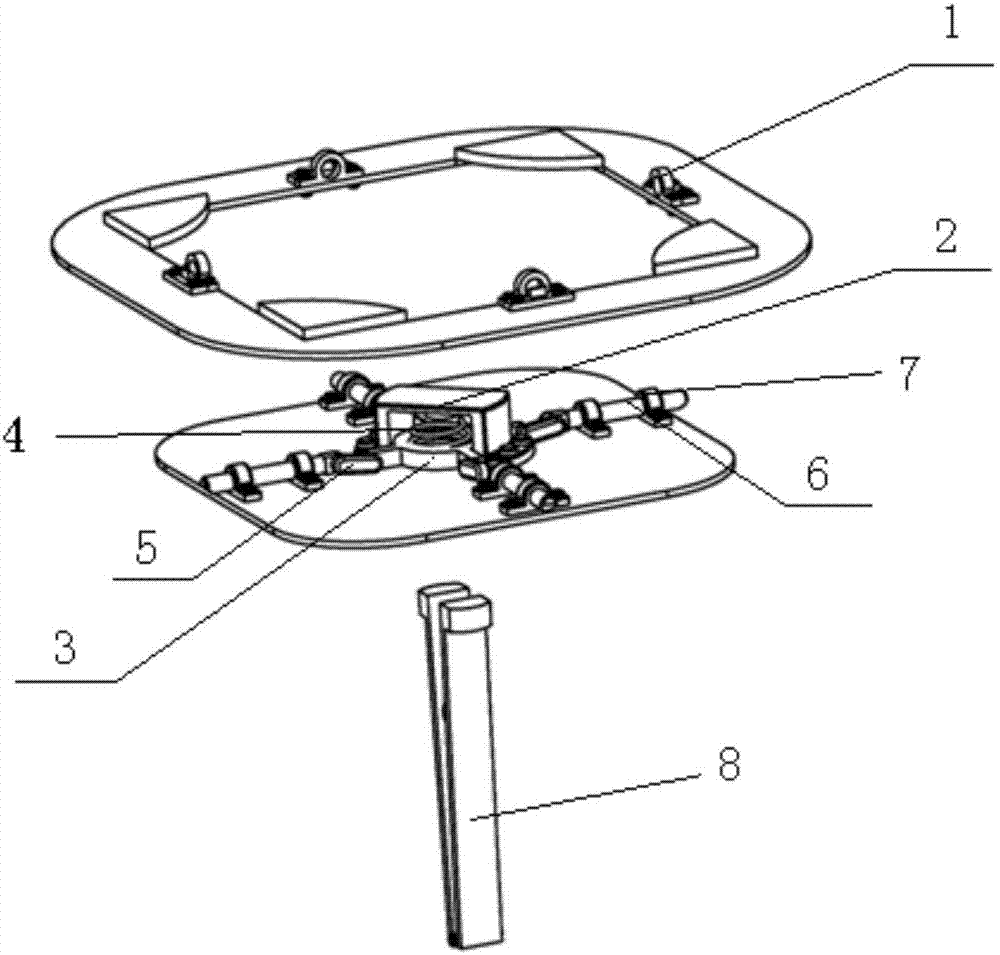

Opening cover lock device based on linkage mechanism

A technology of linkage mechanism and flap lock, which is applied in building locks, building structures, building fastening devices, etc., can solve the problems of unsuitable flaps, etc., reduce the link of human judgment that the unlocking is in place, improve the disassembly efficiency, The effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

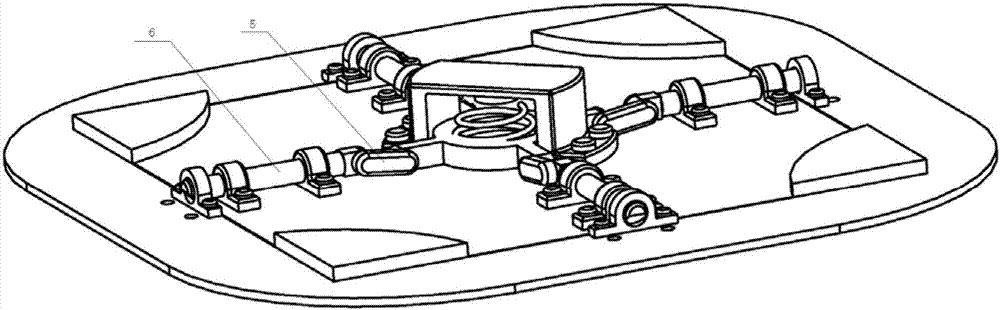

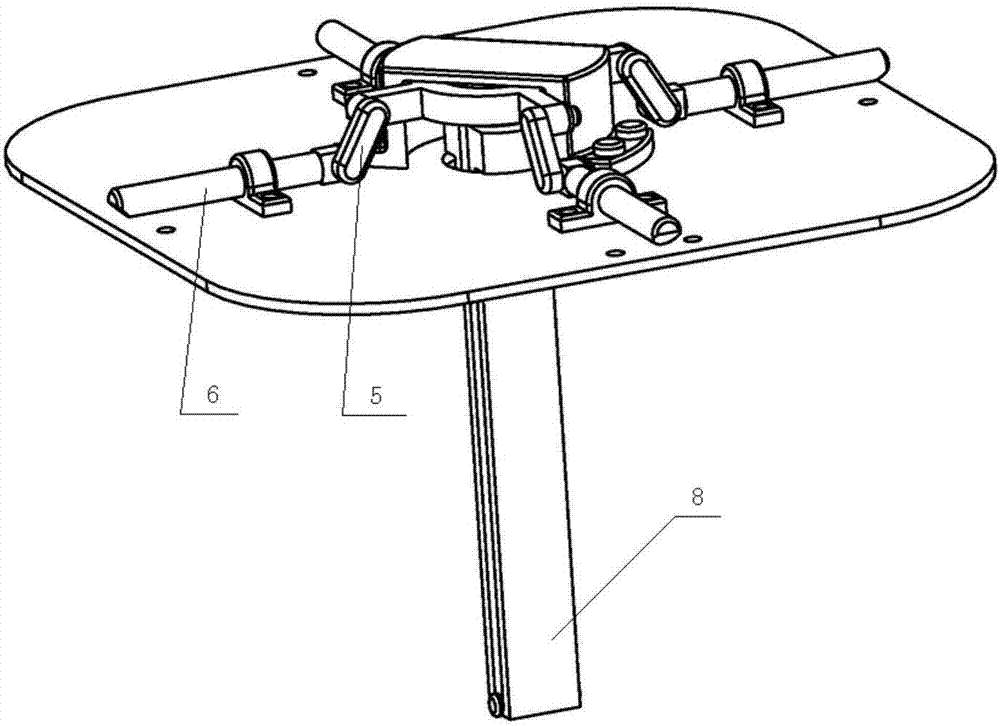

[0038] Each cover mechanism comprises parts such as locking bar, guide ring and connecting rod among the present embodiment. There is an opening in the center of the cover, and a lock cylinder is installed in the opening to operate the locking and unlocking of the cover mechanism. There are four protruding lugs around it, and the lugs are connected with the locking bar through a connecting rod. , the locking rod moves linearly along the guide ring. The lock core moves along the normal direction of the mouth cover under the action of the limit block, and a spring is arranged between the lock core and the limit block.

[0039] When the spring is in the longest state, the lugs, connecting rods and locking rods are in the over dead point position, the locking rod is stretched out, inserted into the locking ring on the mouth frame, and the lid lock mechanism is in a locked state, as figure 2 shown. Under the action of the spring, the lock cylinder remains in the locked position,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com