A kind of preparation method of reduced graphene and polyimide nanocomposite material

A nanocomposite material and polyimide technology, which is applied in the field of preparation of reduced graphene and polyimide nanocomposite materials, can solve the problems of low temperature resistance, poor dispersion stability, and graphene oxide re-agglomeration, etc. The process is simple and reliable, the effect of improving dispersion stability and overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

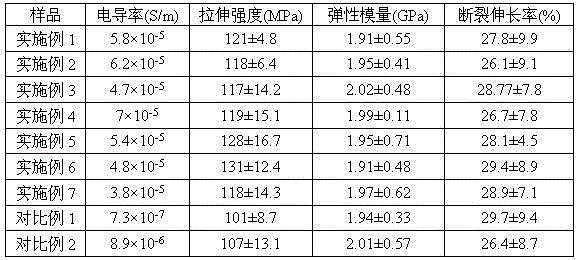

Embodiment 1

[0025] Add 5.0 g of graphene oxide into 1 L of deionized water, and use an ultrasonic generator to ultrasonically disperse for 180 min at an ultrasonic power of 150 W and room temperature to prepare an aqueous graphene oxide dispersion with a concentration of 5 mg / ml for future use.

[0026] Weigh 200.24g of 4,4'-diaminodiphenyl ether and 218.12g of pyromellitic dianhydride, add it to 1.77L of N,N'-dimethylformamide, and place it at 25°C under nitrogen protection The reaction was stirred for 24 hours under the conditions to obtain a polyamic acid solution. 306.64 ml of triethylamine was added to the solution, and the reaction was continued for 1 h to obtain a hydrophilic polyamic acid solution. Next, under the condition of stirring, 1L of the prepared aqueous graphene oxide dispersion was added to the hydrophilic solution, and stirred for 60 minutes to realize the uniform dispersion of graphene oxide in the polyamic acid. The above solution was filmed by a spin coating mechan...

Embodiment 2

[0028] Add 0.52 g of graphene oxide into 260 ml of deionized water, and use an ultrasonic generator to ultrasonically disperse for 60 min at an ultrasonic power of 100 W and room temperature to prepare an aqueous graphene oxide dispersion with a concentration of 2 mg / ml for future use.

[0029] Weigh 32.22g of 3,3',4,4'-benzophenonetetracarboxylic dianhydride and 20.02g of 3,3'-diaminodiphenyl ether, add to 300ml of N,N' - In dimethylformamide, stirring and reacting for 2 hours at 0° C. under the protection of argon to synthesize a polyamic acid solution. 30.67ml of triethylamine was added to the solution, and the reaction was continued for 0.5h to obtain a hydrophilic polyamic acid solution. Then, under the condition of stirring, the aqueous graphene oxide dispersion liquid prepared above was added to the hydrophilic solution, and stirred for 30 minutes to realize the uniform dispersion of graphene oxide in the polyamic acid. Take 100ml of the above solution to coat a film o...

Embodiment 3

[0031] Add 0.03 g of graphene oxide into 60 ml of deionized water, and use an ultrasonic generator to ultrasonically disperse for 120 min at an ultrasonic power of 120 W and room temperature to prepare an aqueous graphene oxide dispersion with a concentration of 0.5 mg / ml for future use.

[0032] Weigh 5.02g of bisphenol A dianhydride and 1.08g of m-phenylenediamine, and add them to 50ml of N,N'-dimethylformamide under stirring conditions. The reaction was stirred for 6 hours to synthesize a polyamic acid solution. 1.15 ml of tributylamine was added to the solution, and the reaction was continued for 1 h to obtain a hydrophilic polyamic acid solution. Then, under the condition of stirring, the above-mentioned aqueous graphene oxide dispersion liquid was added to the hydrophilic solution, and stirred for 45 minutes to realize the uniform dispersion of graphene oxide in the polyamic acid. The above solution was coated on a film, and dried under vacuum at 70° C. to obtain a grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com