4-aminopyridine based on Hofmann degradation and supercritical/subcritical fluid, and preparation method of 4-aminopyridine

A subcritical fluid, Hoffman degradation technology, applied in the field of 4-aminopyridine and its preparation, can solve the problems of heavy pollution, high cost, stimulation of the central nervous system, etc., to reduce side reactions, improve yield, and improve reaction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

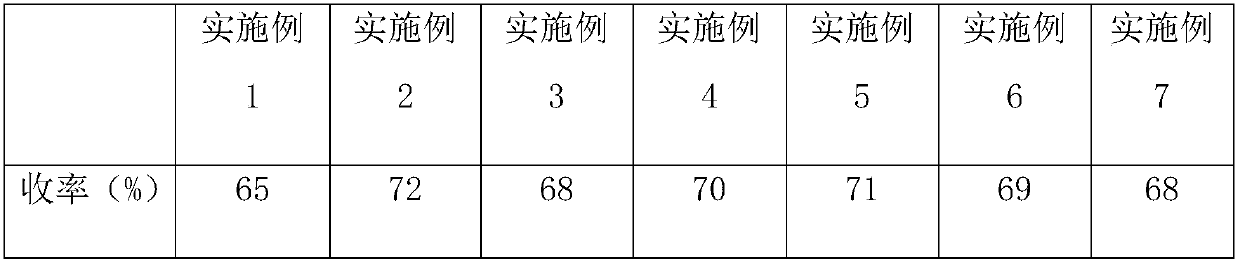

Examples

Embodiment 1

[0025] (1) Add ethyl isonicotinate into the reactor, press liquid ammonia with a flow rate of 0.6m / s into the reactor, first raise the temperature to -34°C at a rate of 3°C / min, and adjust the pressure to 0.1MPa, Stabilize for 5 minutes, then raise the temperature to 128°C at a rate of 5°C / min, adjust the pressure to 10MPa, stabilize the subcritical state for 10 minutes, and finally raise the temperature to 132.5°C at a rate of 1°C / min, adjust the pressure to 11.4MPa, and stabilize the supercritical state After 20 minutes, the temperature was rapidly cooled to terminate the reaction to obtain isonicotinic acid amide.

[0026] (2) Continue to pass bromine water with a flow rate of 1.5m / s into the isonicotinic acid amide, first raise the temperature to 95°C at a rate of 5°C / min, adjust the pressure to 5MPa, stabilize for 10min, and then increase the temperature at 20°C / min The temperature was raised to 365°C, the pressure was adjusted to 15MPa, and the subcritical state was stab...

Embodiment 2

[0029] (1) Add ethyl isonicotinate into the reactor, press liquid ammonia with a flow rate of 0.9m / s into the reactor, first raise the temperature to -32°C at a rate of 6°C / min, and adjust the pressure to 0.5MPa, Stabilize for 10 minutes, then raise the temperature to 132°C at a rate of 10°C / min, adjust the pressure to 11MPa, stabilize the subcritical state for 20 minutes, and finally raise the temperature to 134°C at a rate of 3°C / min, adjust the pressure to 11.5MPa, and stabilize the supercritical state After 30 minutes, the temperature was rapidly cooled to terminate the reaction to obtain isonicotinic acid amide.

[0030] (2) Continue to pass bromine water with a flow rate of 3.2m / s into the isonicotinic acid amide, first raise the temperature to 98°C at a rate of 15°C / min, adjust the pressure to 8MPa, stabilize for 20min, and then increase the temperature at 30°C / min The temperature was raised to 370°C, the pressure was adjusted to 18MPa, and the subcritical state was sta...

Embodiment 3

[0033] (1) Add ethyl isonicotinate into the reactor, press liquid ammonia with a flow rate of 0.6m / s into the reactor, first raise the temperature to -34°C at a rate of 6°C / min, and adjust the pressure to 0.5MPa, Stabilize for 5 minutes, then raise the temperature to 128°C at a rate of 10°C / min, adjust the pressure to 11MPa, stabilize the subcritical state for 10 minutes, and finally raise the temperature to 132.5°C at a rate of 3°C / min, adjust the pressure to 11.5MPa, and stabilize the supercritical state After 20 minutes, the temperature was rapidly cooled to terminate the reaction to obtain isonicotinic acid amide.

[0034] (2) Continue to pass bromine water with a flow rate of 3.2m / s into the isonicotinic acid amide, first raise the temperature to 98°C at a rate of 5°C / min, adjust the pressure to 5MPa, stabilize for 20min, and then increase the temperature at 20°C / min The temperature was raised to 370°C, the pressure was adjusted to 15MPa, and the subcritical state was sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com