Device and method for measuring actual maximum torque of motor

A technology of maximum torque and measuring device, applied in the direction of measuring device, torque metering, power metering, etc., can solve the problems of high cost, complex structure of measuring equipment, complicated modification of different motor test structures, etc., and achieve the effect of meeting experimental requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

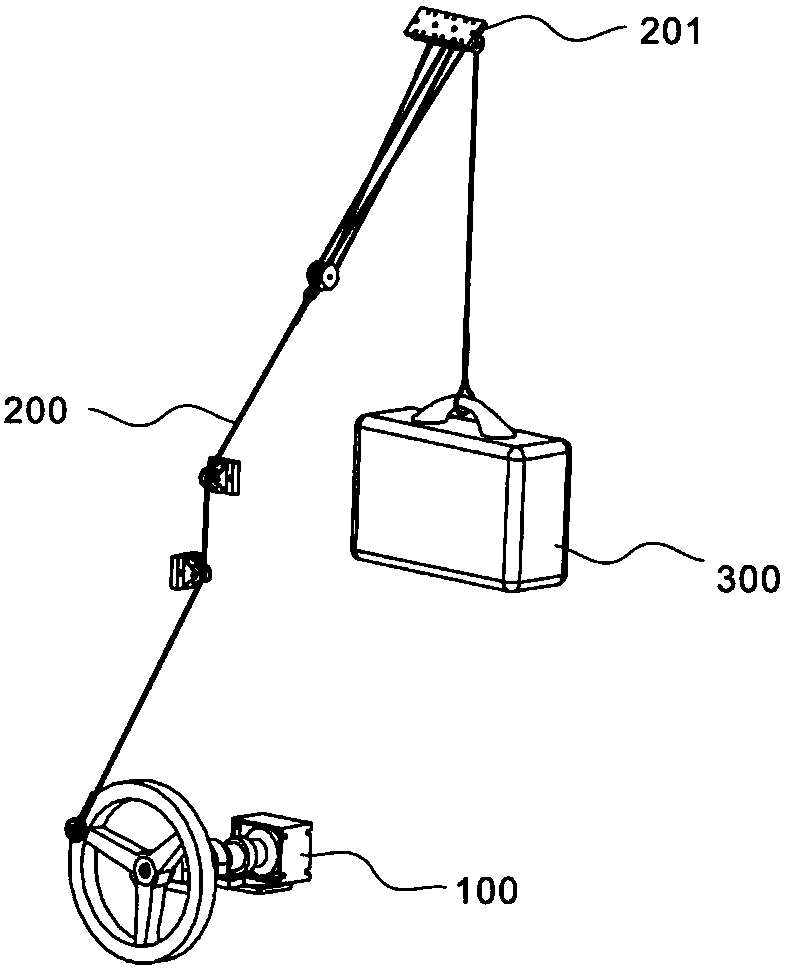

[0032] Such as Figure 1~2As shown, in this embodiment, in order to be able to measure the actual maximum torque of a motor at different speeds using simple conditions and low cost without a torque measuring instrument and a torque sensor, and without the need for different motor test structures Complicated modifications can better meet the experimental needs of general small businesses and schools. The measuring device for the actual maximum torque of the motor includes a mounting assembly 100 , a transmission mechanism 200 and a weight component 300 . Specifically, the installation assembly 100 is used to install and fix the measured motor, the input end of the transmission mechanism 200 is connected to the measured motor, and the output end is connected to the pulley block 201 for transmitting the rotational motion of the measured motor to the pulley block 201, The weight component 300 is connected to the output end of the transmission mechanism 200, and is suspended below ...

Embodiment 2

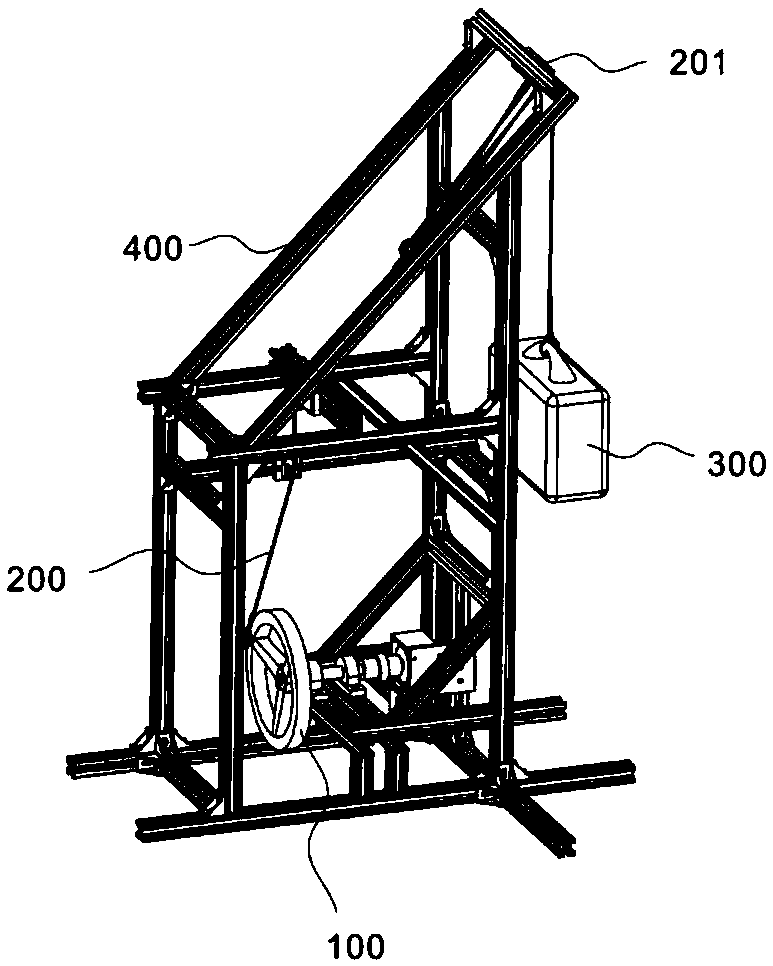

[0034] Such as Figure 3-4 As shown, in order to realize that the motor transmission mechanism 200 converts the rotational motion of the measured motor into the reciprocating motion of the weight component 300 in the vertical direction, the difference between this embodiment and the first embodiment is that the transmission mechanism 200 also includes a transmission part 202 , a bearing seat 203 , a handwheel 204 , a “U” groove bearing 205 and a coupling 206 . Specifically, the measuring device for the actual maximum torque of the motor includes a mounting assembly 100 , a transmission mechanism 200 and a weight component 300 . Wherein the installation assembly 100 is used for the installation and fixing of the measured motor, the input end of the transmission mechanism 200 is connected to the measured motor, and the output end is connected to the pulley block 201, and is used to transmit the rotational motion of the measured motor to the pulley block 201, and the weight compo...

Embodiment 3

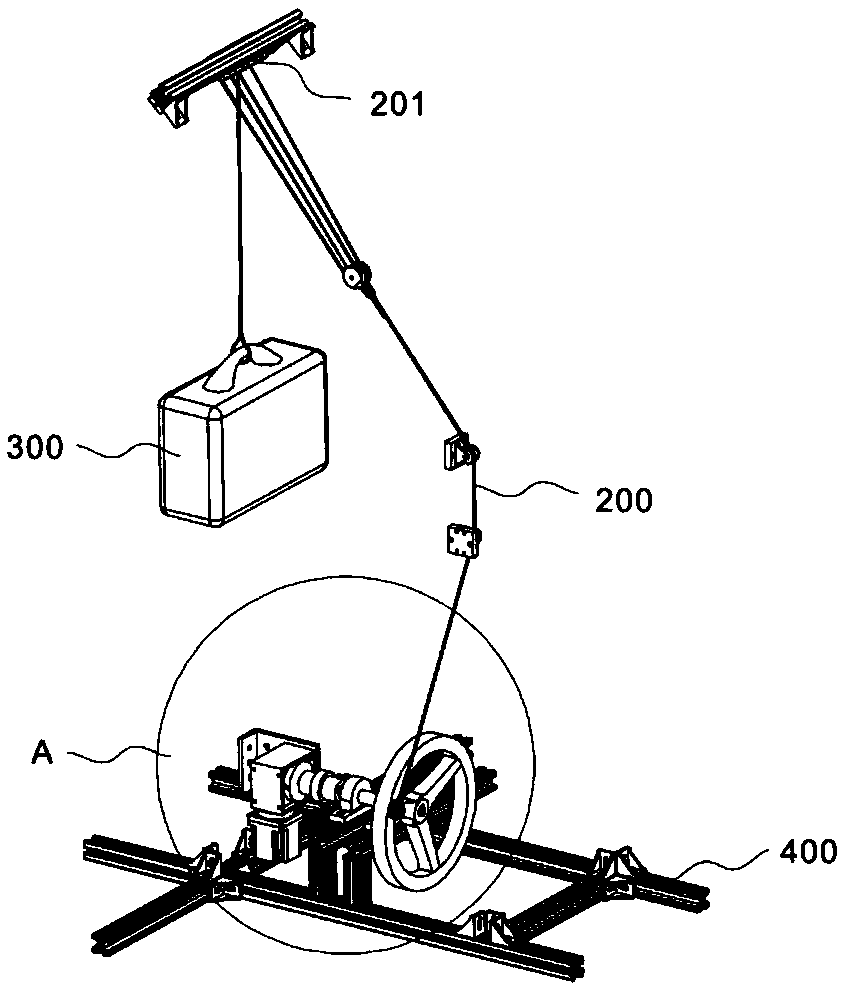

[0037] refer to Figure 5-6 In this embodiment, in order to divert the movement mode of the measured motor and use several pulleys to effectively reduce the weight of the heavy object, it is convenient to increase or decrease the mass of the weight box when measuring the maximum torque of the motor. It is also possible to reduce the weight of the heavy object And increase the stability and balance of the structure. The difference between this embodiment and the second embodiment is: the device also includes a fixed pulley block 201a and a double row pulley 201b. Specifically, the measuring device for the actual maximum torque of the motor includes a mounting assembly 100 , a transmission mechanism 200 and a weight component 300 . Wherein the installation assembly 100 is used for the installation and fixing of the measured motor, the input end of the transmission mechanism 200 is connected to the measured motor, and the output end is connected to the pulley block 201, and is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com