Liquid bag quick disassembling structure and assembling and disassembling methods

A liquid bag, fast technology, applied in the quick disassembly structure of liquid bag and the field of assembly and disassembly, which can solve the problems of troublesome installation and disassembly, wrong disassembly, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

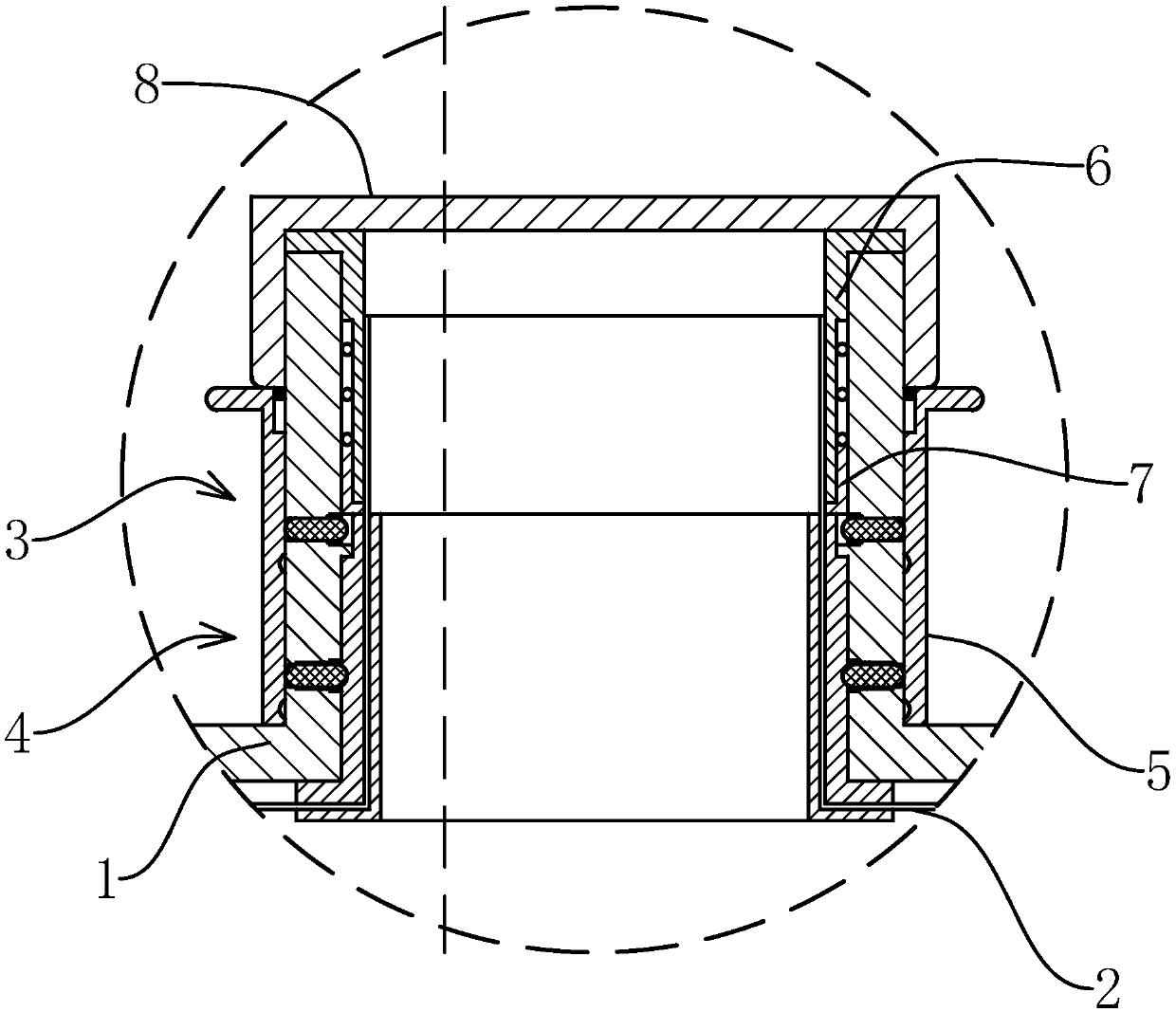

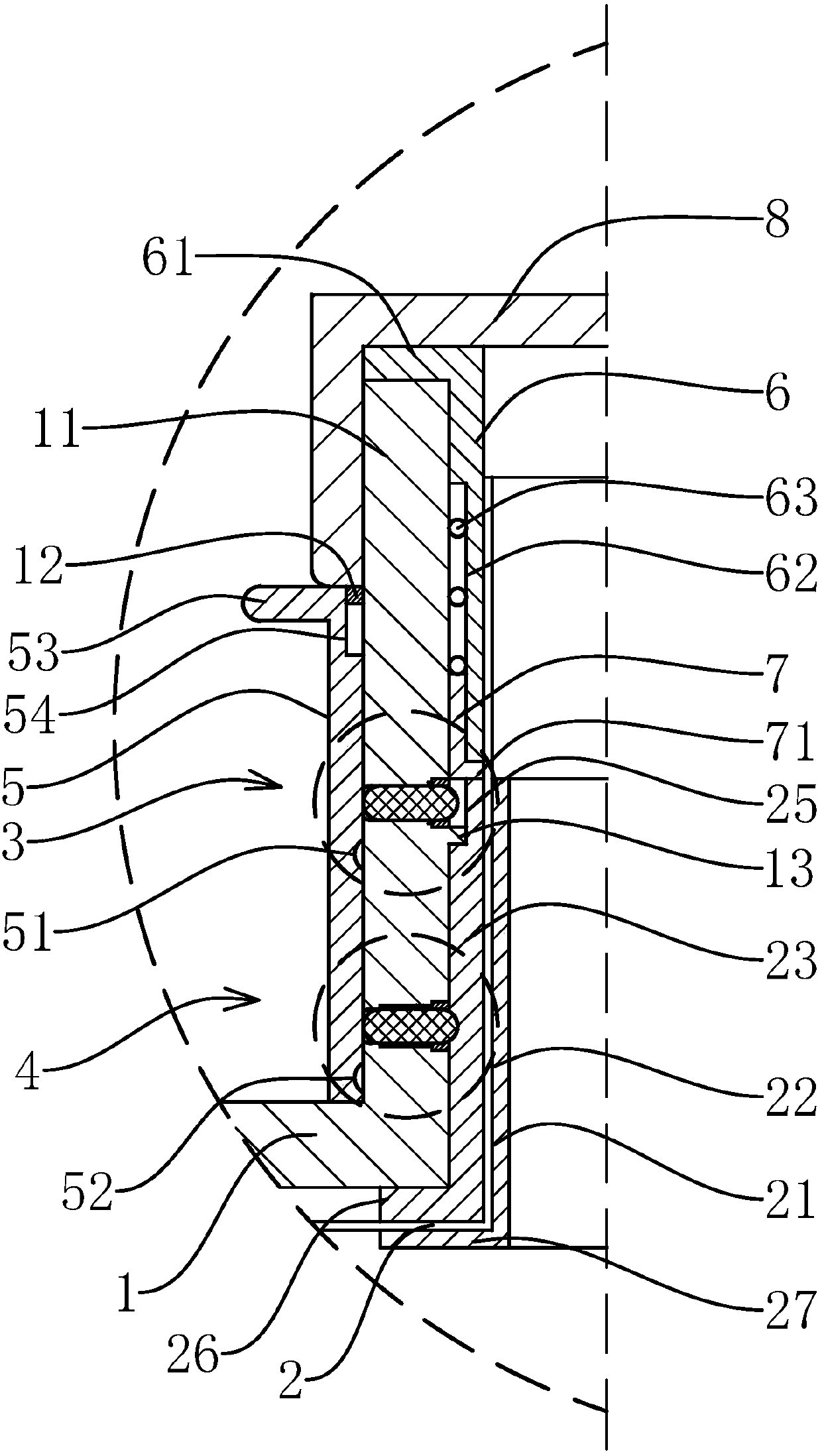

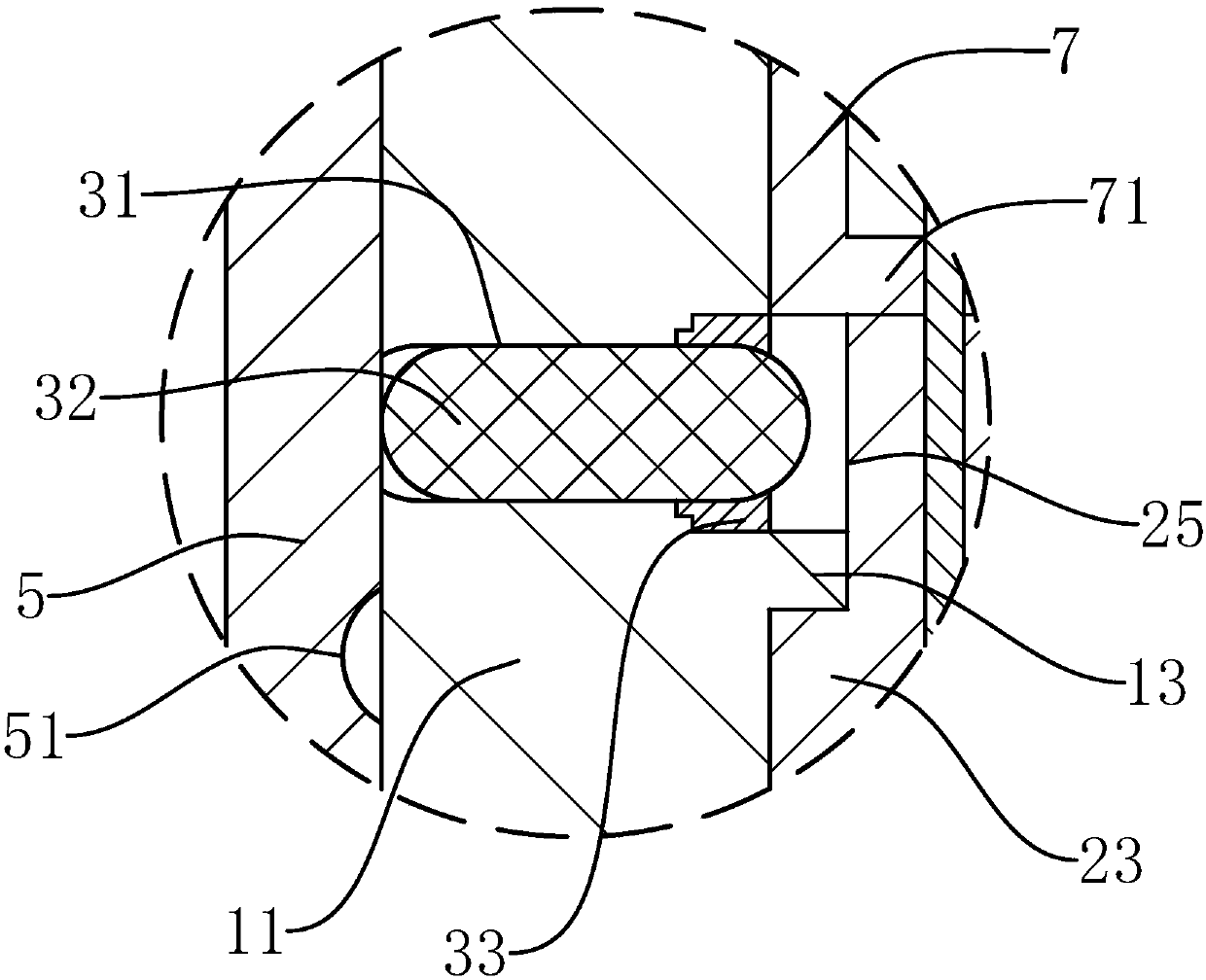

[0044] like Figure 1-5 As shown, a liquid bag quick disassembly structure of the present invention includes a carriage 1, the top of the carriage 1 has a bottom end communicating with the interior of the carriage 1, and a cylindrical inlet and outlet barrel 11 with a vertical axis, and also includes a 1, and a sealed flexible liquid bag 2 for placing food. The liquid bag 2 is provided with a cylindrical inlet and outlet, and a soft liner 21 is fixed on the inlet and outlet. The inlet and outlet barrel 11 is provided with a number of marble mechanisms. 3 and some pinball mechanism two 4, and pinball mechanism one 3 comprises cylindrical pinhole one 31 and the cylindrical pinball one 32 that is movably embedded in bead hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com