Constant temperature-constant humidity laboratory

A constant temperature and humidity, laboratory technology, applied in the laboratory field, can solve problems such as uneven temperature and humidity, staff hypoxia, laboratory temperature and humidity fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

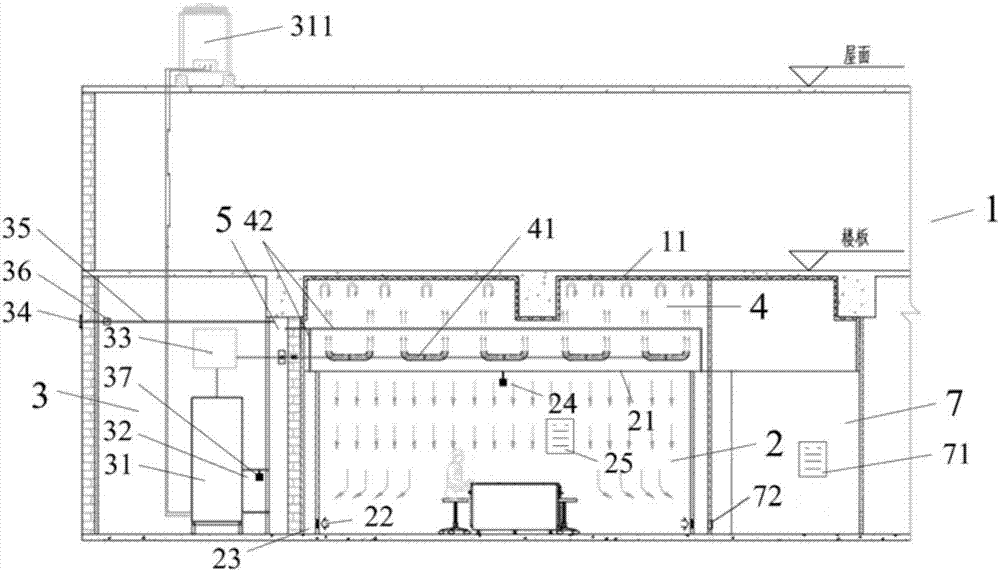

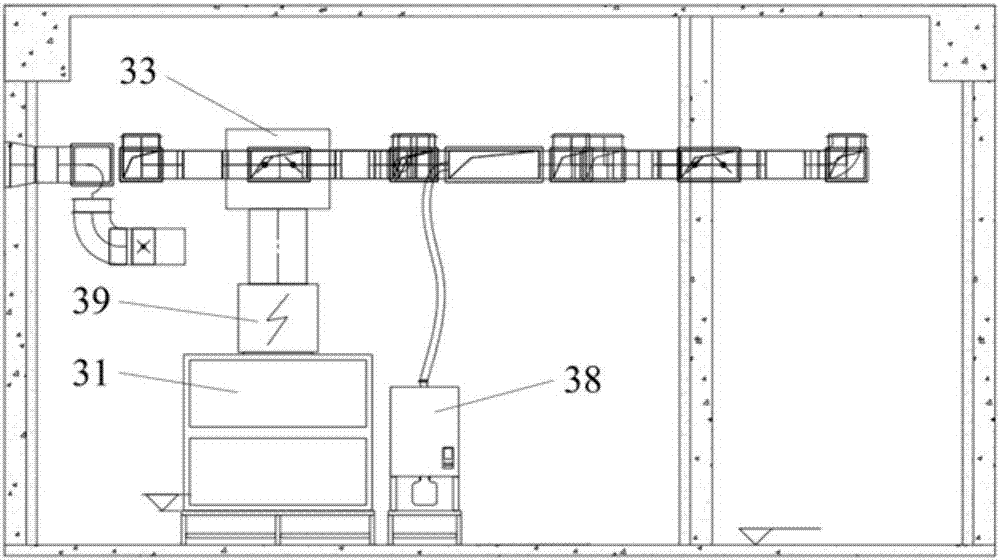

[0046] The invention provides a constant temperature and humidity laboratory, such as Figure 1-2 As shown, including the laboratory 1, the laboratory 1 is provided with a working room 2 and an equipment room 3, the top of the working room 2 is provided with an air supply chamber 4, and between the working room 2 and the equipment room 3 is provided with a mixed air chamber 5, in:

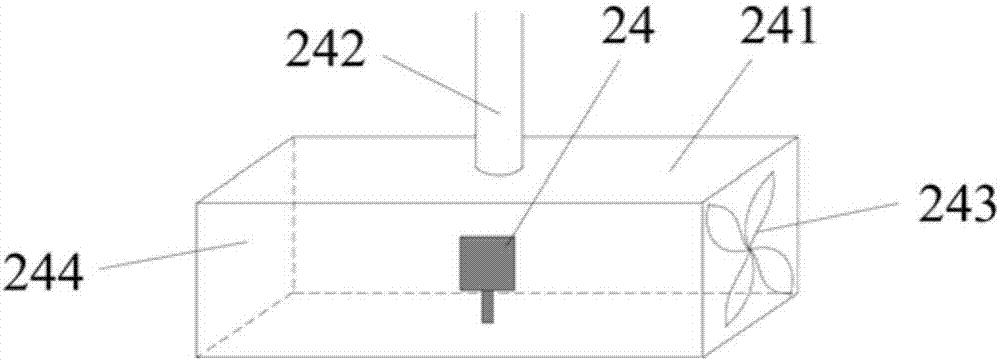

[0047] The top of the working room 2 is provided with an orifice ceiling 21, and the closed space between the orifice ceiling 21 and the roof 11 of the laboratory 1 forms an air supply chamber 4, and the air supply chamber 4 is provided with an air supply pipe 41, and the orifice ceiling 21 There are several air outlets on the top;

[0048] There is a fresh air outlet 34 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com