Plugging and unplugging effect evaluation method for plugging material

A technology of plugging materials and evaluation methods, applied in the field of drilling plugging materials, can solve the problems of plugging cracks, large experimental errors, and single function, etc. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

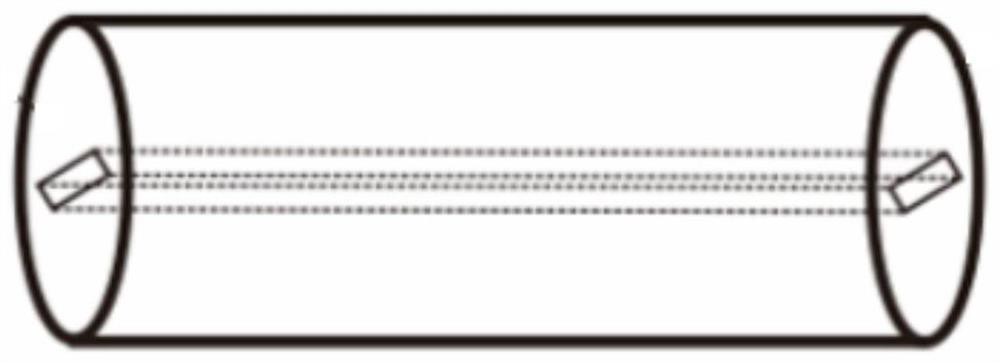

[0058] see Figure 1-5 , in an embodiment of the present invention, a method for evaluating the effect of plugging and plugging removal with plugging materials, including a core column, liquid plugging materials, and a dynamic damage evaluation instrument, the steps are as follows,

[0059] S1: Prepare a plurality of core pillars with different fracture widths, the core pillars are made of stainless steel, and the fracture width is in the range of 0.05-8mm;

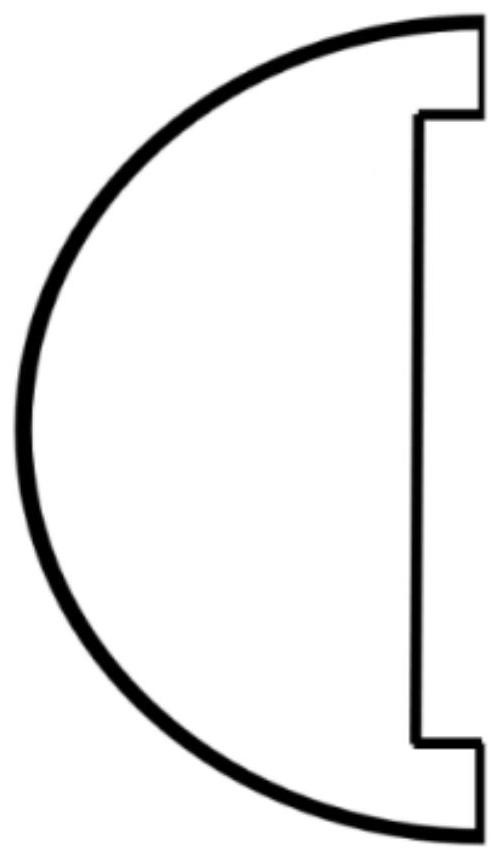

[0060] Among them, a plurality of core pillars with different fracture widths are prepared. The core pillars are prepared through the following sub-steps. Two symmetrical stainless steel half cylinders are prepared, and the diameter surfaces of the two half cylinders are wire cut to make fracture grooves, and the two half cylinders are The length of the crack grooves cut by one half cylinder is the same, and the cut two half cylinders are combined, wrapped with sealing tape, so that the two half cylinders fit closely, and...

Embodiment 2

[0099] A method for evaluating the effect of plugging and plugging removal with plugging materials, comprising a core column, liquid plugging materials, and a dynamic damage evaluation instrument, the steps are as follows,

[0100]S1: Prepare a plurality of core pillars with different fracture widths, the core pillars are made of stainless steel, and the fracture width is in the range of 0.05-8mm;

[0101] S2: Inject the liquid leakage plugging material into the fracture of one of the core columns, and perform curing under simulated formation temperature and pressure conditions, and obtain the core column after the liquid leakage plugging material is consolidated;

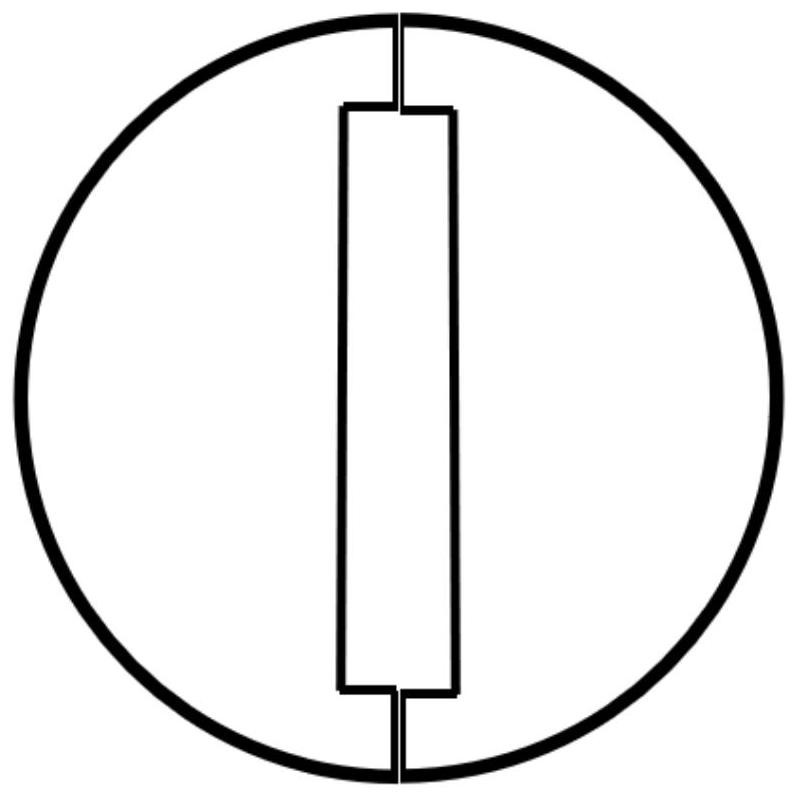

[0102] S3: Use a dynamic damage evaluation instrument to evaluate the plugging of the core column obtained in step S2. The dynamic damage evaluation instrument includes a connected wellbore simulation system, a core holder, and a base fluid collection device. The inlet end of the core holder is equipped with Pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com