Fireproof paint for electrical equipment and preparation method of fireproof paint

A technology for fire-resistant coatings and electrical equipment, applied in the direction of fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor impact resistance, water resistance, and corrosion resistance, and achieve excellent flexibility and corrosion resistance. Strong solvent resistance, water resistance and ablation radiation resistance, excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

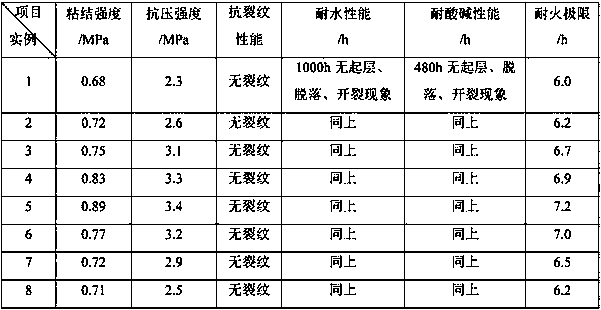

Examples

Embodiment 1

[0022] A fireproof coating for electric equipment, made of the following raw materials in parts by weight:

[0023] 20 parts of phenyl vinyl silicone resin, 25 parts of vinyl chloride-acrylate latex, 8 parts of bisphenol A type epoxy resin, 10 parts of pentaerythritol, 15 parts of ammonium polyphosphate, 15 parts of melamine, 10 parts of mullite, vermiculite 5 parts, 1 part of polyimide fiber, 0.4 part of hydroxypropyl cellulose, 2 parts of lauryl alcohol ester and 30 parts of water.

[0024] The preparation method of above-mentioned fireproof coating for electric equipment, comprises the following steps:

[0025] (1) Mix pentaerythritol, ammonium polyphosphate, melamine, mullite and vermiculite evenly, and grind them to less than 75 μm to obtain a mixed powder;

[0026] (2) Add polyimide fiber, hydroxypropyl cellulose, lauryl alcohol ester and water to the mixed powder in step (1) and stir evenly to obtain a mixed solution;

[0027] (3) Disperse the mixed solution in step (...

Embodiment 2

[0029] A fireproof coating for electric equipment, made of the following raw materials in parts by weight:

[0030] 22 parts of phenyl vinyl silicone resin, 28 parts of vinyl chloride-acrylate latex, 9 parts of bisphenol A type epoxy resin, 10 parts of pentaerythritol, 16 parts of ammonium polyphosphate, 16 parts of melamine, 11 parts of mullite, vermiculite 6 parts, 2 parts of polyimide fiber, 0.5 part of hydroxypropyl cellulose, 2 parts of lauryl alcohol ester and 32 parts of water.

[0031] See Example 1 for the preparation method of the above-mentioned fireproof coating for electric equipment.

Embodiment 3

[0033] A fireproof coating for electric equipment, made of the following raw materials in parts by weight:

[0034] 23 parts of phenyl vinyl silicone resin, 30 parts of vinyl chloride-acrylate latex, 10 parts of bisphenol A type epoxy resin, 11 parts of pentaerythritol, 18 parts of ammonium polyphosphate, 18 parts of melamine, 12 parts of mullite, vermiculite 6 parts, polyimide fiber 2 parts, hydroxypropyl cellulose 0.6 parts, lauryl alcohol ester 3 parts and water 33 parts.

[0035] See Example 1 for the preparation method of the above-mentioned fireproof coating for electric equipment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com