Connector and sectional type wind turbine blade using same

A technology for connecting parts and wind rotor blades, which is applied in the direction of connecting components, wind power generation, threaded fasteners, etc., can solve the problems of high transportation costs and difficult transportation of super-large blades, and achieve simple connection operations, easy on-site operation and installation , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

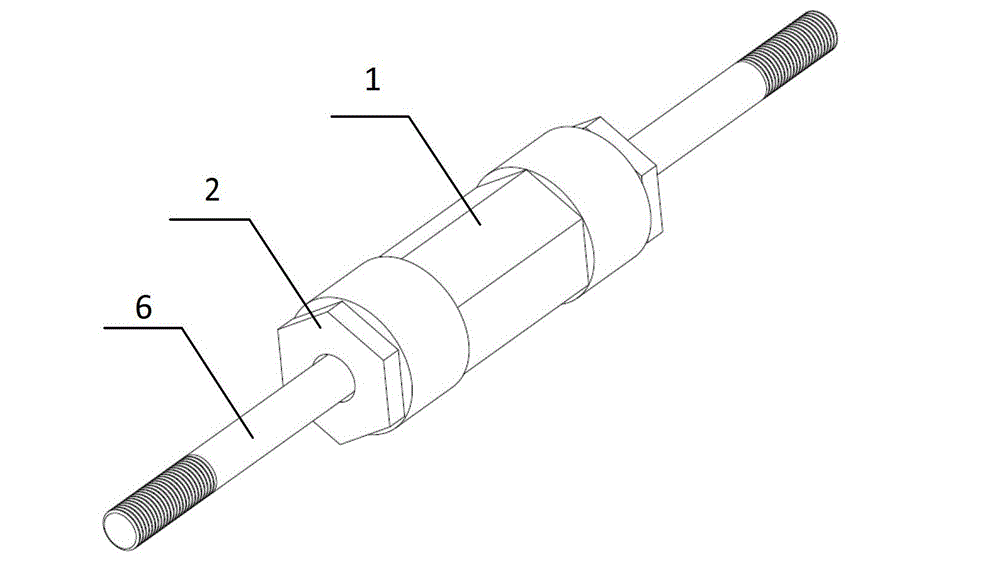

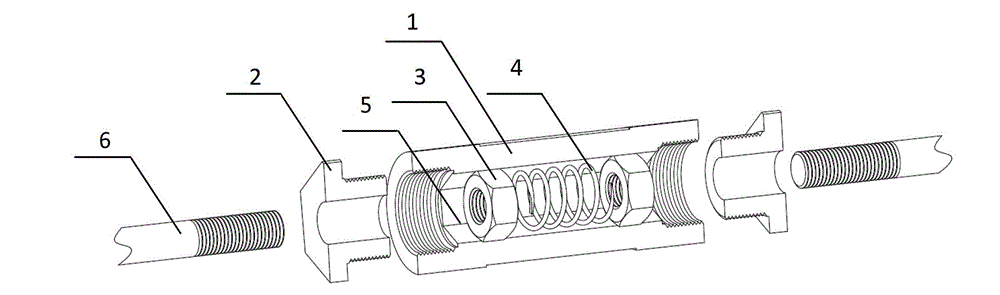

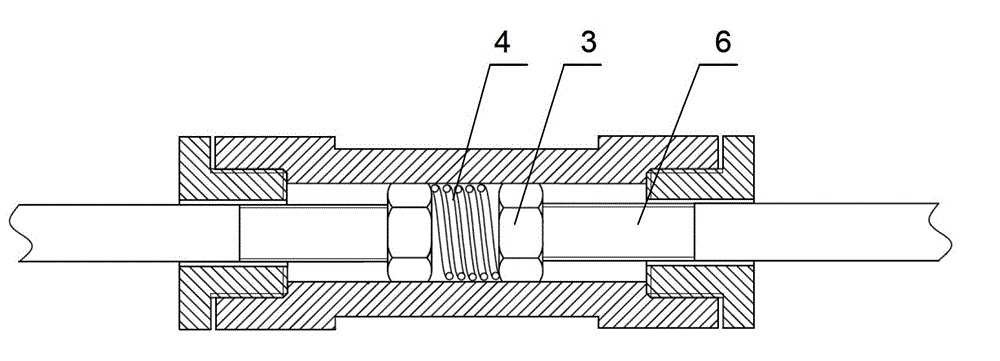

[0032] The connecting parts involved in the present invention are as figure 1 As shown in and 2 , it is used to connect two screws or bolts 6 together. The connecting parts include: a sleeve 1 , two nut retaining rings 2 , two hex nuts 3 and a spring 4 . A hexagonal channel 5 is arranged inside the sleeve 1 . The channel 5 forms a clearance fit with the hex nut 3 , and the two hex nuts 3 are located in the channel 5 and can slide in the channel 5 . The screw threads of the two hex nuts 3 are in opposite directions. The spring 4 is placed in the channel 5 between the two hex nuts 3. The inner diameter of the spring 4 is larger than the screw diameter of the screw o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com