Supercritical fuel oil heating device in supercritical oil bath type

A fuel oil heating device and heating device technology, applied in the field of supercritical oil bath type supercritical fuel heating device, can solve the problems of impurities in fuel oil, large heat dissipation, uneven temperature of fuel oil, etc., and achieve convenient cleaning and enhanced heat transfer performance, compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings.

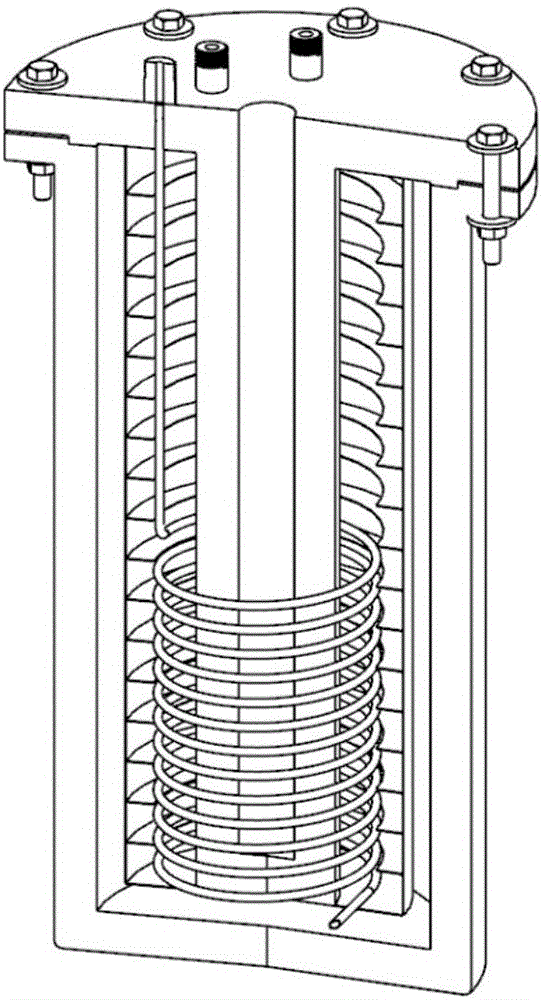

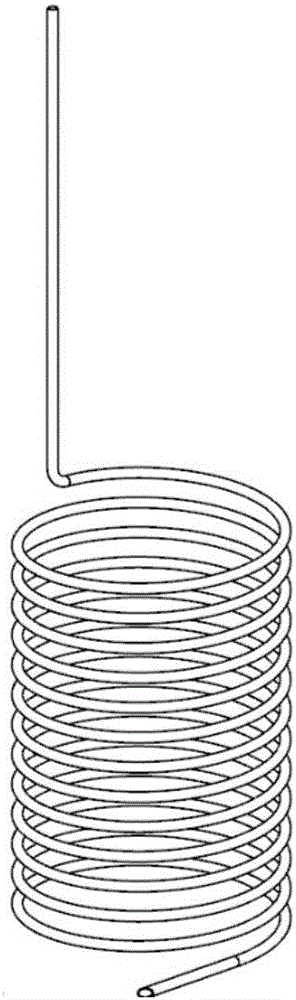

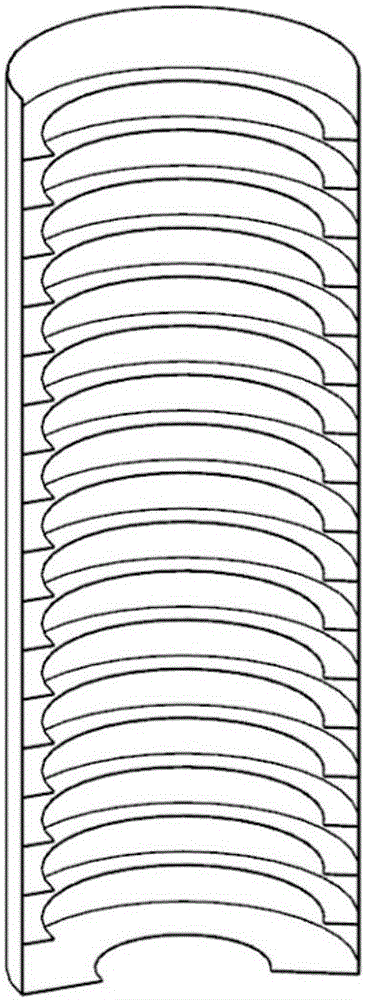

[0048] The invention is a supercritical oil bath type supercritical fuel heating device suitable for supercritical fluid experiments, such as Figure 4 and Figure 5 shown. It includes: top cover 1, tank body 2, fuel separator 3, annular fin 4, spiral tube 5, bolt connection 6, graphite gasket 7, negative feedback heating device 8, oil bath chamber 9, preheating chamber 10, Oil bath cavity temperature measuring port 11, oil bath cavity pressure measuring port 12, supercritical fuel oil outlet 13, preheating chamber temperature measuring port 14, preheating chamber pressure measuring port 15.

[0049] The supercritical oil bath type supercritical fuel oil heating device is designed based on oil bath heating and partition wall heat exchange method, so the spiral tube with relatively large length and diameter is selected as the main heat exchange element. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com