Method for correcting offset of base

A basic and deviation correction technology, applied in the field of basic deviation correction, to achieve the effect of easy implementation, simple structure and processing method, and large practical scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

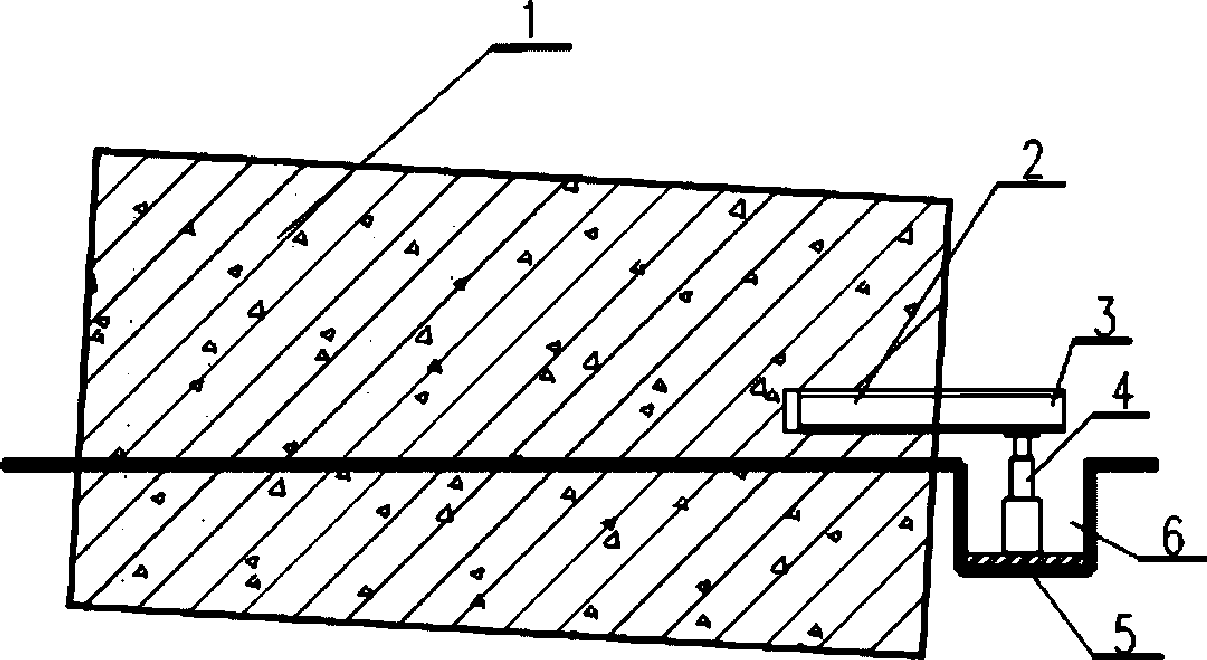

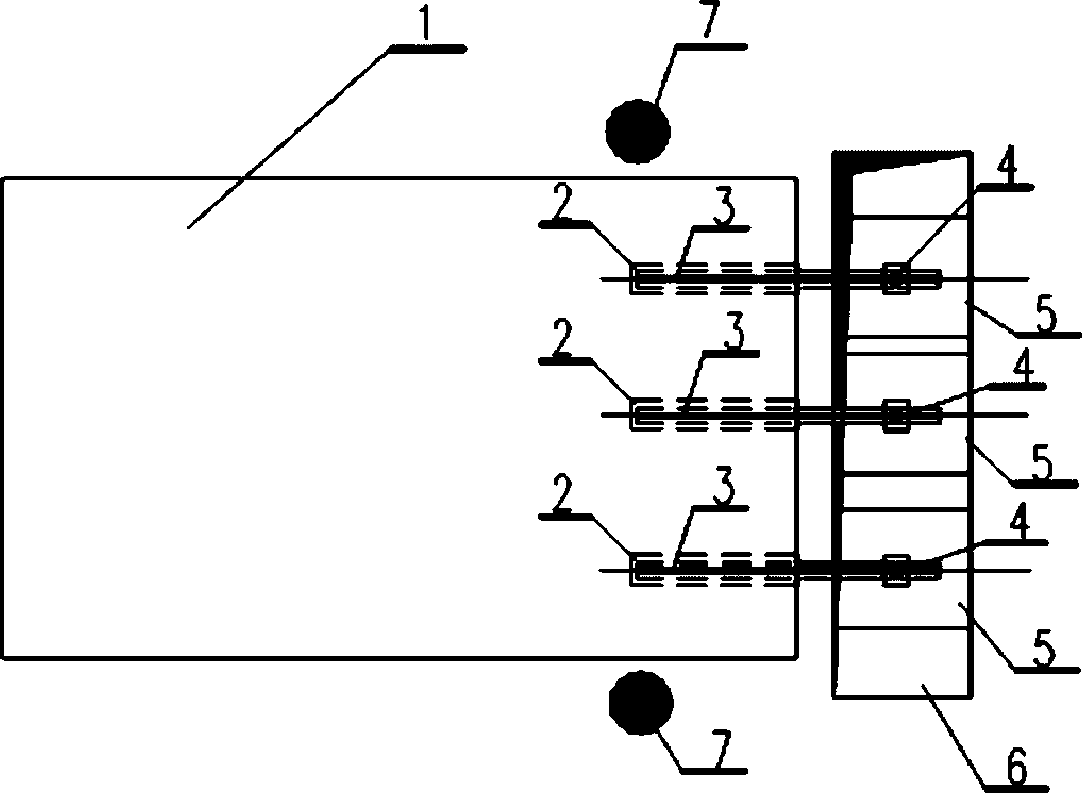

[0010] Embodiment: in the direction of large-scale equipment foundation 1 offset, according to the calculation (load value: equipment and foundation self-weight), determine the number of required drilling 2, and at the same time excavate the foundation trench 6 at the same direction as the position of the drilling hole 2, the foundation trench 6 After the excavation is completed, the soil layer at the bottom of the foundation trench 6 is compacted, leveled with fine stone concrete, the thickness of the leveling layer is 150mm, and the steel plate 5 is laid on the top of the leveling layer. When ready, insert the section steel 3 at the drill hole 2, use the jack 4 to support the other end of the section steel 3 and start jacking up to the normal elevation of the large-scale equipment foundation 1. When the large equipment foundation 1 is adjusted in place, see figure 2 , on both sides of the large-scale equipment foundation 1, use single-pipe high-pressure rotary grouting equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com