Pressure plate clamping mechanism

A technology of clamping mechanism and pressure plate, applied in clamping, metal processing mechanical parts, supports, etc., can solve problems such as workpiece cannot be processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

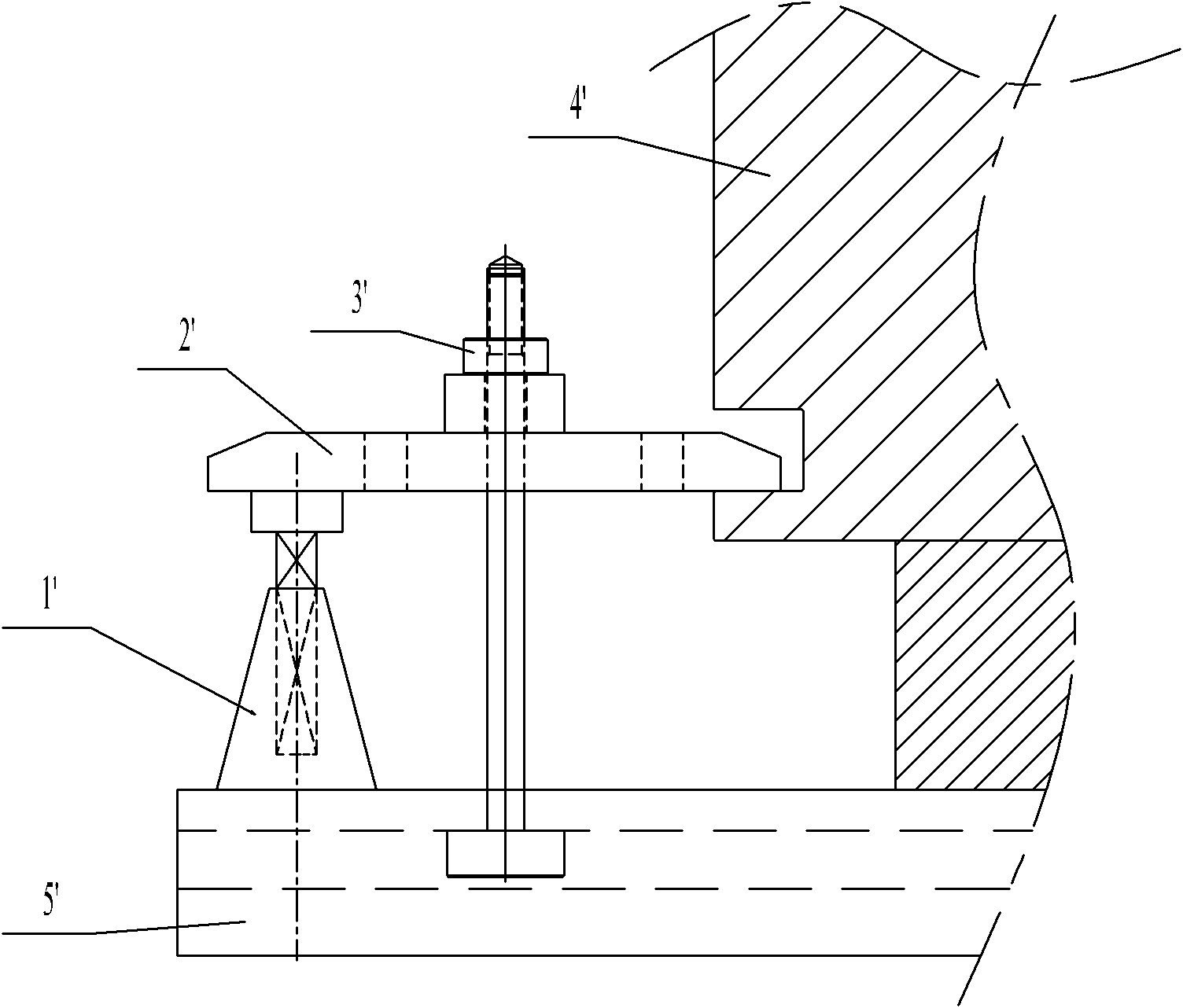

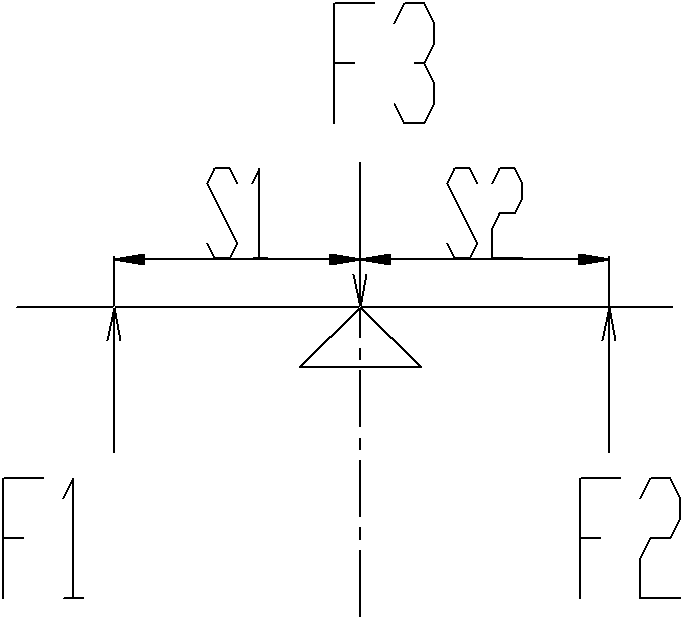

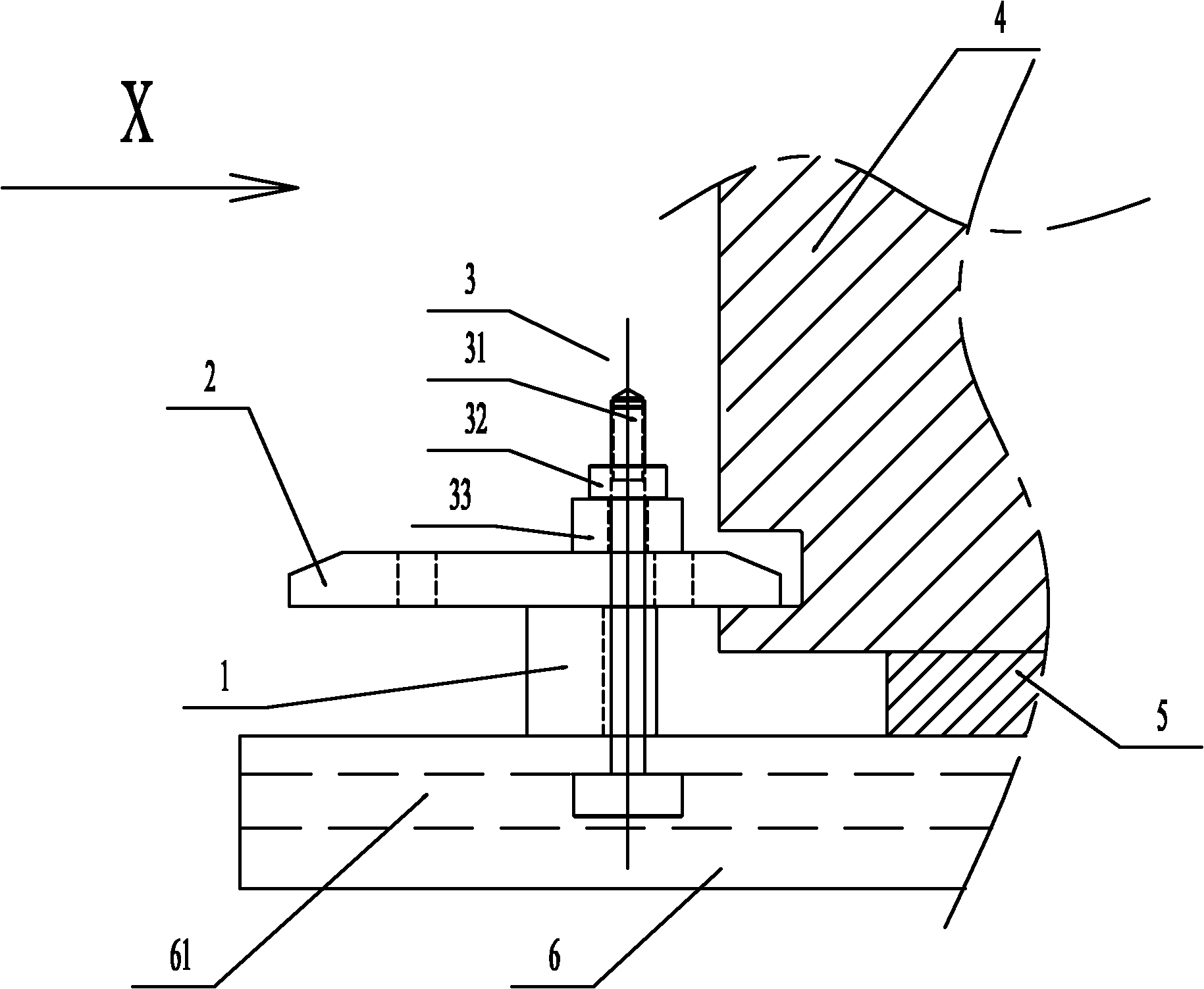

[0020] see image 3 , is the pressing plate clamping mechanism involved in the present invention. The invention is suitable for workpiece clamping (such as large plastic moulds) on horizontal machine tools. The pressing plate clamping mechanism includes a pressing plate 2 and a force applying rod 3 passing through the pressing plate 2. One end of the pressing plate 2 is supported on the pad 1, and the other end is used for pressing the workpiece. The cushion block 1 includes a support portion and a relief portion, the top surface 11 of the support portion is in contact with the pressure plate 2, and the relief portion is provided with a relief hole 15 for the force applying rod 3 to pass through, and the relief portion There is a gap between the top surface 12 of the upper part and the pressing plate 2.

[0021] The bottom of the pressing plate 2 forms first and second contact surfaces 21 and 22 on both sides of the force applying rod 3 respectively. The top of the spacer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com