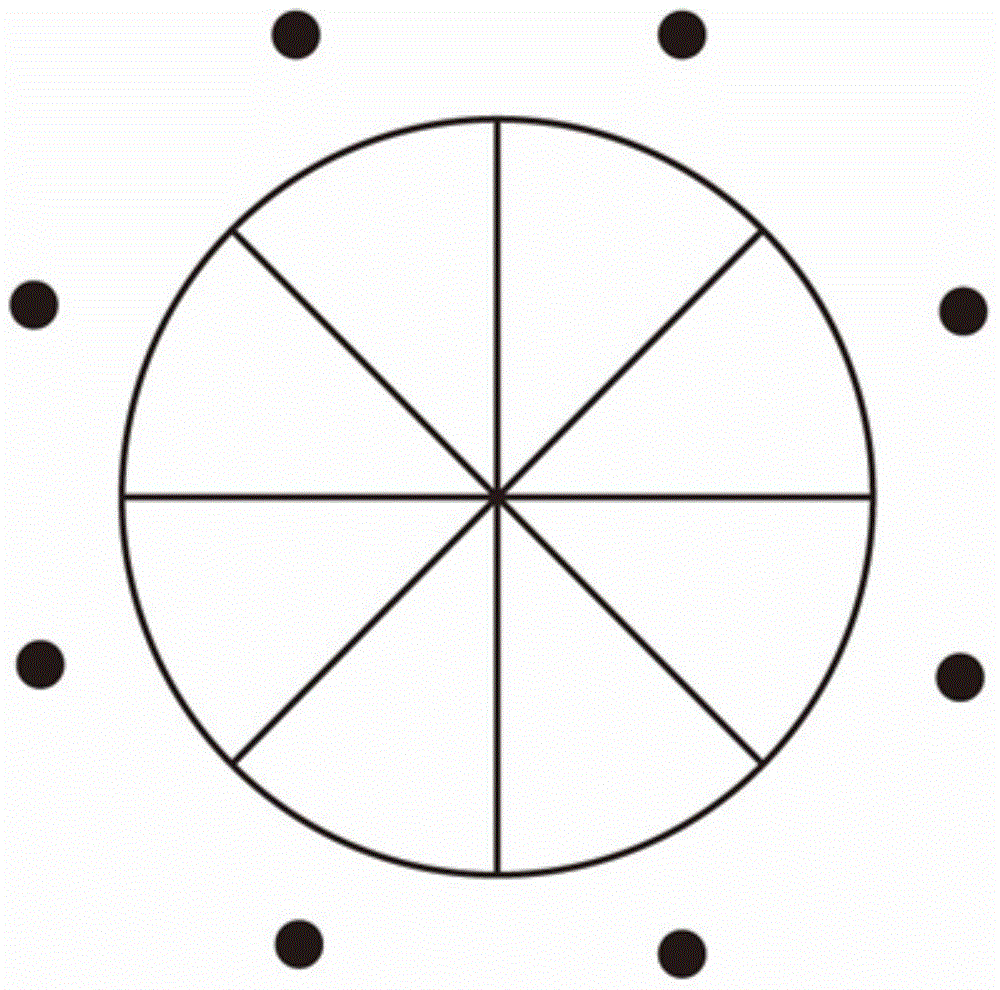

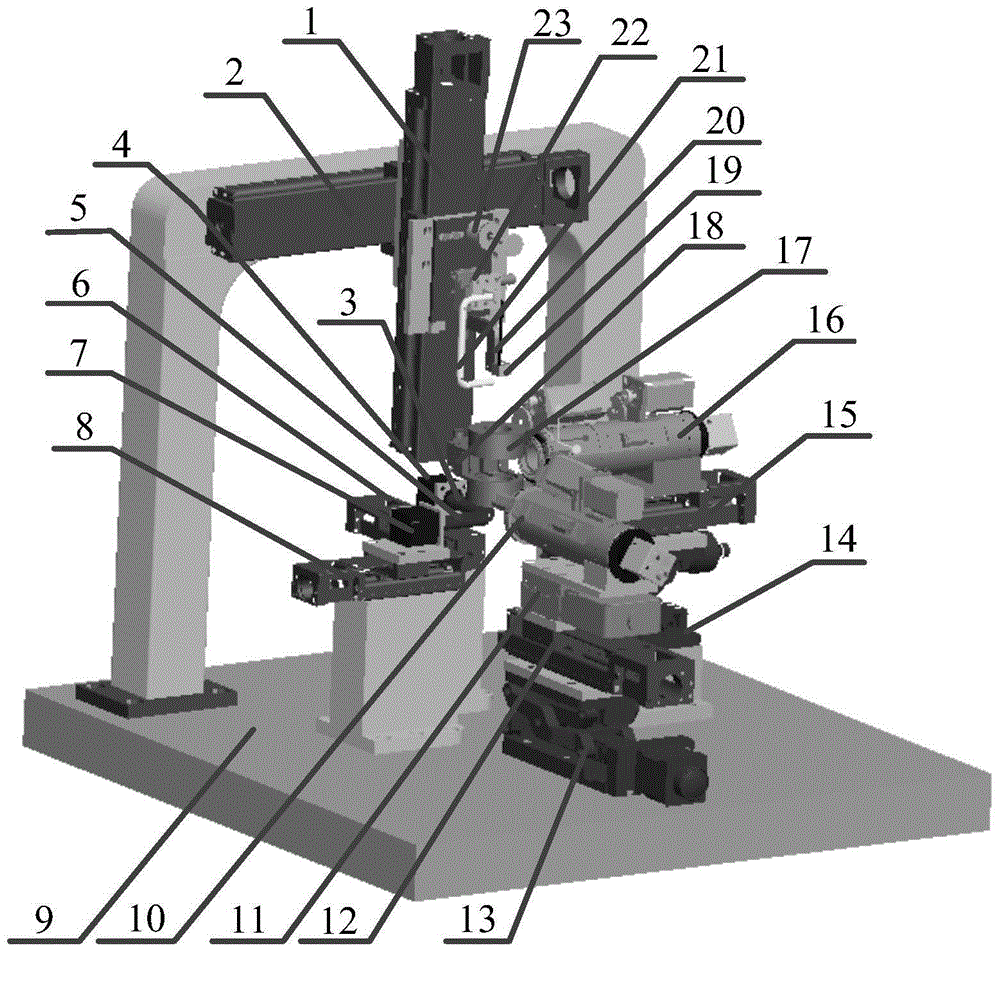

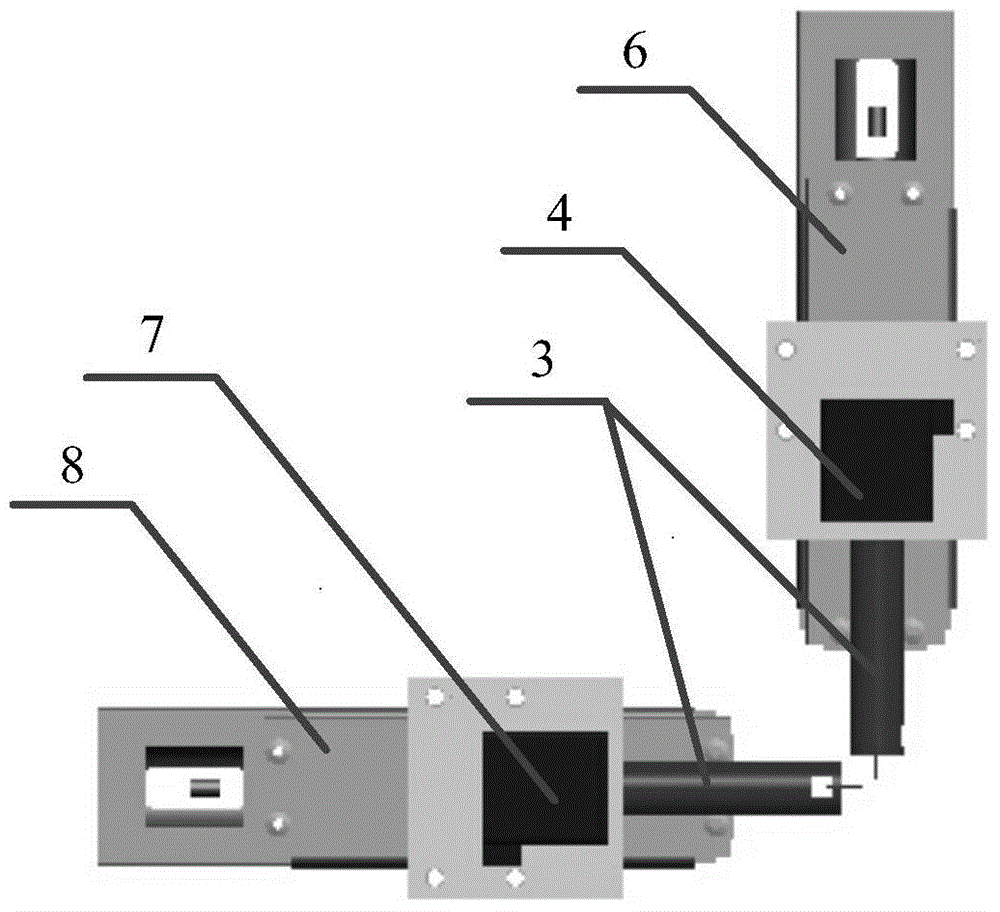

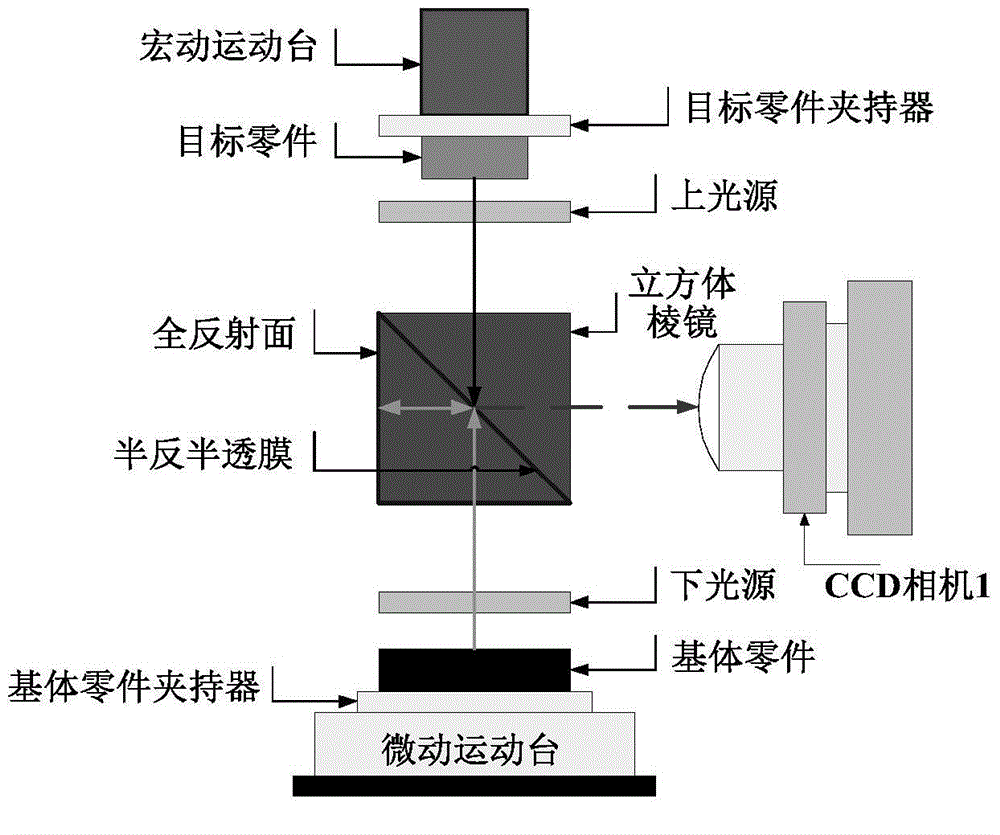

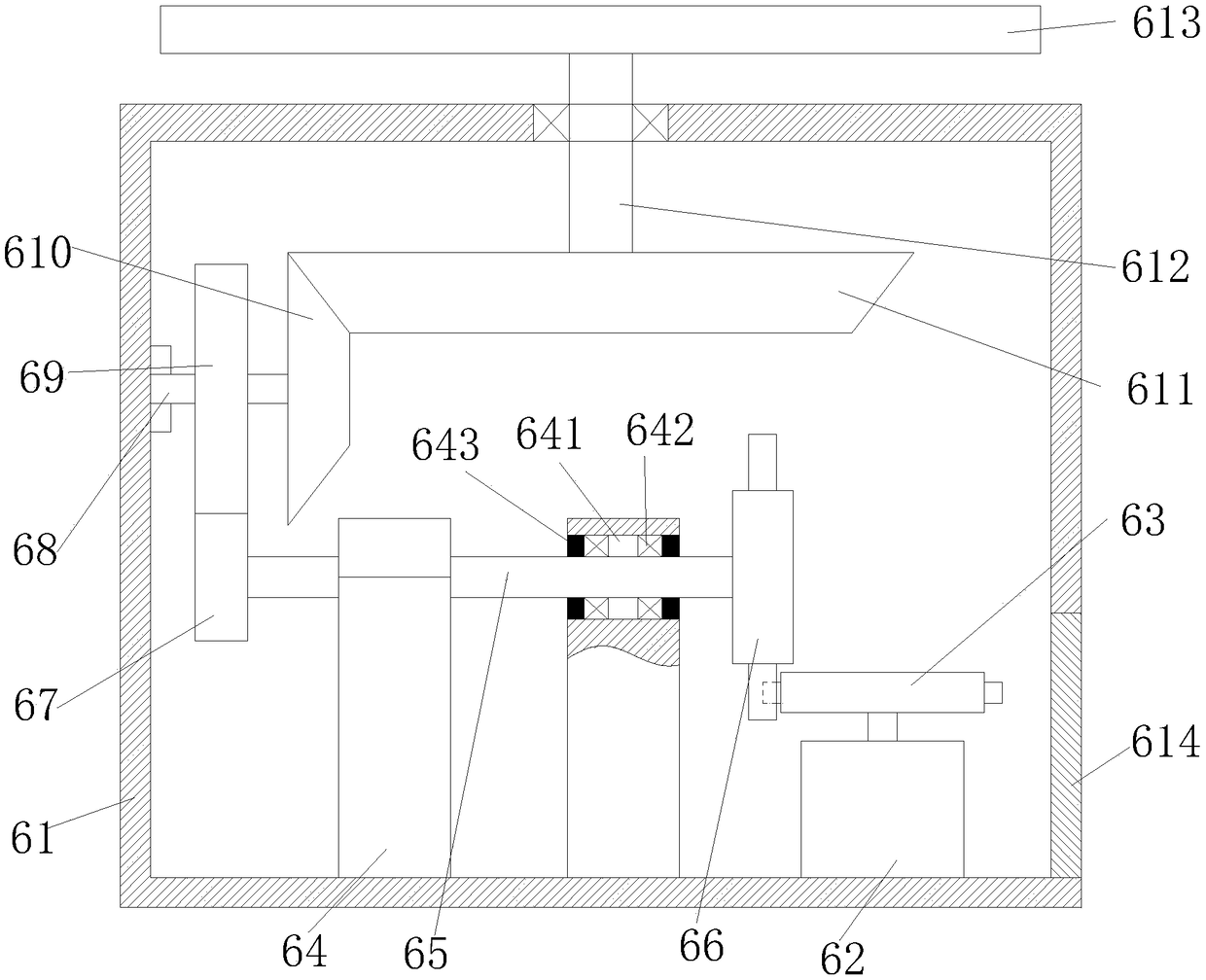

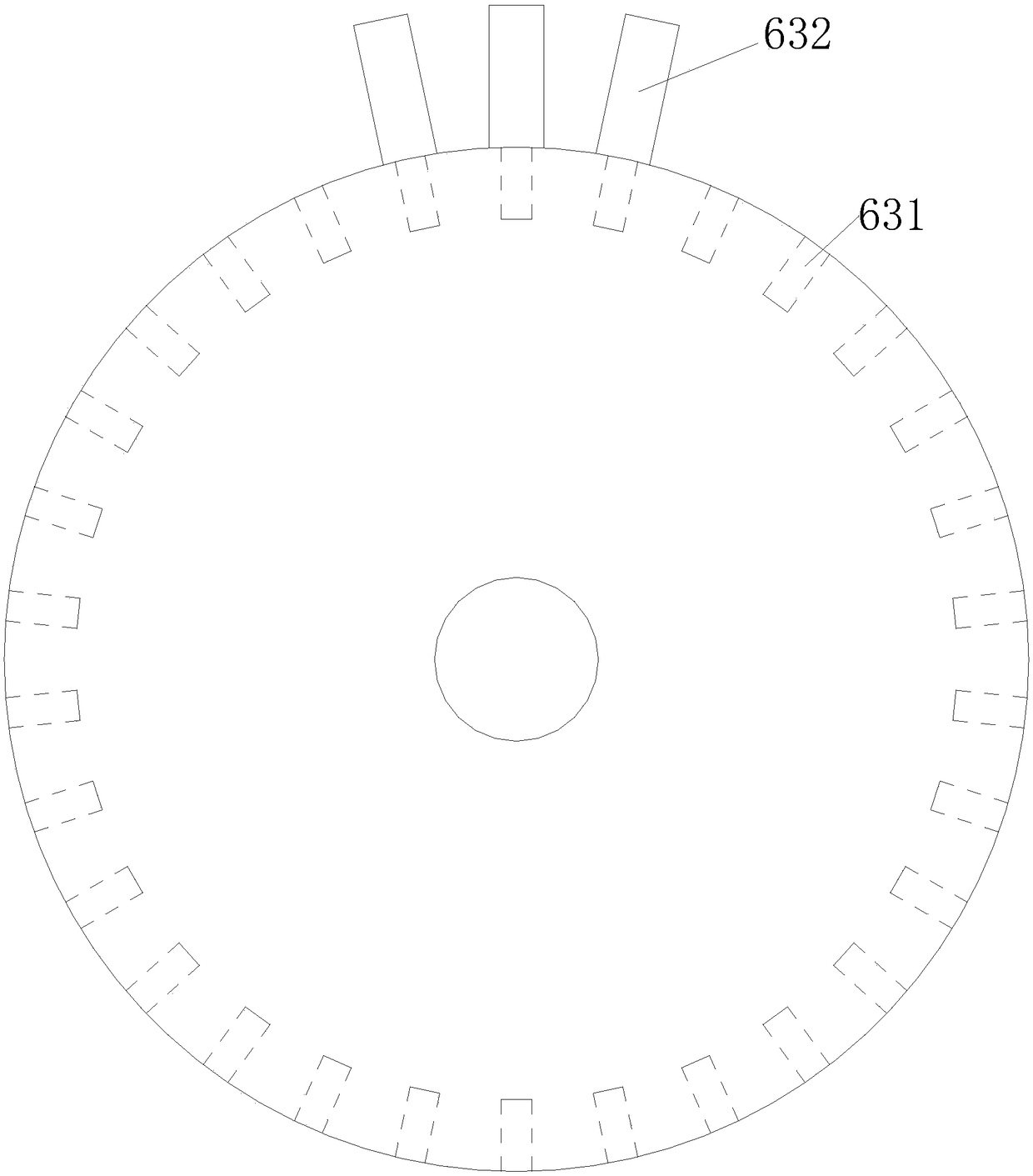

Assembly system oriented to micron-size hose and microsphere component

ActiveCN104959971AHigh precisionHuman-machine collaborationTelevision system detailsMicromanipulatorMicrosphereMan machine

The invention discloses an assembly system oriented to a micron-size hose and a microsphere and belongs to the automatic assembly field of micron-size hoses and precise assembly. The micro-assembly system is composed of a clamping and assembling object, an auxiliary moving platform, a coaxial alignment detection system, a real-time monitoring system, a micro-device clamping system and a quadrature axis microsphere space positioning system. The assembly process of the assembly system includes the steps that a diagnosis ring is positioned through the coaxial alignment detection system, and the hose is inserted in the diagnosis ring; spatial orientation is performed on the microsphere, the hose is inserted in a micro hole of the microsphere, and glue is applied; the hose and the microsphere are vertically stretched upwards, the microsphere is adsorbed to a microsphere fixing fixture and fixed to the center of the axial direction and the radial direction of the diagnosis ring, and the whole assembly process is monitored by the real-time monitoring system. The assembly system has the advantages that man-machine coordination is achieved, and reconfiguration is achieved, and practical space is expanded for flexible automatic assembly. The invention further provides a high-precision assembly method which has the advantages of being easy and convenient to operate and low in freedom degree.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

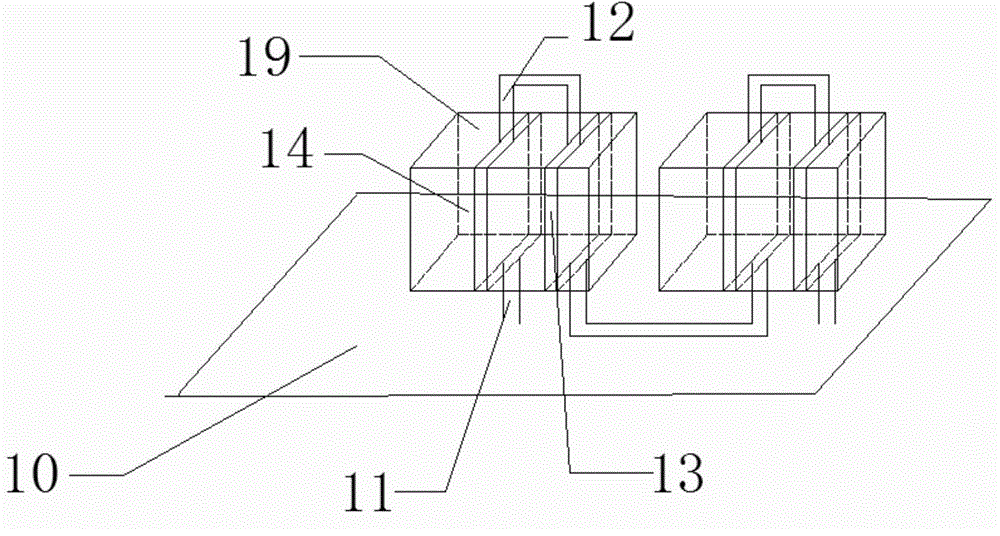

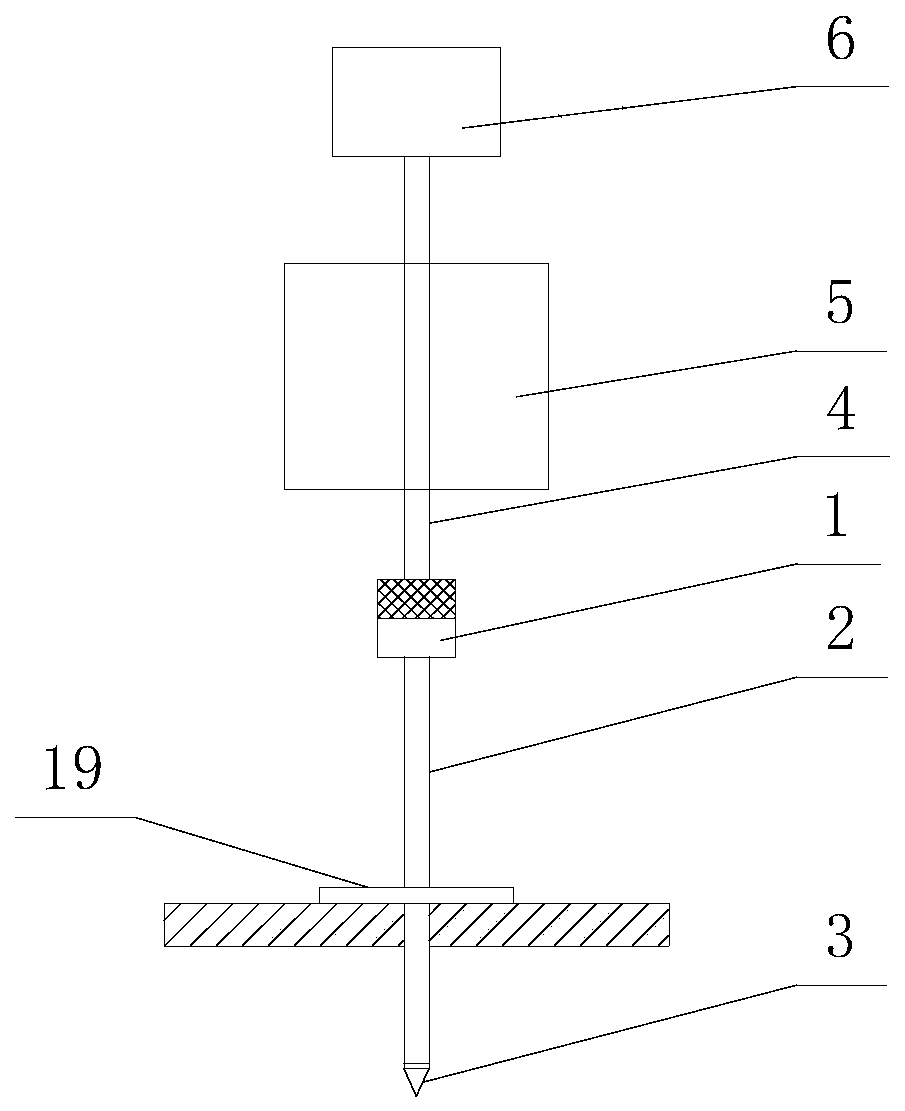

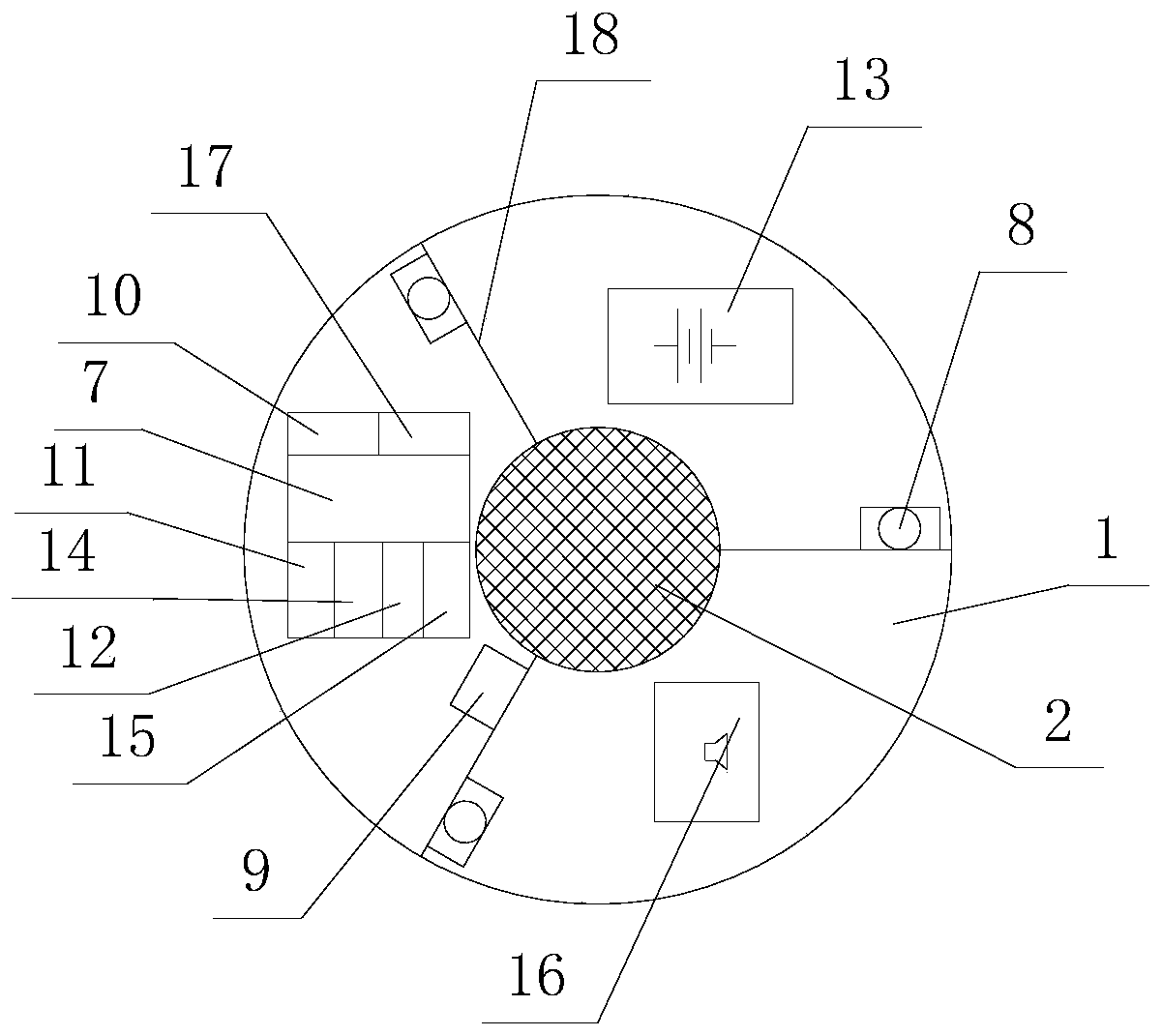

Dynamic-sounding automatic test instrument and implementation method

PendingCN110904940AHigh measurement accuracyImprove work efficiencyIn situ soil foundationLaser rangingTester device

The invention discloses a dynamic-sounding automatic test instrument. The dynamic-sounding automatic test instrument comprises a hammer base. A drill stem is detachably mounted at the bottom of the hammer base. A probe is mounted at the bottom of the drill stem. A guide rod is mounted at the top of the hammer base. A center penetration hammer is movably mounted on the guide rod. A data processingmodule, a laser ranging module and an acceleration module are arranged at the bottom of the hammer base, and the laser ranging module and the acceleration module are connected with the data processingmodule. The laser ranging module is used for measuring distance data between the bottom of the hammer base and the ground and sending the distance data to the data processing module. The center-penetration hammer hammers the hammer base repeatedly, the distance data are measured every time hammering is completed, and the data processing module works out the sounding depth according to the multiple pieces of distance data. The acceleration module is used for measuring the acceleration speed and speed of downward movement of the drill stem after every time of hammering and sending measured datato the data processing module. The data processing module determines whether every time of hammering is effective according to the acceleration speed and speed data. The dynamic-sounding automatic test instrument can achieve automatic measurement, judgment, recording and data processing and is high in efficiency and precision.

Owner:苟印祥

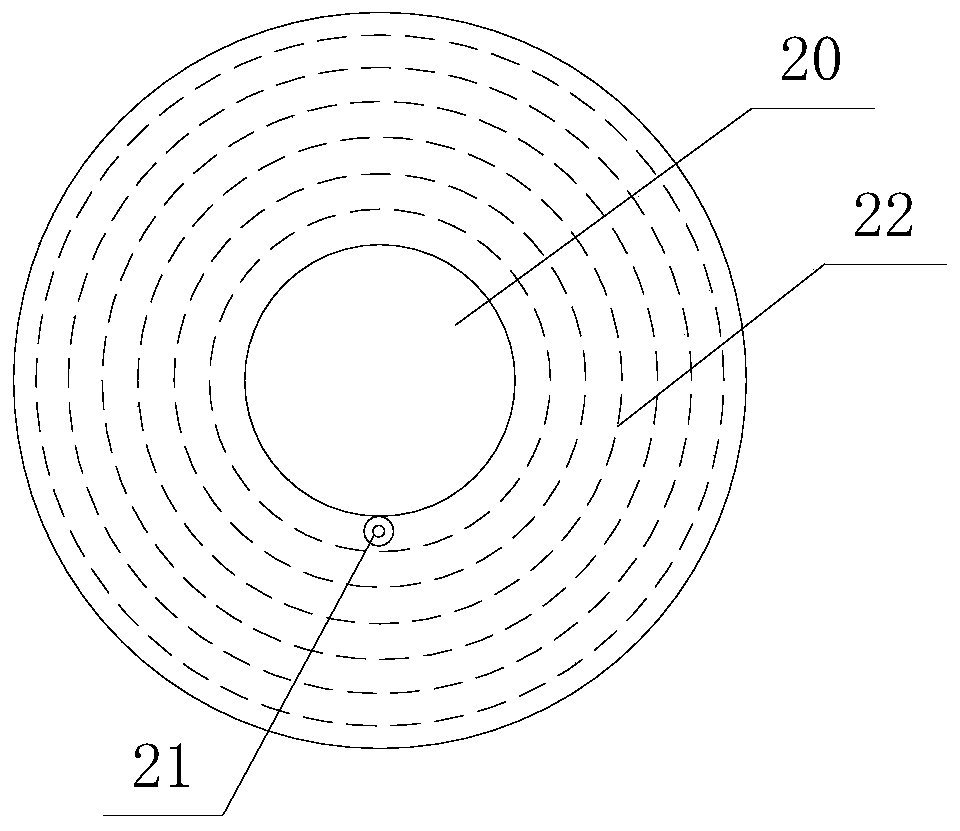

Bionic road roller steel wheel and operation method thereof

The invention discloses a bionic road roller steel wheel and an operation method thereof. The bionic road roller steel wheel comprises a steel wheel, a bionic compaction device, a fixed end cover, an electromagnetic positioning column and a polygon drawing prism. According to the bionic road roller steel wheel and the operation method thereof, the bionic compaction device carries out rough surface rolling on a rigid-flexible combined surface of cement-stabilized soil by using a bionic technology; and the steel wheel carries out plane compaction on a pavement. The bionic road roller steel wheel can be applicable to rolling of a plane and a rough surface at the same time, a user is greatly facilitated, the practical range is improved, and the bionic road roller steel wheel has the advantages of being simple in structure, convenient to disassemble and assemble, reasonable in setting and low in cost.

Owner:CHANGAN UNIV

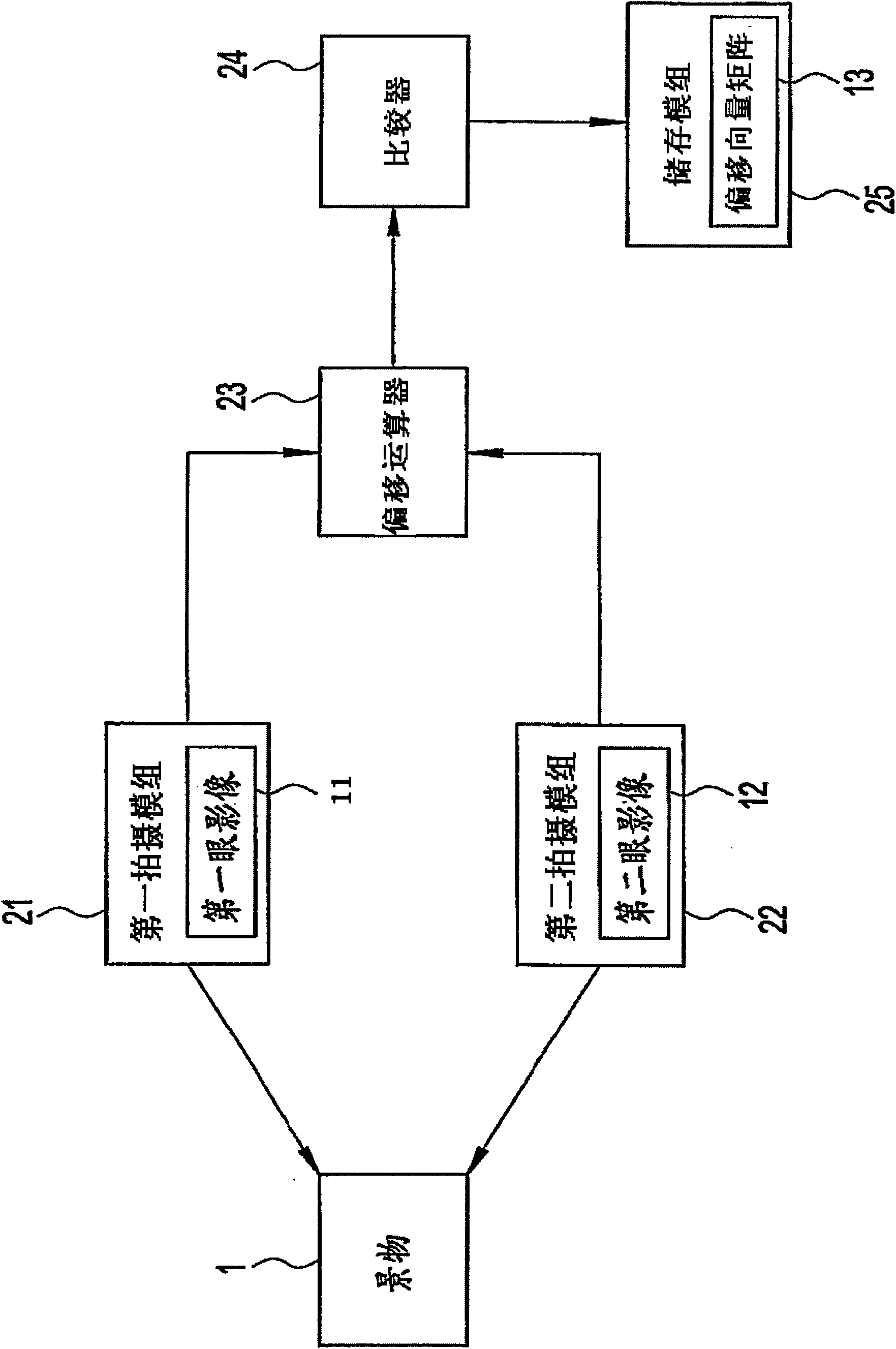

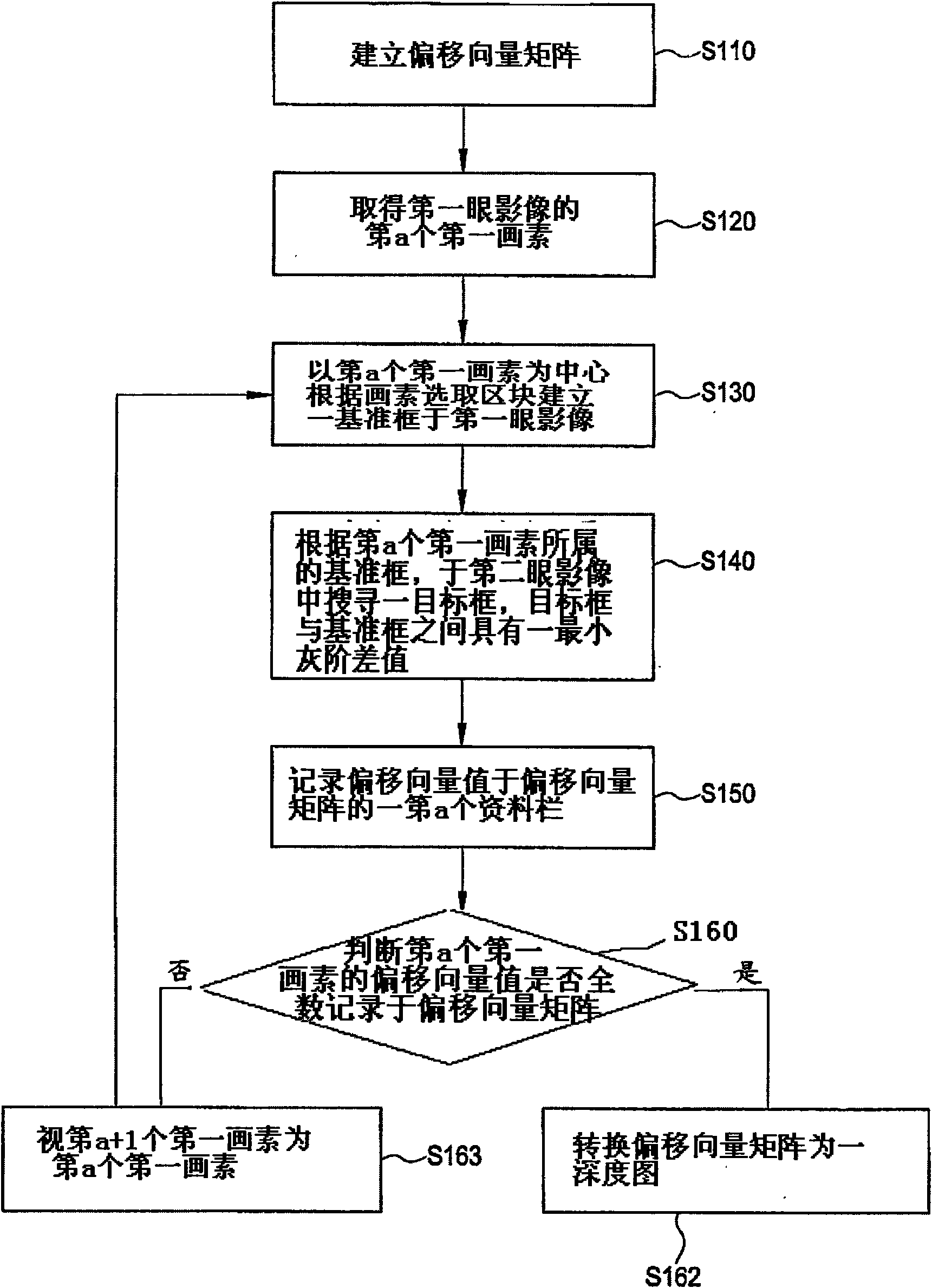

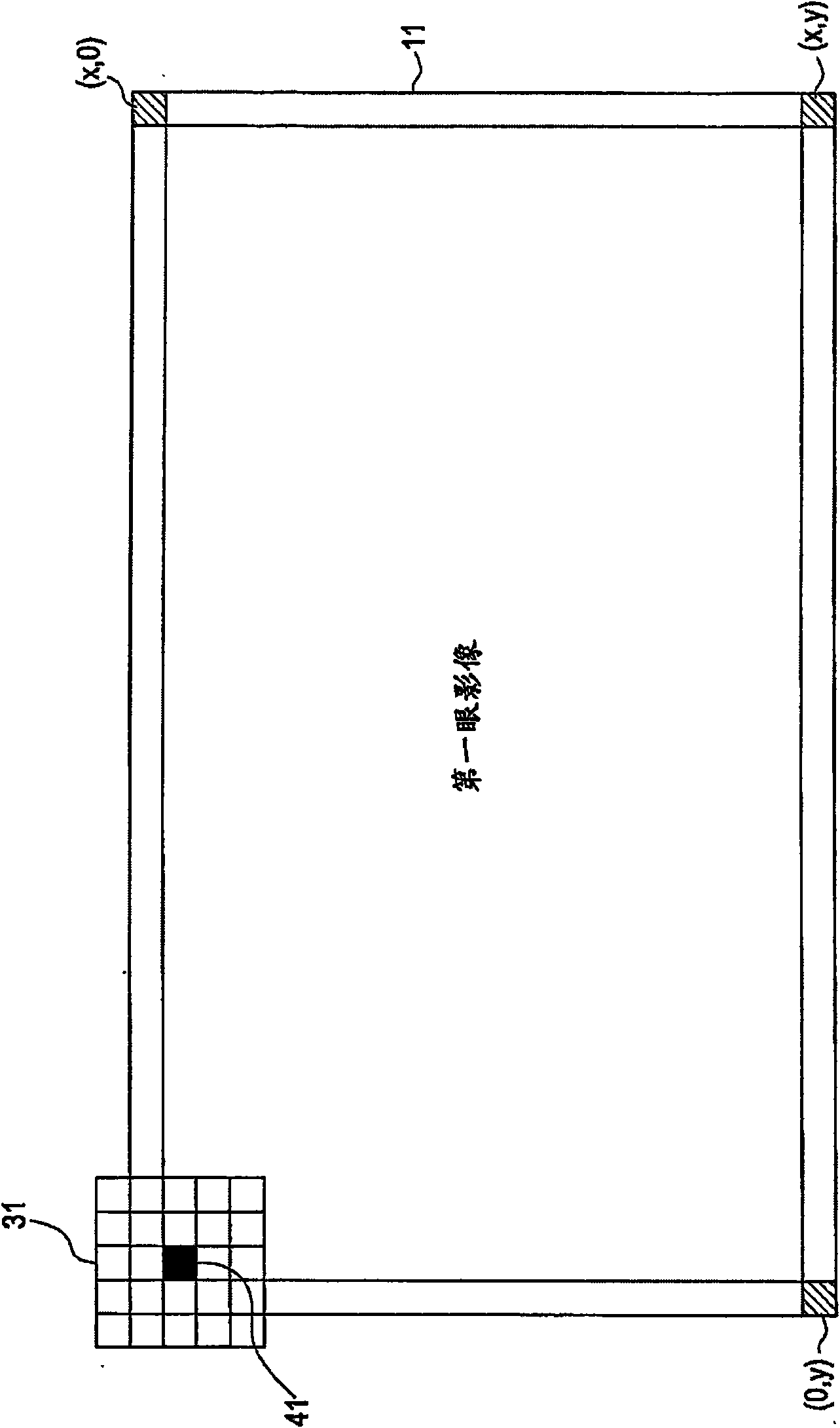

Method for establishing depth of field data for three-dimensional image and system thereof

InactiveCN101566784AGood synthesis effectIncrease practical rangeImage analysisStereoscopic photographyGray levelDepth of field

The invention discloses a method for establishing depth of field data for three-dimensional video and system thereof, applied in an three-dimensional image containing a first eye image and a second eye image. The system contains a bias vector matrix, a bias arithmetic device and a comparator. The bias vector matrix contains a data field with identical picture element number and corresponding position of the first eye image, the bias arithmetic device uses the ath first picture element of the first eye image as the center. A reference frame is divided; a target frame is found in the second eye image, and the target frame and the reference frame have a minimum gray level differential value, and a bias vector value is calculated according to the minimum gray level differential value. The comparator judges bias vector quantities values recording all the ath first picture elements in the bias vector matrix, thereby switching the bias vector matrix into a depth chart.

Owner:CHUNGHWA PICTURE TUBES LTD

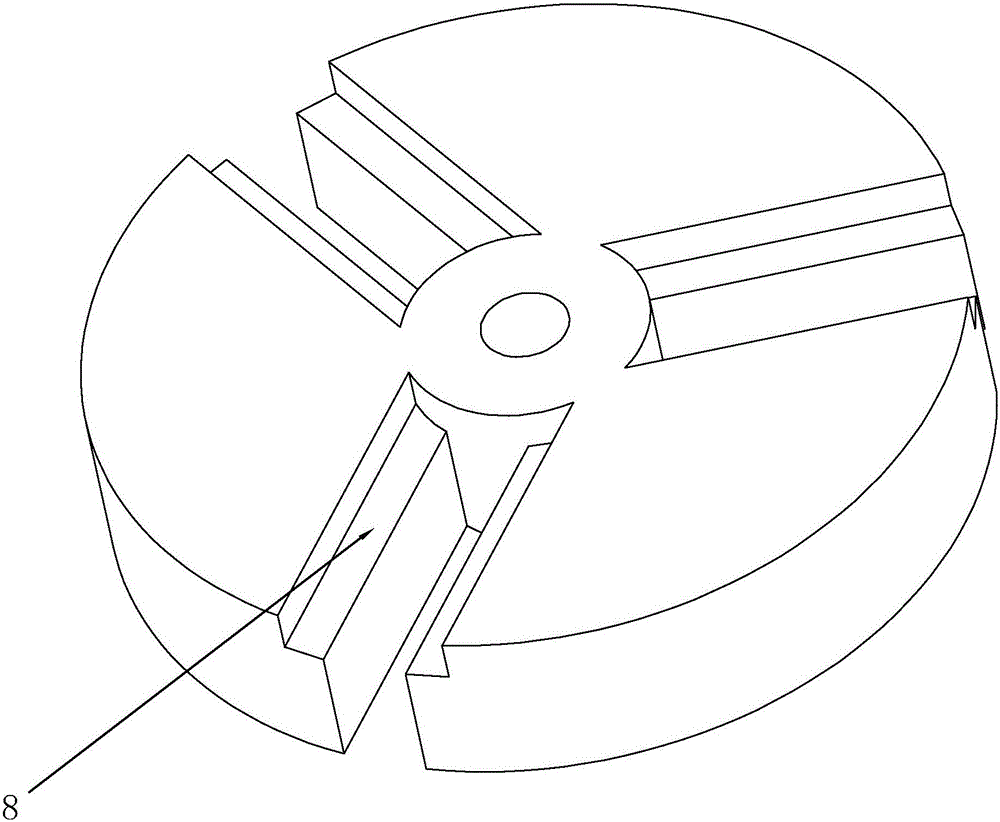

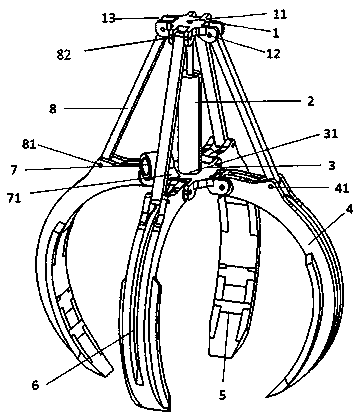

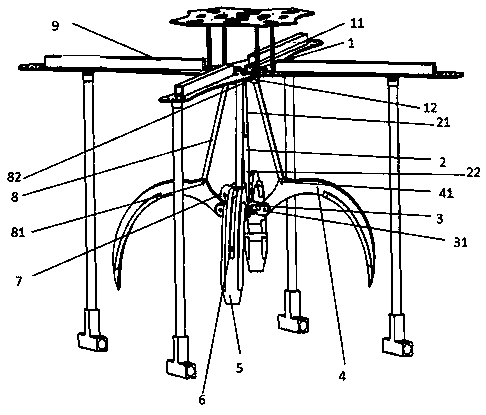

A small unmanned aerial vehicle adjustable bird claw type mechanical gripper device

PendingCN109250118ANot easy to fall offSimple structureGripping headsFreight handlingEngineeringControllability

An adjustable bird claw type mechanical gripper device for small unmanned aerial vehicles relates to a mount device for a small unmanned aerial vehicle. A connecting plate of the gripper (1) is a pie-shaped body of a positive cross type. A geometrical center of the pie-shaped body is provided with a threaded hole (11), to connect the power source structure (2), four U-shaped clamping grooves (13)are drawn out in four mutually perpendicular directions on the upper surface of the cake-like body, the spacing dimension of the two solid surfaces of the clamping grooves is consistent with the widthdimension of the head of the power lever, a special-shaped hole (12) is formed on the two solid surfaces of the clamping grooves, and the special-shaped hole (82) on the upper head of the power lever(8) is serially connected with an inner hexagon screw; a grasp center connecting plate (3) is different in shape from a grasp upper connecting plate (1) in that the grasp center connecting plate (3)is provided with a cylindrical center threaded hole (31). The device uses a telescopic rod to control the opening and closing of four grippers, which can control the position and force of gripping stably and accurately, and is more suitable for precise manipulation, and has strong stability and controllability, and obvious gripping effect.

Owner:SHENYANG UNIV

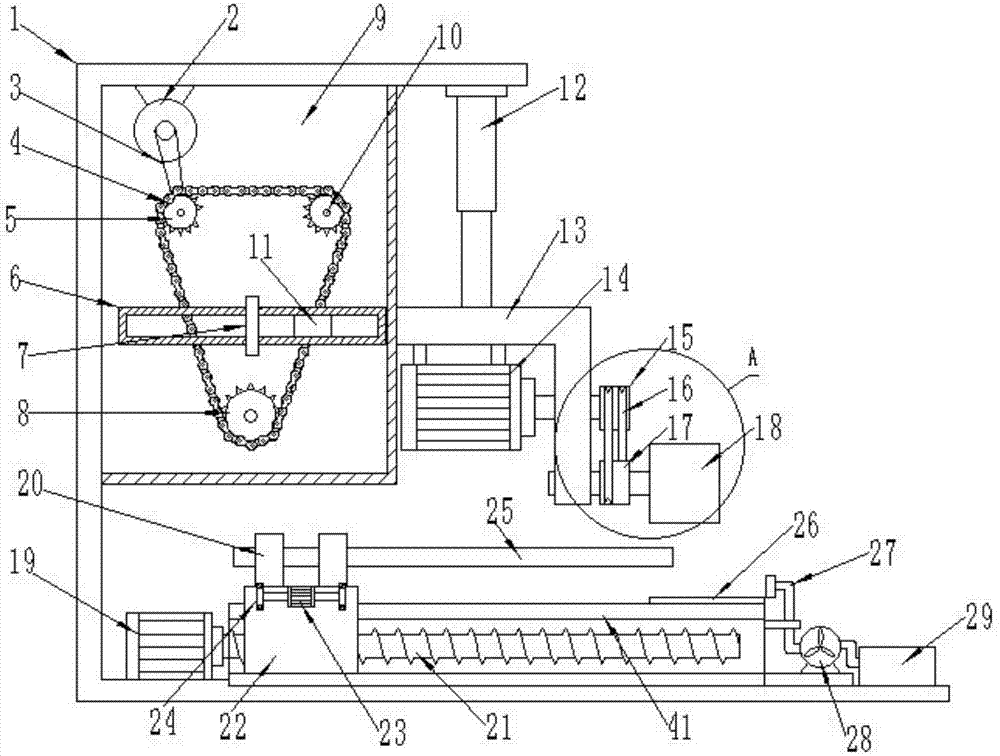

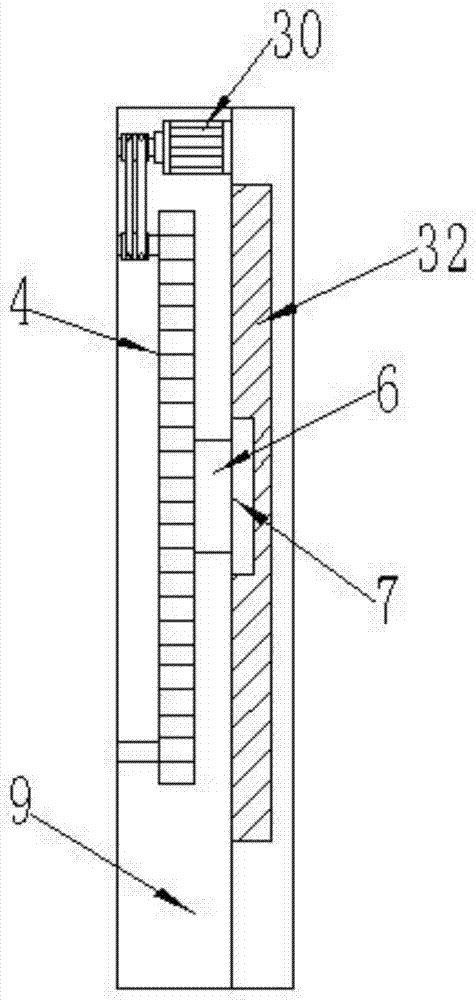

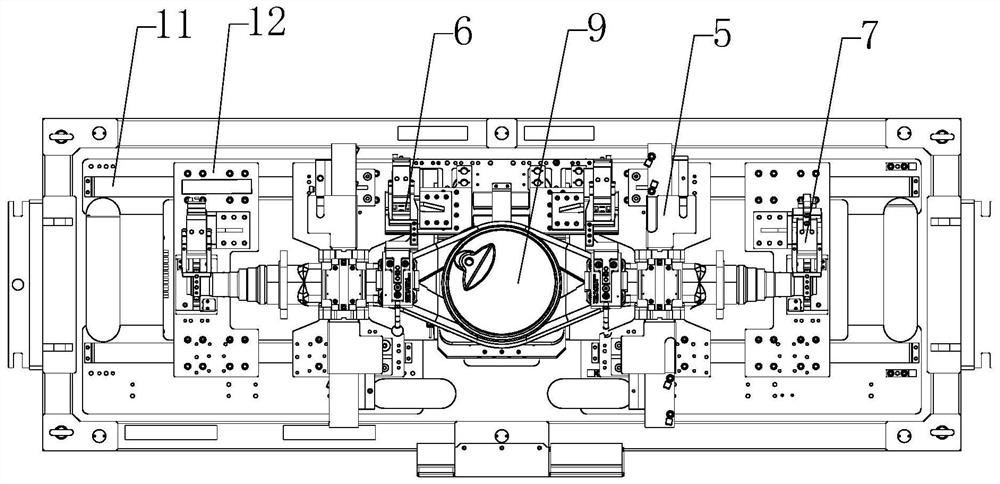

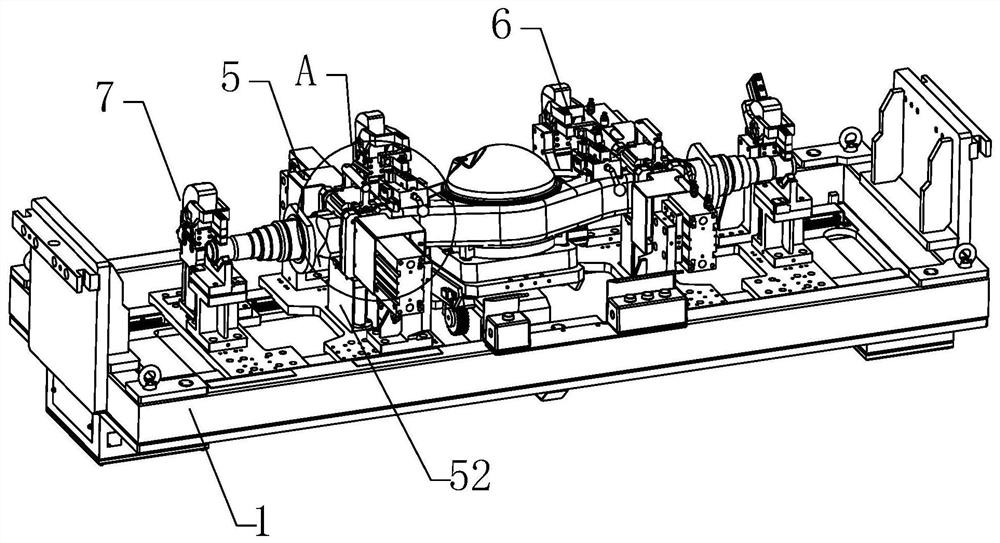

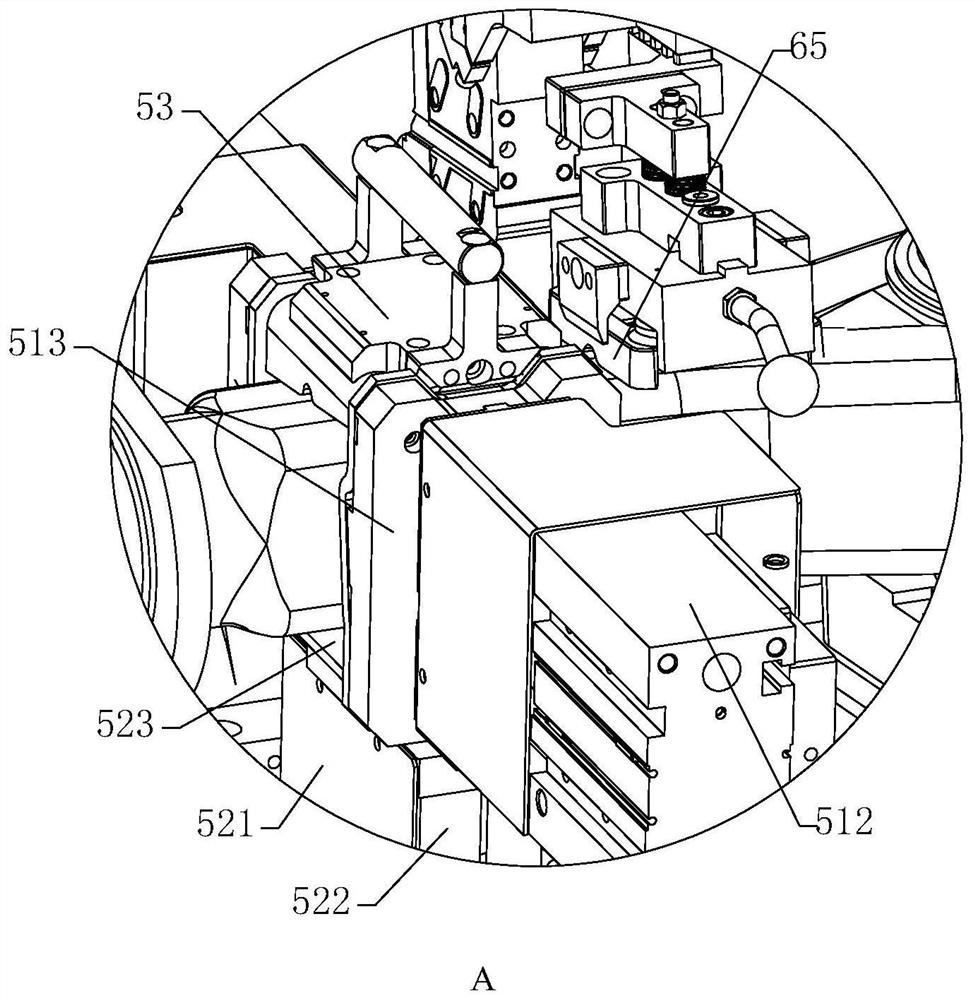

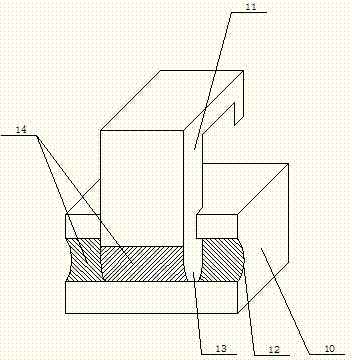

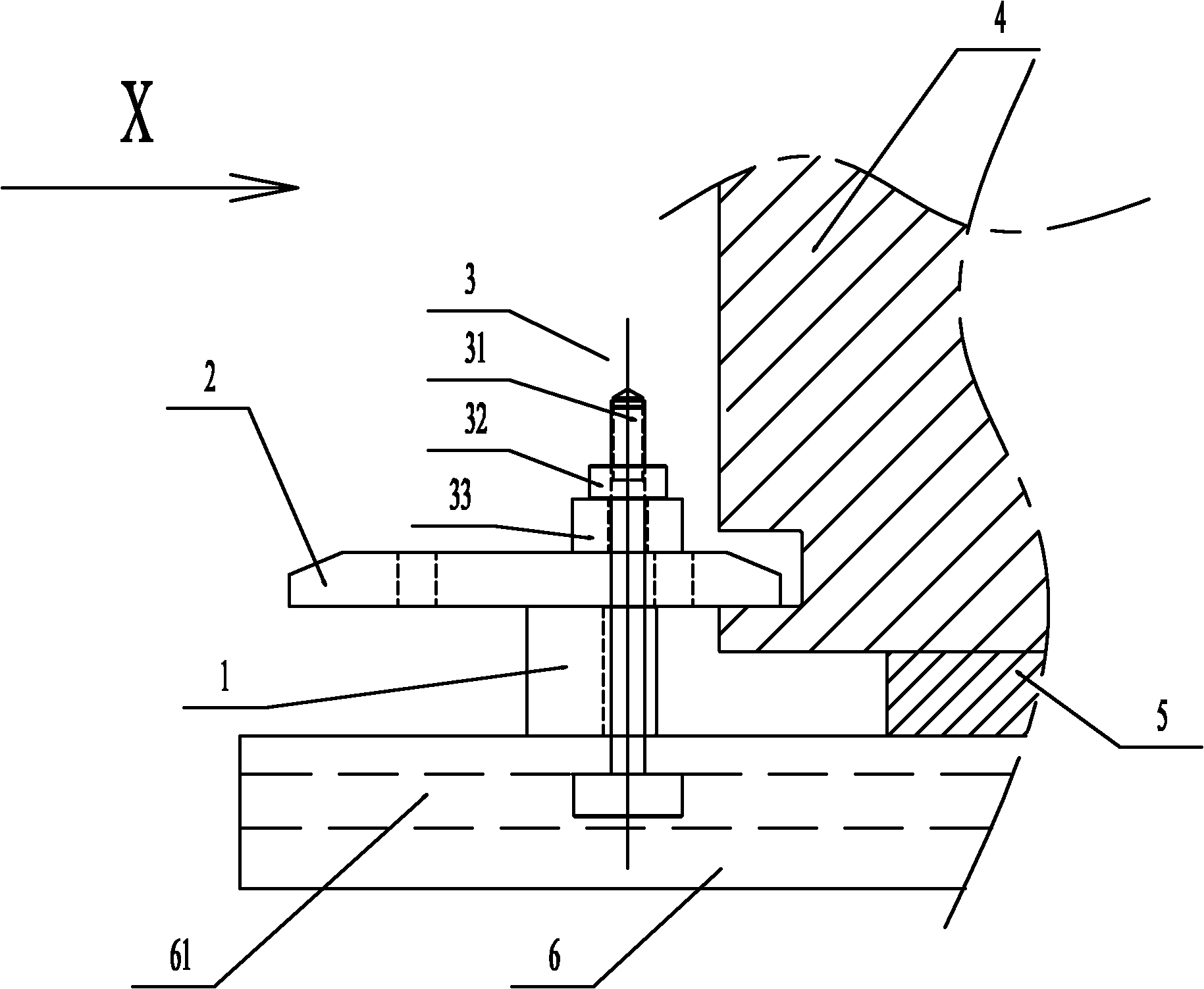

Flexible spot welding tool clamp for axle body

ActiveCN113245777AImprove work efficiencyImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesElectric machineSpot welding

The invention relates to the technical field of axle assembly, and discloses a flexible spot welding tool clamp for an axle body. The flexible spot welding tool clamp comprises a workbench, and a positioning and pressing unit, a mounting unit, a centering unit and an angle adjusting mechanism which are arranged on the workbench. The centering unit comprises a rotating motor arranged below the workbench, a rotating shaft fixedly connected to the rotating motor, a chain transmission piece connected to the rotating shaft and a centering rod fixedly connected to the chain transmission piece, and the rotating motor drives the chain transmission piece to drive the centering rod to contract inwards or stretch outwards. The flexible spot welding tool clamp has the following advantages and effects that the mode of automatic centering, clamping, angle adjusting, pressing and automatic spring seat and air cushion block mounting is adopted, the working efficiency in the welding process can be remarkably improved, the centering unit is adopted for centering the axle body, all parts of the axle body are welded after centering, and the mode can greatly improve the welding precision.

Owner:HUBEI AXLE

Novel wood cutting equipment

InactiveCN104760089AAvoid offsetIncrease practical rangeFeeding devicesCircular sawsPulp and paper industryRejection rate

The invention provides novel wood cutting equipment and relates to the field of electromechanical technologies. The upper portion of a connecting rod is connected with a sliding block, a working platform is arranged at the upper portion of a rack, a saw blade is arranged on the working platform, and a support is arranged on one side of the upper portion of the rack. A sliding rail is arranged on one side of the support, one side of the sliding rail is connected with a movable top plate through sliding blocks, the lower portion of the movable top plate is connected with compression rollers through connecting rods, a sliding chute is formed in the lower side of the movable top plate, the sliding blocks are arranged in the sliding chute, and each sliding block is provided with a positioning device. One side of each sliding block is provided with an arc-shaped groove, each positioning device is arranged in the corresponding arc-shaped groove in a rotational connecting mode, the lower end of each positioning device is provided with an arc-shaped cylinder, and each arc-shaped cylinder is matched with the corresponding arc-shaped groove. The arc-shaped grooves are matched with the arc-shaped cylinders, and the surface of each arc-shaped groove and the surface of each arc-shaped cylinder are each provided with a rubber layer. The novel wood cutting equipment is simple in structure, reasonable in design, convenient to operate and capable of effectively preventing wood from skewing, the rejection rate of wood is reduced, and the practical range of the novel wood cutting equipment is widened.

Owner:JINLING INST OF TECH

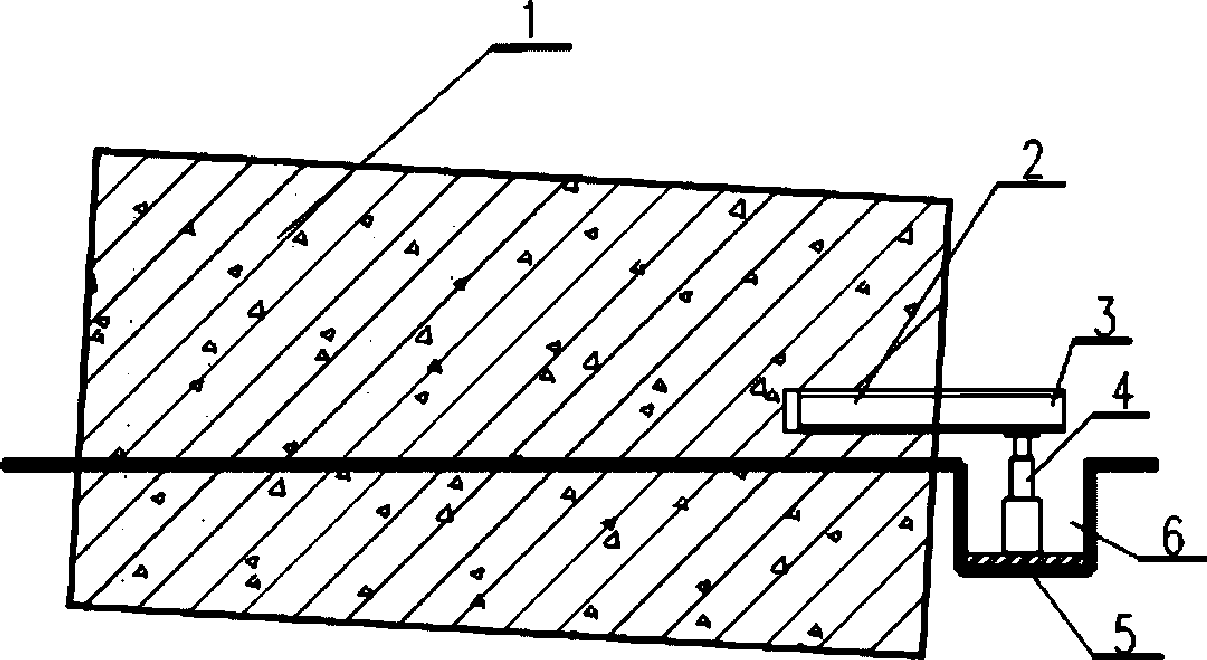

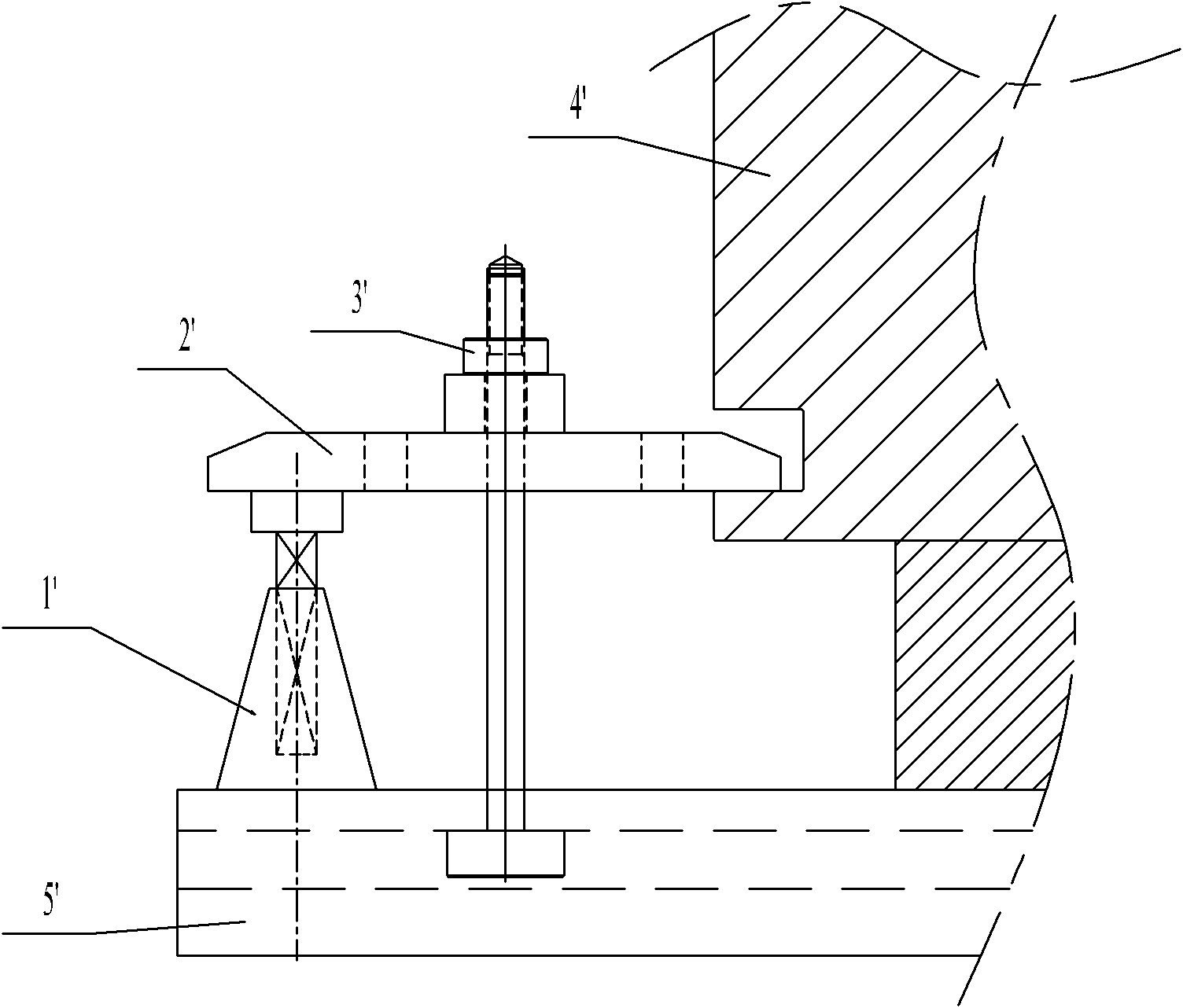

Method for correcting offset of base

InactiveCN101545272AIncrease practical rangeSimple structureSoil preservationSlurryStructural engineering

The invention provides a method for correcting the offset of a base, which comprises the following steps: firstly, drilling a hole (2) along an offset direction of the base (1), at the same time, digging a below base groove (6) near the base (1) and additionally padding a steel plate (5) after the bottom of the base groove (6) is tamped and leveled; secondly, inserting a profiled bar (3) in the drill hole (2) and jacking up the profiled bar (3) so as to ensure that the offset base (1) is jacked up to a normal standard height; thirdly, injecting slurry into a foundation for reinforcing and then removing a jacking device; and finally, infilling the drill hole (2) of the base (1) with high-grade fine gravel concrete without contraction. Under the condition that large equipment does not need to be moved, the method can correct the offset of the base of the large equipment and has simple structure and processing method, easy implementation and larger practical range.

Owner:GUIYANG AL-MG DESIGN & RES INST

Three-dimensional image acquisition device

ActiveCN108600569AEasy to shootIncrease resistanceTelevision system detailsColor television detailsRubber ringUnderactuation

The invention discloses a three-dimensional image acquisition device, comprising a base, wherein an upright post is arranged on the base along a vertical direction, a bracket is arranged on the upright post, a microscope eyepiece is arranged at one end of the bracket far away from the upright post, a camera is arranged above the microscope eyepiece, the camera is in signal connection with a computer, a bearing table capable of driving a detection object to perform equidistant and intermittent rotation is arranged below the microscope eyepiece, and the bearing table is arranged on the base. According to the scheme of the invention, the detection object is photographed at an intermittent moment when the bearing table rotates, the operation of photographing steady and clear images can be facilitated, the practical range of the device can be increased through the arrangement of incomplete driving wheels, so that the device can be applied to image acquisition detection of the detection objects with different sizes; and through the arrangement of a rubber ring, the resistance of the rotation of a transmission shaft can be increased, the rotation inertia of the transmission shaft can be reduced, so that the transmission shaft can only rotate when the incomplete driving wheels are meshed with a transmission column gear, the transmission accuracy can be ensured, and the accuracy of image acquisition can be further guaranteed.

Owner:芜湖市奥尔特光电科技有限公司

Kitchen robot

InactiveCN105615609AReduce utilization costShorten the timeCooking vesselsManipulatorDrive wheelFuel tank

The invention discloses a kitchen robot. The kitchen robot comprises a rectangular outer body. A first layer inside the kitchen robot is provided with a preservation area composed of a rice box, an oil box, a water box, all kinds of vegetable-storage holes and seasoning holes. A second layer of the kitchen robot is provided with a raw material processing area composed of a driving wheel, a rotary pan, an evaporator, a steam pipe, a steaming machine and a steaming pot. The bottom of the robot is provided with a finished product storage area. The kitchen robot has following beneficial effects: the kitchen robot can prepare the meals before a user finishes his day and returns home by computer settings in the well-set time and wait for the user; dishes are finished cooking while being kept warm and stored so that utility cost is reduced and a lot of time is saved; and the application range is extended.

Owner:傅国要

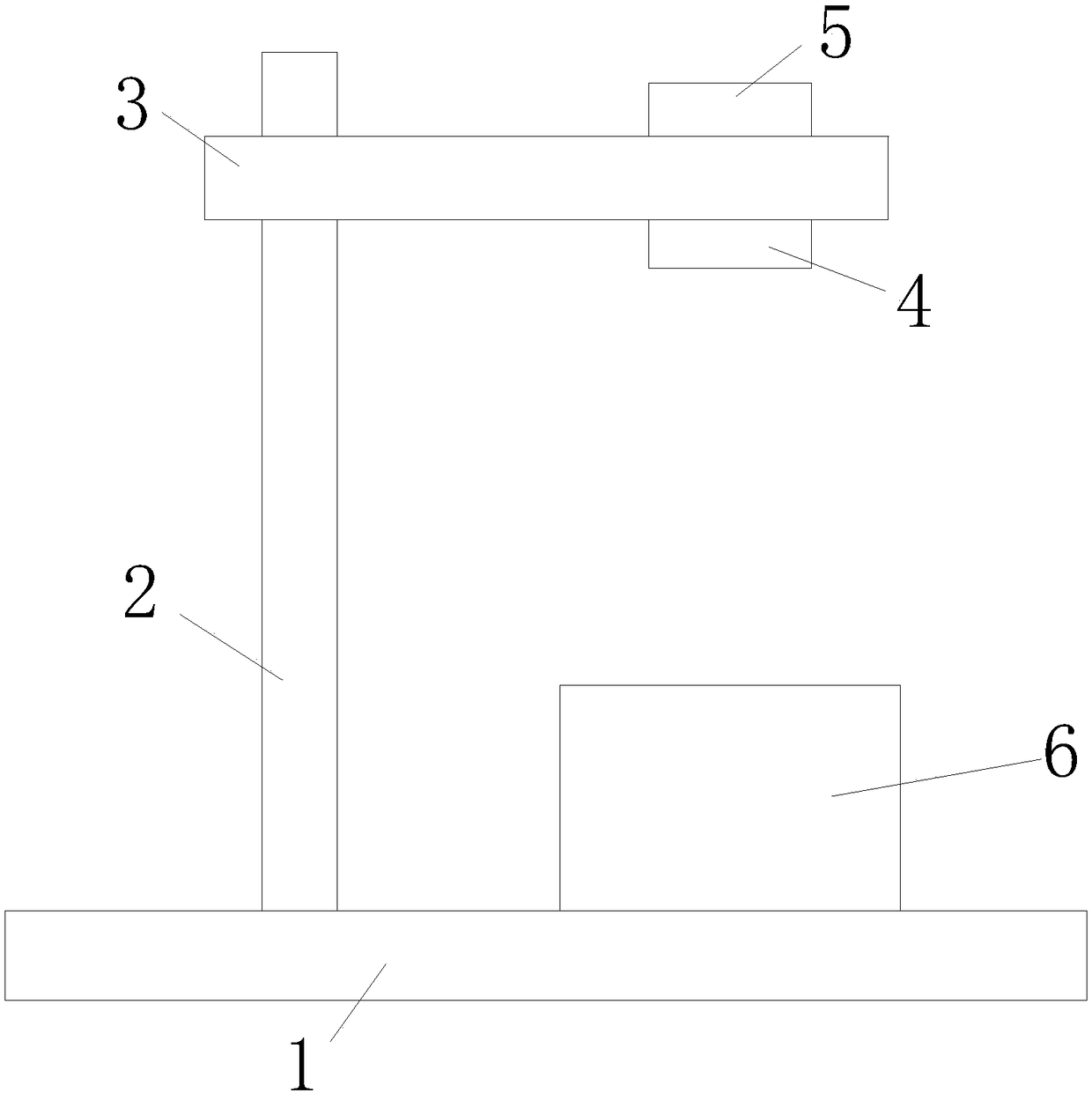

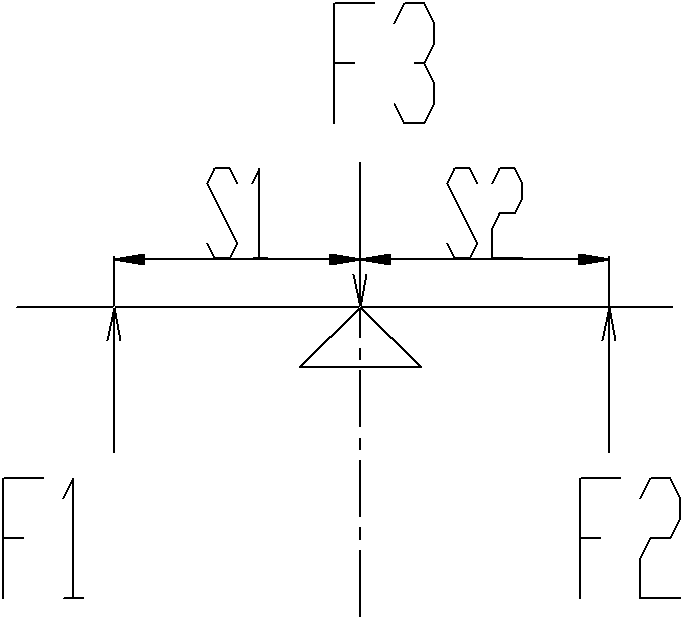

Pressure plate clamping mechanism

ActiveCN102756293AIncrease practical rangeEnsure reasonable balancePositioning apparatusMetal-working holdersEngineering

The invention discloses a pressure plate clamping mechanism. The pressure plate clamping mechanism comprises a pressure plate and a force application rod penetrating the pressure plate, one end of the pressure plate is supported on a cushion block, the other end of the pressure plate is used for compressing a workpiece, the cushion block comprises a support part and an abdication part, the top surface of the support part is in contact with the pressure plate, the abdication part is provided with an abdication hole for enabling the force application rod to penetrate, and a gap is arranged between the top surface of the abdication part and the pressure plate. The pressure plate clamping mechanism disclosed by the invention can achieve the purpose of expanding the range of applications of ordinary clamping by reducing the spatial size of the cushion block. The force at the fulcrum of the cushion block can be balanced at the lower part of the whole cushion block by ingenious force conversion. Simultaneously, the pressure plate clamping mechanism can ensue that the force at the fulcrum can be close to the workpiece as far as possible and ensure the reasonable equilibrium of a lever. Compared with the ordinary clamping, the stress situation of theoretical calculation is the same. The pressure plate clamping mechanism disclosed by the invention has the characteristics of simple and compact structure, and stability and reliability in operation.

Owner:华域视觉科技(长沙)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com