Upsetting plasma arc welding fixture for aluminum-based composite material and arc welding method thereof

An aluminum-based composite material and plasma arc technology, which is applied in plasma welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problem of inability to realize the instantaneous extrusion of the aluminum-based composite material rod molten pool and the inconvenient opening distance of the spring due to the pressure Adjustment, can not produce joint impact and upsetting, etc., to improve the deterioration of weld structure, shorten the connection time, and achieve the effect of full weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

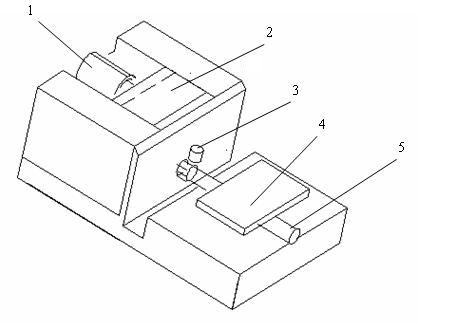

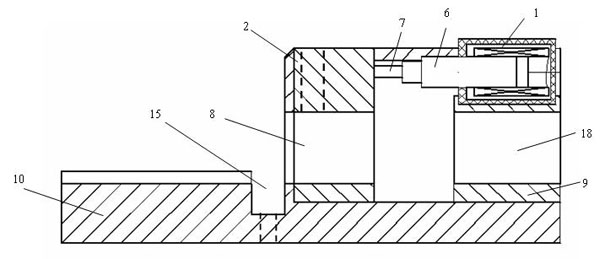

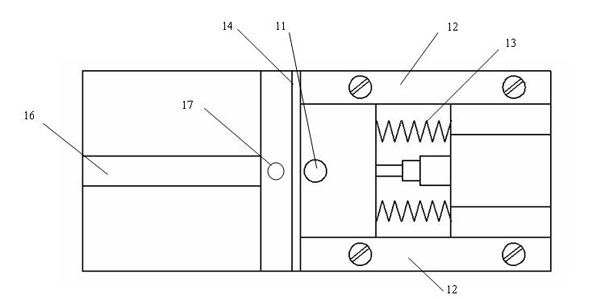

[0021] combine figure 1 , figure 2 , image 3 , an aluminum-based composite material upsetting plasma arc welding fixture of the present invention includes an electromagnet 1, a dynamic pressure plate 2, a static pressure plate 4, a moving iron core 6 of the electromagnet, a connecting rod 7, a rear baffle plate 9, a base 10, Baffle plate 12, spring 13, front baffle plate 14;

[0022] A rear baffle 9 is arranged on the base 10, and an electromagnet 1 is fixedly connected on the rear baffle 9, and a dynamic pressure plate 2 is arranged in front of the electromagnet 1, and the electromagnet 1 passes through the moving iron core 6, the connecting rod 7 and the dynamic pressure plate 2 Connected to push the dynamic platen 2 to move, the two sides of the dynamic platen 2 are provided with baffles 12 fixedly connected to the base 10, the baffles 12 limit the lateral position of the dynamic platen 2, and the front of the dynamic platen 2 is fixedly connected to the base 10 The fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com