An Intelligent Casing Pliers with Back Tongs

A technology of casing tongs and backup tongs, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of safety doors without protection devices, low degree of automation, and low safety guarantee, so as to increase the practical range, reduce labor intensity, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

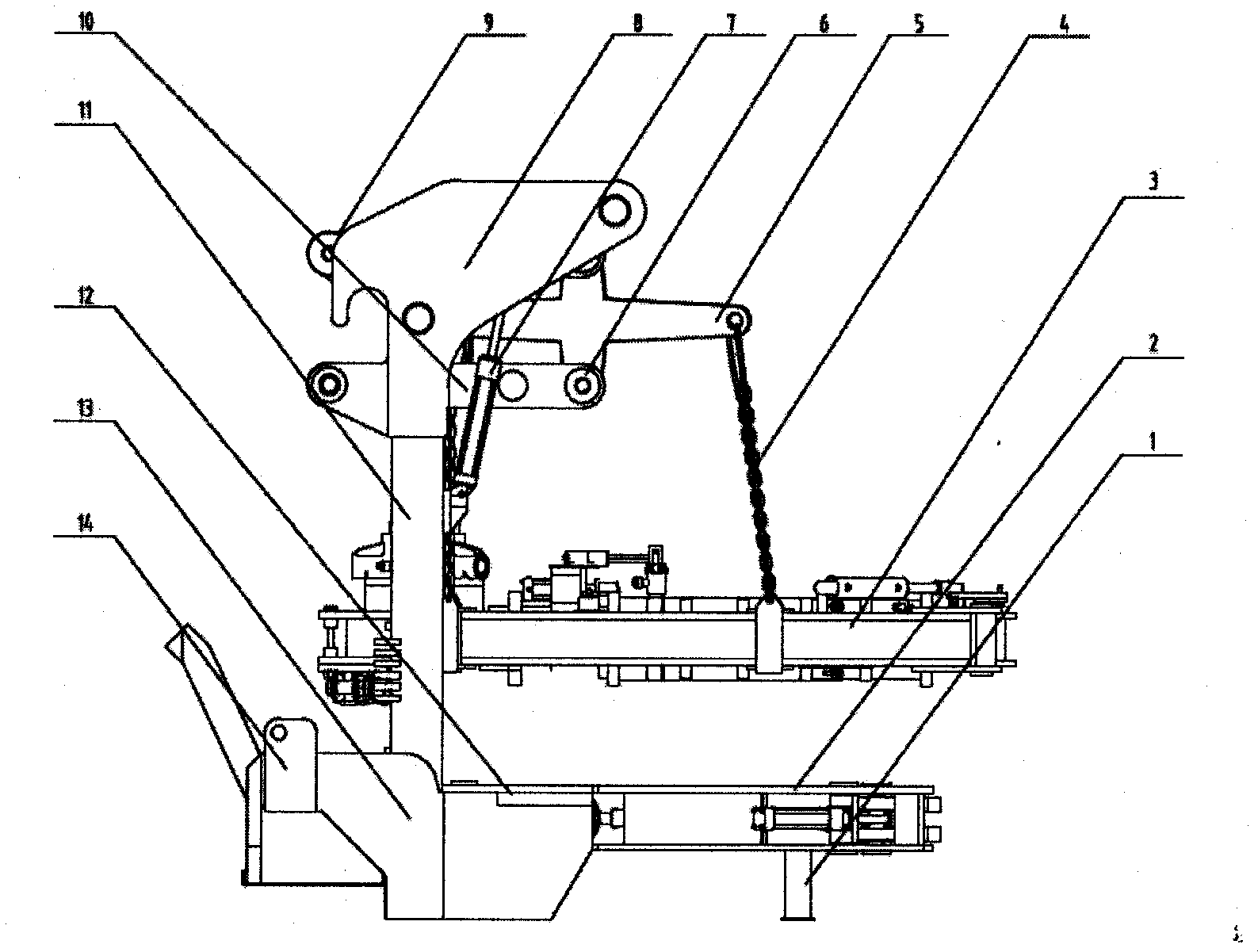

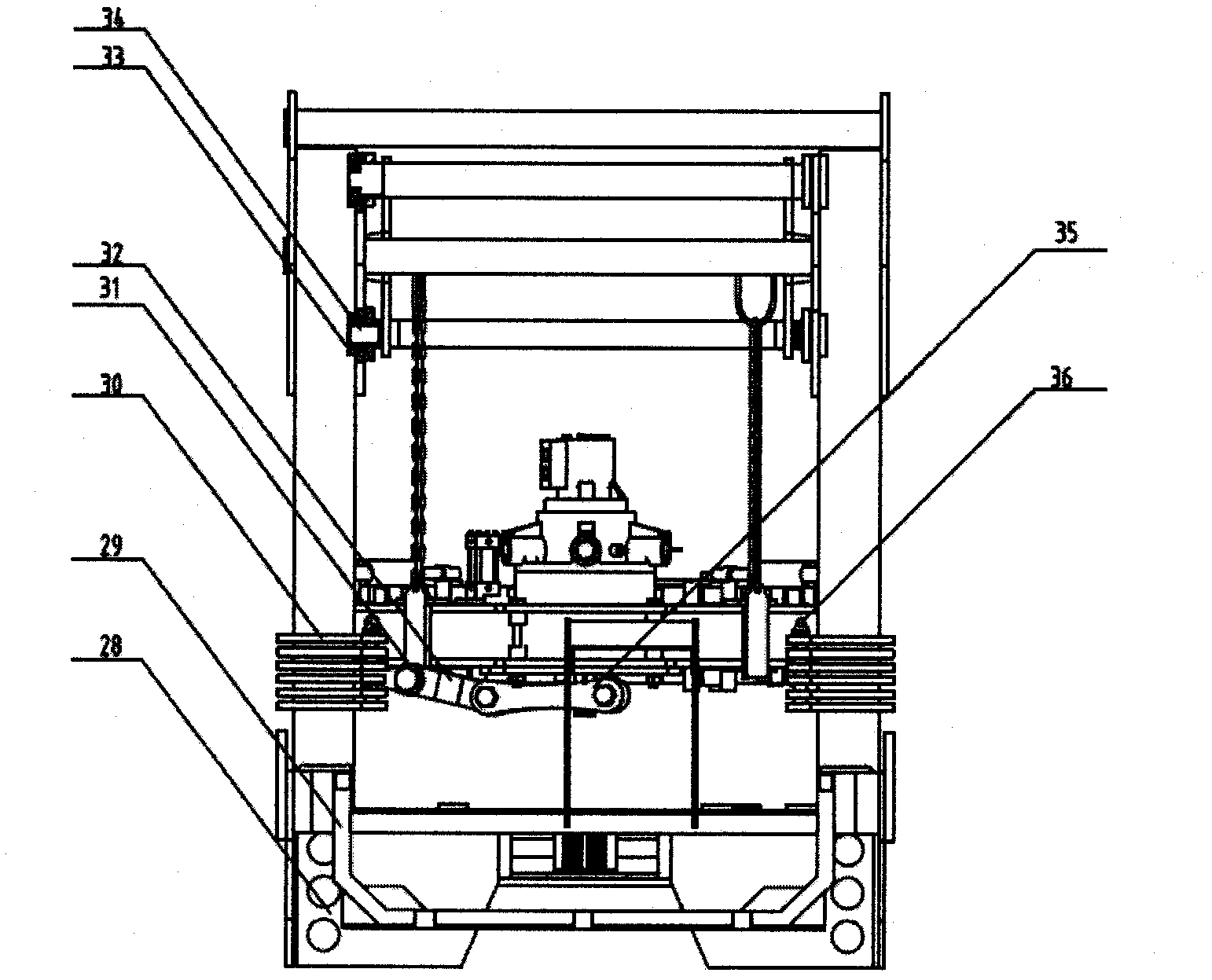

[0019] Example 1: Combining Figure 1-Figure 7 , the present invention is an intelligent casing tong with a backup tong, which is composed of a main frame, a hanger, a main tong (3) and a back tong (2), and the main tong (3) is connected to the back tong (2) On the main frame, the main tongs (3) are suspended on the hanger connected to the main frame by chains (4), and the back tongs (2) are welded to the main frame and supported by two feet (1).

[0020] The present invention also has the following technical characteristics:

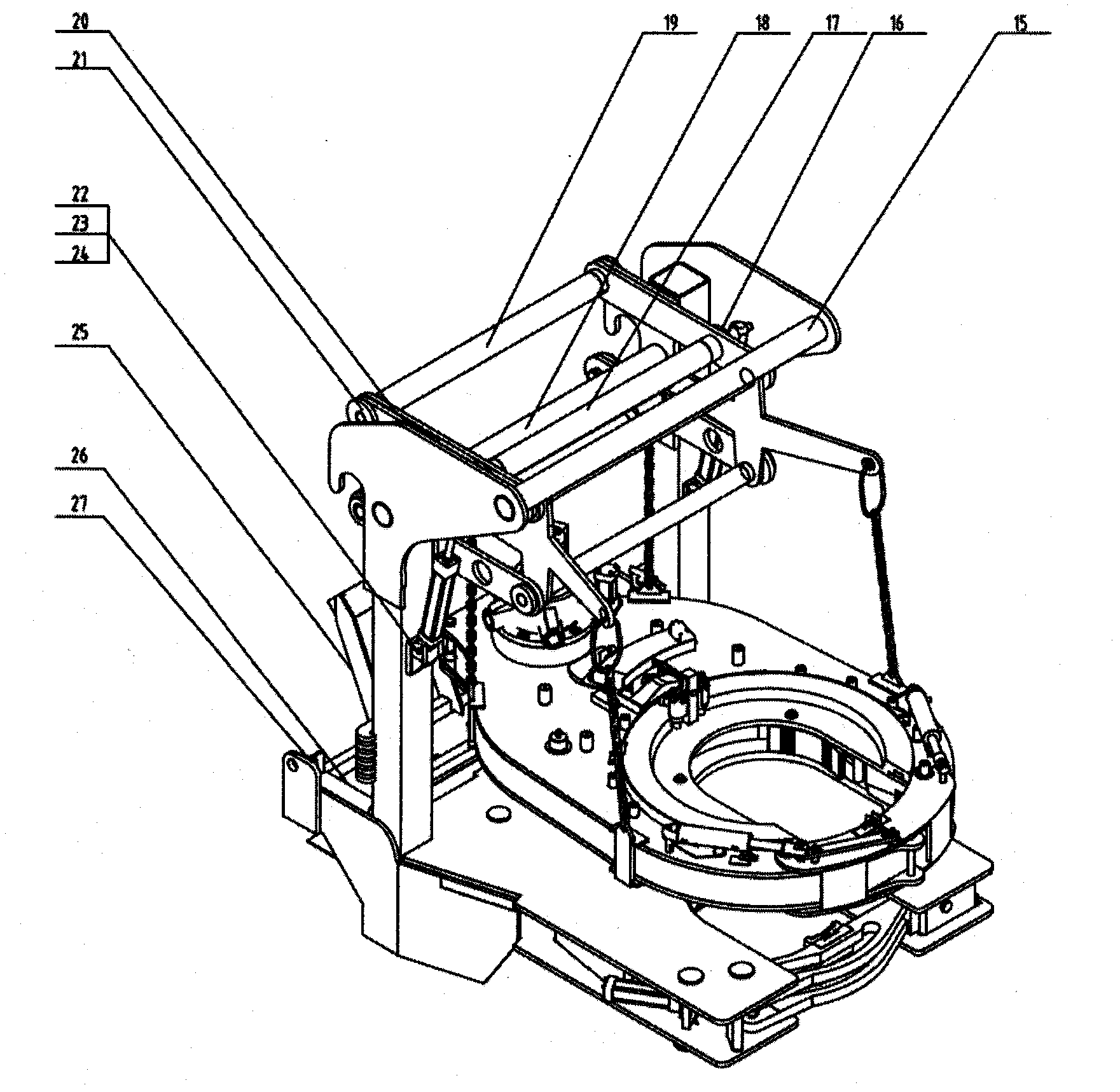

[0021] The hanger is a parallelogram structure, including a hanging plate (5), an upper plate (20), a lower plate (10), a rear beam (19), two front beams (17), a first flange (6) , the second flange (16), the third flange (21), the fourth flange (33) and short pins (34), the hanging plate (5) is enclosed within two front beams (17), and the front beam ( 17) It is hingedly connected with the upper plate (20) and the lower plate (10), the rear beam (19)...

Embodiment 2

[0025] Example 2: Combining Figure 1-Figure 7 , the present invention realizes the full automation of the working process. The shift fork hydraulic cylinder (239) controls the switching of the fast and slow gears of the power tongs. A travel switch is installed on the shift fork hydraulic cylinder (239) to detect the switching situation of the gear positions. The left safety door (250) is opened and closed by the left door cylinder (248), and the pressure protection after the door is closed is provided by the left door cylinder (248). The left safety door is installed on a roller shaft. The two ends of the left hydraulic cylinder are connected by clevis, and the afterbody is installed on the clevis shaft of the upper plate (227), and the piston rod end clevis is connected on the clevis shaft of the left safety door (250). The right safety door (257) is symmetrical with respect to the left safety door (250), and can be opened and closed by the right door cylinder (260). In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com