Tire dismounting equipment

A tire disassembly and equipment technology, applied in tire installation, tire parts, wheel assembly and disassembly equipment, etc., can solve the problems of poor efficiency of tire disassembly equipment, and achieve the effect of improving the practical scope, strong practicability, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

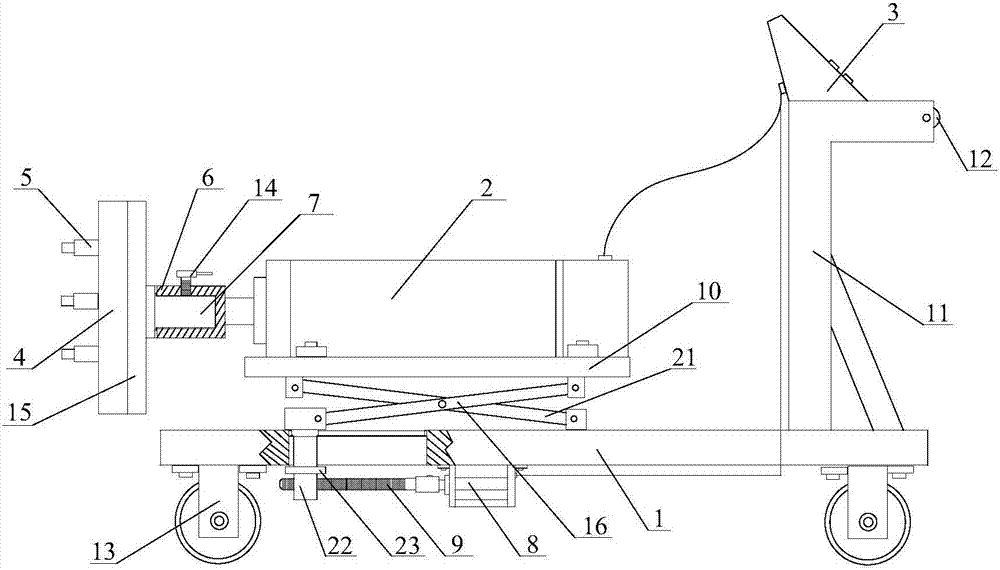

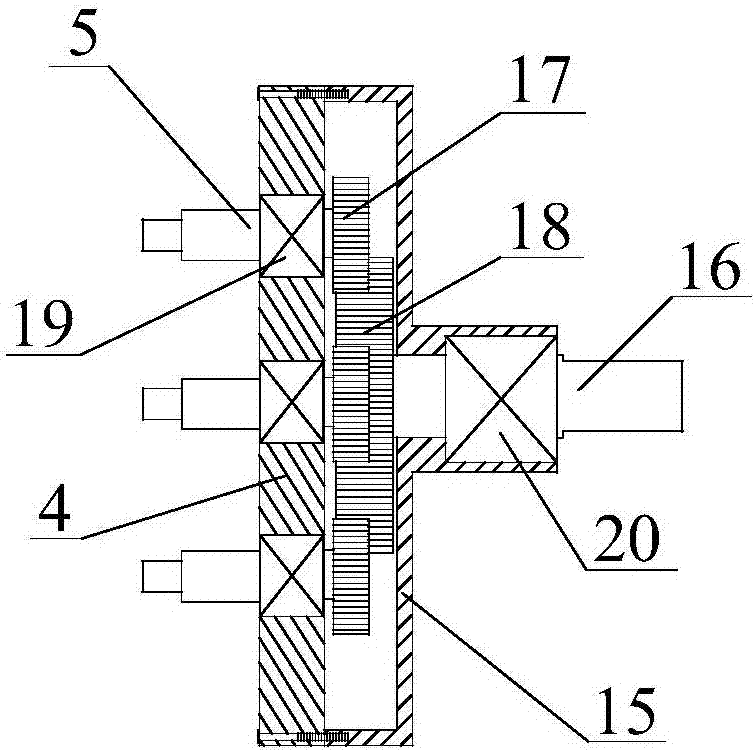

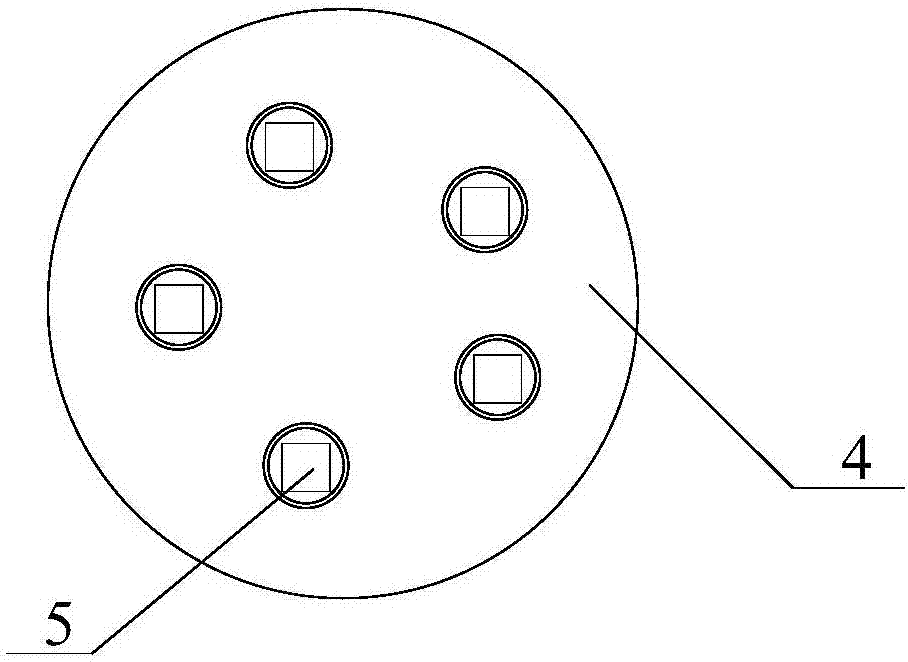

[0024] Such as Figure 1~3 As shown, the present invention discloses a tire removal device, which includes a base 1, a wind gun 2, a controller 3, and a multi-axis rotating head device. Wherein, the multi-axis rotating head device such as figure 2 As shown, it includes a carrier 4, a housing 15, a plurality of secondary shafts 5, small teeth 17, a main shaft 7, and large teeth 18.

[0025] During implementation, the base 1 serves as the support and carrier of the entire device. In order to facilitate the movement of the device, rollers 13 are respectively provided on the four corners of the bottom surface of the base 1. The jackhammer 2 and the controller 3 are respectively arranged on the base 1, and the controller 3 is connected with the jackhammer 2, and the controller is connected with an external power source. The power source in this embodiment is implemented by a DC battery. In order to facilitate our use of the controller 3, a bracket 11 for installing the controller 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com