Assembly system oriented to micron-size hose and microsphere component

A technology of microspheres and hoses, which is used in microstructure devices, manufacturing microstructure devices, components of TV systems, etc. The effect of transplantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

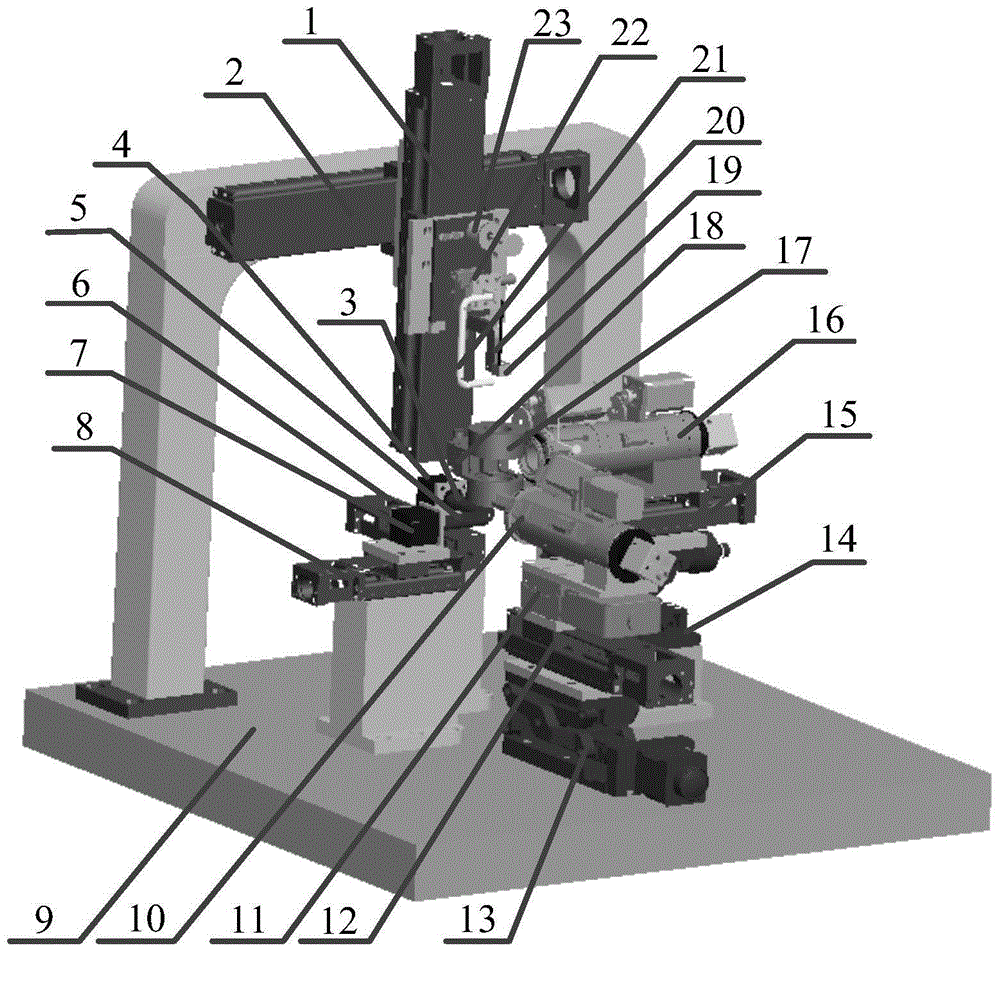

[0048] In the micro-assembly system of this embodiment, the three parts of the ignition target device in the inertial confinement fusion (Inertial Confinement Fusion, ICF) assembly, the micron-scale hose, the diagnostic ring and the microsphere, are used as the clamping and assembly objects in the micro-assembly system; Among them, the micrometer-level hose is a flexible and slender hose, with micropores on the microsphere shell and micropores on the diagnostic ring, both of which are in the micrometer-level, and are matched with the hose respectively.

[0049] The assembly accuracy index is shown in Table 1 below:

[0050] Table 1 Assembly accuracy index requirements for different assembly objects

[0051]

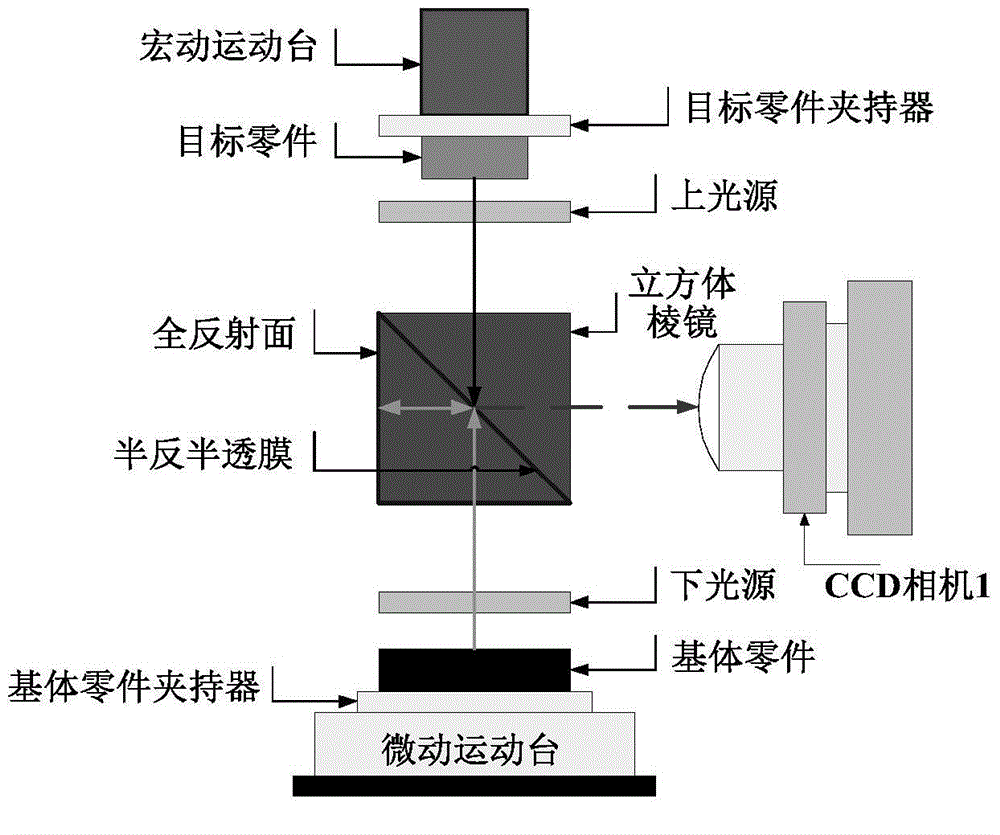

[0052] figure 2 The principle of spatial positioning of the orthogonal axis microspheres is to adjust the feed motion of the α and β rotation axes through the X2 and Y2 linear motion stages perpendicular to each other on the horizontal plane, and to adjust the feed m...

Embodiment 2

[0056] In the real-time monitoring system of the present embodiment, the X3 linear motion platform is used to adjust the focal length between the lens of the target part, the base part and the CCD camera 2; Obtain the image of the part to obtain its space pose information; the camera pitch adjustment table can adjust the lens angle of the CCD camera 2 so as to observe the contact state between the target part and the base part. The real-time monitoring system dynamically monitors the entire assembly process, including the contact state of the hose and the diagnostic ring assembly, the clamping state of the upward movement of the hose and diagnostic ring assembly, the contact state of the microsphere and the hose assembly, the hose The upward movement process of the stretched microspheres and the positioning process of the microspheres in the radial direction of the diagnostic ring.

Embodiment 3

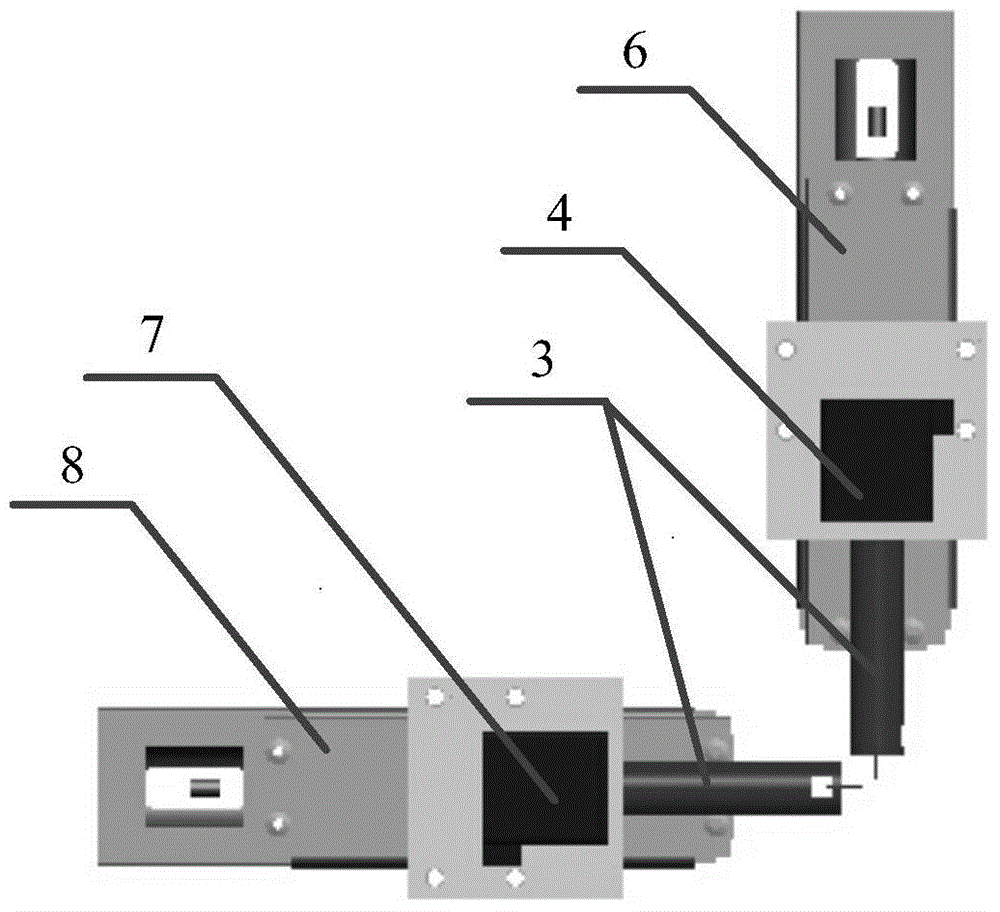

[0058] This embodiment is aimed at the "micro-device clamping system" in the assembly system for micron-scale hose and microsphere components of the present invention. The micro-device clamping system in this embodiment includes four vacuum adsorption clamps, respectively It is a microsphere fixing fixture, a diagnostic ring fixing fixture, a microsphere adsorption fixture, and a diagnostic ring adsorption fixture; a positioning tube, that is, a hose positioning tube; two fine-tuning movement mechanisms, including a microsphere fixing fixture micro-adjustment mechanism and a hose movement mechanism . The micro-device clamping system is used for the clamping and positioning of the hose, the diagnostic ring and the microsphere in the embodiment. Among them, the microsphere fixing fixture (such as Figure 6 shown), diagnostic ring fixing fixture (such as Figure 7 shown) are respectively used for the clamping and positioning of the microsphere and the diagnostic ring on the Z1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com