Closing assembly for a blade ring of turbomachinery

A technology of closed components and turbines, applied in the direction of supporting components of blades, engine components, mechanical equipment, etc., can solve the problems of raising the closed component seat, raising tension parts, etc., and achieve long life, economical dismantling and reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

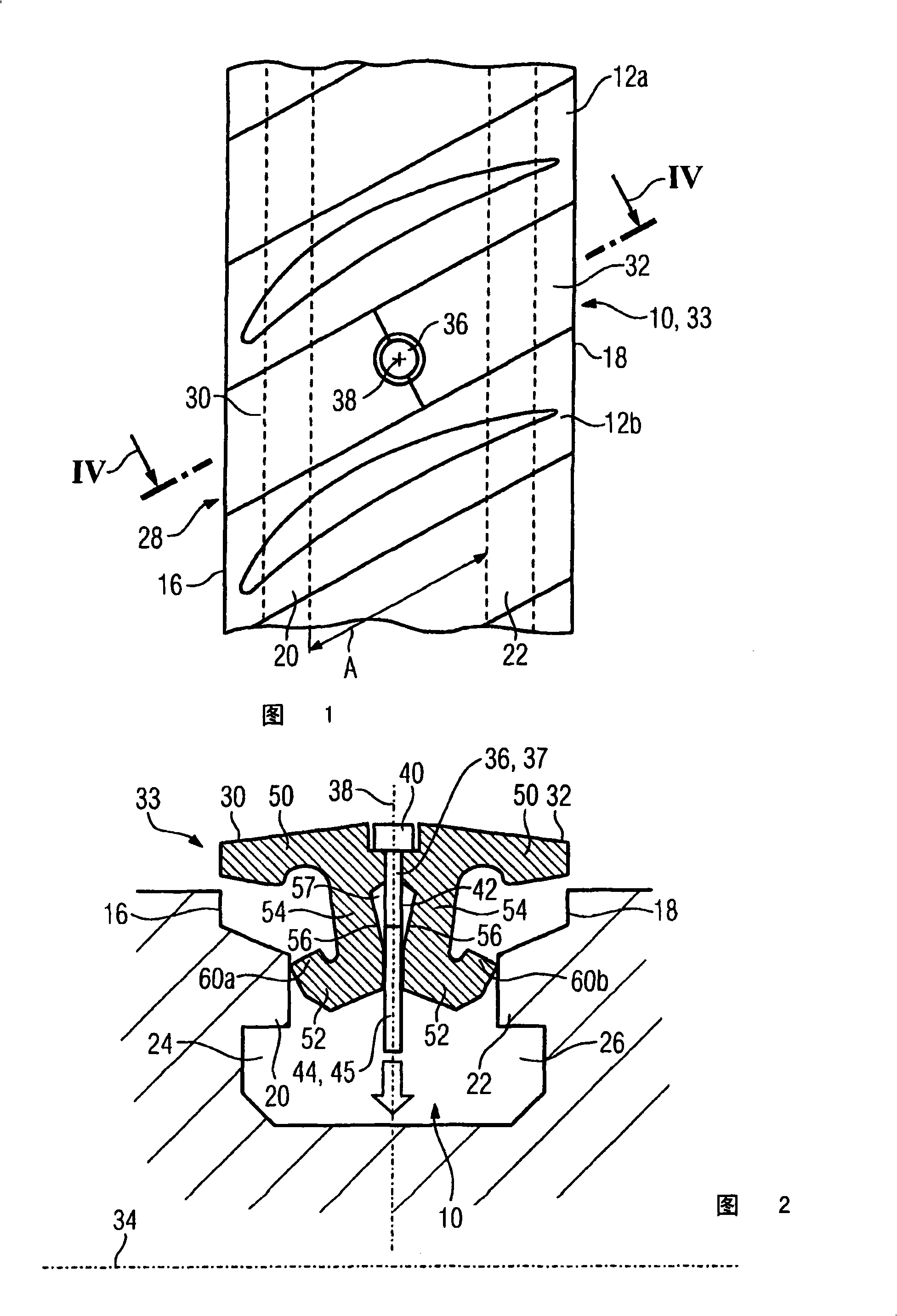

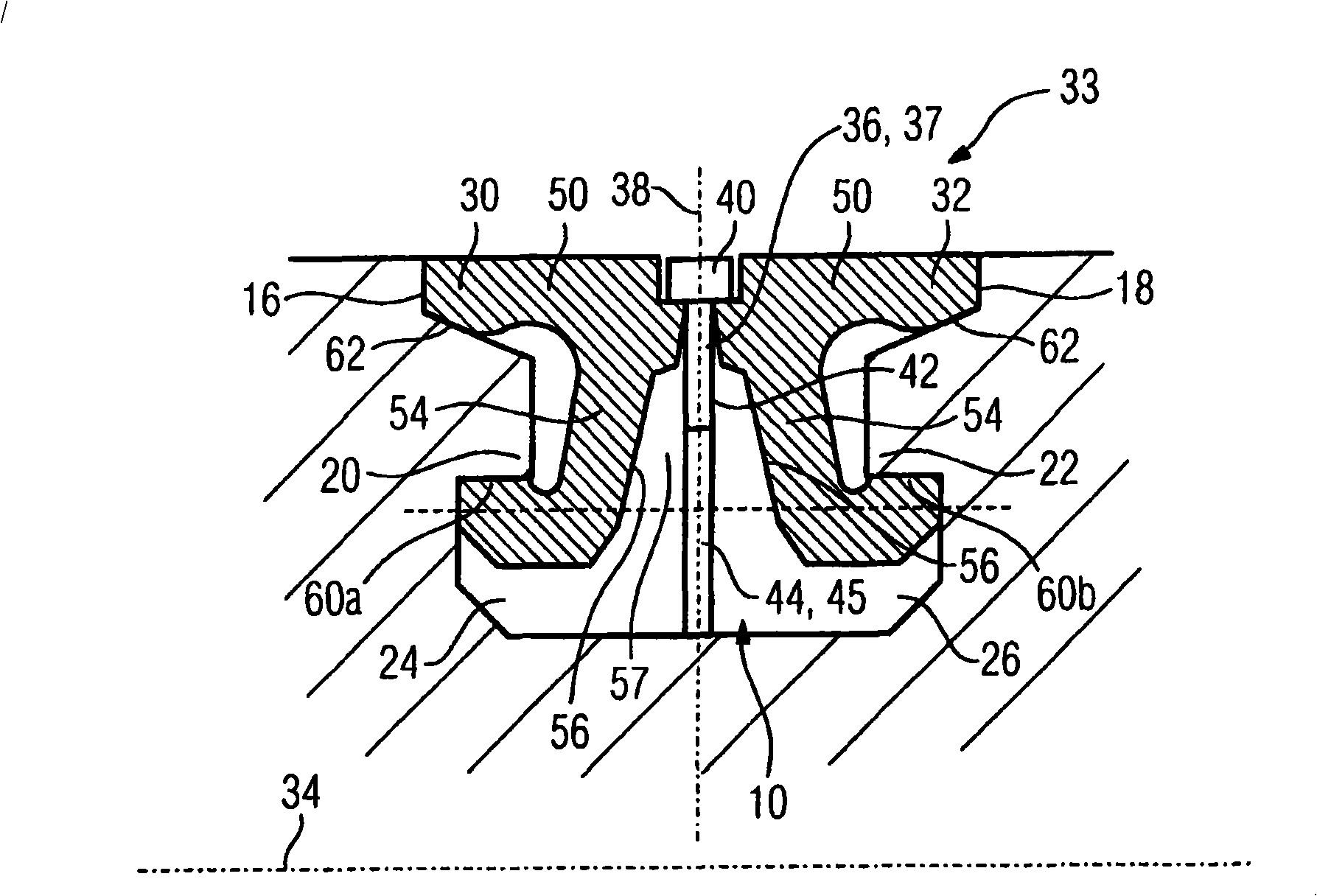

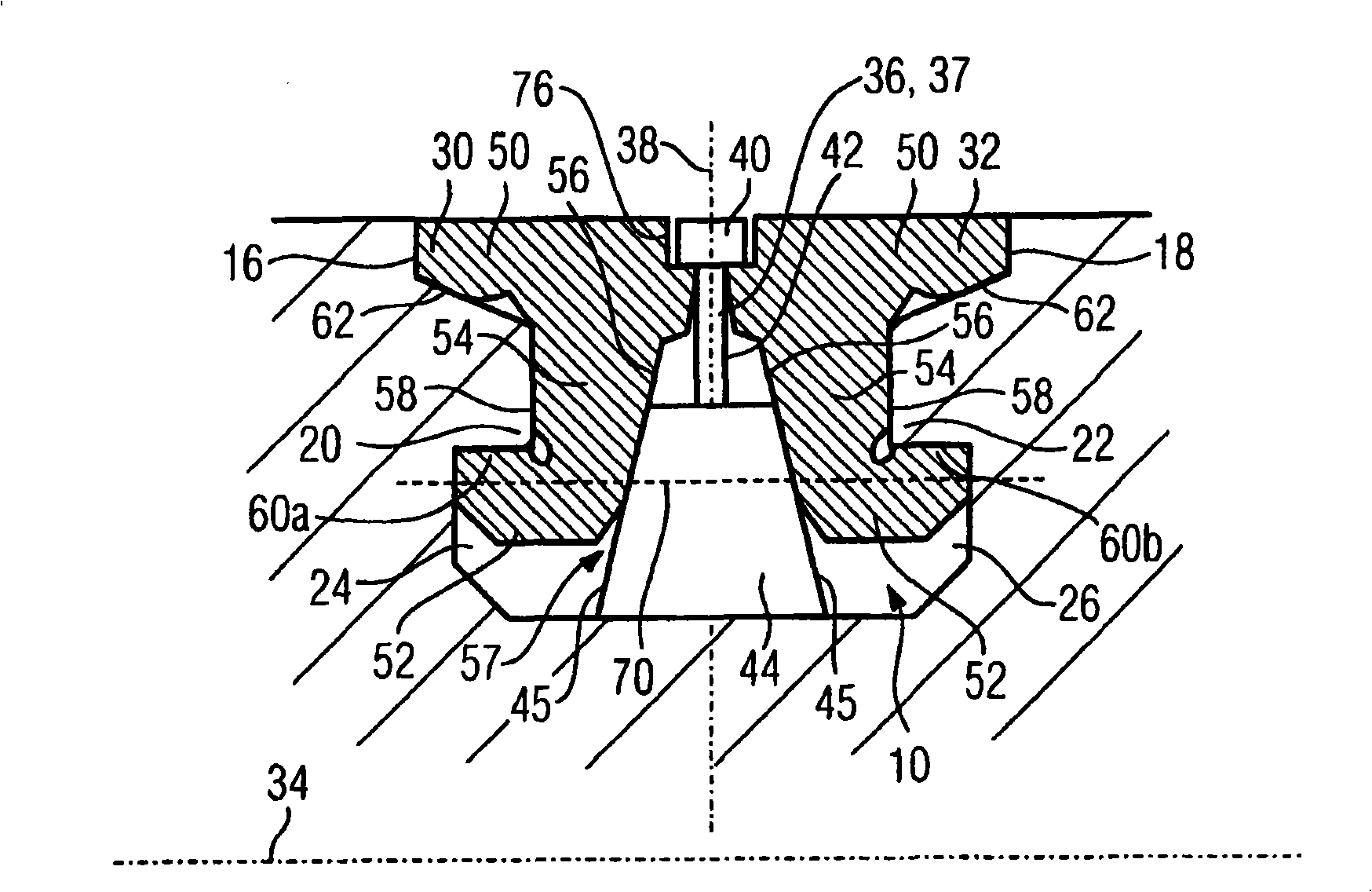

[0029] FIG. 1 shows a section of an annular groove 10 fitted with a turbine blade 12 . An annular groove 10 is provided on the outer surface of the turbine rotor. The ring groove 10 can also be provided on the inner compressor casing of the aircraft turbine, to which the turbine blades are fastened. The annular groove 10 has a front side wall 16 and a rear side wall 18 viewed in the axial direction of the rotor. On these side walls are respectively provided with protrusions 20 and 22 distributed in the circumferential direction and extending in the axial direction, which form the front side respectively. And the undercut position 24,26 (FIG. 2) of the back.

[0030] The working blades 12 a , 12 b are inserted into the ring groove 10 , and the working blades 12 a , 12 b have hammer-shaped blade roots corresponding to the undercuts 24 , 26 . In this case the rotor blades 12 a , 12 b are inserted into the ring groove 10 and then turned so far, for example through 45° or 60°, un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com