Patents

Literature

91results about How to "Reduce pressure area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

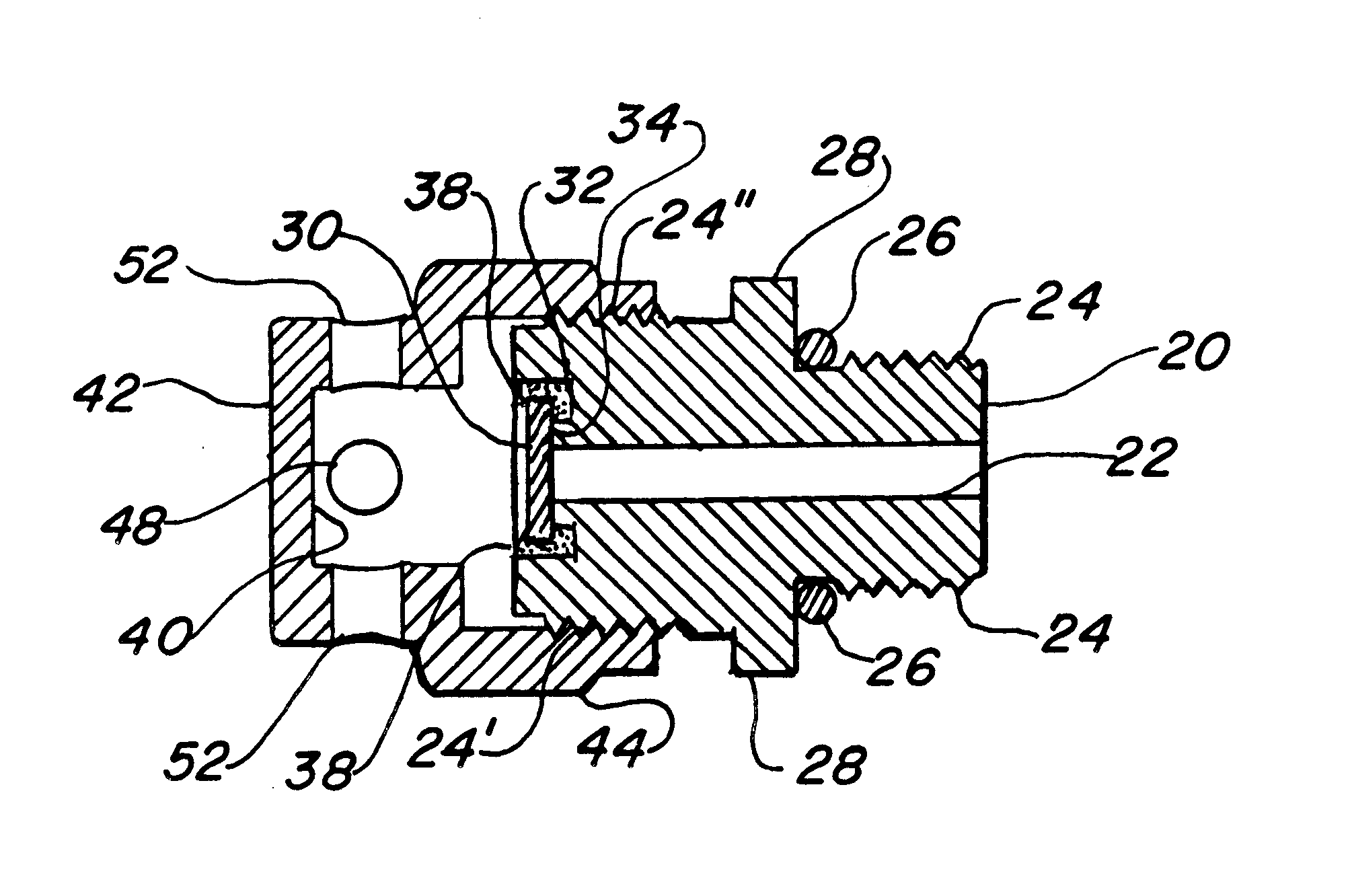

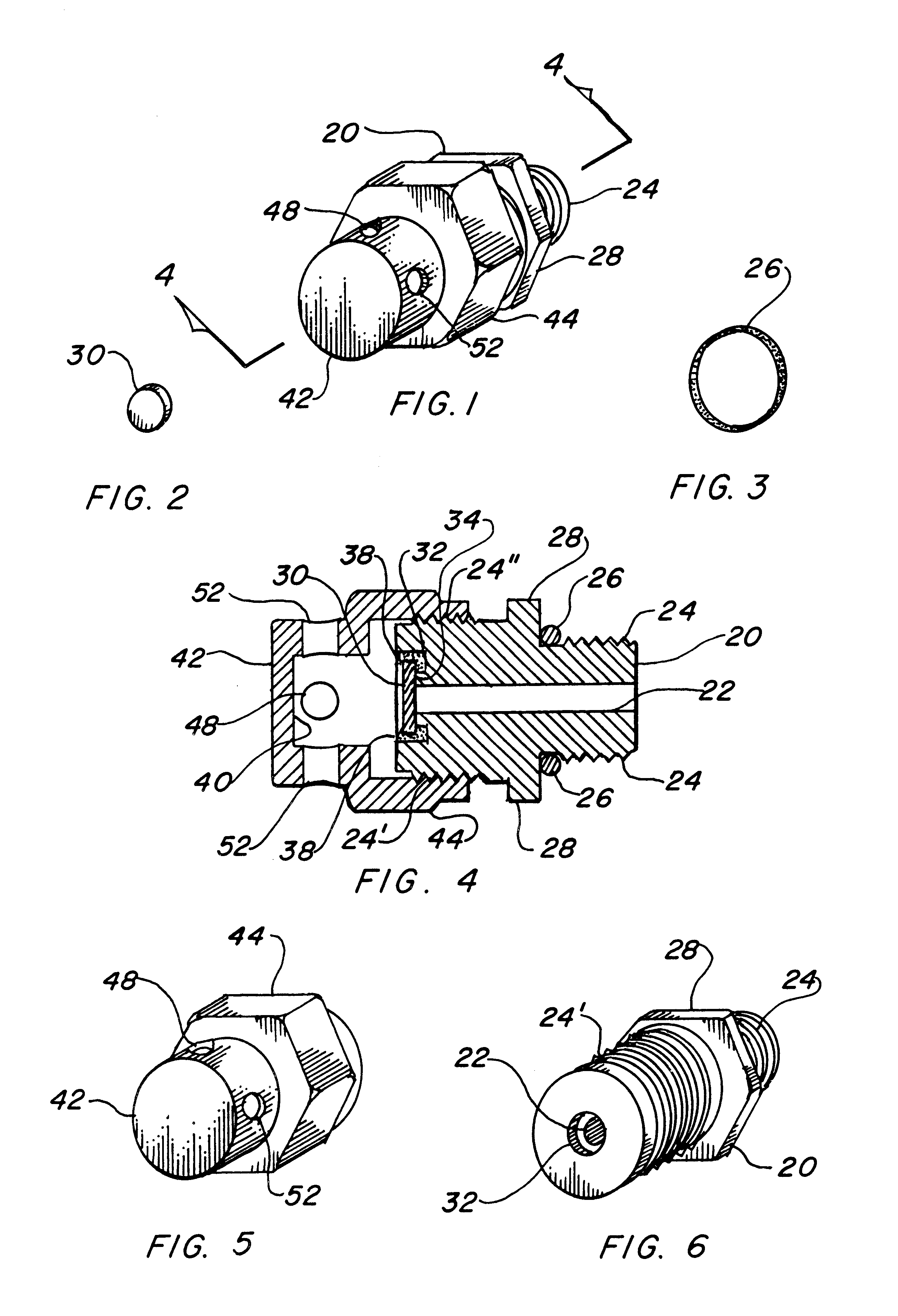

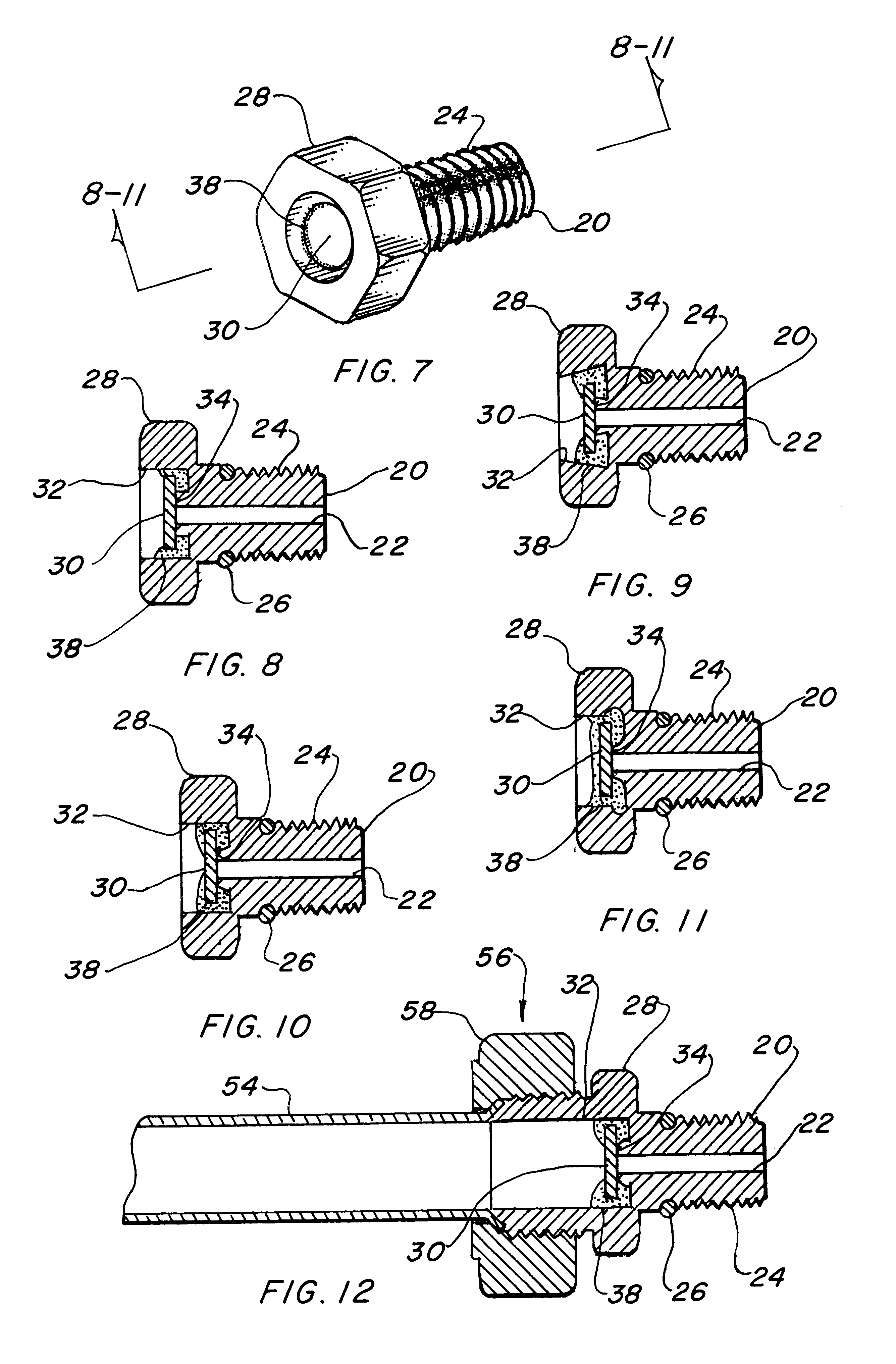

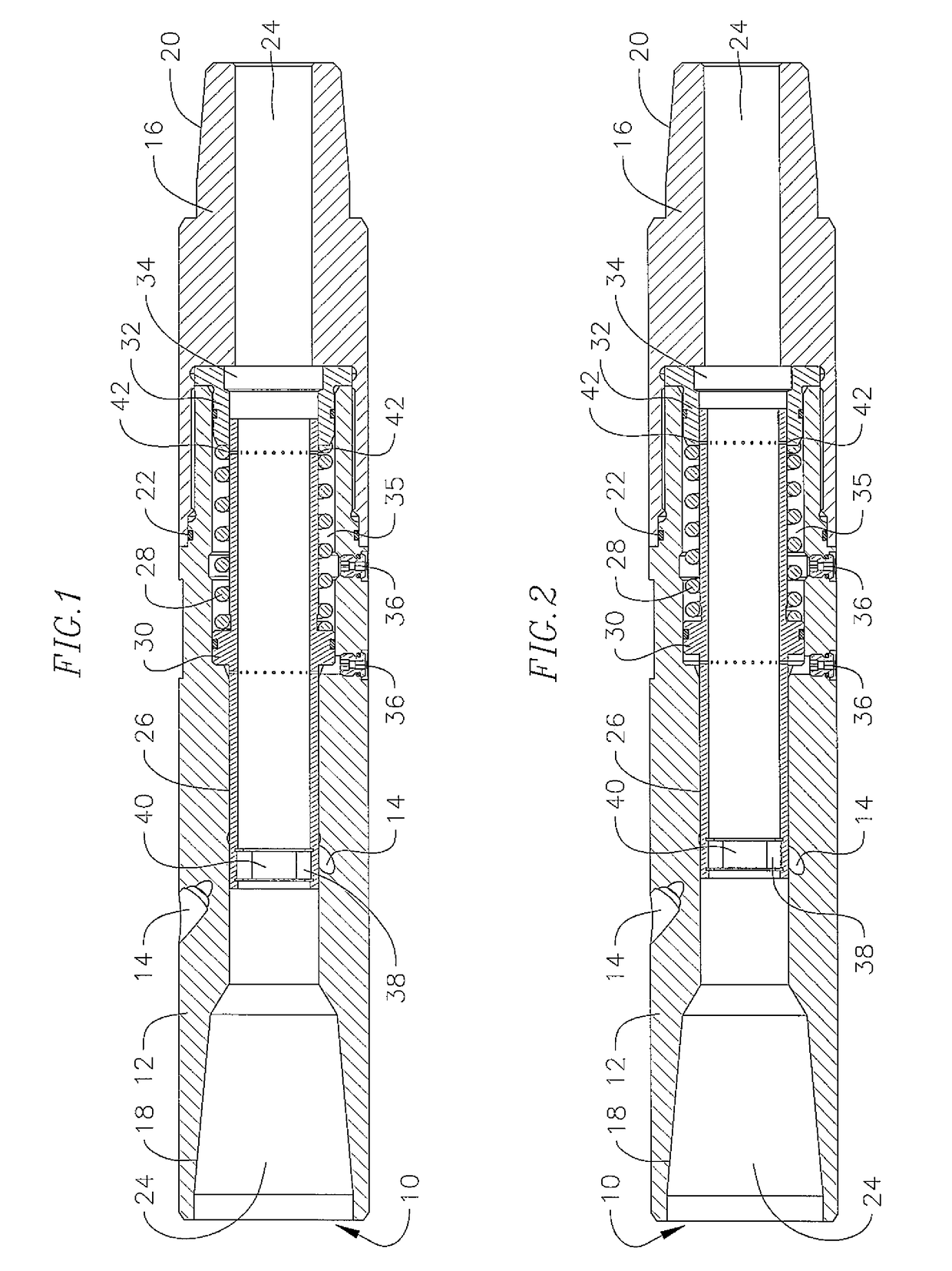

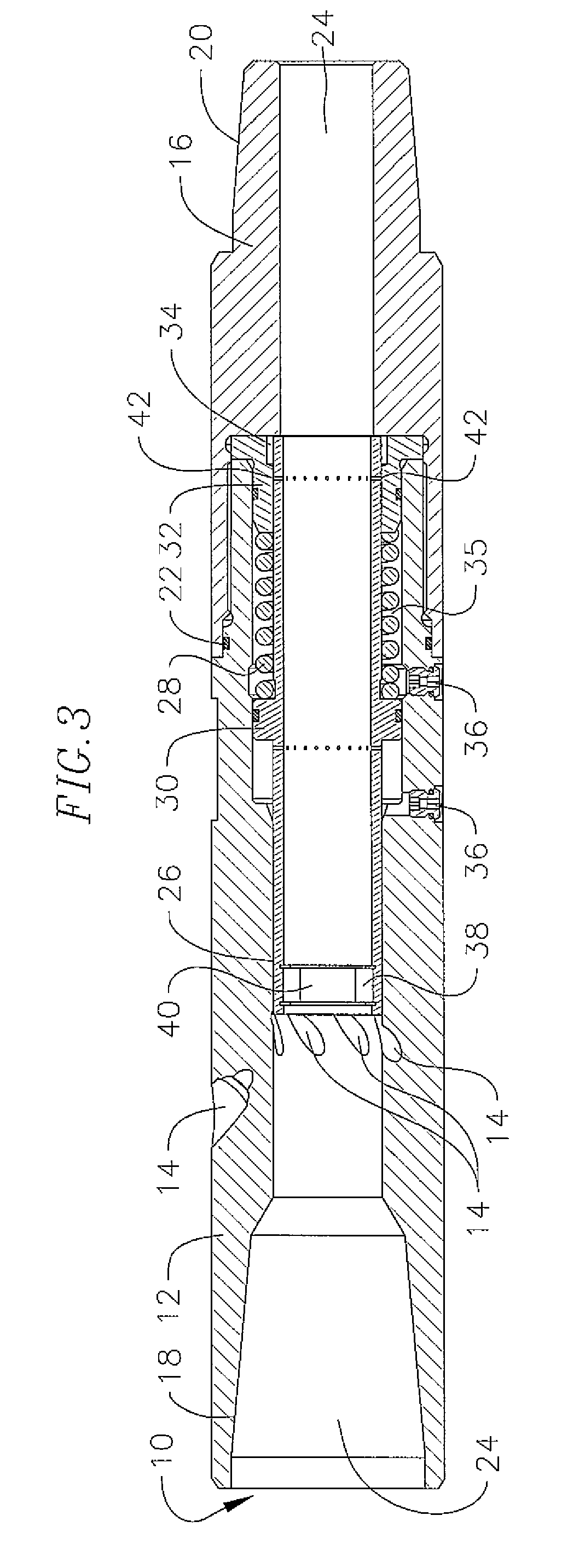

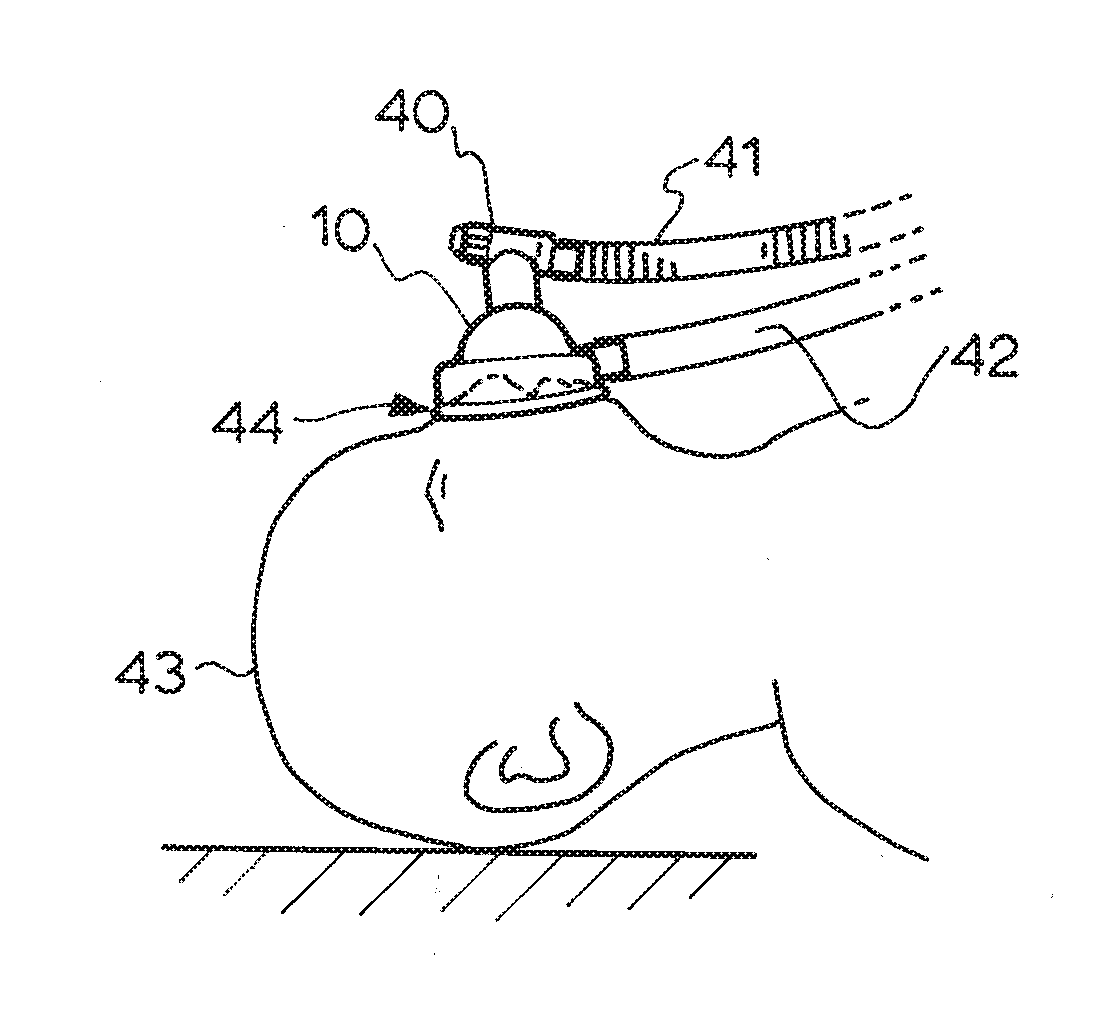

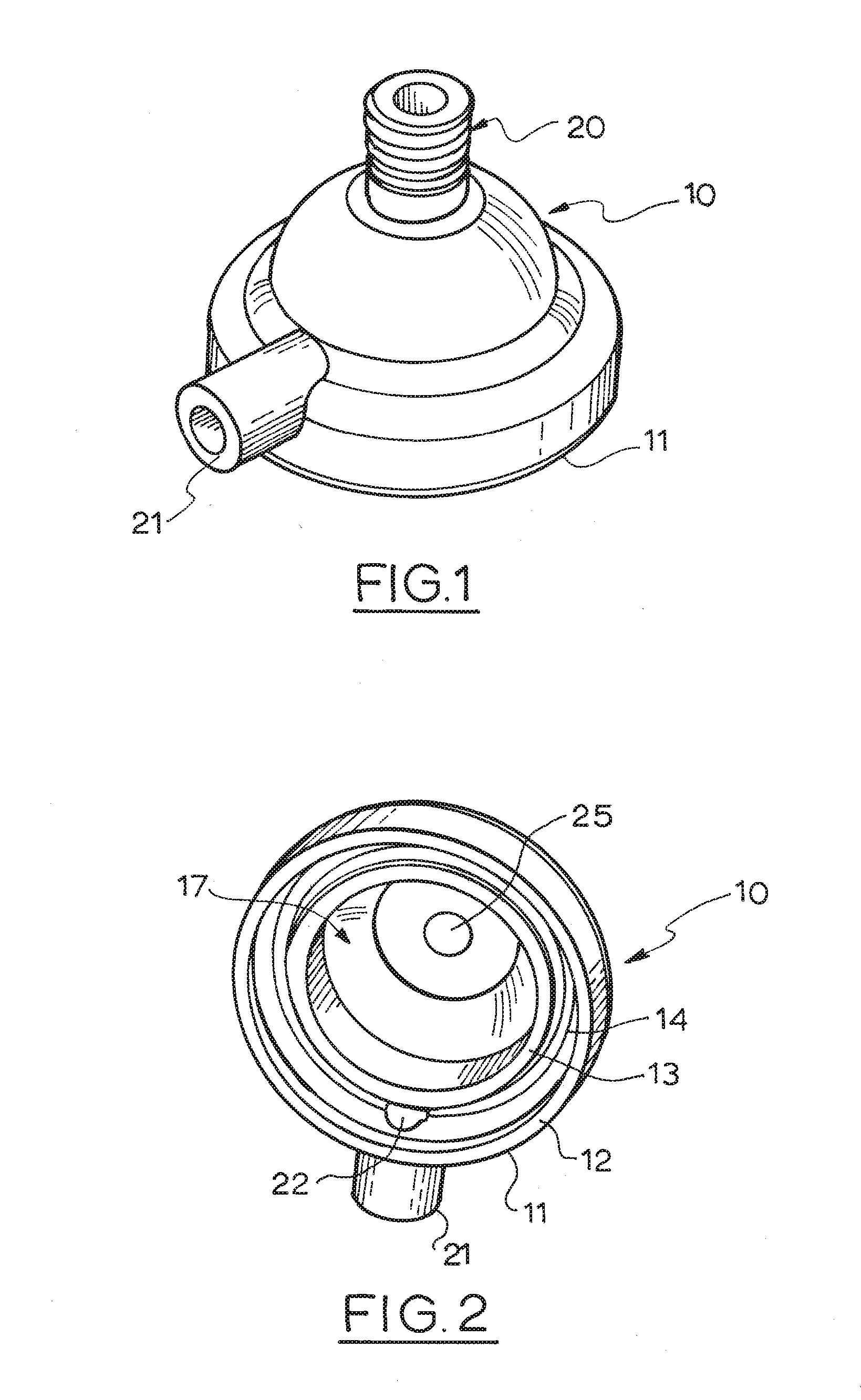

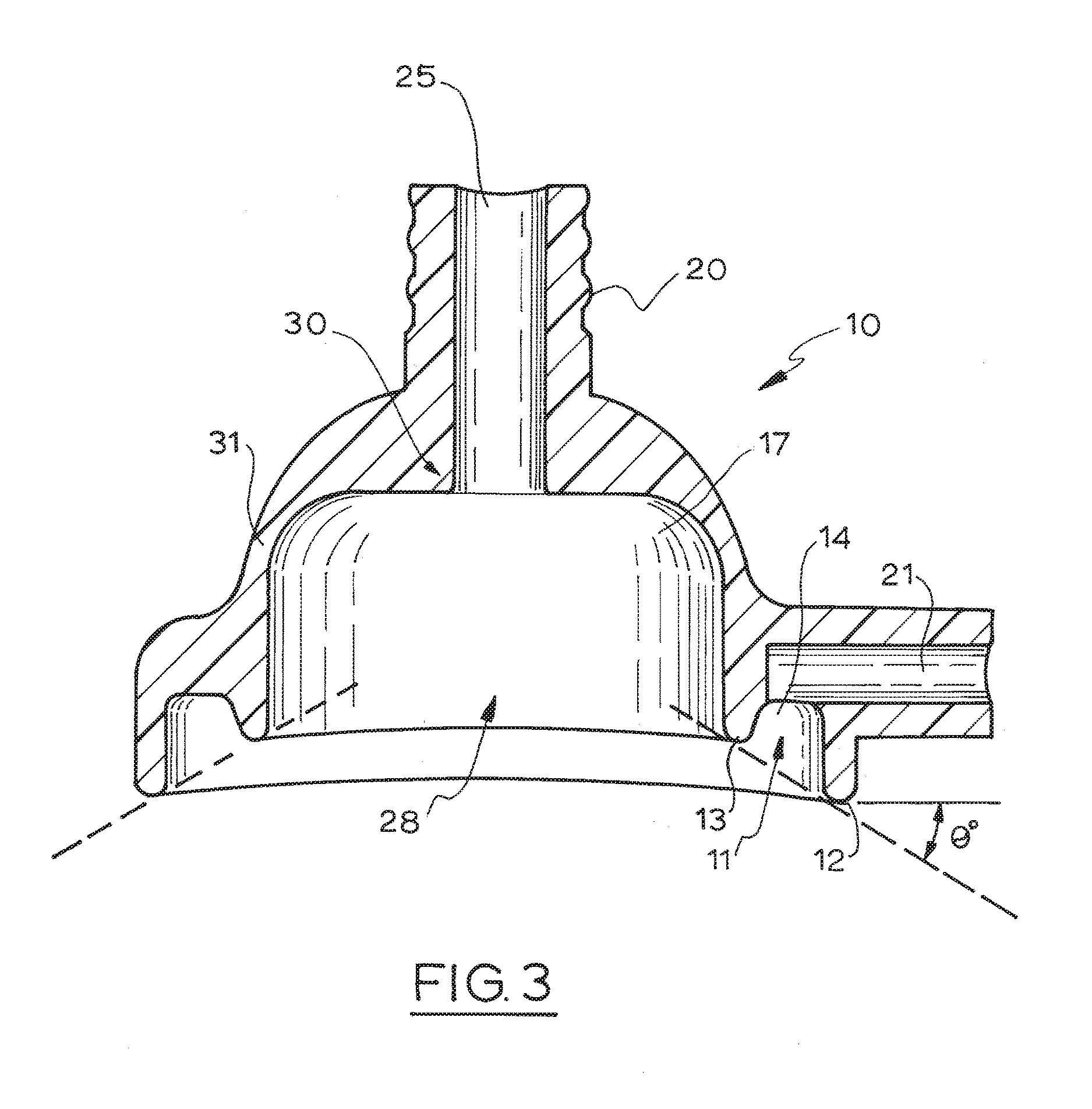

Thermal-pressure relief device

InactiveUS6866057B1Increase bonding areaReduced pressure areaLarge containersEqualizing valvesThermal compressionHot press

A thermal-pressure relief device, which has an adapter (20) threaded into the wall of a pressure vessel. The adapter contains an orifice (22) therethrough in line with a recessed cavity (32) which includes a raised stem (34). A blow out member (30) rests on the stem and overlaps the orifice to obstruct communication with the fluid inside the vessel. The blow out member is attached within the cavity by brazing with a filler metal in the form of a temperature responsive amalgam (38), preferably a eutectic alloy. When ambient temperatures are elevated above the melting point of the amalgam the blow out member is released freeing the orifice relieving the pressure within the vessel preventing a sudden structural failure. Optionally a protective cover in the form of a cap (42) with an impact surface (40) contains the blow out member when it separates from the adapter and a number of vents (48) diffuse the fluid from the pressure vessel in a safe direction. Another option for the protective cover is a tube (54) attached to the adapter with fastening means such that when the blow out member is released the conduit provides a safe structurally sound flow path permitting the pressurized fluid to be directed into a safe zone away from the thermal-pressure relief device.

Owner:BUEHRLE II HARRY W

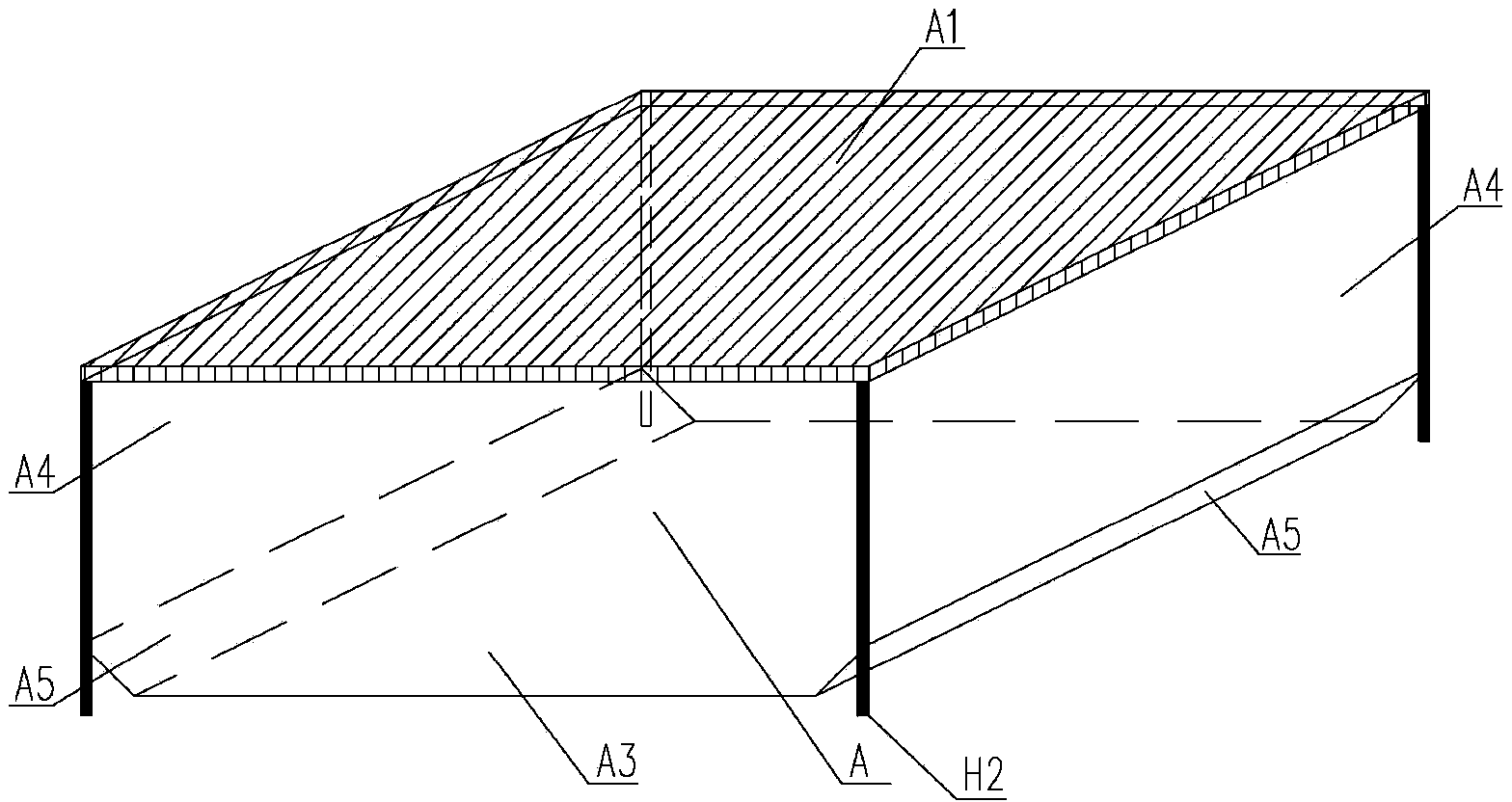

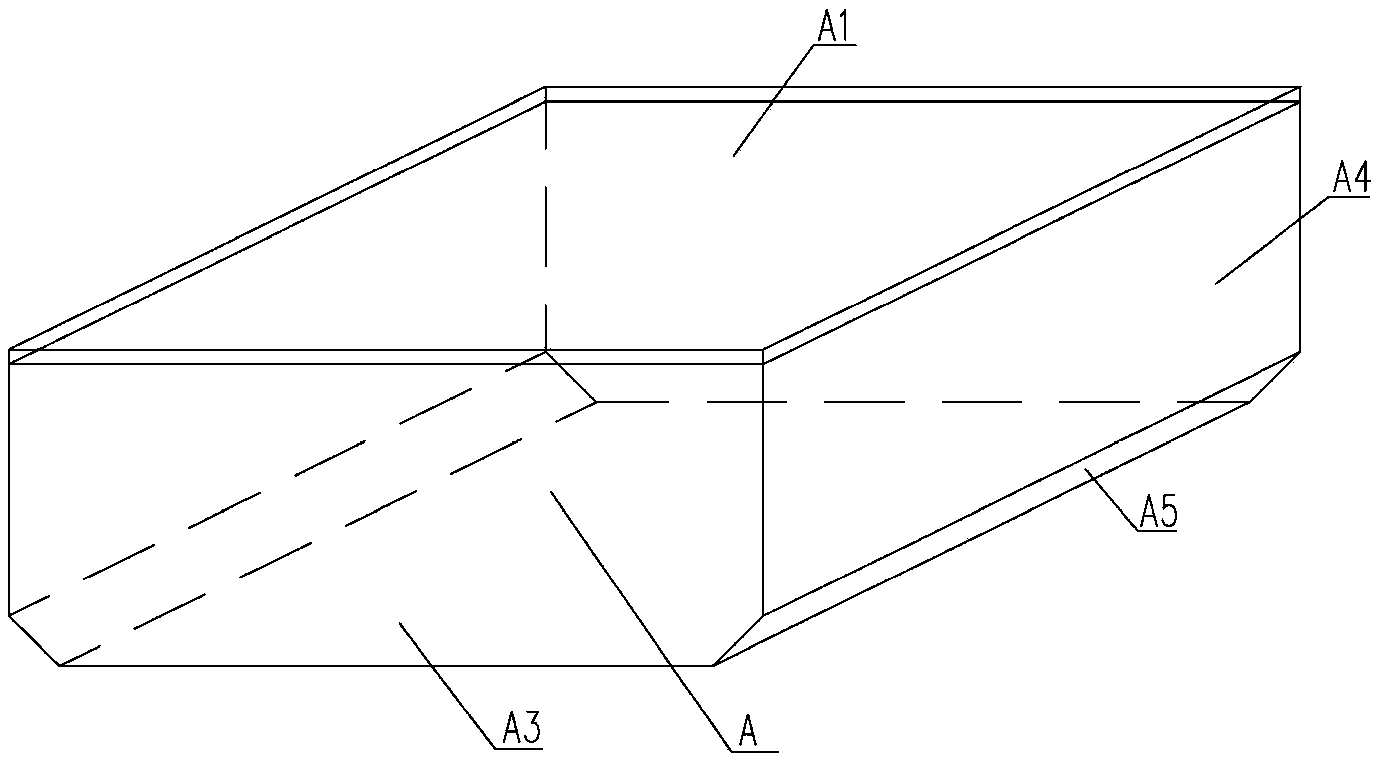

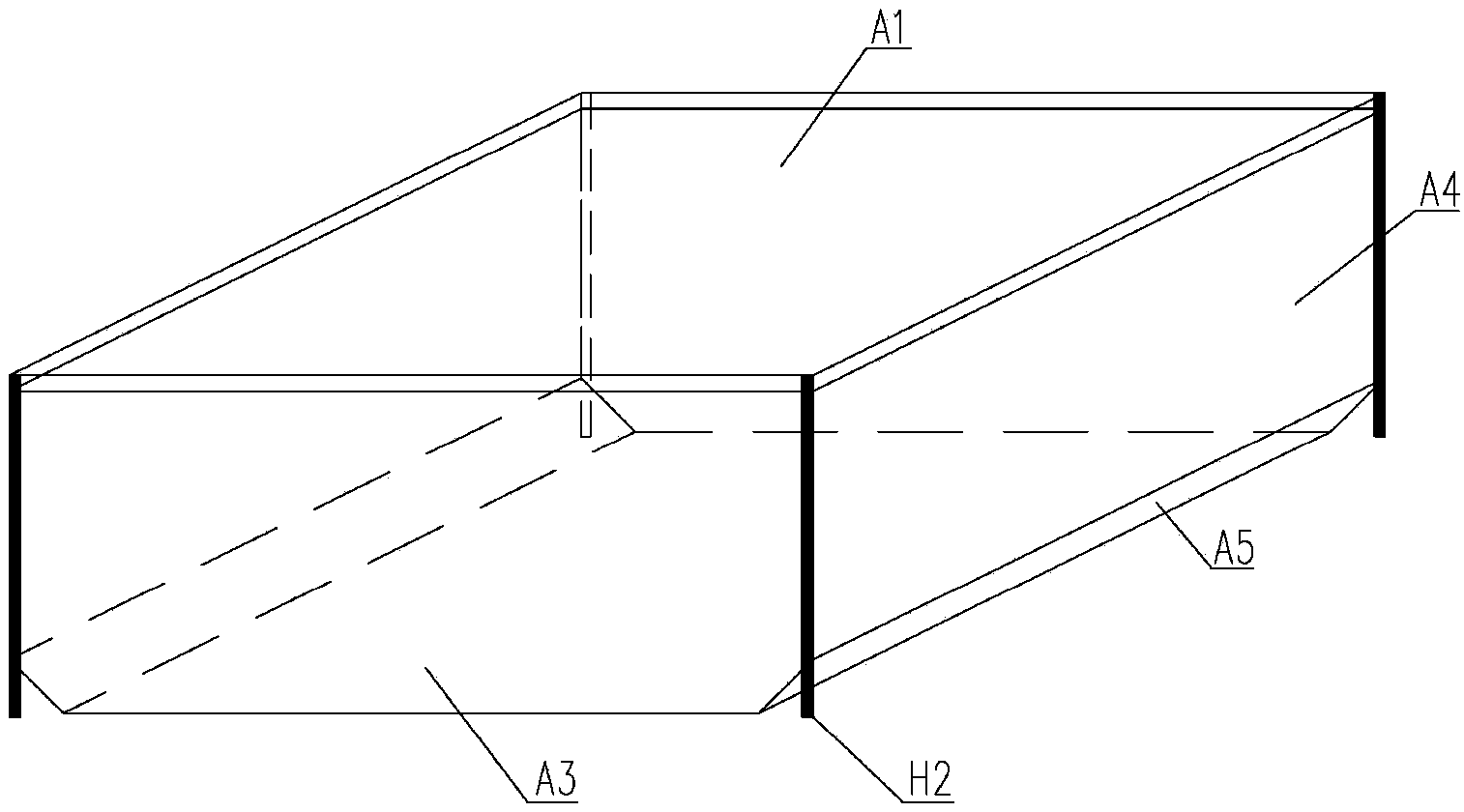

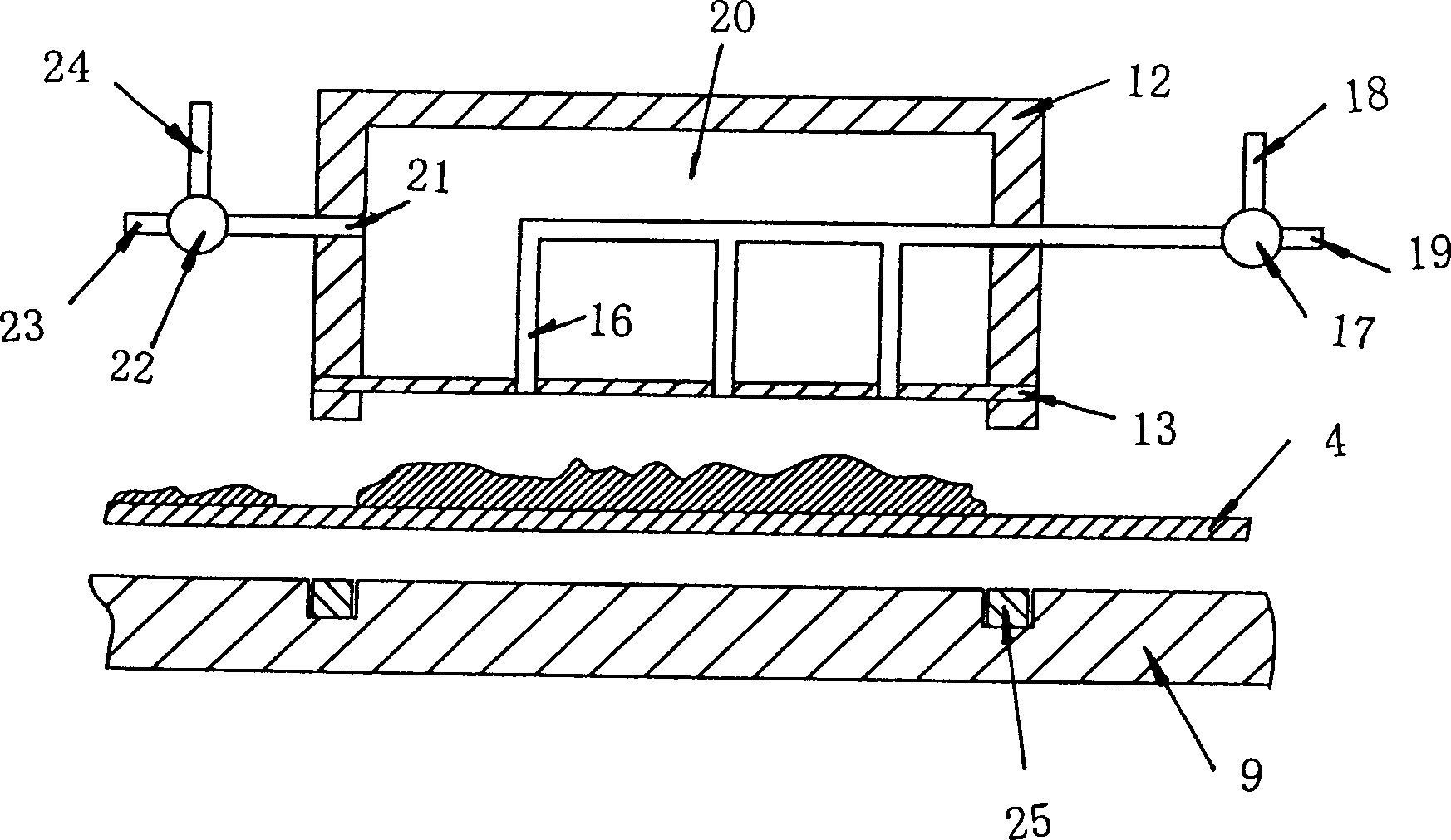

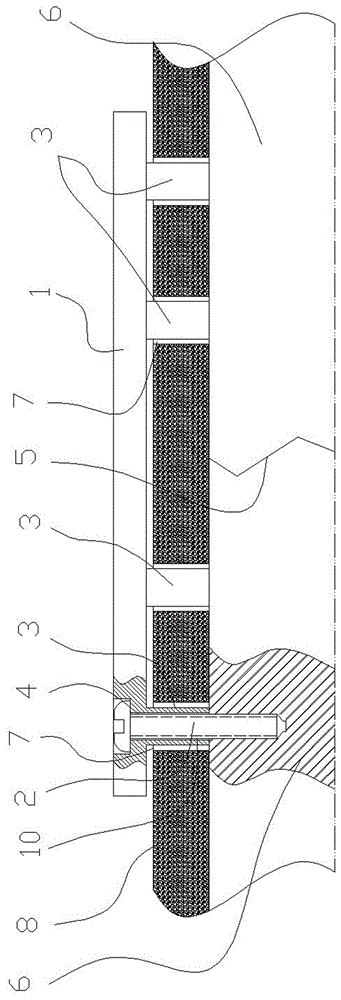

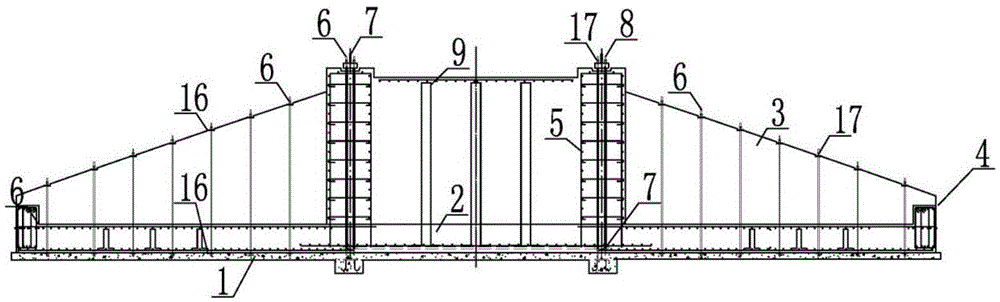

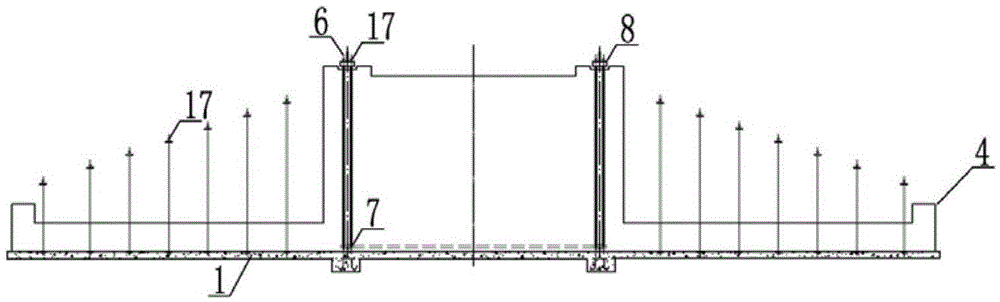

Cast-in-situ hollow floor with pores formed by reticular box-shaped component

The invention provides a cast-in-situ hollow floor with pores formed by a reticular box-shaped component. The cast-in-situ hollow floor comprises a reinforced concrete girder or a profile steel girder, a reinforced concrete ribbed beam, an upper flange plate, a lower flange plate and the reticular box-shaped component, wherein the reticular box-shaped component comprises a box roof, a box body and a box bottom; the box roof is compounded with cement mortar, polyfoam or a panel; the box body and the box bottom are made of reticular bodies; each reticular body comprises a reticular plate, a reinforcing rib and a connecting net, which constitute an integral structure with mutual effect; each of the reinforcing ribs is V-shaped; the reticular box-shaped component comprises at least two reticular bodies; at least two structural slopes are arranged at the corner parts between the box bottom and the box body of the reticular box-shaped component; the reticular bodies of the reticular box-shaped component are made of a steel material or a molding material. The cast-in-situ hollow floor with the pores formed by the reticular box-shaped component adopts the unsealed reticular box-shaped component to substitute the existing fully-sealed hollow fillers and solid fillers as the cast-in-situ hollow floor pore-forming technology. The cast-in-situ hollow floor with the pores formed by the reticular box-shaped component is favorable to realization of building and energy conservation integration and the multifunctional floor.

Owner:HUNAN BDF ENERGY SAVING TECH

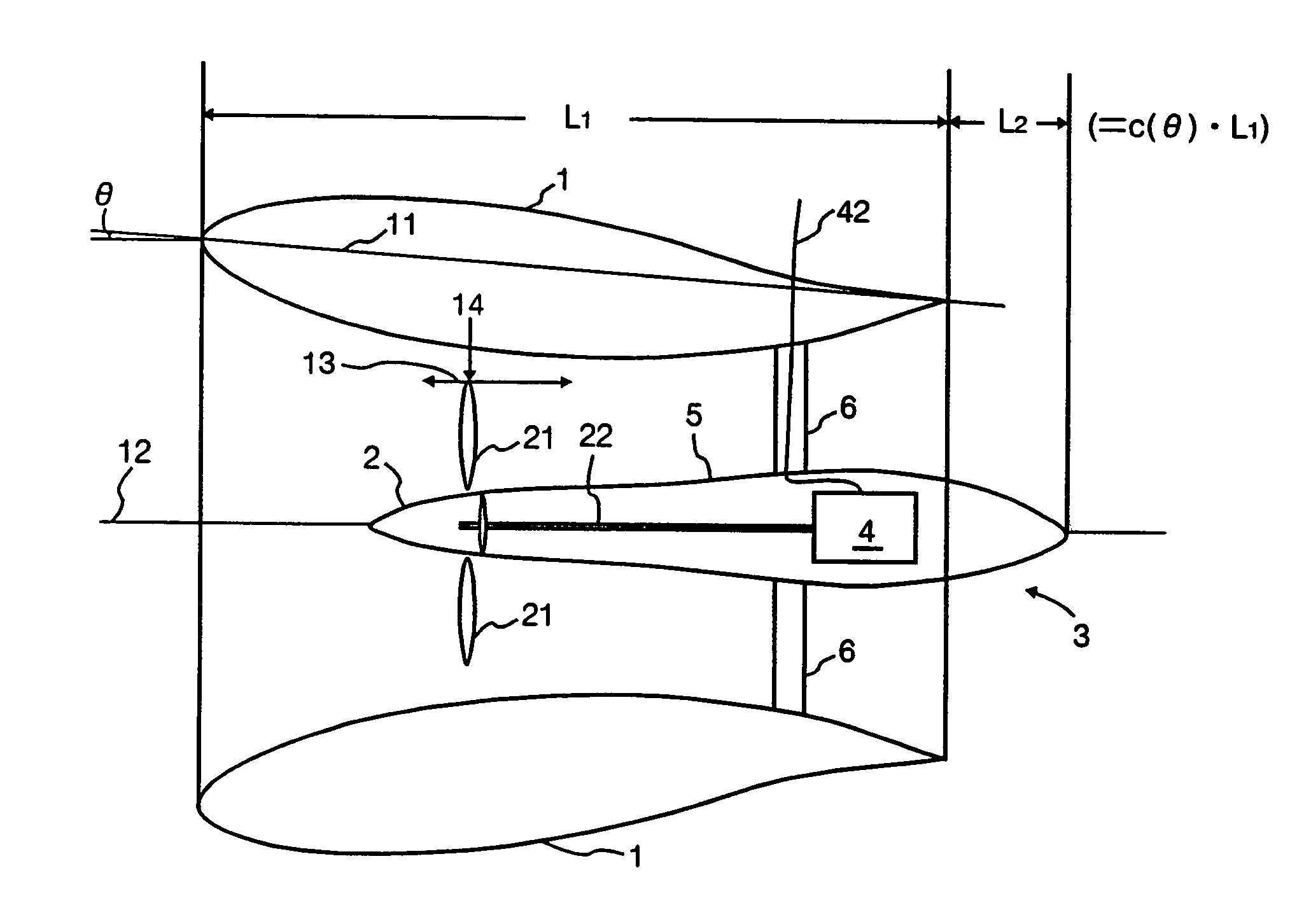

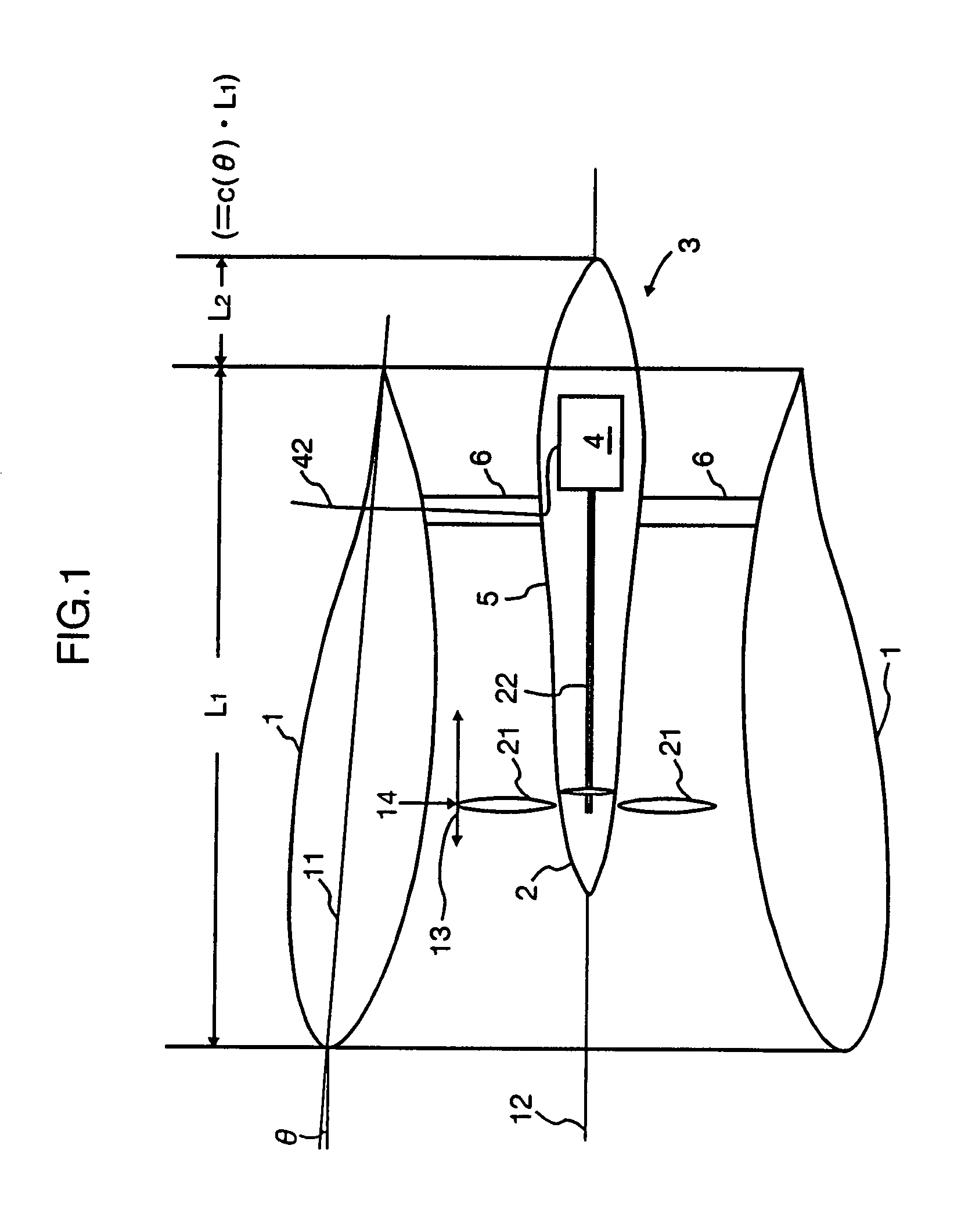

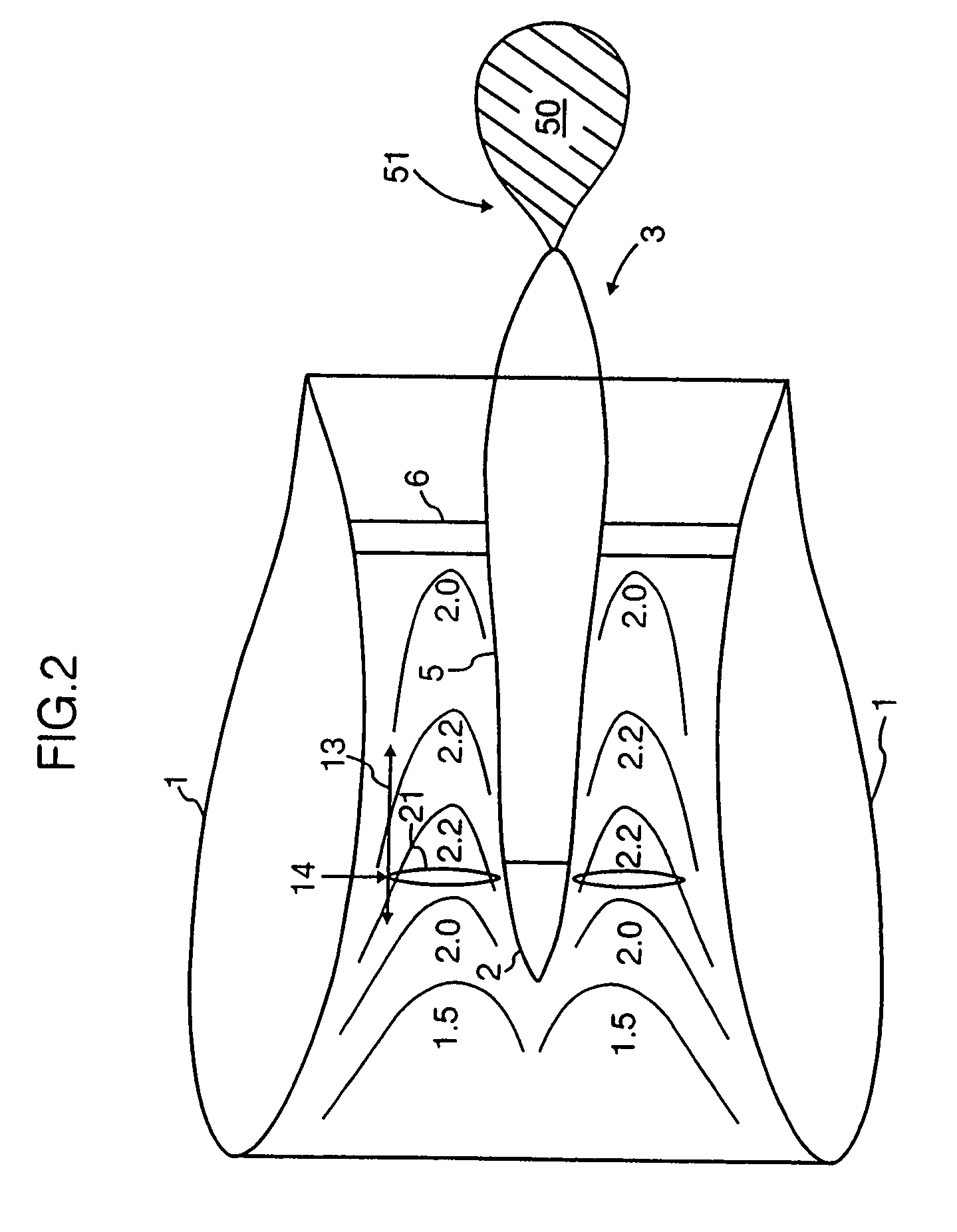

Wind power generation device

InactiveUS7354245B2Increase wind speedEliminating flow of windWind motor controlPump componentsImpellerNacelle

A wind power generation device capable of improving power generation efficiency is provided. The wind power generation device according to the present invention comprises: a substantially cylindrical duct 1 having a side wall with a substantially wing section; an impeller 2 rotatable around an axis of the duct 1; and a nacelle 5 that constitutes a streamlined pencil body 3 together with the impeller 2 and houses a generator 4 that uses torque of the impeller 2. The duct 1 has the side wall with the wing section so as to be able to produce a reduced pressure area at a rear of the duct and prevent generation of swirl at the rear of the duct 1. The pencil body 3 is provided so that a tip thereof is placed in the duct 1 and a rear end thereof protrudes from a rear end of the duct 1 so as to be close to a tip of the reduced pressure area produced at the rear of the duct 1. Blades 21 of the impeller 2 are provided in a maximum wind speed area 13 in the duct 1.

Owner:BABA TECHN LAB

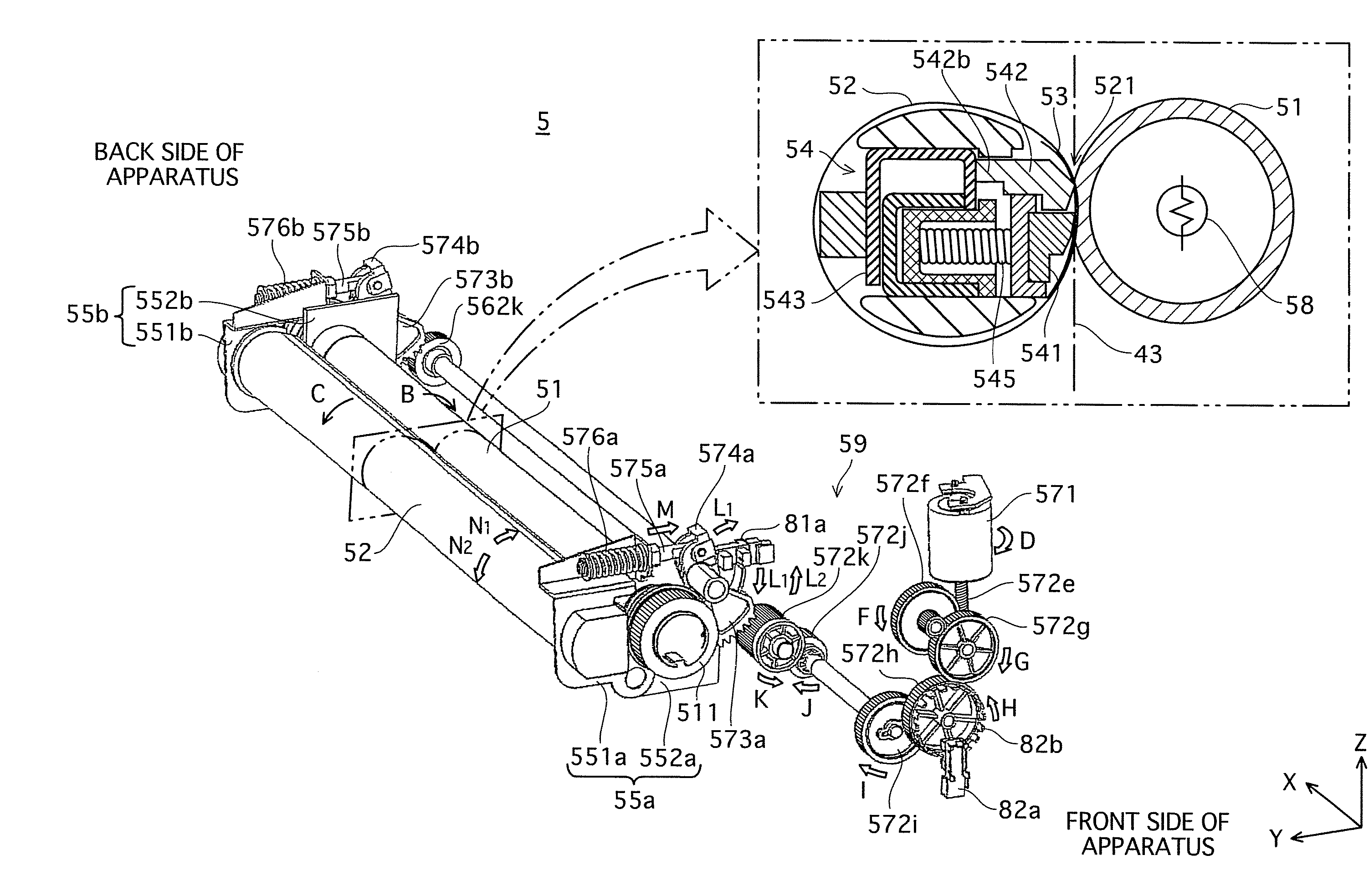

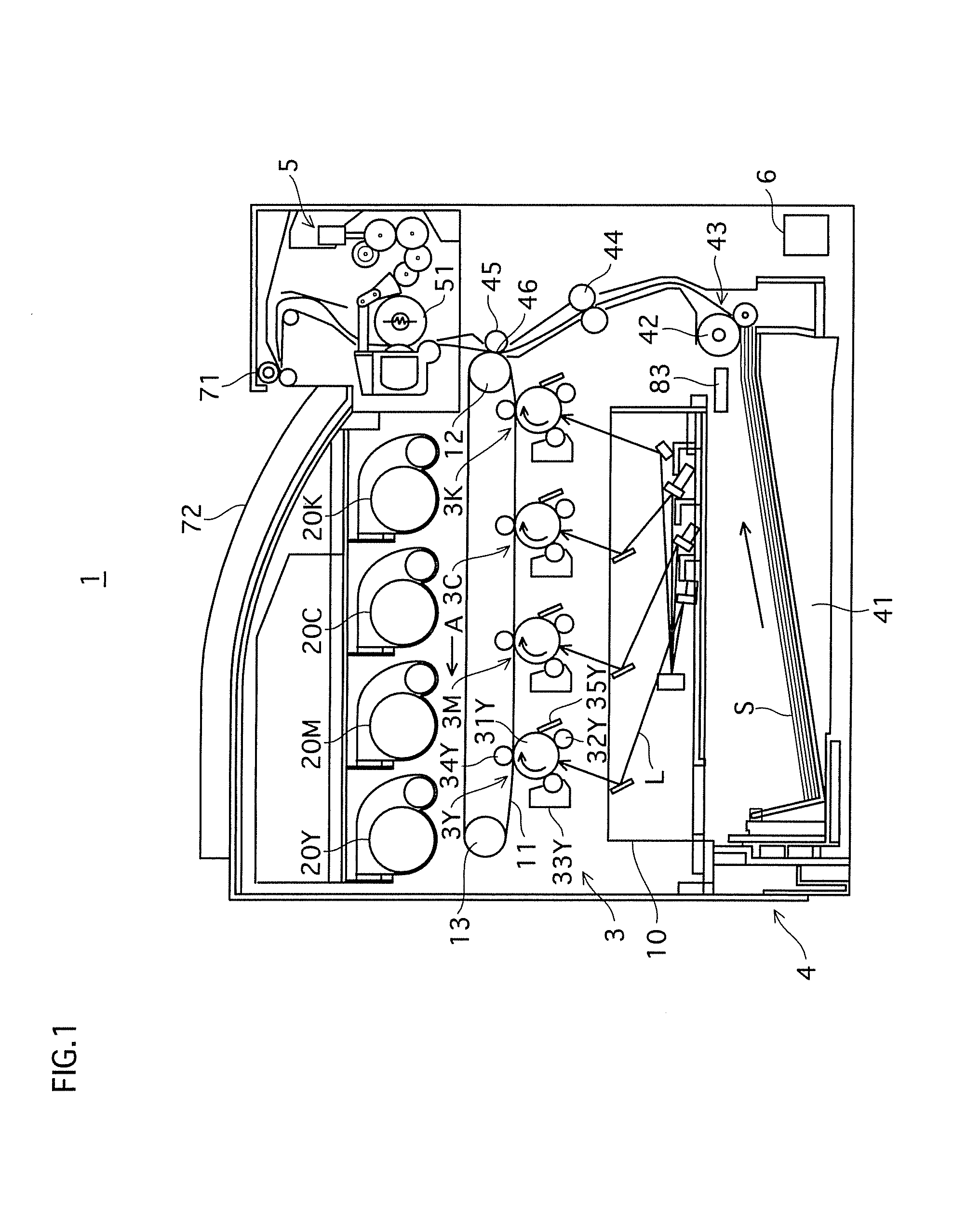

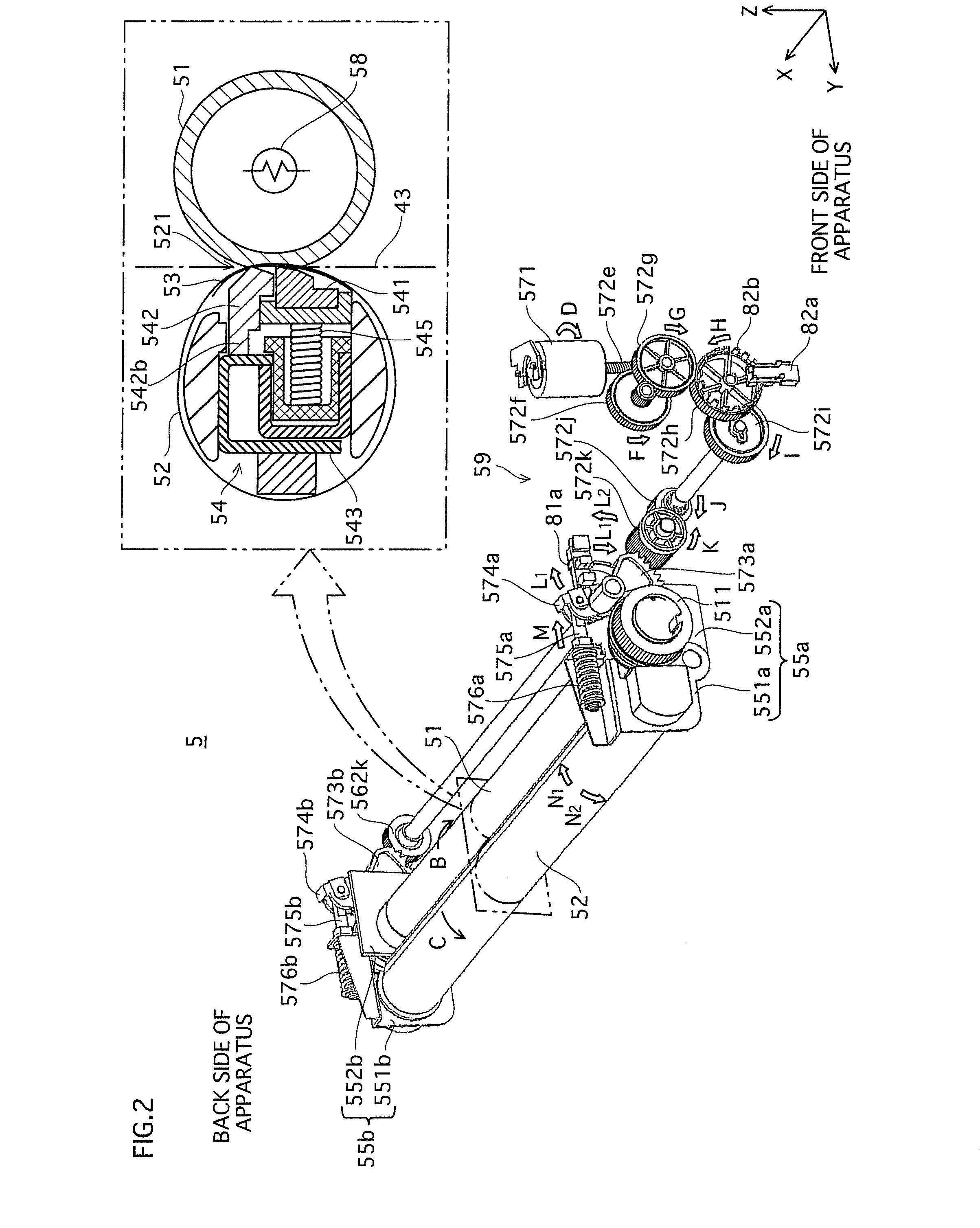

Fixing apparatus in which a fixing nip is secured by a pressure belt and a fixing roller, and image formation apparatus that includes the fixing apparatus

InactiveUS20090052925A1Reduce pressure areaAvoid it happening againElectrographic process apparatusImage formationEngineering

A belt-nip system fixing apparatus or an image formation apparatus including the fixing apparatus reduces the frequency of replacing a pressure belt or a sliding sheet. In accordance with a sheet measurement in a roller axis direction, the fixing apparatus or image formation apparatus switches a pressure distribution in the roller axis direction between a low-pressure load distribution in which pressure is greatest at a center pressure switching projection (542b) of a hard pad (542), and pressure gradually lessens towards pressure switching projections (543c) near the ends of the hard pad (542), and the pressure in a range of 216 [mm] in a center in the roller axis direction is greater than or equal to a necessary pressure for fixing (a predetermined value Nm) while the pressure in other projections near the ends is below the predetermined value Nm, and a high-pressure load distribution in which the pressure throughout the total area in the roller axis direction equals or exceeds the predetermined value Nm.

Owner:KONICA MINOLTA BUSINESS TECH INC

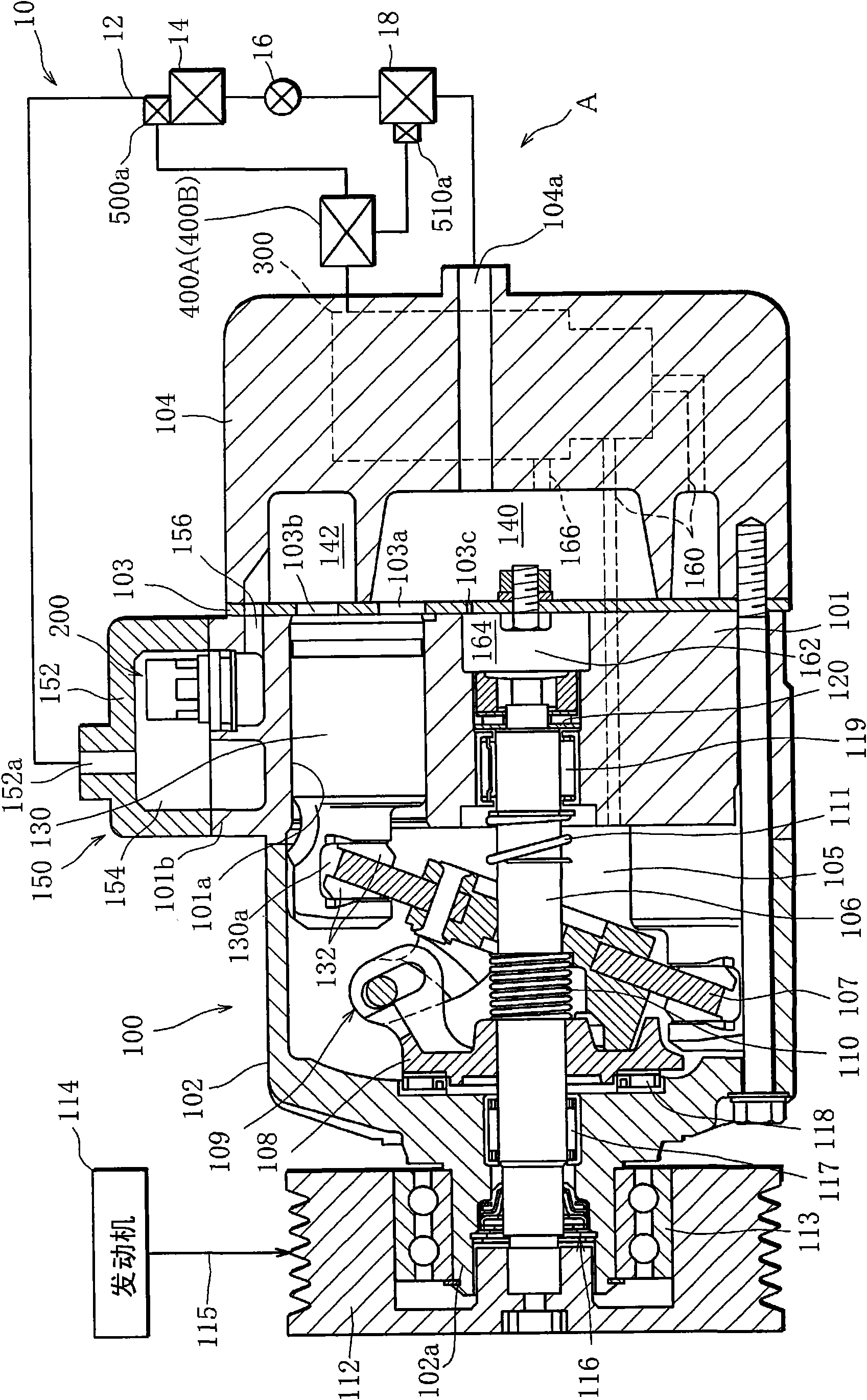

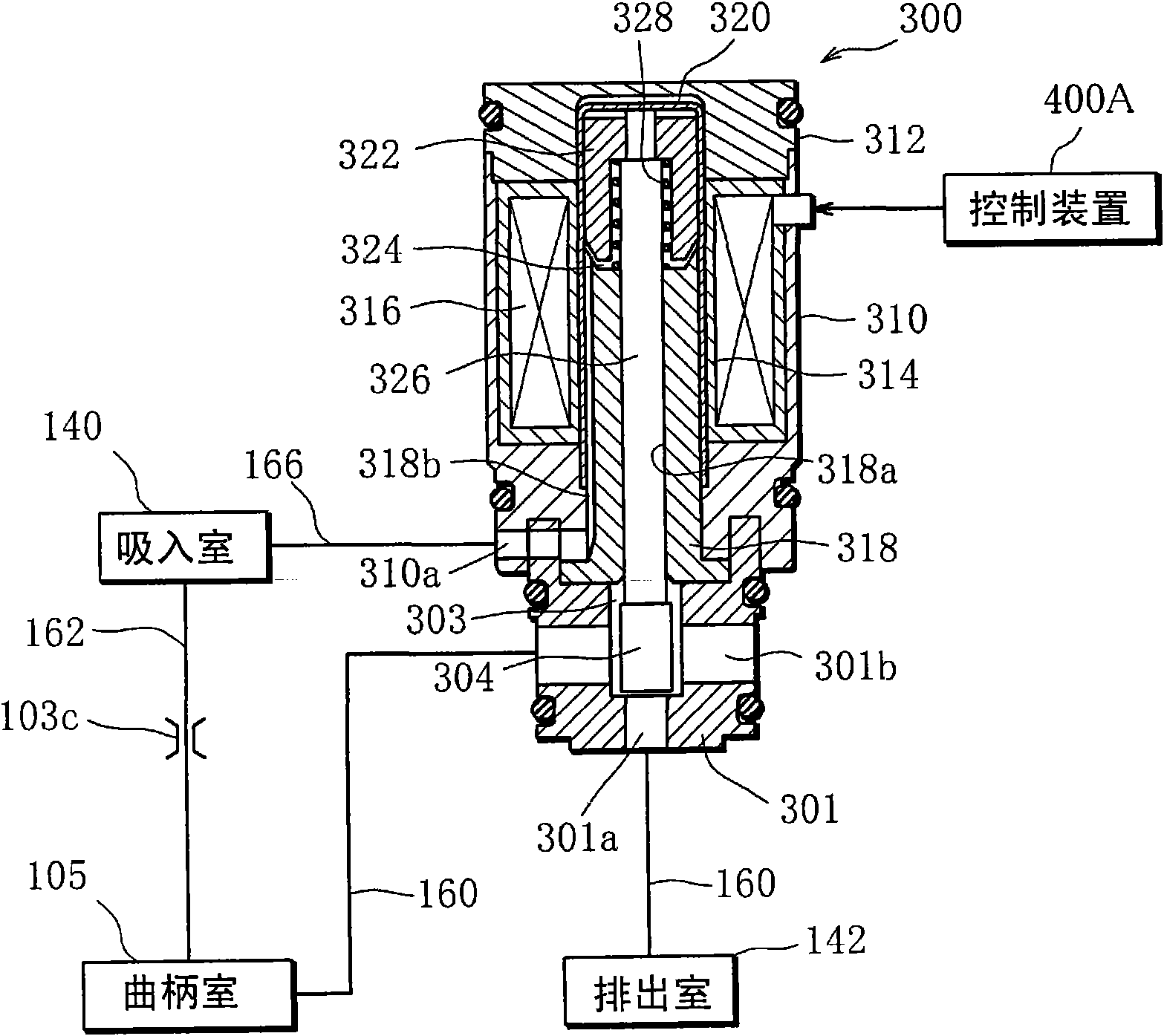

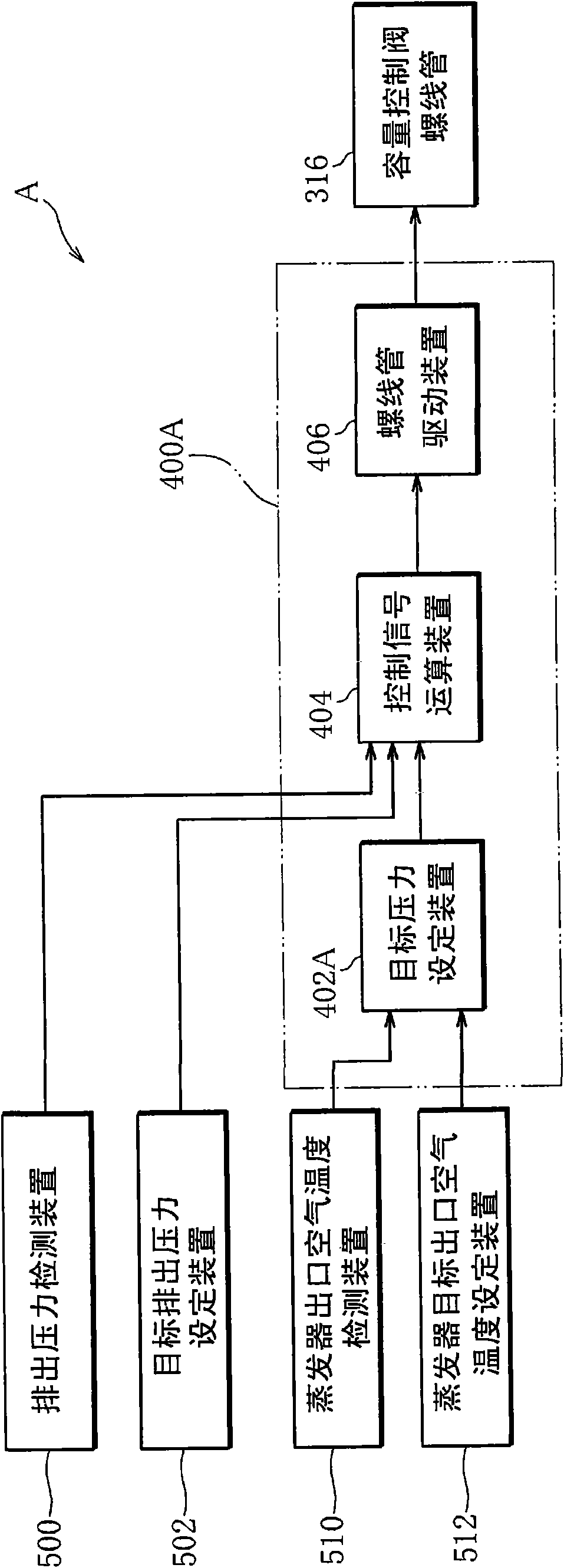

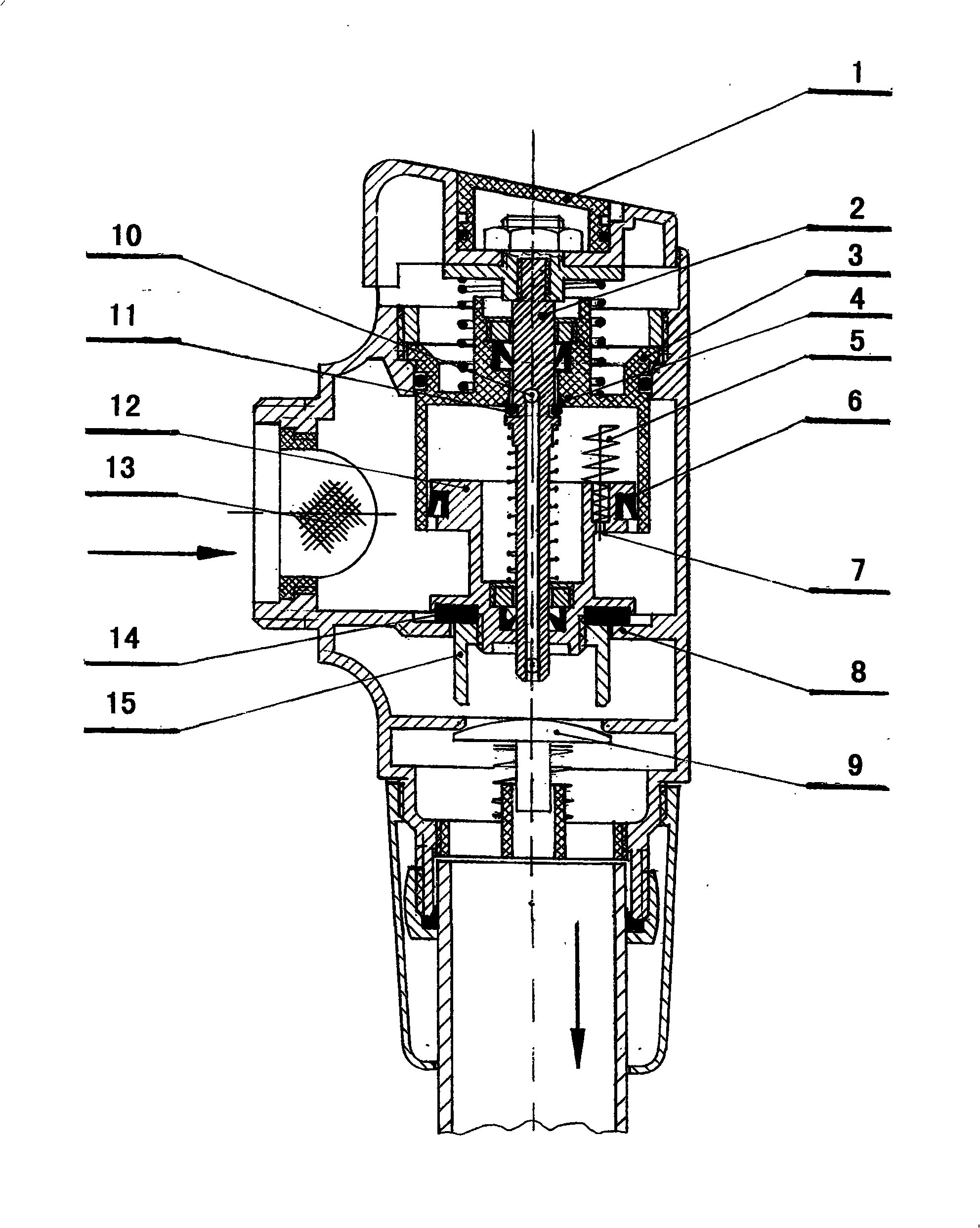

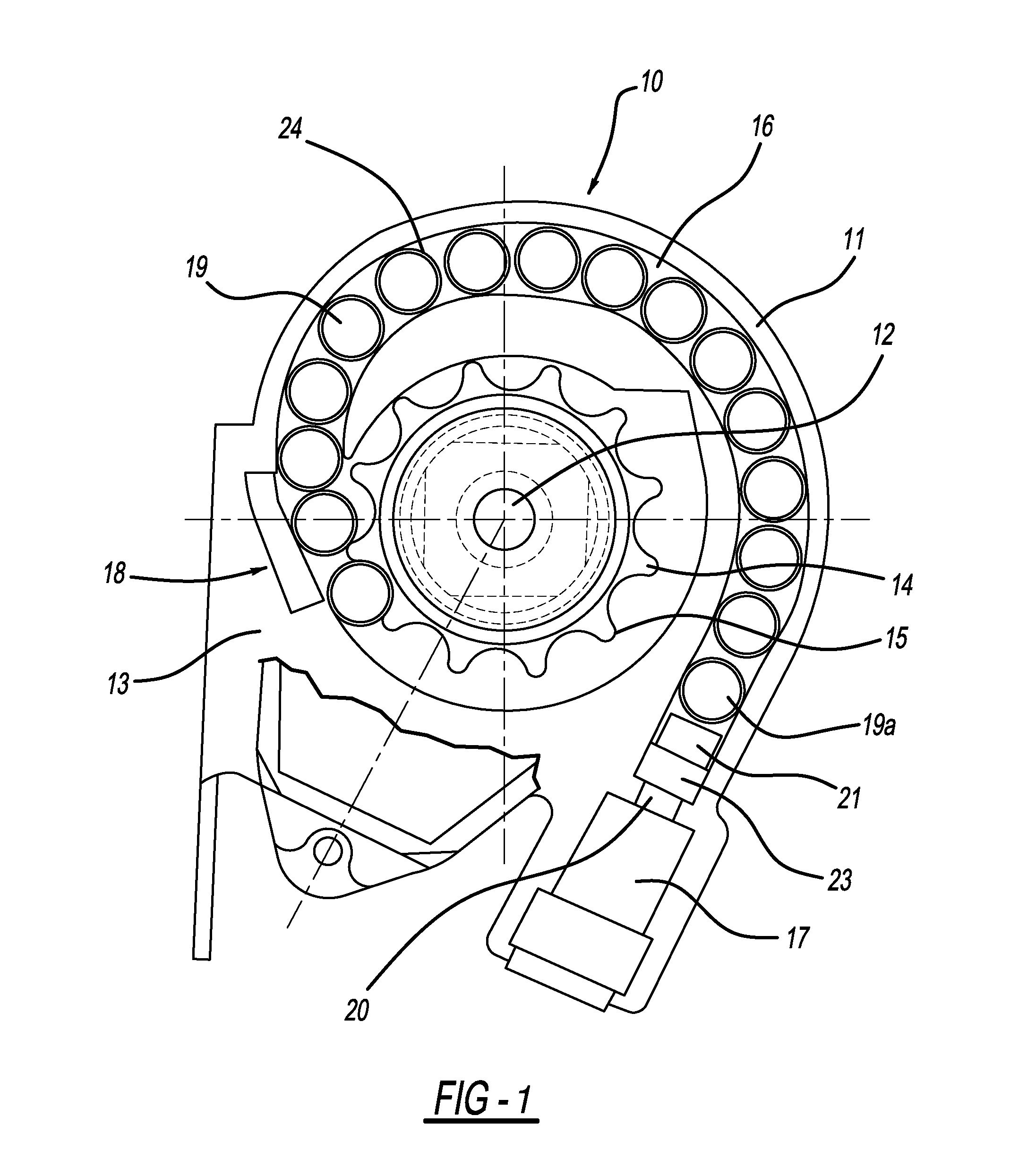

Displacement control system for variable displacement compressor

ActiveCN101605990AComfort adjustment stateOptimum Discharge Capacity ControlAir-treating devicesCompression machines with non-reversible cycleControl systemEngineering

A discharge displacement control system (A) of a variable displacement compressor has target pressure setting means (402A), discharge pressure detection means (500), and electric current regulation means (404, 406). The target pressure setting means (402A) sets a target of either the pressure in a suction chamber or the pressure in a crank chamber based on a target air temperature at the evaporator exit detected by means (510) for detecting the air temperature at the evaporator exit and on a target air temperature at the evaporator exit set by means (512) for setting a target air temperature at the evaporator exit. The discharge pressure detection means (500) detects the pressure of refrigerant in a high-pressure region. The electric current regulation means (404, 406) regulate, based on both the pressure of the refrigerant in the high-pressure region detected by the discharge pressure detection means (500) and the target pressure set by the target pressure setting means (402A), electric current supplied to a solenoid (316) of a displacement control valve.

Owner:SANDEN CO LTD

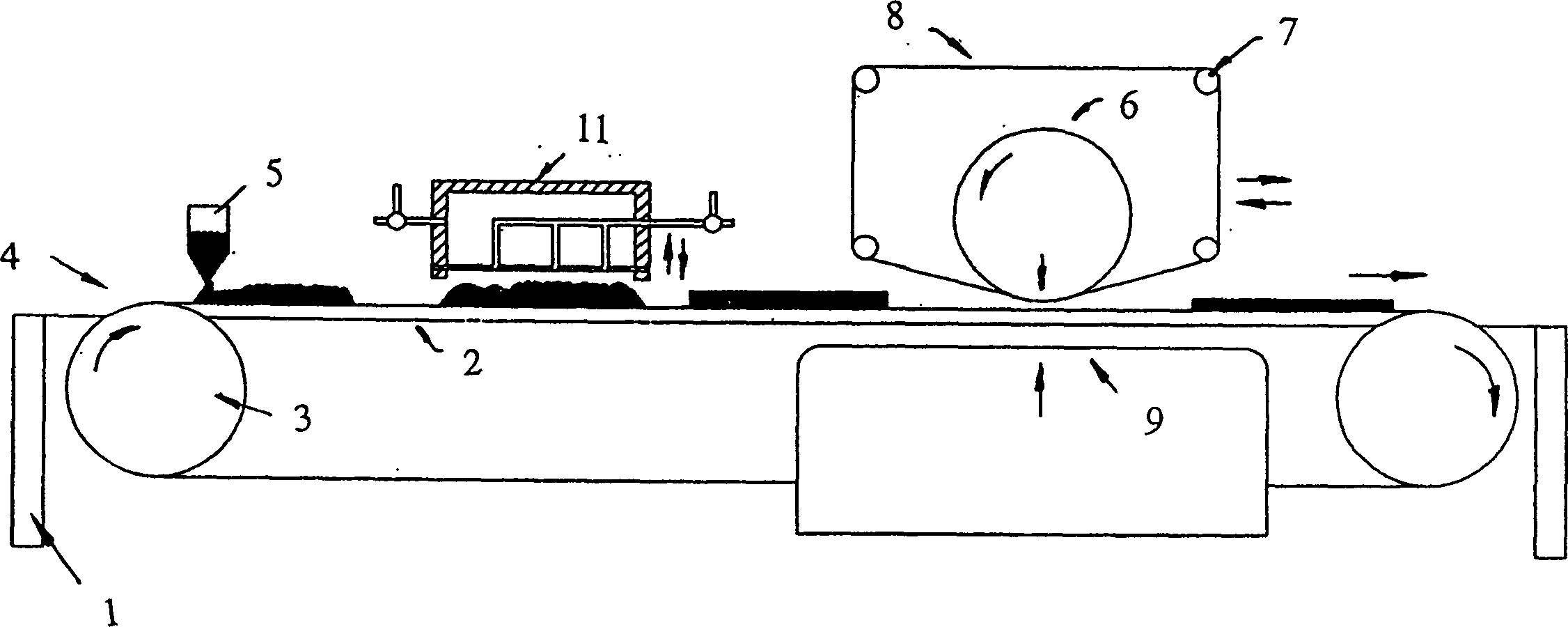

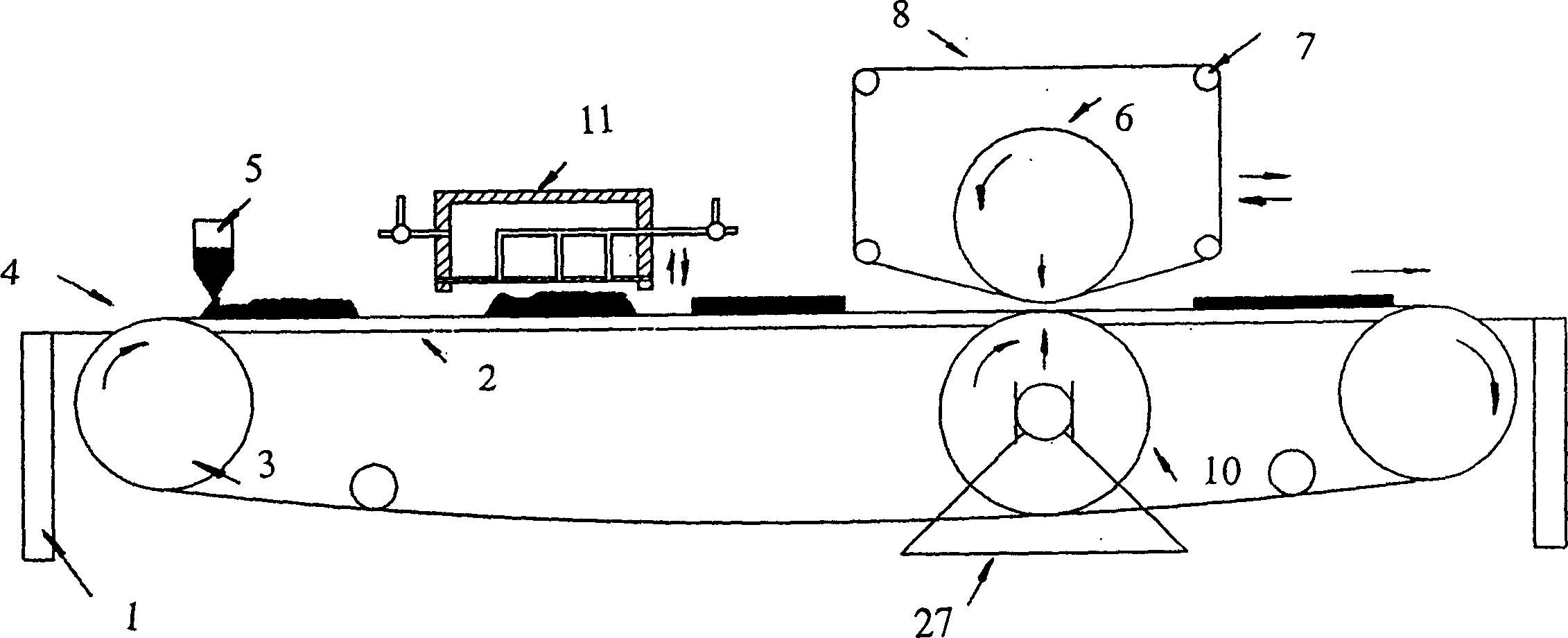

Large size ceramic sheet shaping apparatus and method

InactiveCN1451524AReduce pressure areaReduce thicknessCeramic shaping apparatusDrive wheelEngineering

An apparatus for shaping large-area ceramic tiles is composed of machine frame, supporting plate, lower belt and its driving wheel, hopper, upper pressing wheel, upper belt passing through the surface of upper pressing wheel, and a base on which the upper pressing wheel rolls back and forth for rolling the powder to become tiles. Its advantages are low cost and high productivity.

Owner:徐建

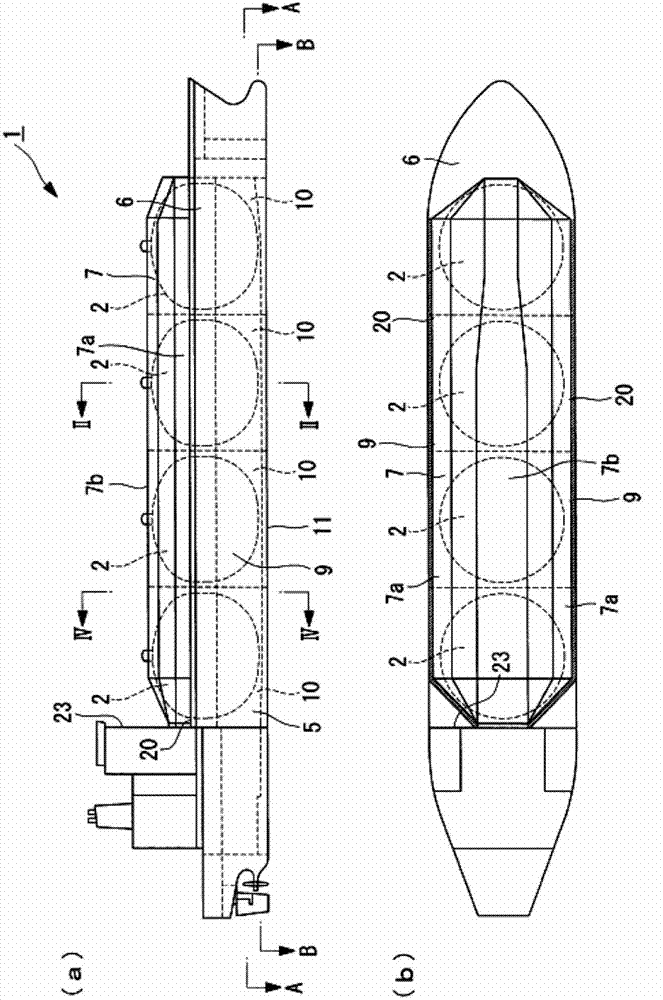

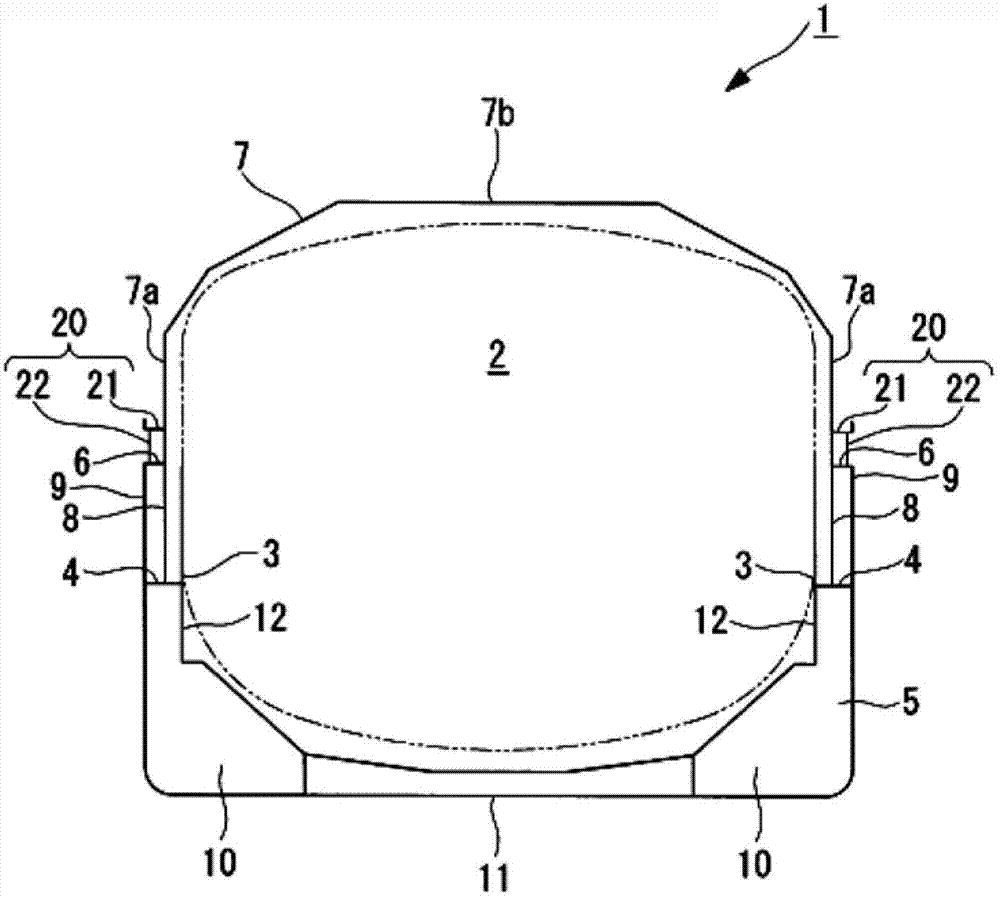

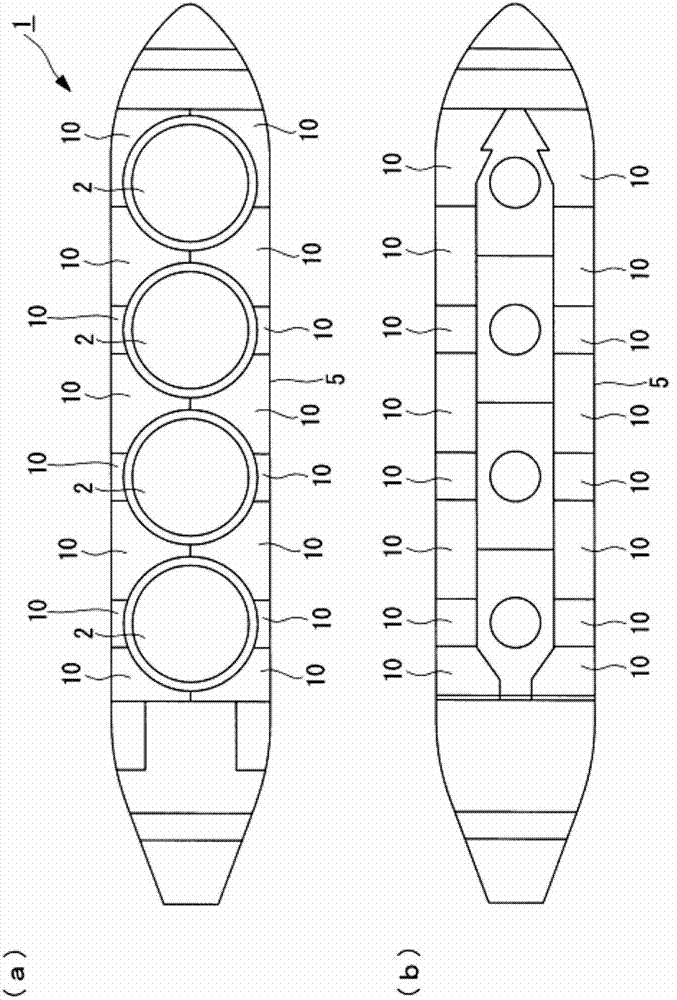

Liquefied gas carrying ship

ActiveCN102958797AReduce pressure areaImprove stabilityVessel superstructuresHull decksMarine engineeringUltimate tensile strength

In order to reduce the pressure receiving area of the entire ship body, reduce the air pressure resistance, lower the position of the center of gravity of the ship, and improve the stability of the ship body, a liquefied gas carrying ship (1) is provided with: flat spherical tanks (2) for storing a liquefied gas therein, the flat spherical tanks (2) being arranged in the bow-stern direction of the ship and affixed to the ship body (5) through skirts (3); and a single continuous tank cover (7) for covering the upper half of the flat spherical tanks (2) and extending along the bow-stern and width directions of the ship. The tank cover (7) is rigidly joined to the ship body (5) and ensures, integrally with the ship body (5), the longitudinal strength.

Owner:MITSUBISHI SHIPBUILDING CO LTD

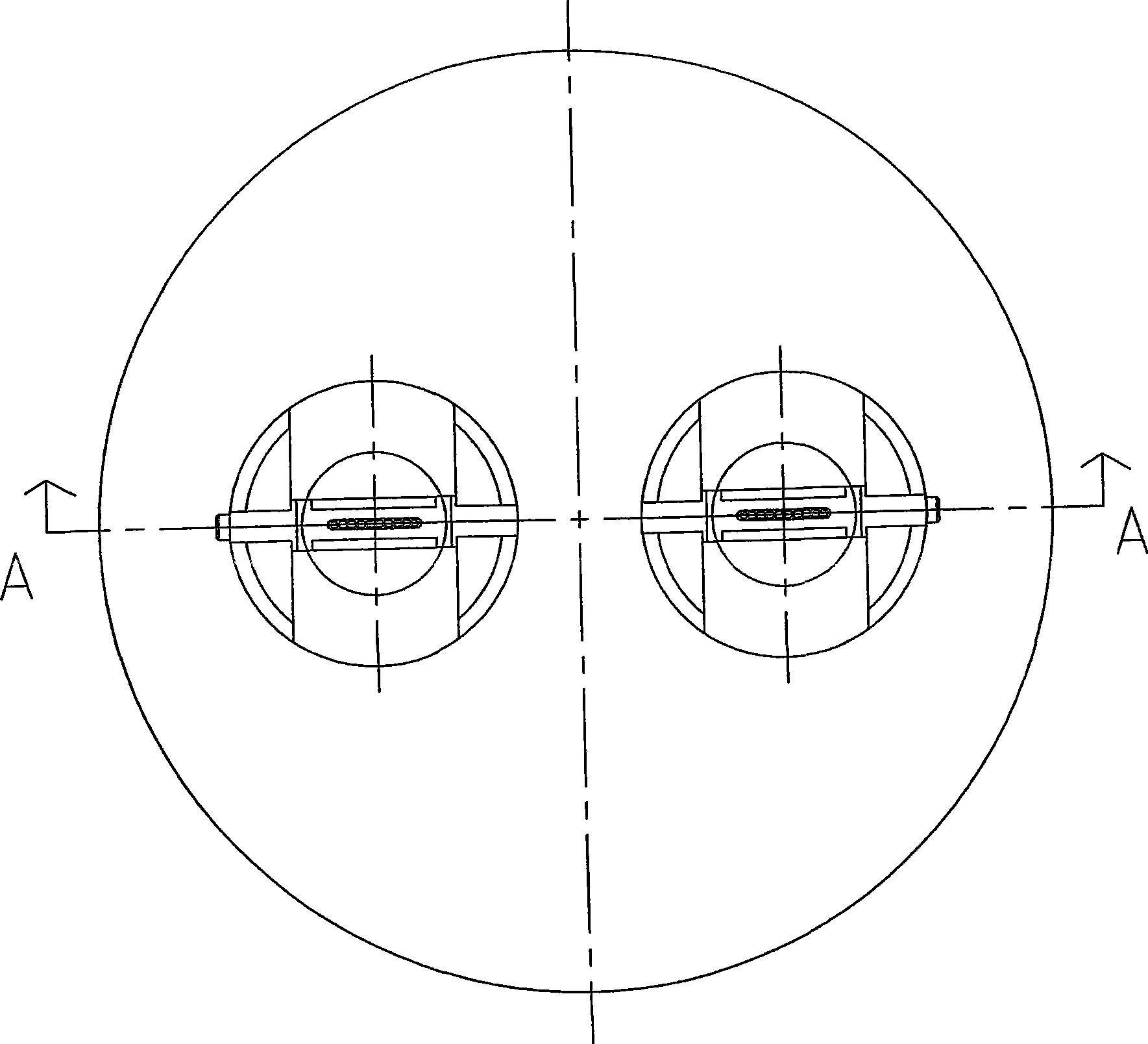

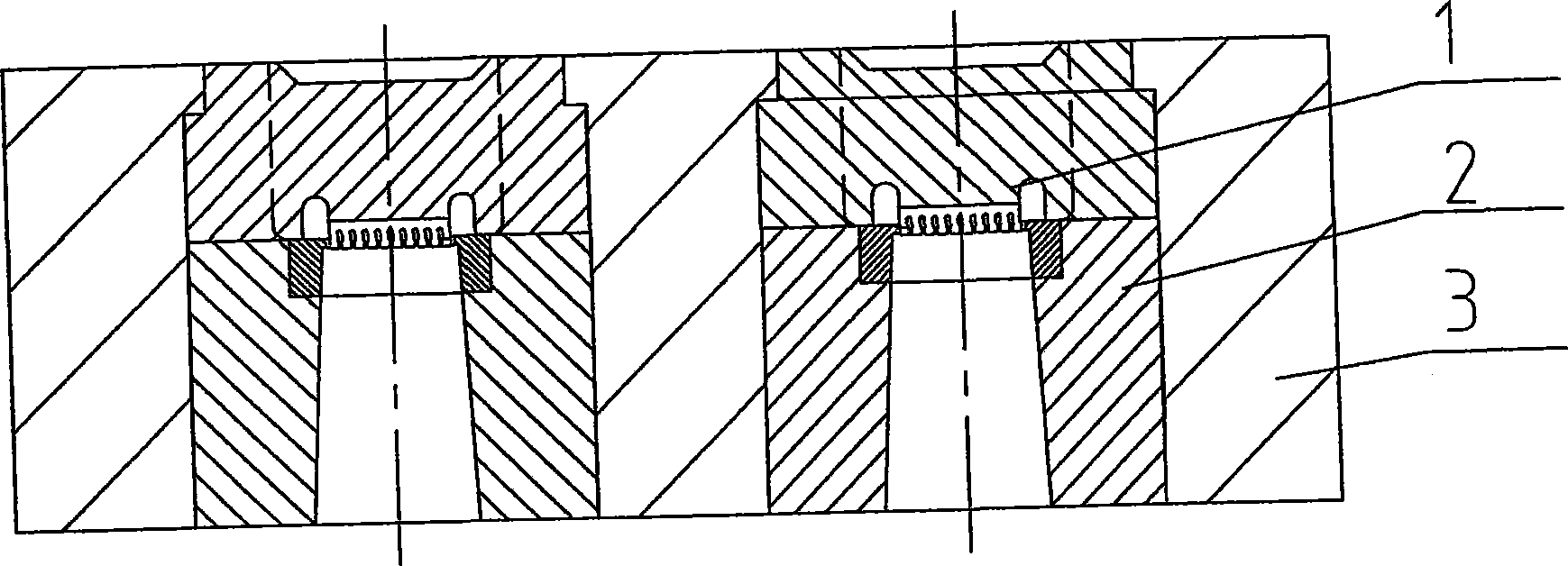

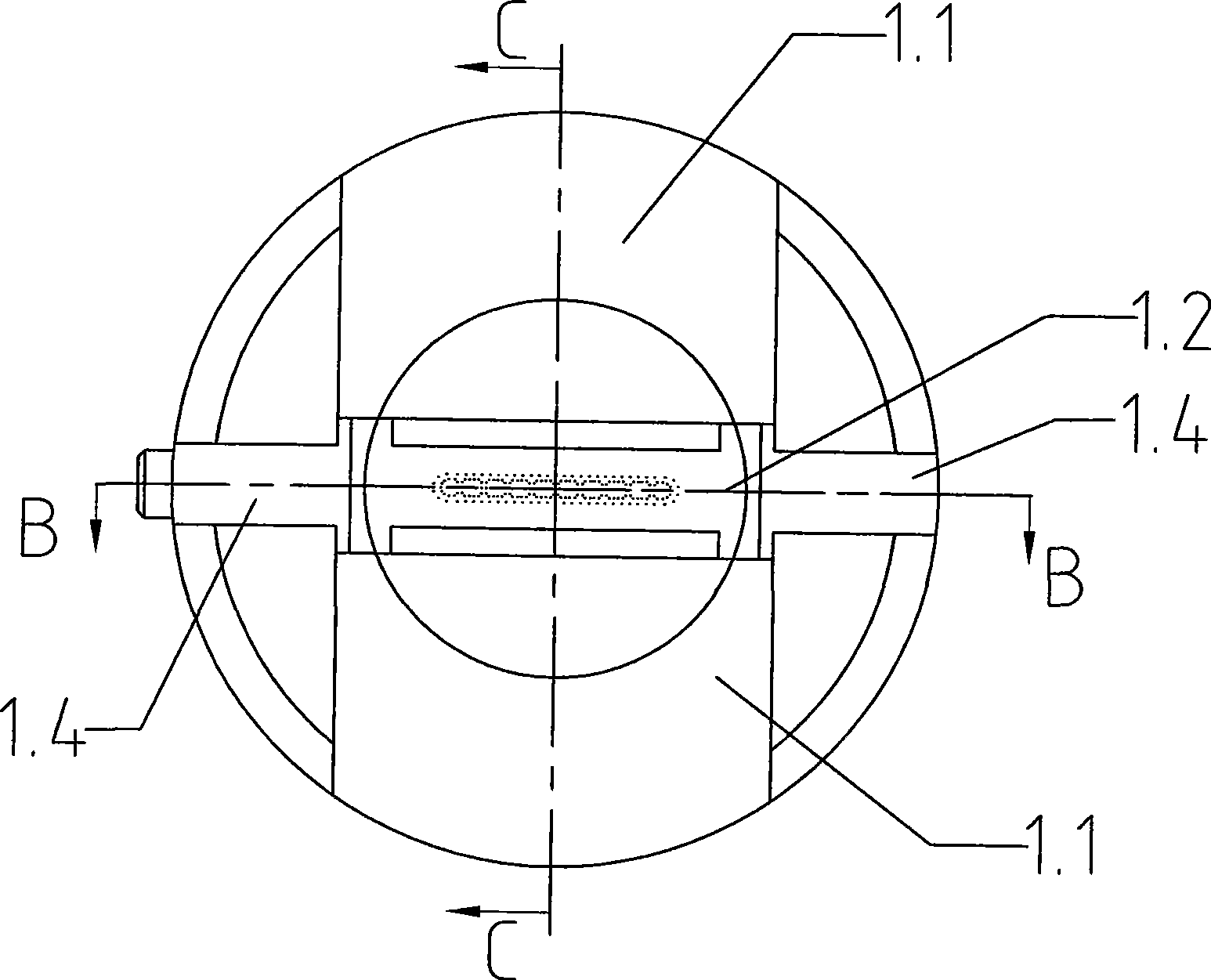

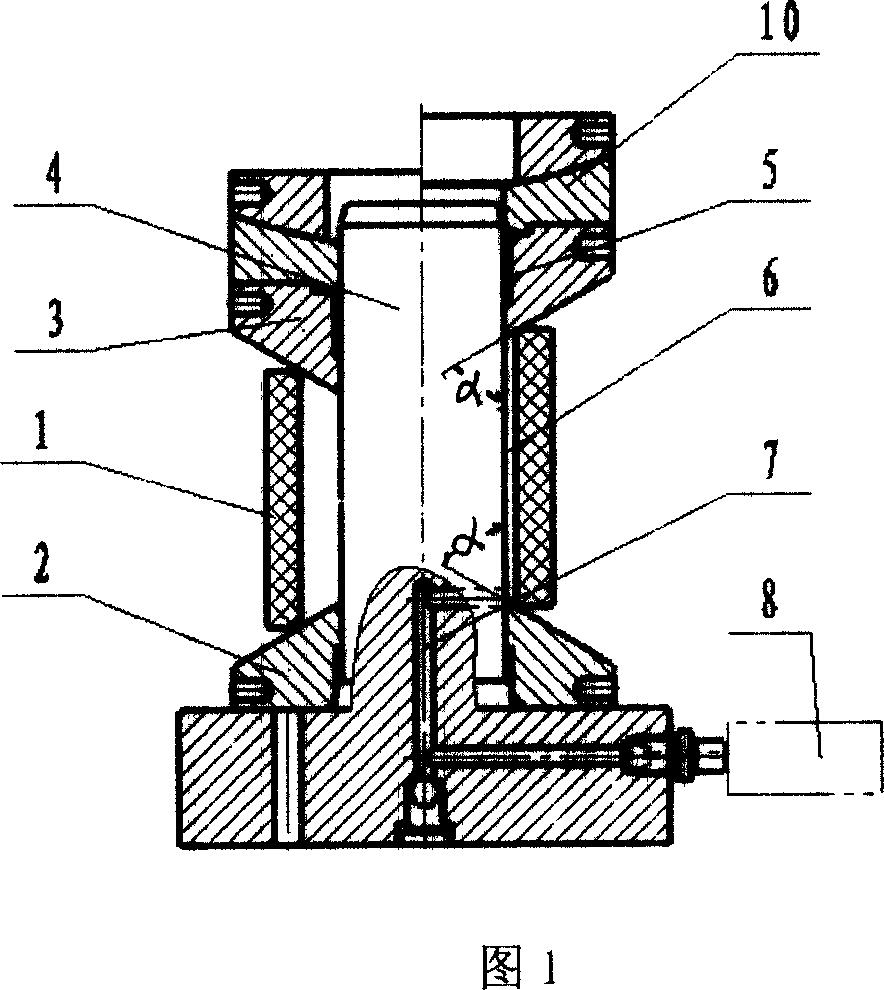

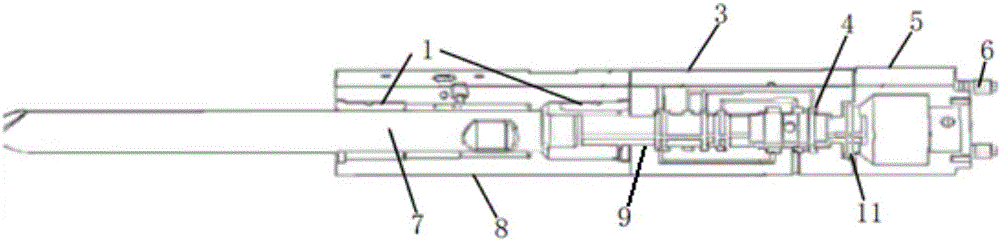

Extruded aluminium section die for vehicle condenser tube

The invention relates to an extruded aluminum section die used in an automobile condenser tube. The aluminum section die is used for the extrusion forming of the automobile condenser tube. A 'cross core insert' type male die (1) is embedded into a 'fork type' female die (2) to form a 'sub-die', and two or more than two 'sub-dies are inserted into a main body die (3) to form a 'main-slave die' together with the main body die (3). A split flow bridge (1.2) is formed in the center of a feeding face of the 'cross core insert' type male die (1); handle parts (1.4) are formed at the left side and the right side of the split flow bridge (1.2); a groove (2.4) is formed by longitudinally milling the center of the feeding face of the 'fork type' female die (2); a die cavity (2.1) formed by hard alloy blocks (2.2) is inserted into the center of the bottom of the groove (2.4), and the center of the bottom of the groove is transversely milled to form a caulking groove (2.5); the split flow bridge (1.2) separates the groove (2.4) into a front and a rear 'open' split flow holes (1.1); after the 'sub-die' is assembled into the main body die (3), a hermetical welded chamber is formed at the 'open' split flow holes (1.1). The die can reduce the stress on the die during extrusion, enhance the production efficiency of the die, and lead wear resistance of the die to be better.

Owner:JIANGYIN GIANSUN MOLD

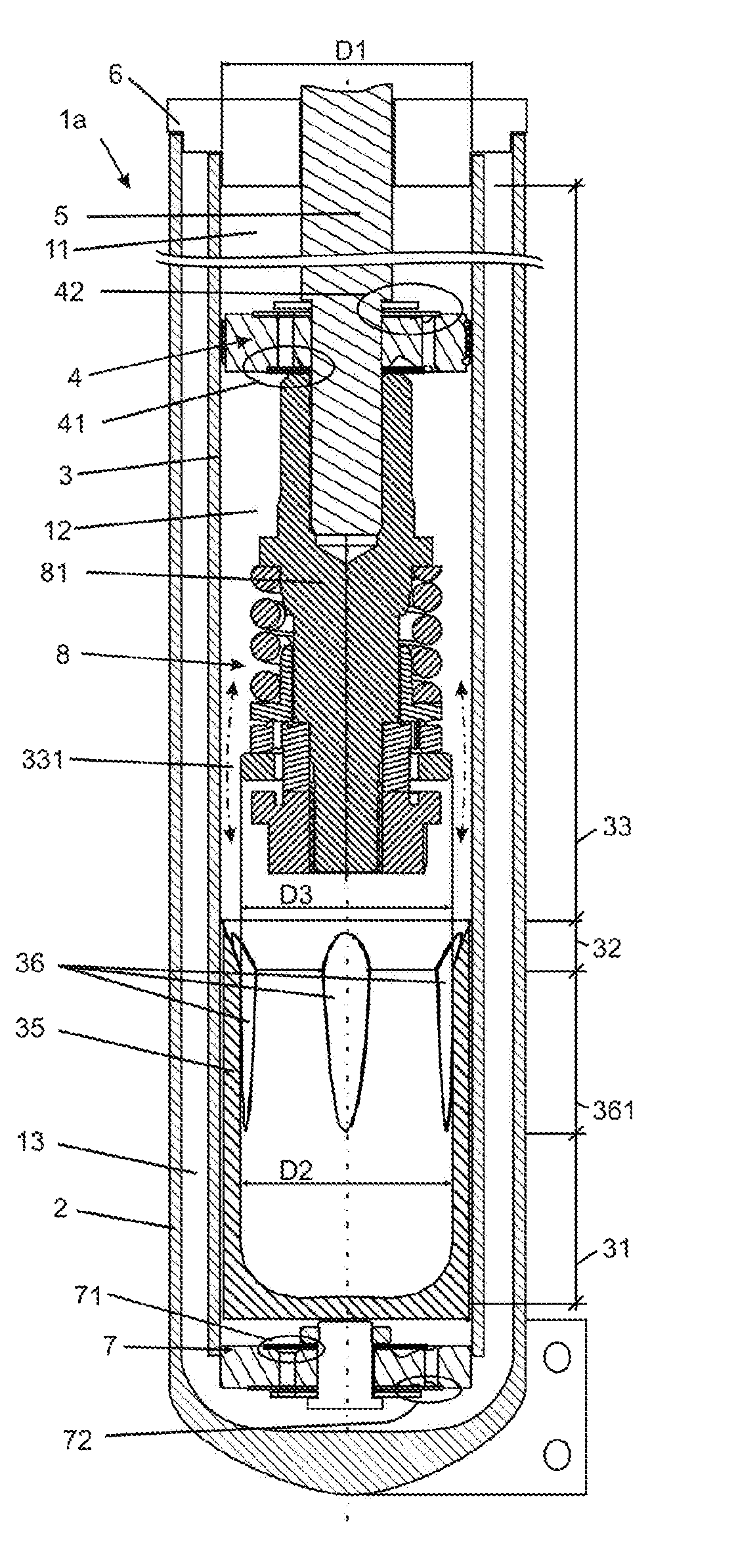

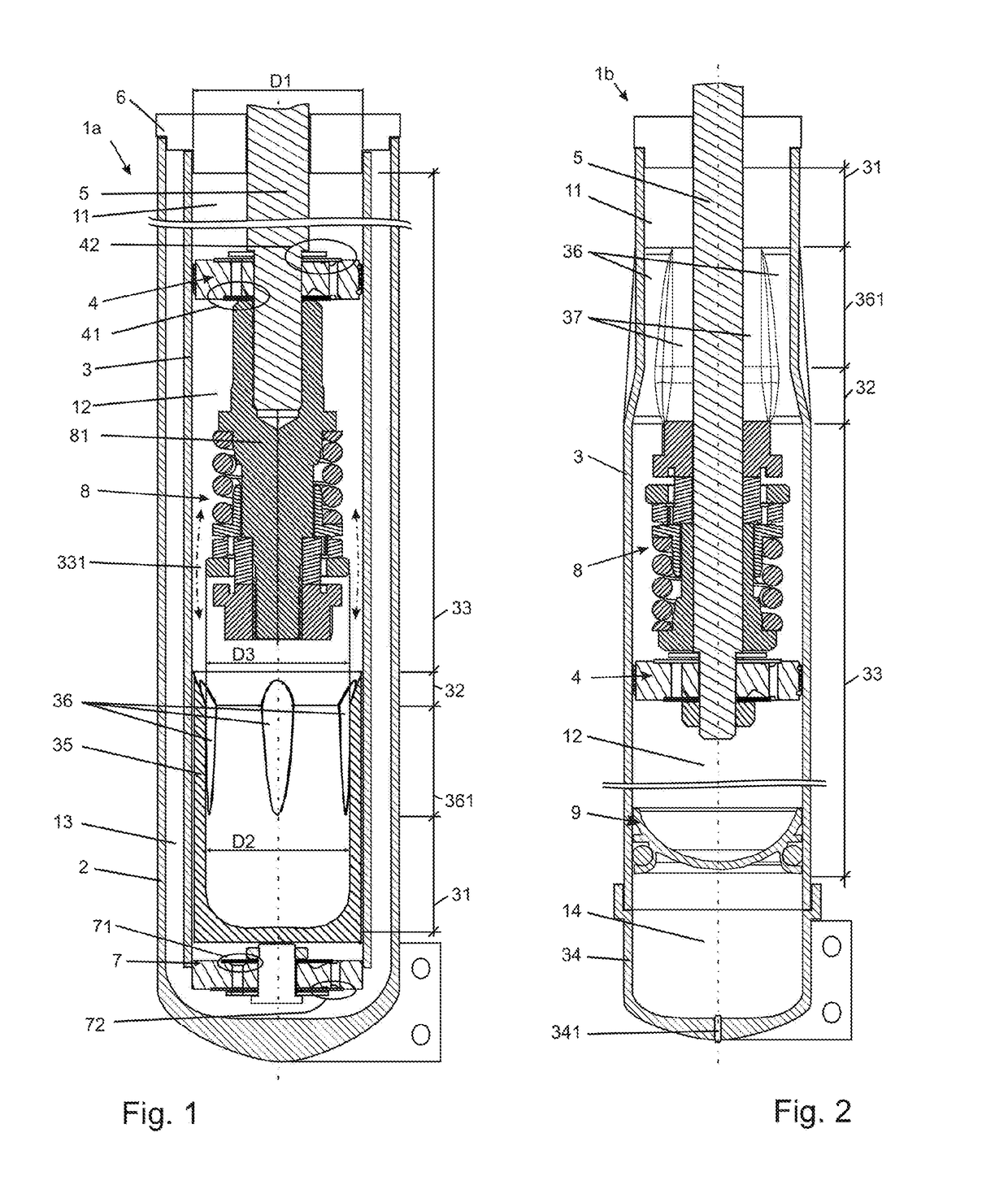

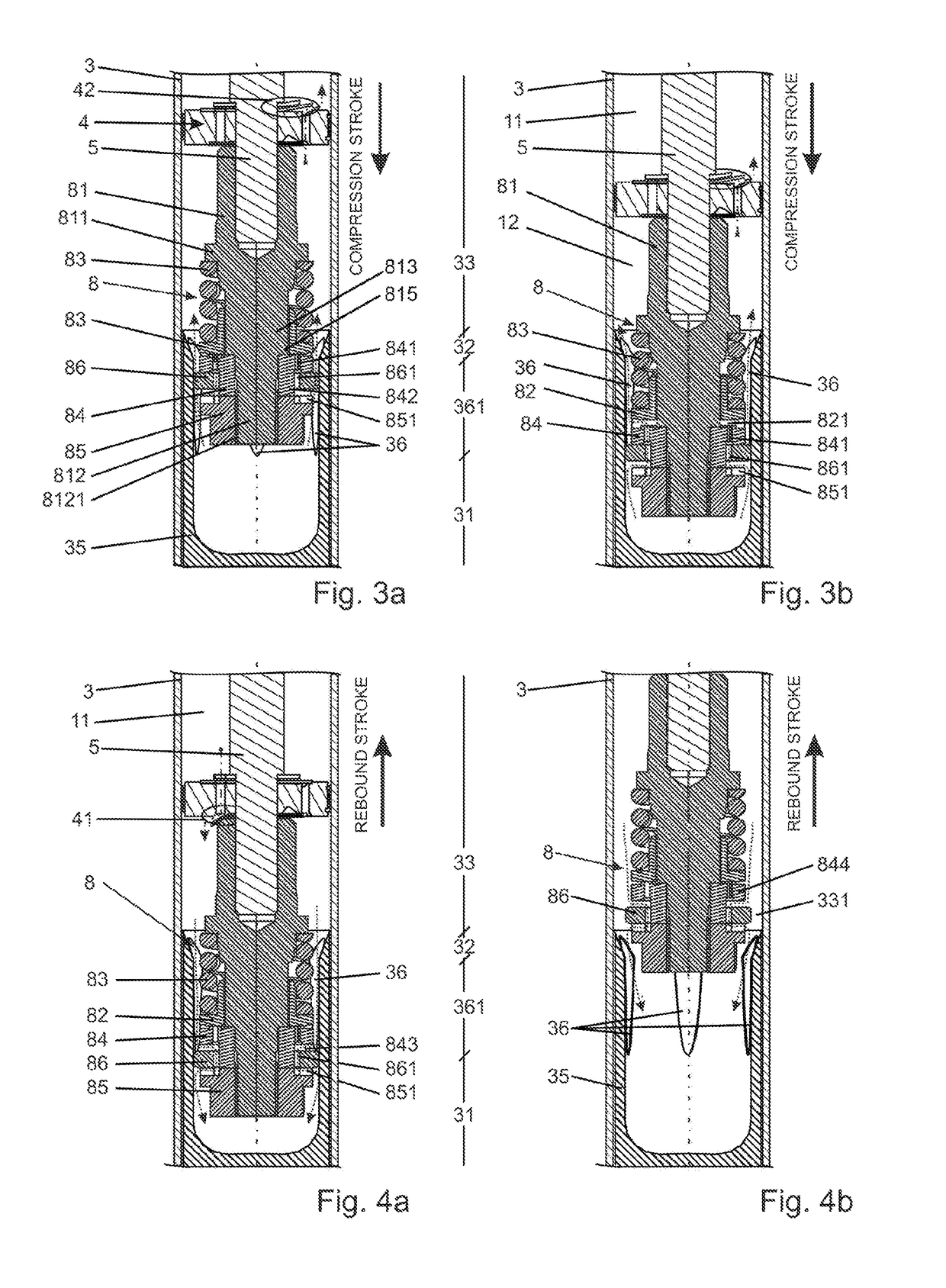

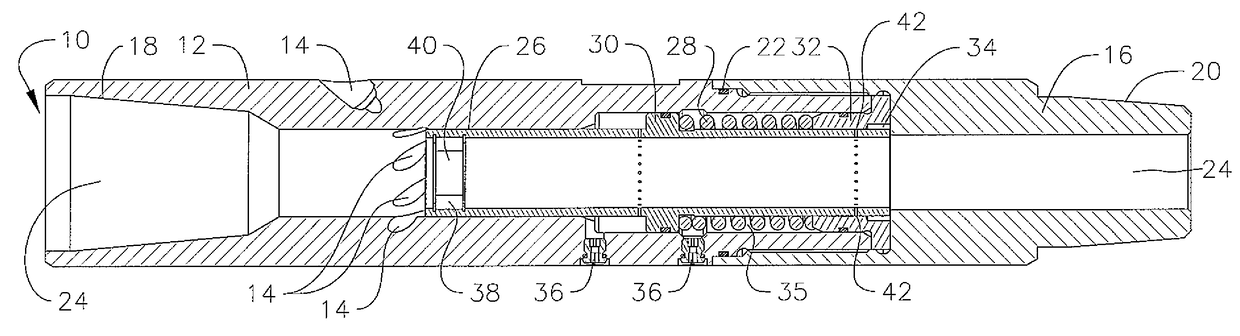

Hydraulic damper with a hydraulic stop arrangement

ActiveUS10107352B2Reduce pressure areaLow stiffnessSpringsShock absorbersEngineeringMotorized vehicle

A hydraulic damper for a motor vehicle including a tube having a main section and a narrowed section. A main piston assembly is disposed inside the main section. A main piston rod is attached to the main piston assembly. A secondary rod is coupled with the main piston rod. A spring seat is disposed about the secondary rod. A spring engages the spring seat and preloads the spring seat. A secondary piston is disposed about and coupled with the secondary rod. The secondary piston has an axial projection and an annular projection that abuts the spring seat. The annular projection defines a plurality of axial slots. A retaining member is fixed to the secondary rod and has an outer face defining a plurality of radial slots. A sealing ring is slidably disposed about the axial projection. An annular channel is defined radially between the sealing ring and the axial projection.

Owner:BEIJING WEST IND CO LTD

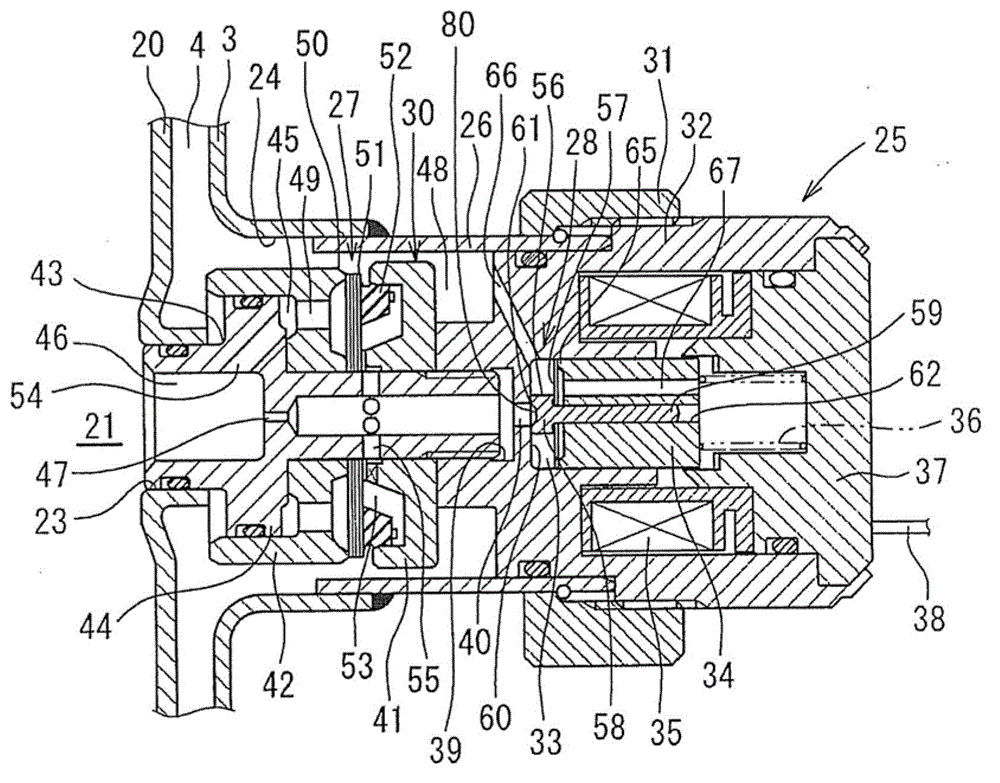

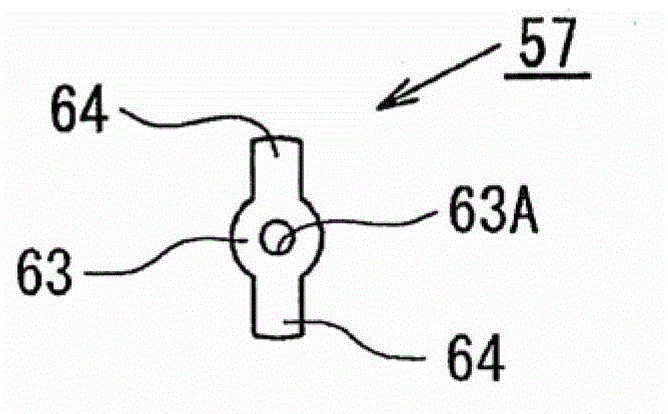

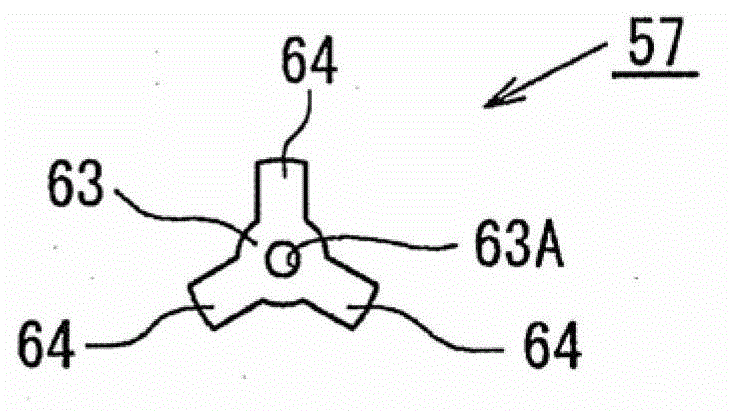

Attenuation force regulating type buffer

ActiveCN102979846AGreat attenuationIncrease valve opening pressureSpringsLiquid based dampersHydraulic cylinderUltrasound attenuation

The invention relates to an attenuation force regulating type buffer which prevents operating lag of a pressure control valve and self-induced vibration of a valve body. The buffer controls oil flow between a cyclic oil channel (21) and an oil chamber (4) through a backpressure main valve 27 and the pressure control valve (28), and generates attenuation force. The oil flow between a cyclic oil channel (21) and an oil chamber (4) is generated by slide of a piston in a hydraulic cylinder. Direct attenuation force is generated through the pressure control valve (28), and internal pressure of a backpressure chamber (53) is adjusted to control open valve pressure of a main valve (27). The pressure control valve (28) is installed with a valve spring between a valve body (56) and a plunger (34), and mass of the valve body (56) is much lower than that of the plunger (34).Spring rigidity of the valve spring (57) is higher than that of the plunger spring (36). Thus, responsiveness of the valve body (56) is improved, and operating lag of attenuation force control is prevented. In addition, inherent frequency of the valve body (56) is improved, thereby preventing the self-induced vibration from occurring.

Owner:HITACHI LTD

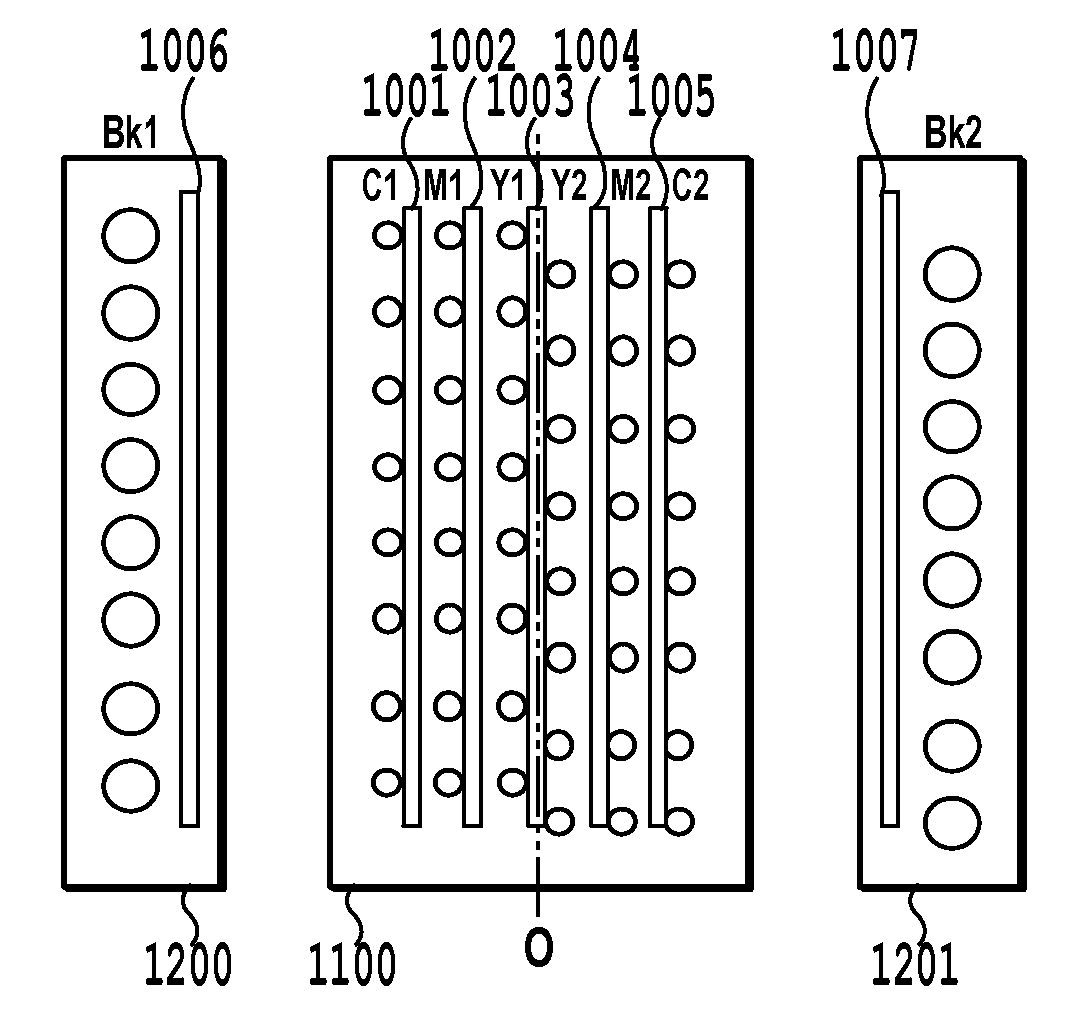

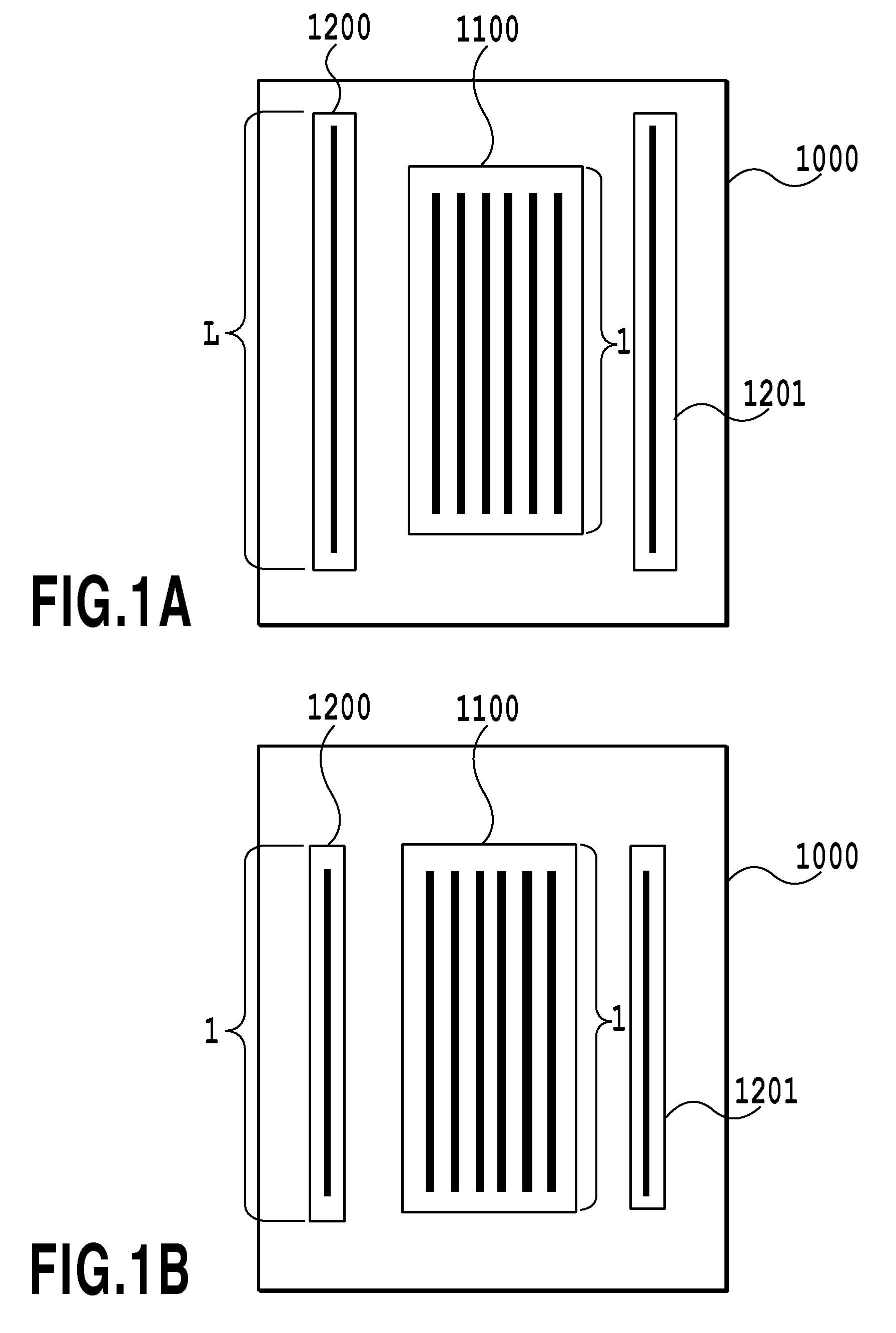

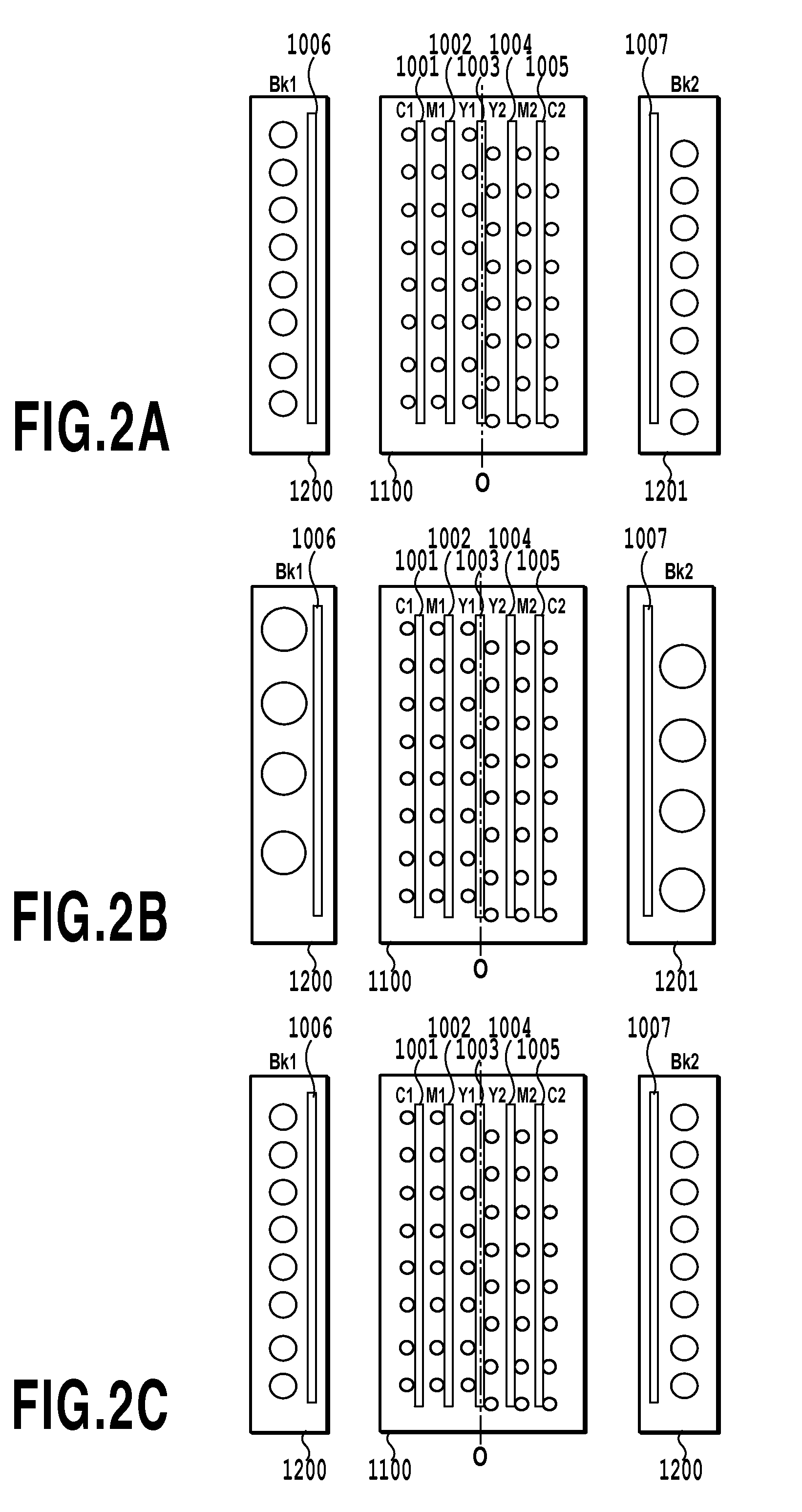

Ink jet print head and printing method and apparatus using the same

The present invention relates to measures for preventing end deviation that may occur during high-duty printing such as one-pass printing, and in particular, to measures for preventing density unevenness (white stripes) in the case of ink with a low lightness such as black ink. According to the present invention, the amount of black ink ejected through the corresponding ejection ports is set to be larger than that of color ink ejected through the corresponding ejection ports. Two black ink ejection chips each having at least one black ink ejection port row are arranged on the respective sides of a color ink ejection chip.

Owner:CANON KK

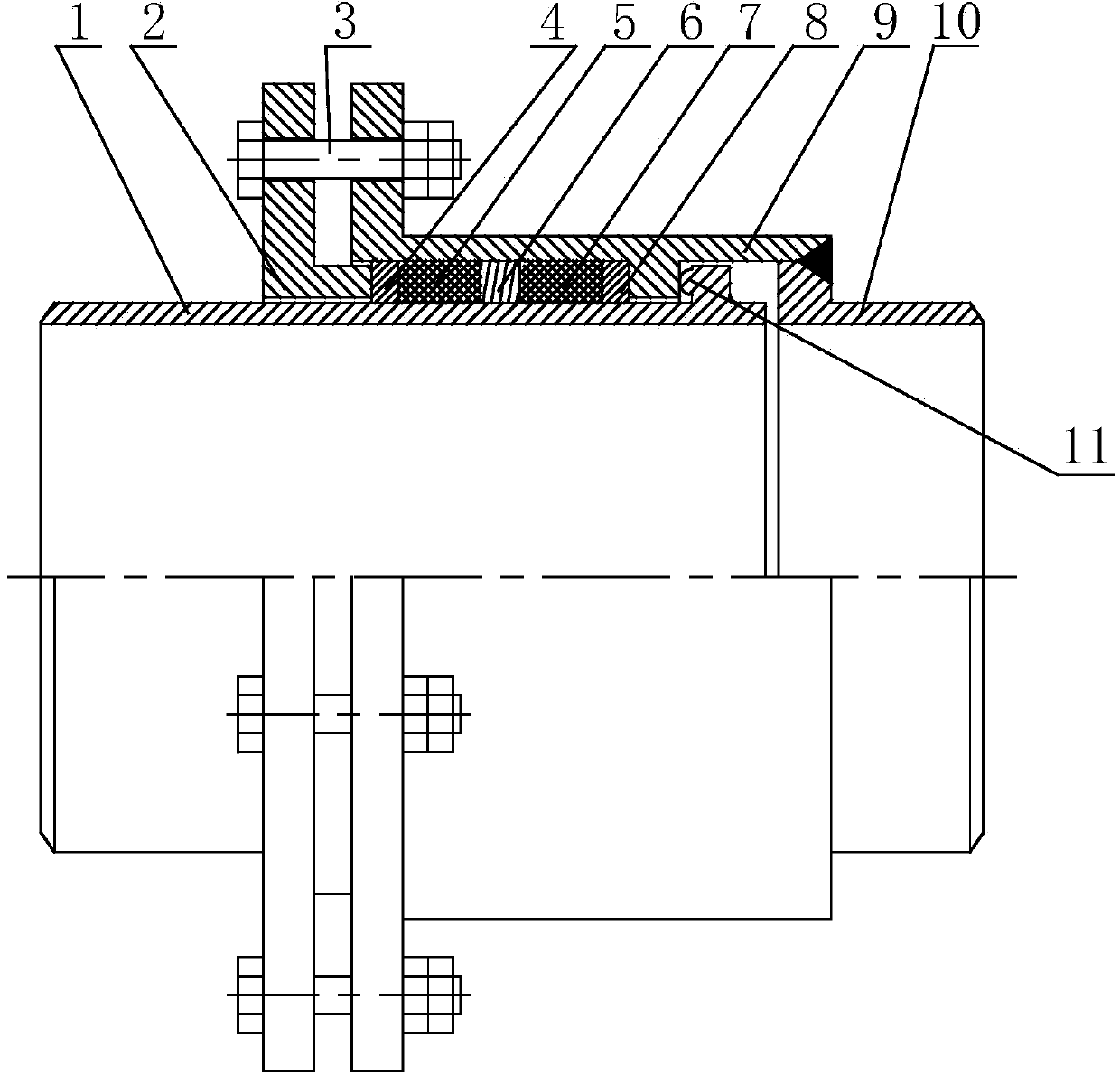

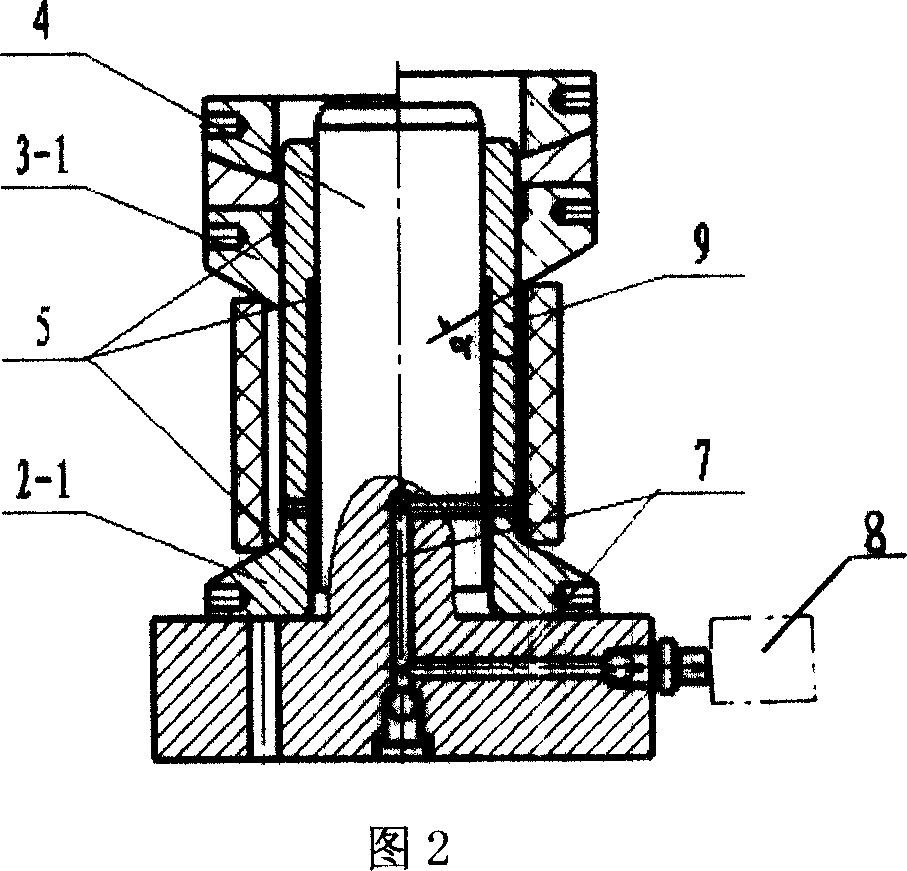

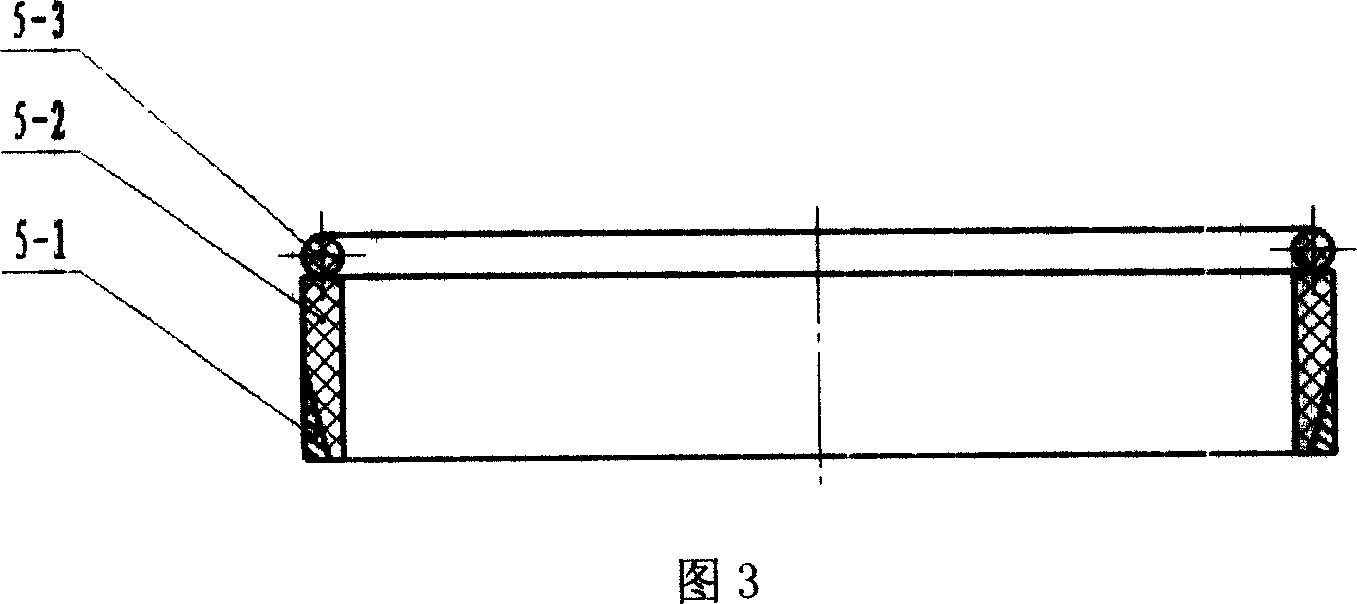

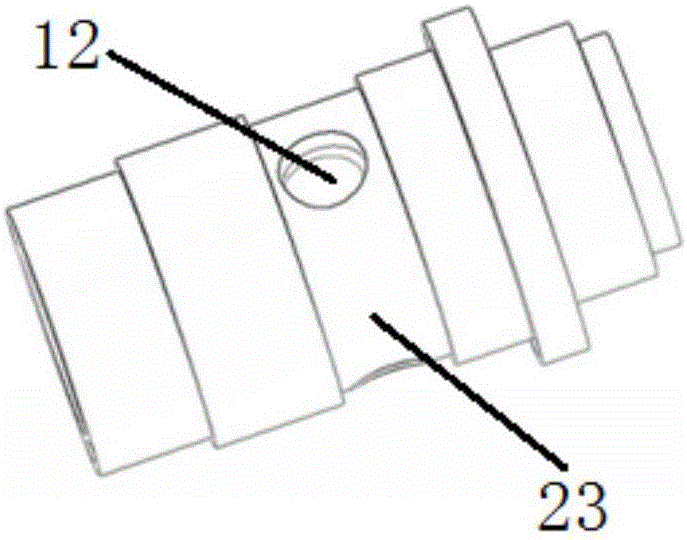

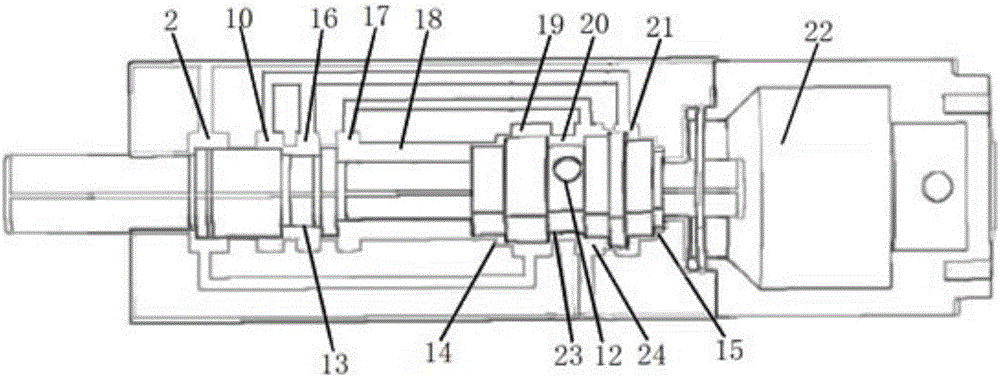

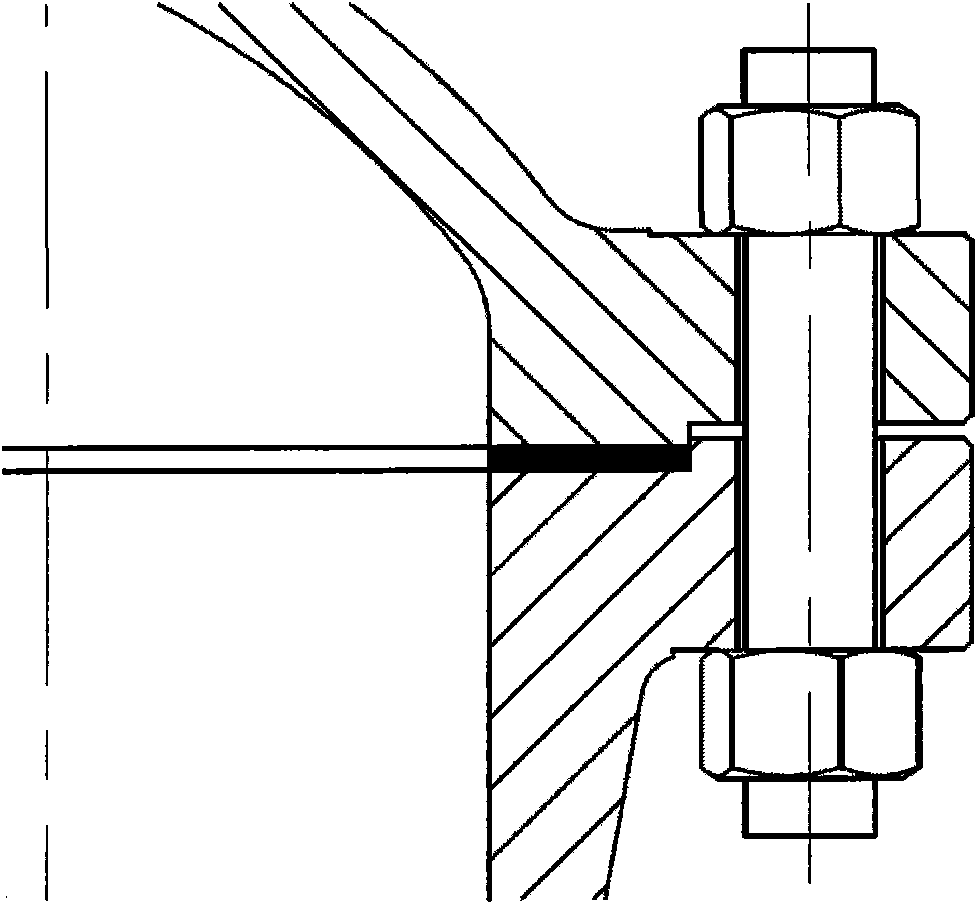

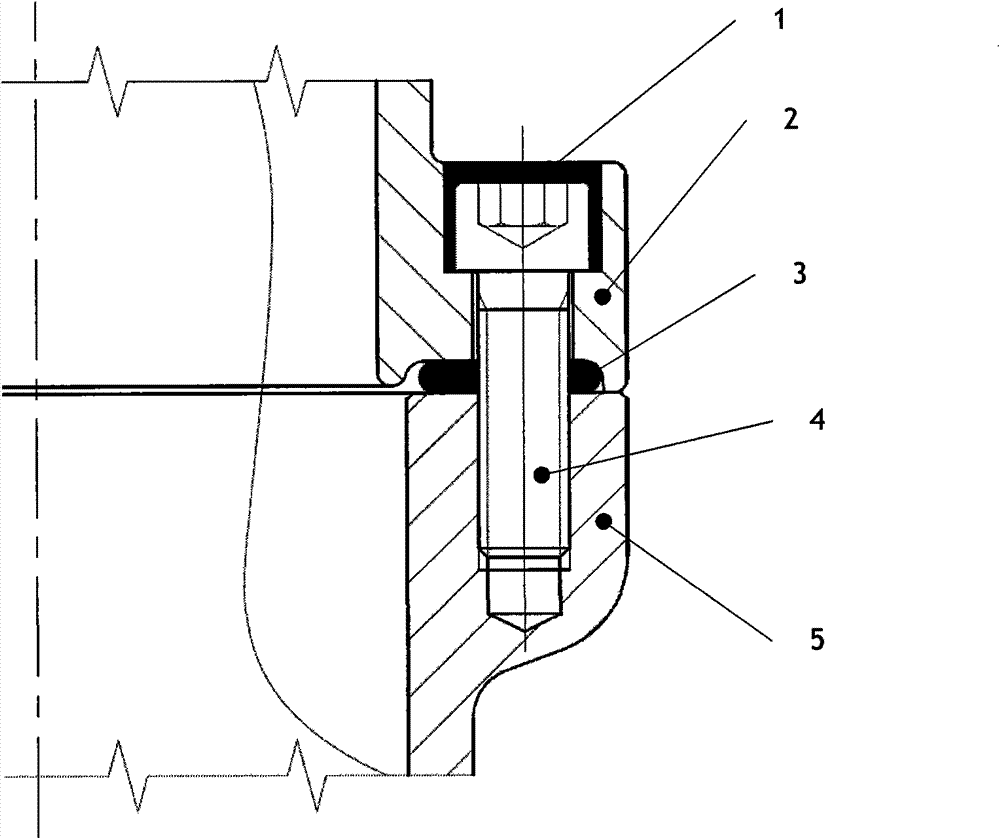

Double-seal high temperature and high pressure rotary compensator and manufacturing method thereof

InactiveCN103470759ASimple structureEasy to manufactureEngine sealsPipeline expansion-compensationEngineeringHigh pressure

The invention discloses a double-seal high temperature and high pressure rotary compensator and a manufacturing method thereof. The double-seal high temperature and high pressure rotary compensator comprises an inner pipe, a packing gland, a left sliding bearing sealing compression ring, a right sliding bearing sealing compression ring, sealing packing, sliding bearing centering rings, an outer pipe and a head joint pipe and is characterized in that a double-seal structure is arranged between the inner pipe and the outer pipe; sliding bearing centering rings which are in clearance fit with the inner pipe and the outer pipe are arranged between opposite ends of the left sealing packing and the right sealing packing; the other ends of the left sealing packing and the right sealing packing are respectively provided with the left self-lubricating sliding bearing sealing compression ring and the right self-lubricating sliding bearing sealing compression ring which are in close fit with the inner pipe and the outer pipe to form into a left double-sealing packing chamber and a right double-sealing packing chamber; an unhook prevention ring is arranged at the right end of the inner pipe. The double-seal high temperature and high pressure rotary compensator has the advantages of being simple in structure, free of pushing force, large in compensation quantity and high temperature and high pressure resistant, having the falling prevention inner pipe, enabling the inner pipe and the outer pipe to rotate coaxially, being stable and flexible, having functions of reducing end surface interspace and compression area of the sealing packing and blocking high temperature and high pressure mediums to perform direct washing damage on the sealing packing, having the double-sealing effect and enabling the sealing performance of the compensator to be safe and reliable under high temperature and high pressure conditions.

Owner:JIANGSU BEST PIPELINE EQUIP

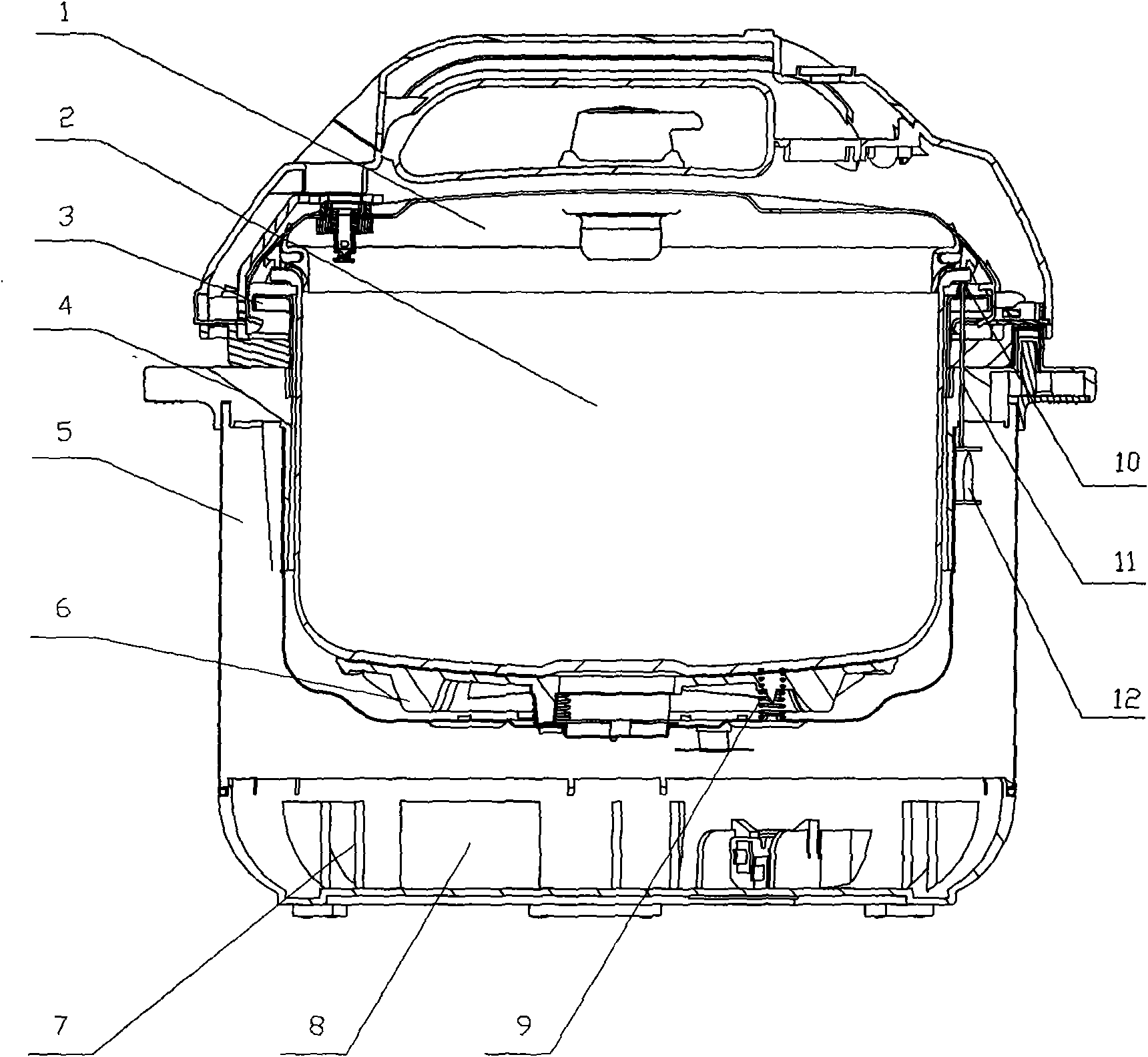

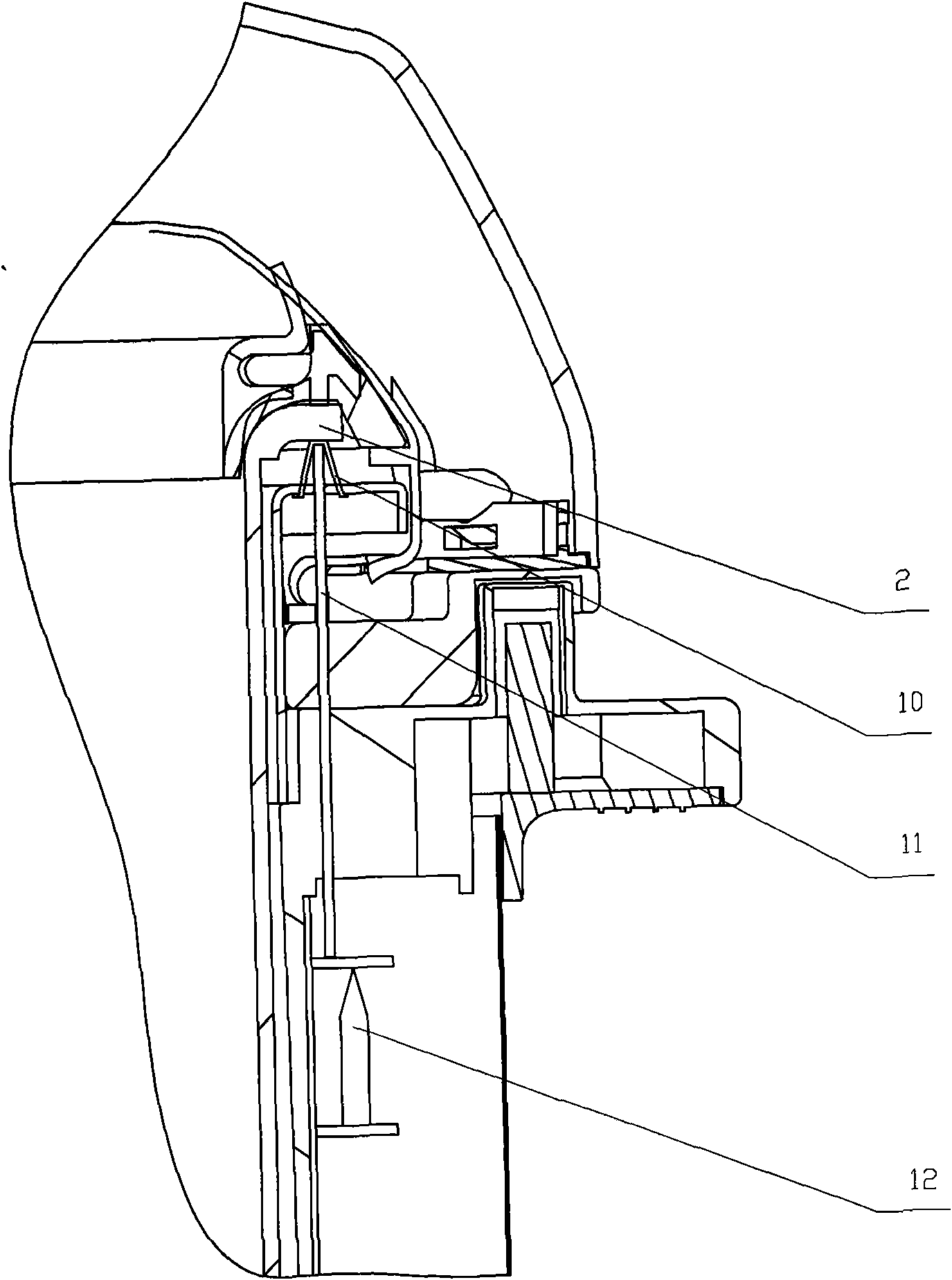

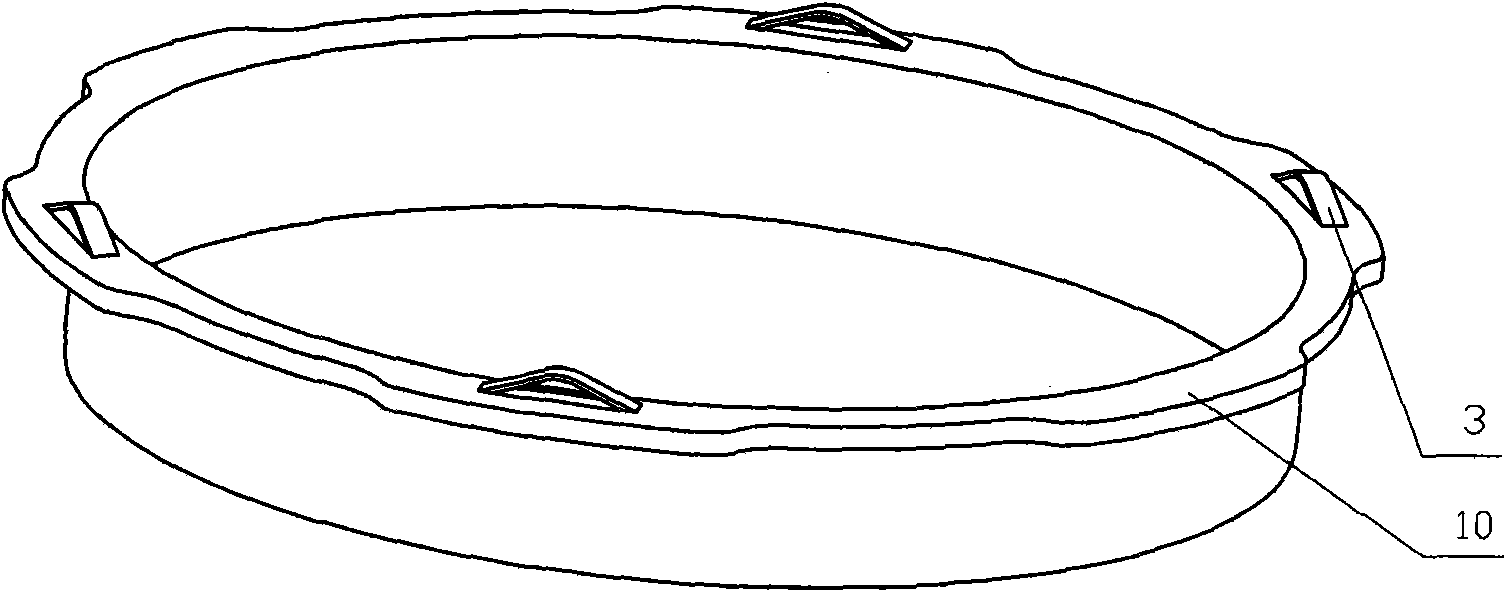

Pressure control structure of pressure cooking appliance

The invention provides a pressure control structure of a pressure cooking appliance, belonging to the technical field of pressure cooking appliances. The structure comprises a pot cover, an external pot, an internal pot, a detecting and collecting part for detecting the displacement amount, and an electric control device for controlling the electric heater according to the information of the detecting and collecting part, the structure is characterized in that the pot cover is buckled to the internal pot through pot teeth; an elastic member is arranged between the pot tooth surface of the opening part of the external pot and the combination surface of the opening part of the internal pot; a displacement linking device is arranged below the elastic member or the internal pot; the detecting and collecting part is located on the lateral part or the bottom of the external pot; the displacement information of the elastic member or the pot body is transmitted to the electric control device by the detecting and collecting part. For the prior art, requirement on the material of the elastic pot teeth is high and cost is increased; in the invention, the pot opening surface is equipped with the elastic member so as to control the pressure correctly, and the strength of the buckling part of the original pot tooth is not change; besides, by using the elastic member as the support part of the internal pot, the bottom of the external pot does not need to bear pressure, the manufacturing cost is reduced, and the processing difficulty is obviously reduced.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

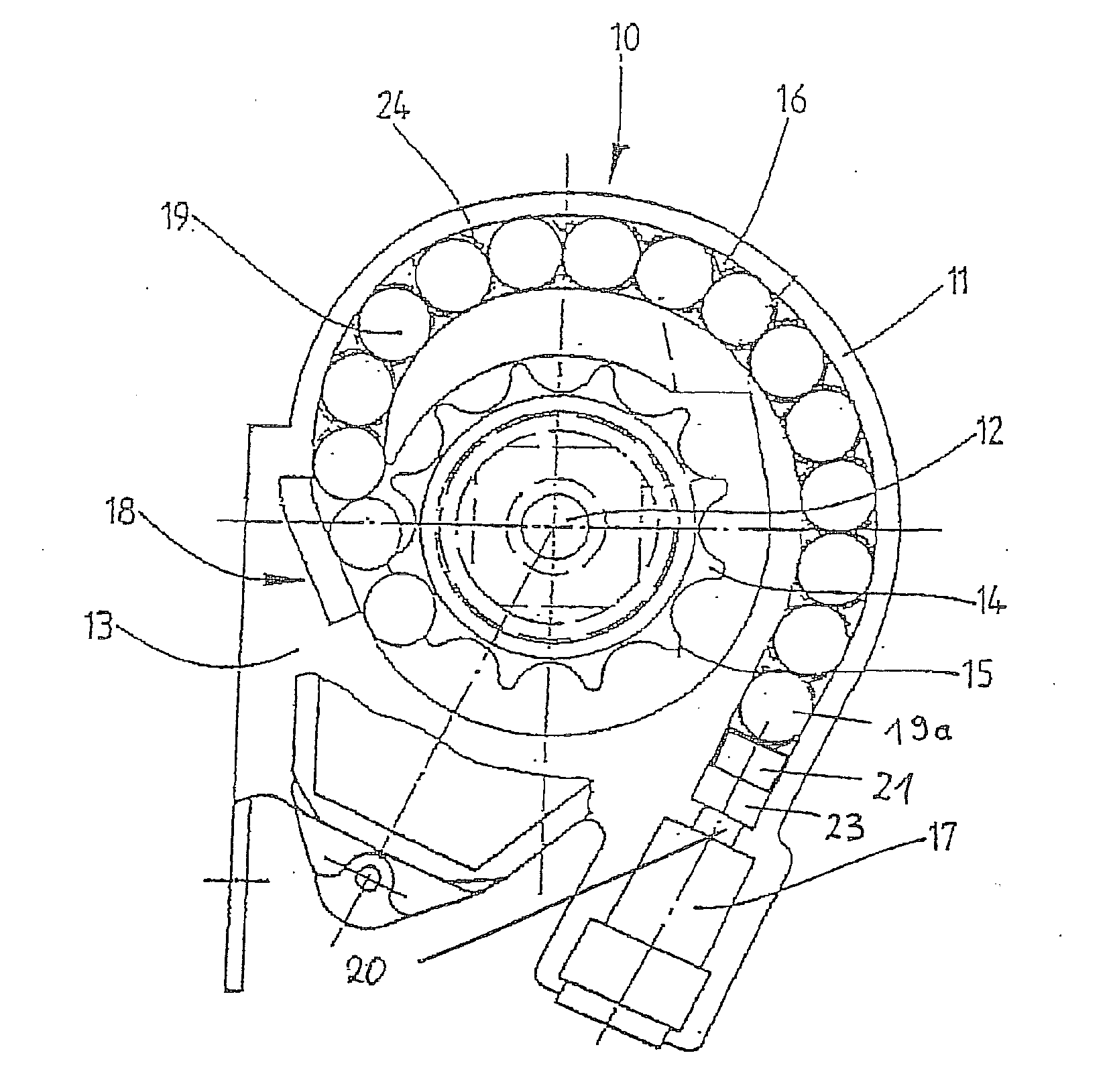

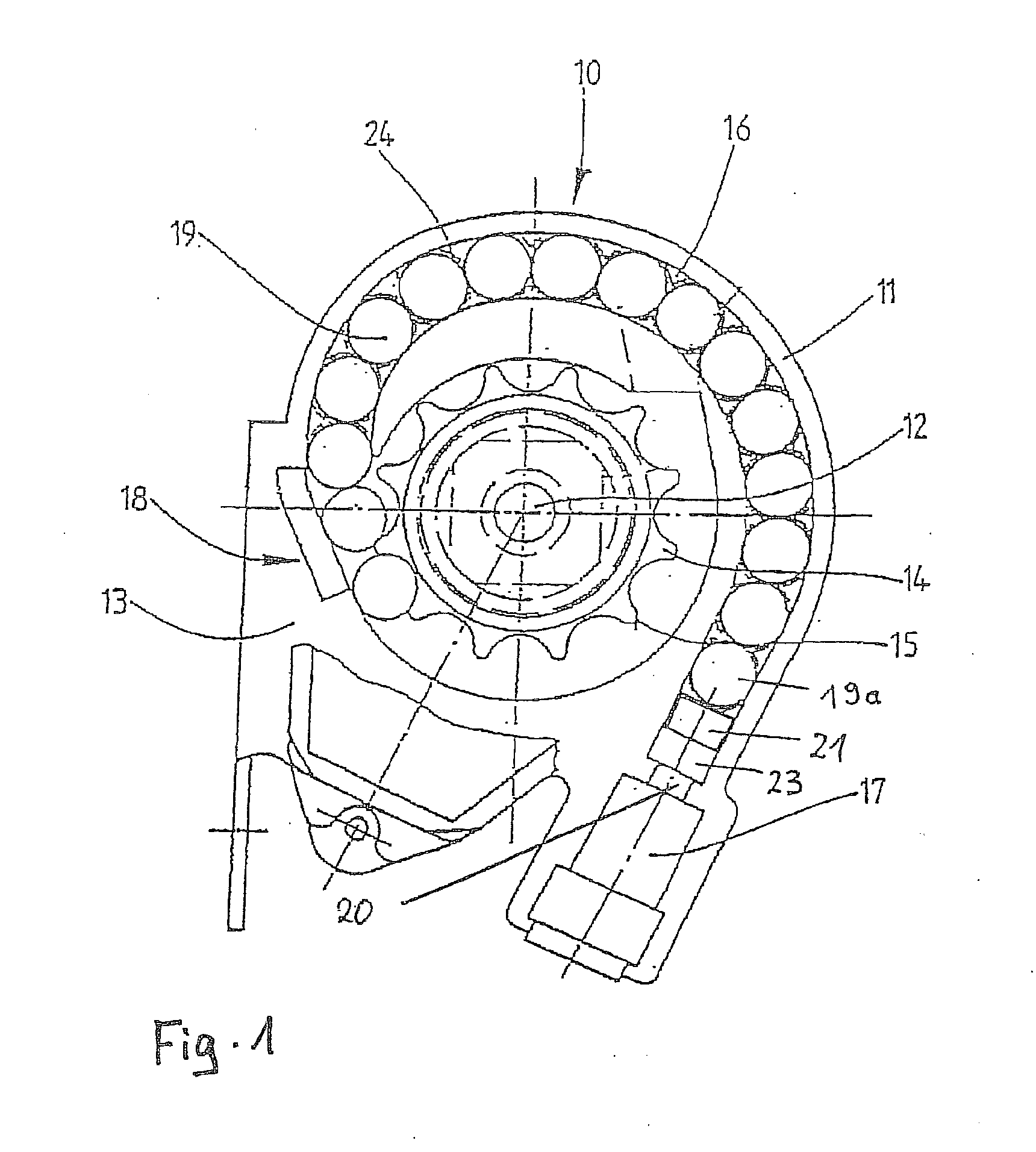

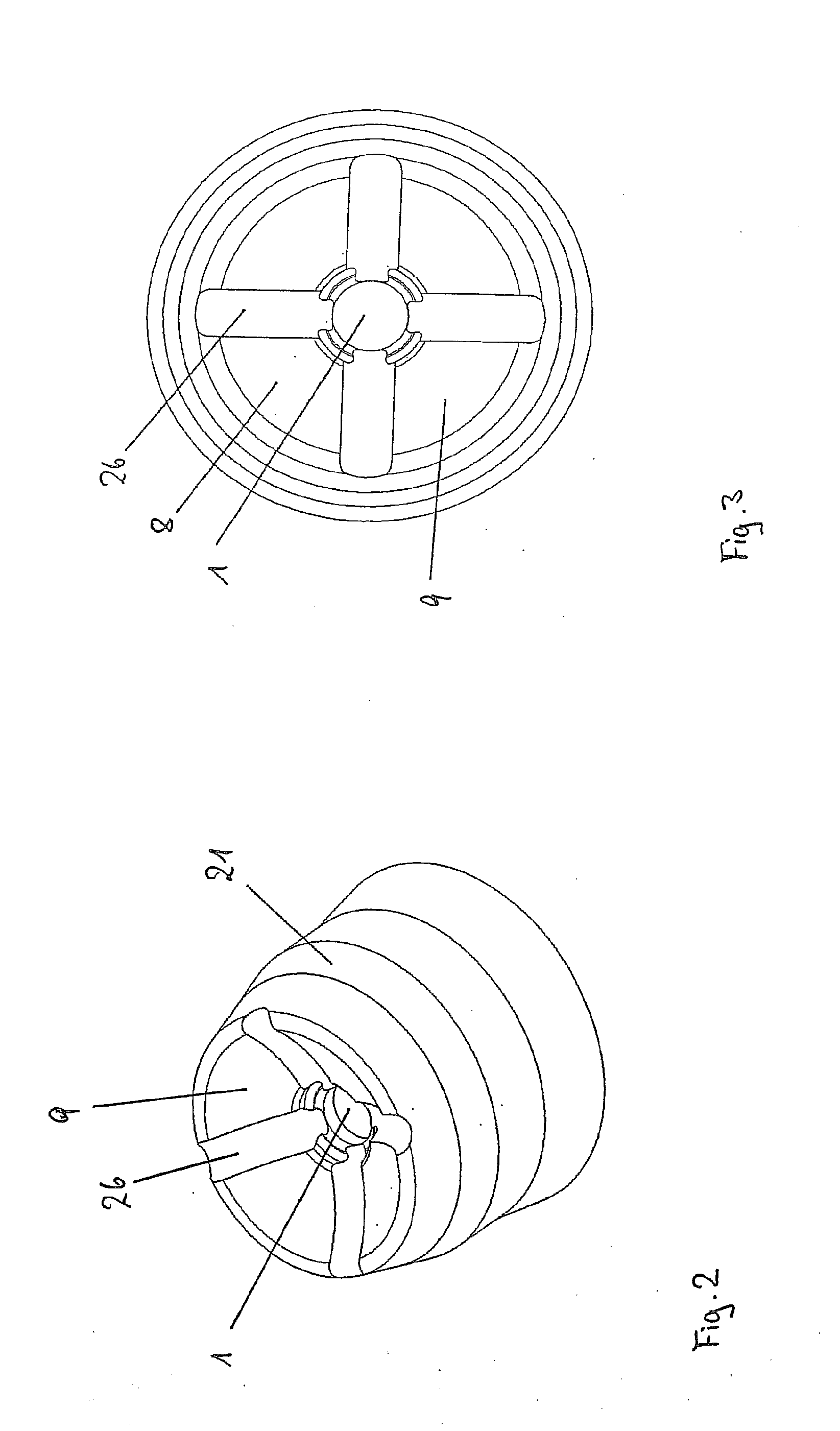

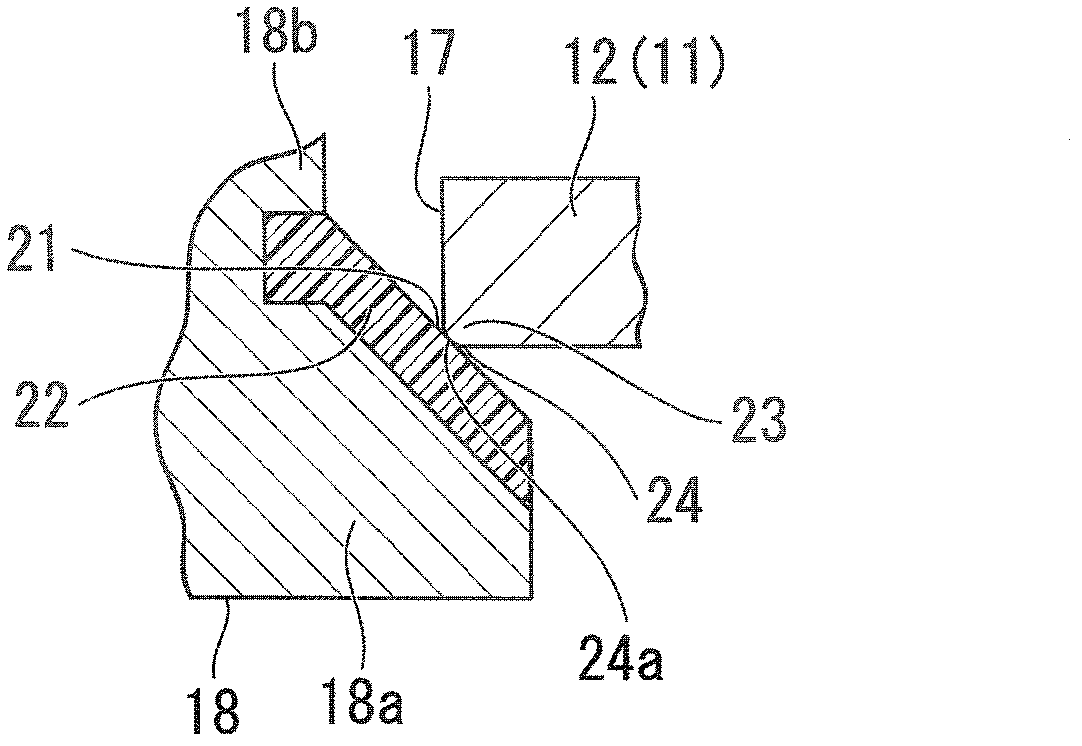

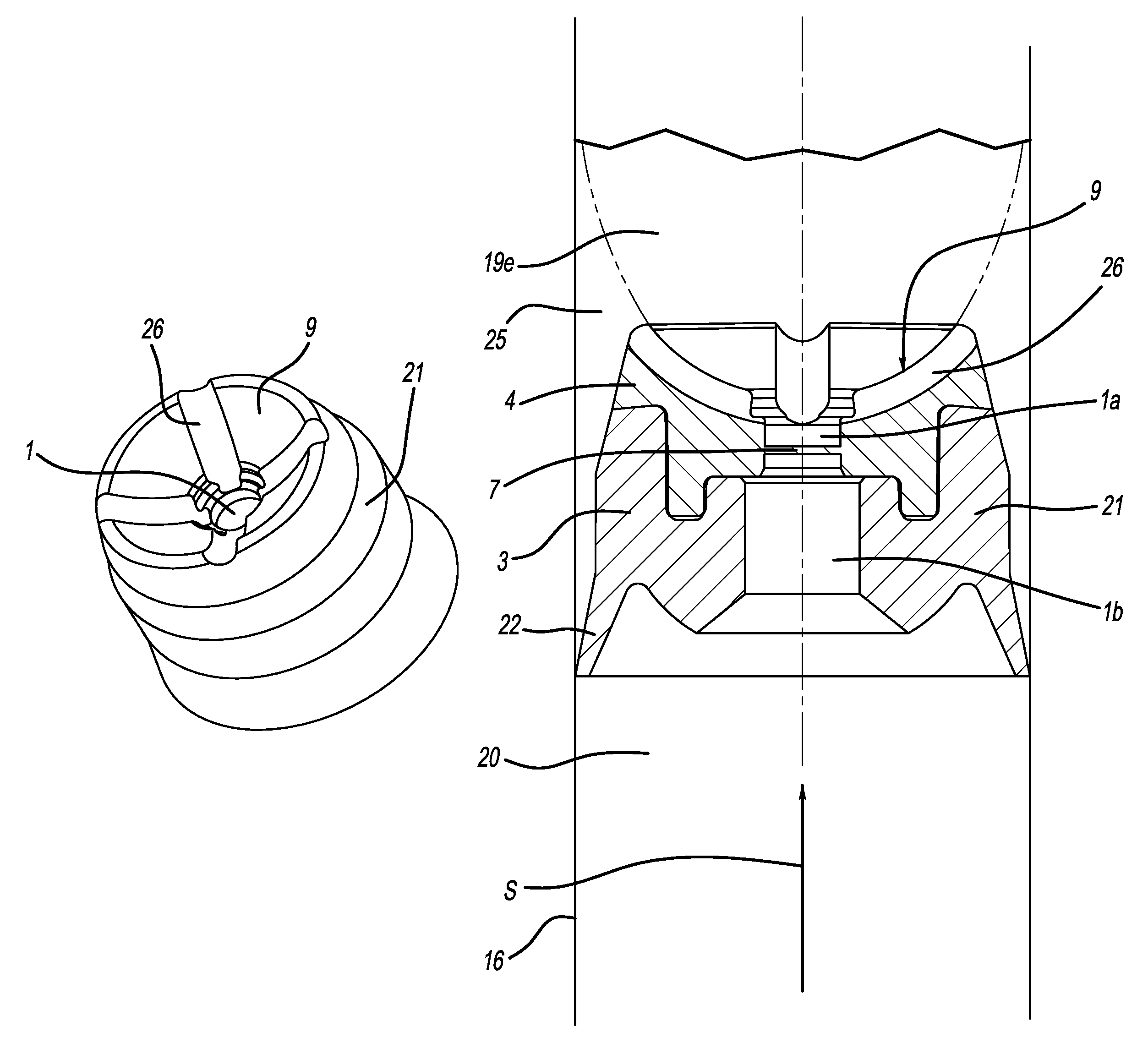

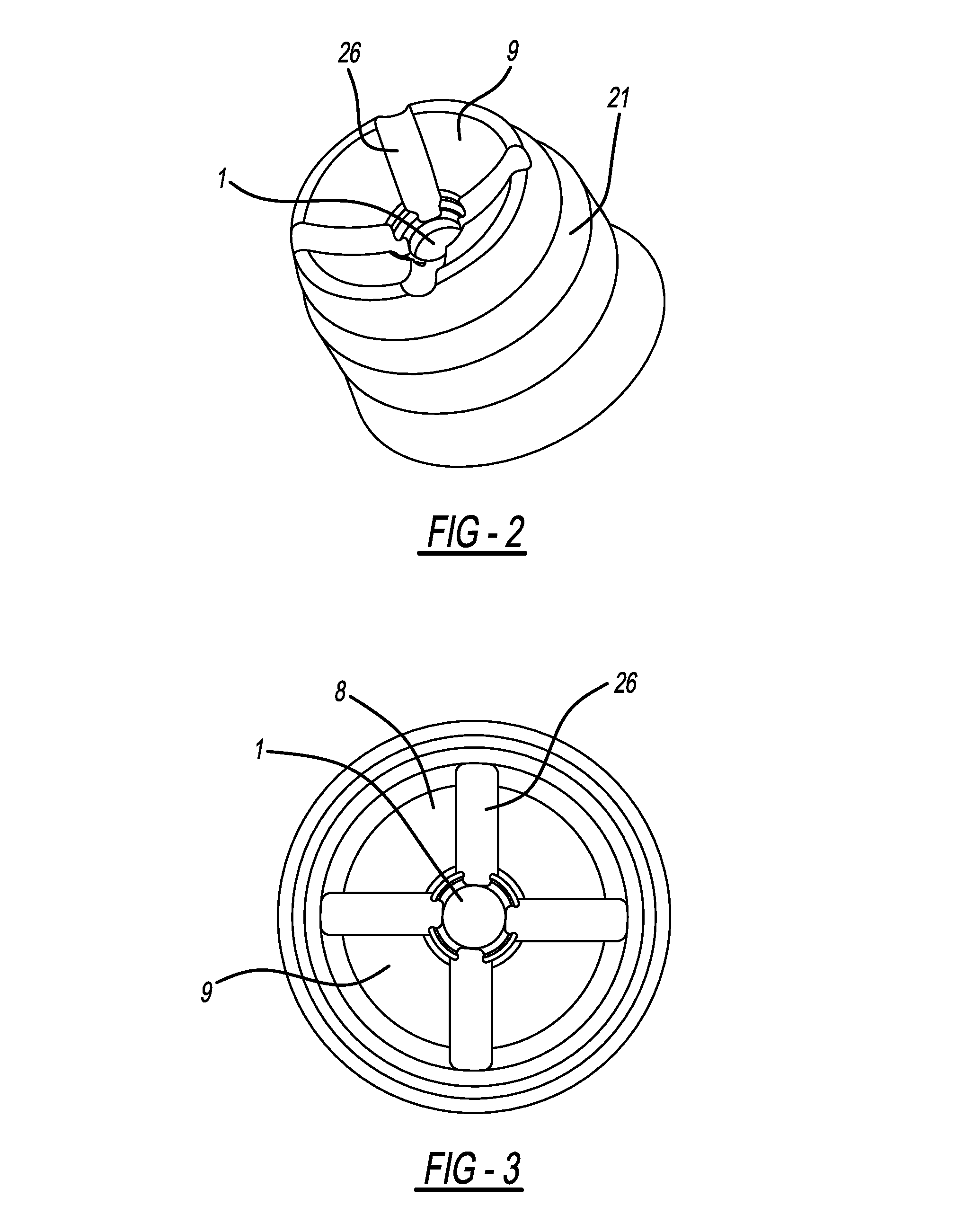

Pretensioning Device for a Safety Belt

A pretensioning device (10) for a safety belt, of a motor vehicle, having a gas generator (17), a piston (21) guided in a tube (16), which closes a pressure area (20) in the tube (16) that is pressurized by the gas generator (17) whereupon the piston (21) is able to move in a pretensioning movement which is able to be conveyed to the safety belt by means of an inertia body (19a) resting on a front face (9) of the piston (21). The piston (21) forms a pass-through opening (1) releasable upon exceeding of a predetermined pressure and a recess (26) is provided in the front face (9) with an inertia body (19a) resting thereon, so that a flow connection is created from the pass-through opening (1) to the area (25) located behind the piston (21) in the direction of the pretensioning movement (S).

Owner:AUTOLIV DEV AB

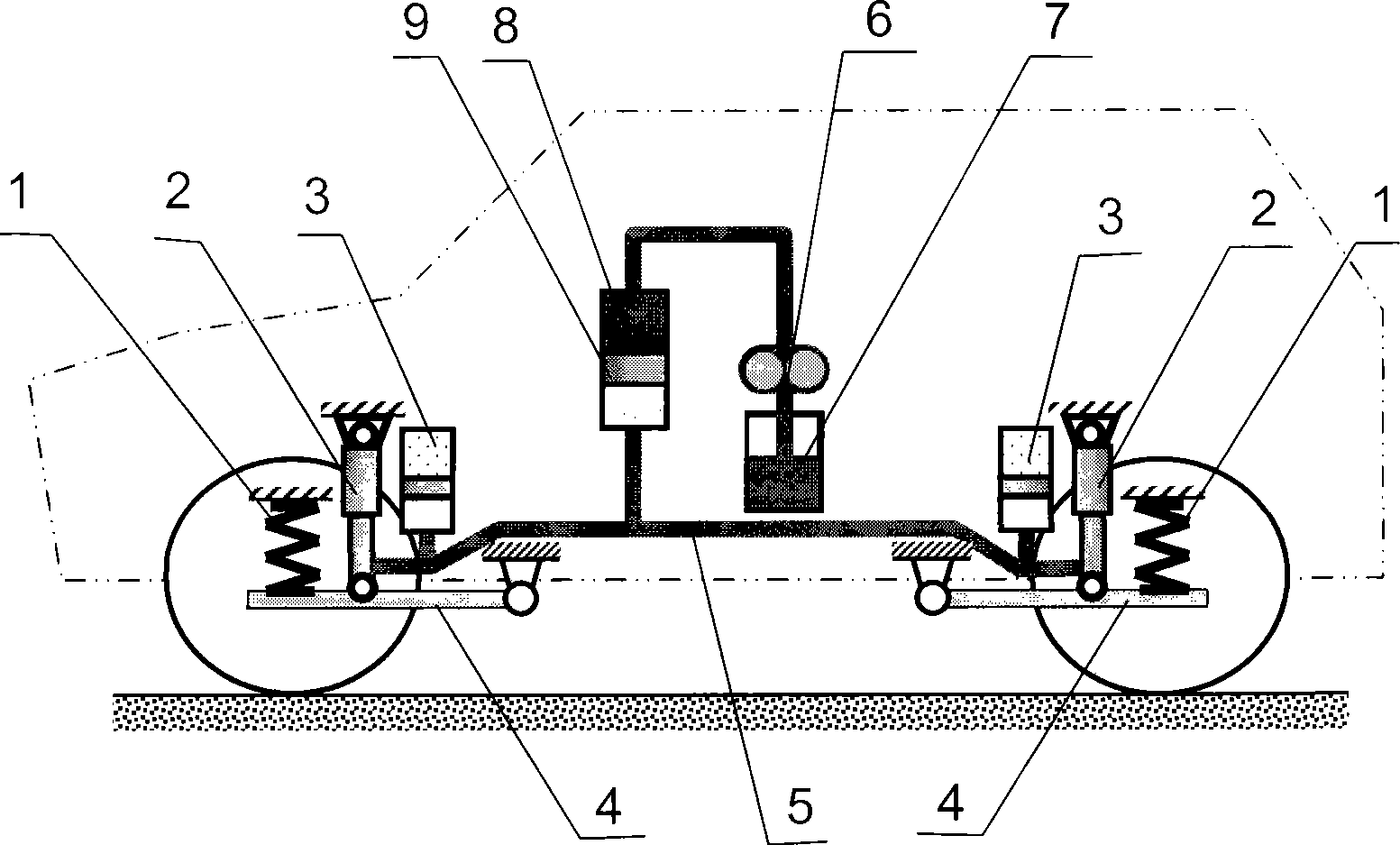

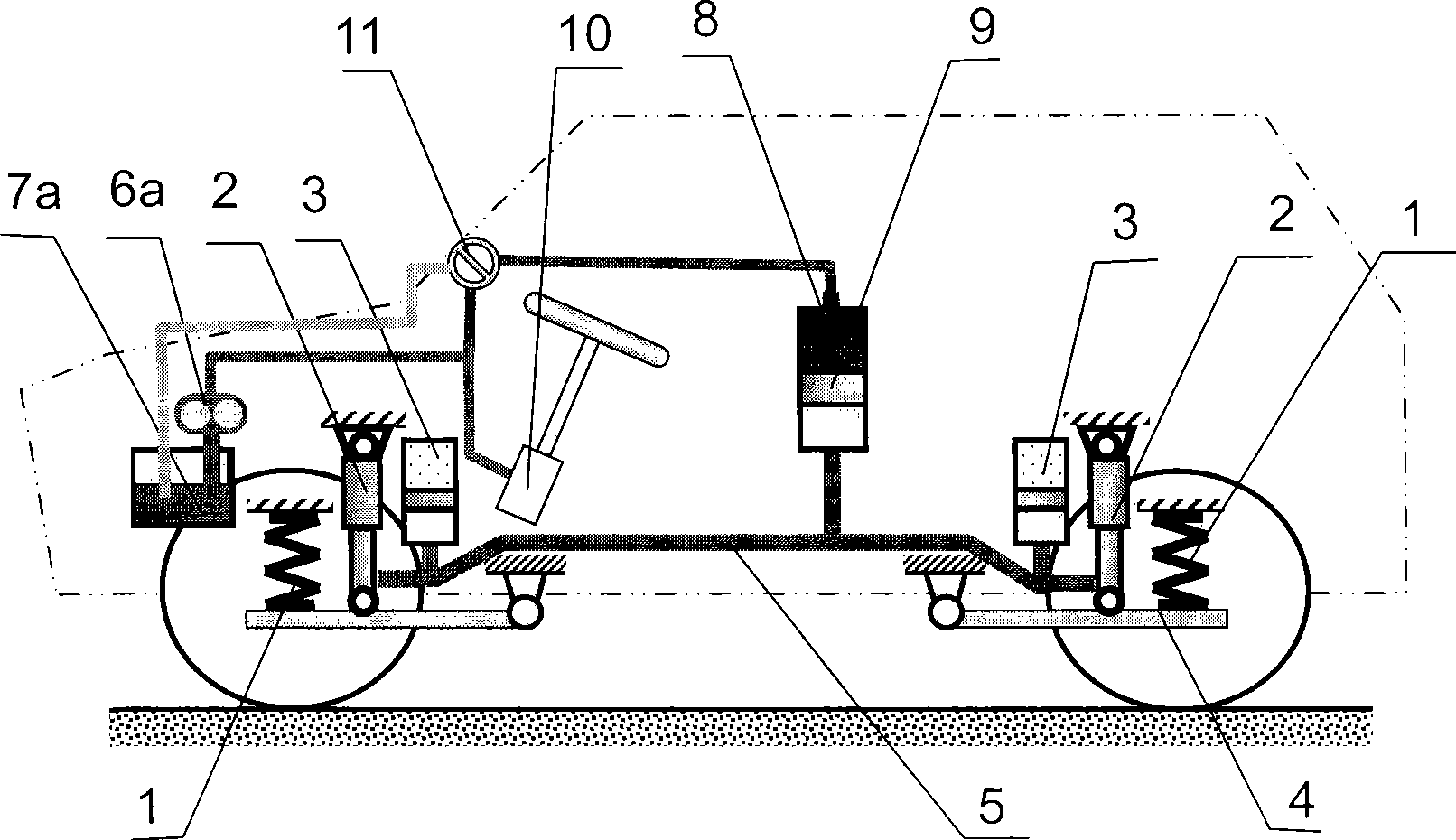

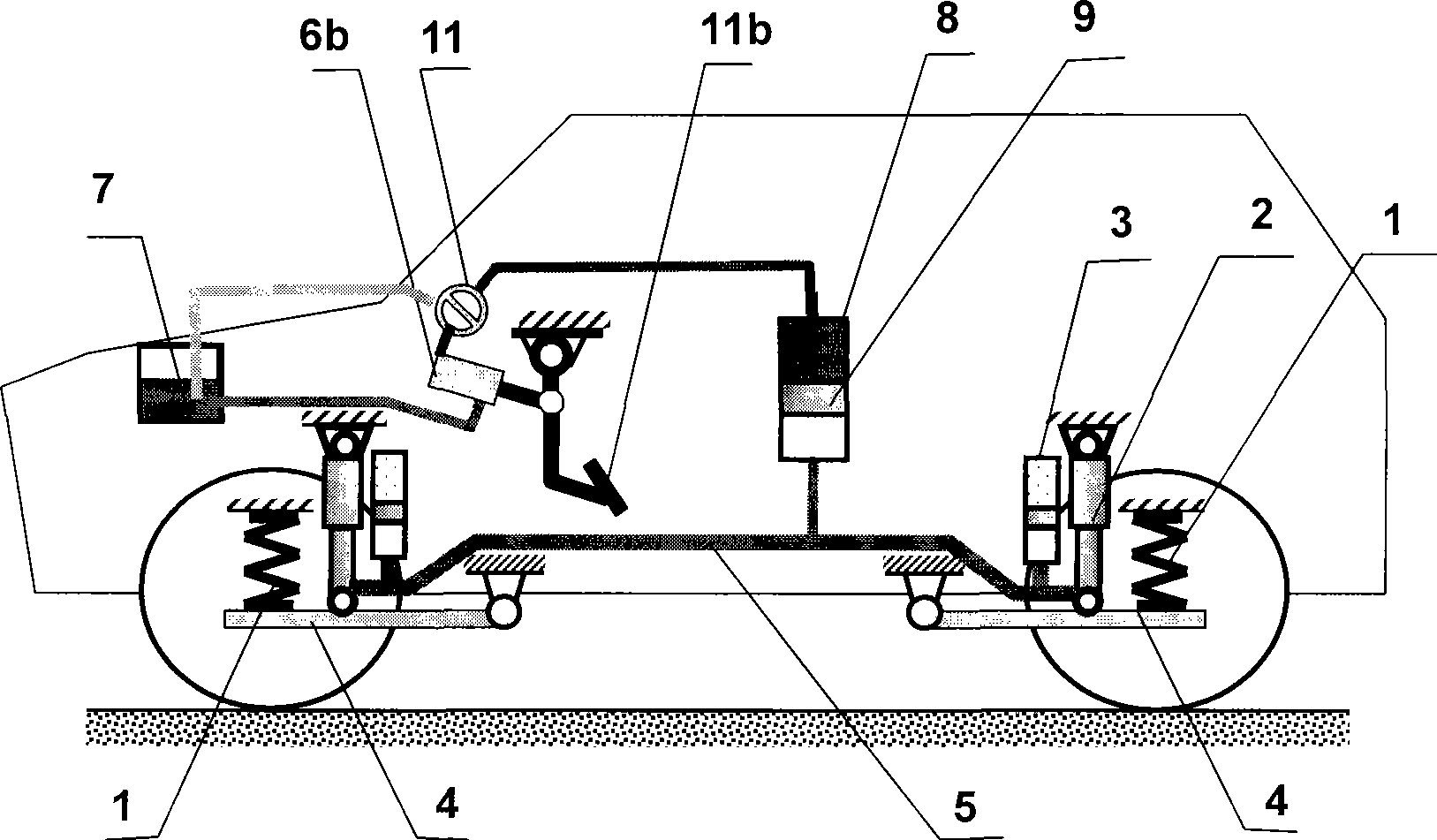

Suspension system of lifting load-bearing impact damper

InactiveCN101362424AImprove obstacle performanceEasy to modifyResilient suspensionsMaster cylinderEngineering

The invention relates to a technology for lifting a suspension. The invention provides a simple and convenient method so as to improve the obstacle performance of various vehicles with arbitrary suspension form under the condition of uneven road. Compared with the general hydraulic lifting suspension system, the technology is characterized in that a high-power oil (air) pump and an actuating cylinder are not required, and the mounted type shock absorber (patent) with structure and size basically identical with the structure and size of the prior shock absorber replaces the ordinary shock absorber and the lifting cylinder. As the mounted type shock absorber only bears small part of dead load, the carrying area is very small, and the required lifting power source is also small; as for the vehicle with power steering, the suspension can be lifted by using the oil source of the power steering; and even the suspension can be lifted by using a manual (for example, treading) master cylinder. The invention has the characteristics that the invention is especially suitable for being modified on the existing vehicle with suspension structure, and has high applicability and low cost.

Owner:郭孔辉

Power-saving apparatus for hydraulic expanding large retaining-ring by using super high pressure system

A labor-saving unit for manufacturing the large protecting ring by hydraulic expanding with ultrahigh-pressure system features that the upper and lower hollow conic punch heads, whose internal hole is matched with a labor-saving guide column in slide mode, are arranged at upper and lower positions relative to a protecting ring blank, at least two labor-saving units are arranged between the bench of ordinary press and movable transverse beam, the labor-saving guide sleeve whose inside and outside are communicated with the ultrahigh-pressure liquid channel is additionally used for said labor-saving guide column, and an ultrahigh-pressure system is used for boosting.

Owner:DEYANG WANXIN POWER STATION PROD DEV

Touch type block-resistant descaling time-delay self-closing water saving device

InactiveCN101324286AEnsure hygiene and safetyAperture unobstructedFiltration separationFluid-delivery valvesWater savingTap water

The invention relates to a soft-touch anti-blockage scale-removal time-delay self-closing water-saving device, which is positioned in a shell body of a domestic water tap, a feces flushing valve, a urine flushing valve or a shower valve, and comprises a button, a valve handle, a cylinder barrel, a piston, a guide holder of the piston, a spring cleaner, a check valve and a water inlet filter screen. Foreign materials in tap water are screened out through the water inlet filter screen so as to prevent blockage; the spring cleaner automatically condenses, passes through and cleans a supercharging hole to prevent scale from forming on the wall of the supercharging hole, prevent the wall of the supercharging hole from being blocked; and the check valve prevents siphoning waste water from being flowed back. When the device is used, the button can be touched lightly by a finger or a tiptoe to automatically close time-delay water consumption. The device has the advantages of simple structure, skillful and convenient use and long service life.

Owner:温州阿母斯丹洁具科技有限公司

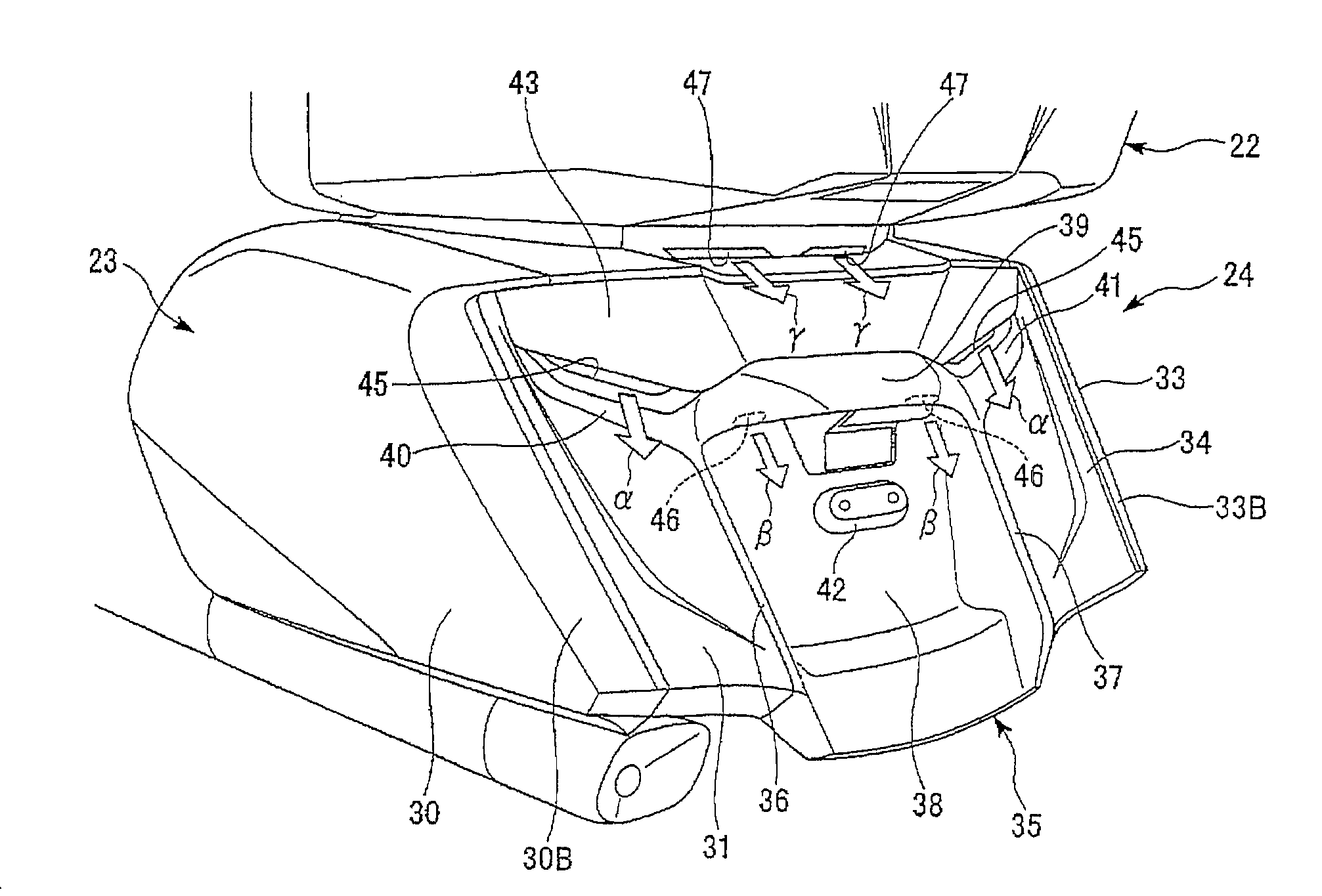

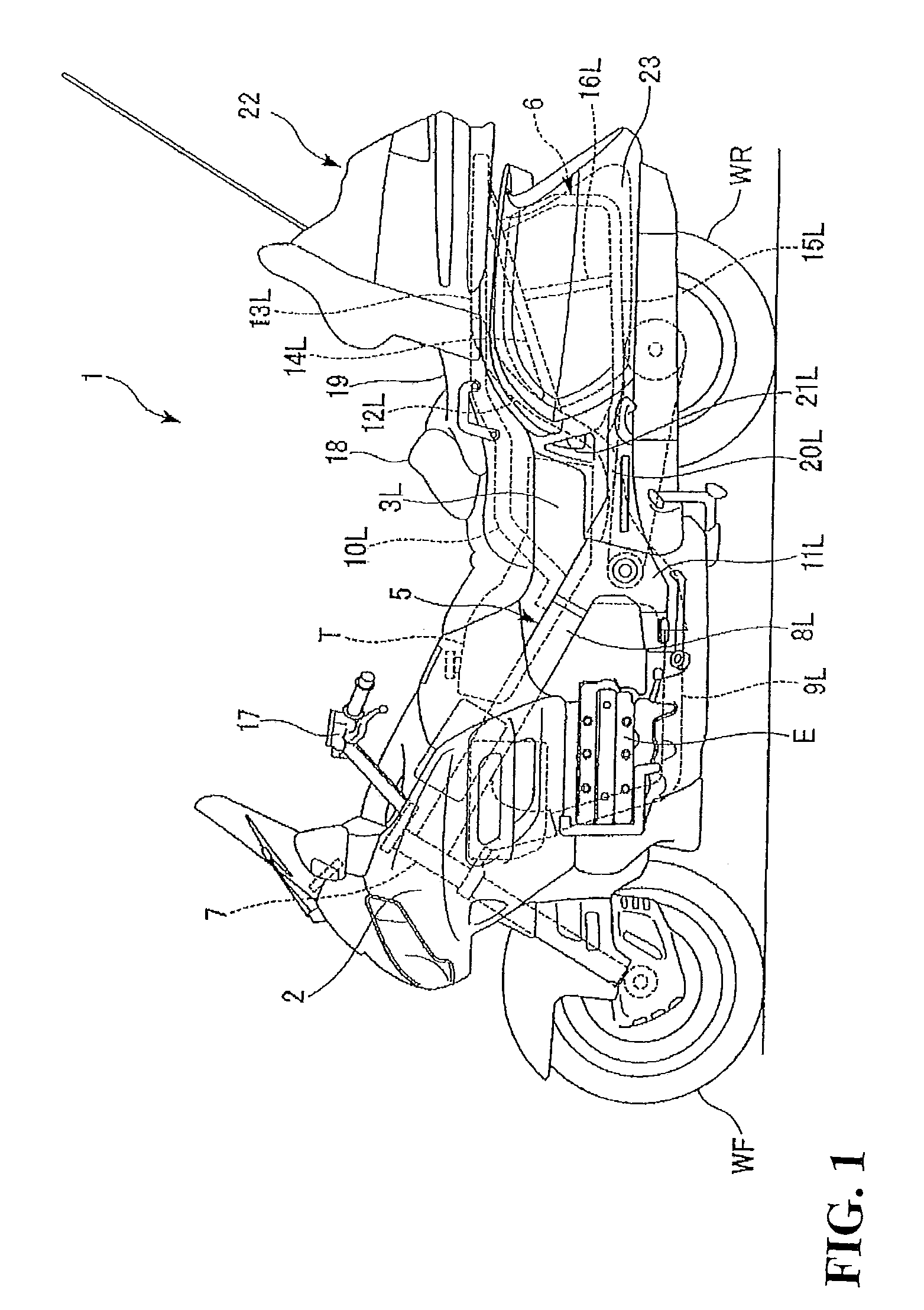

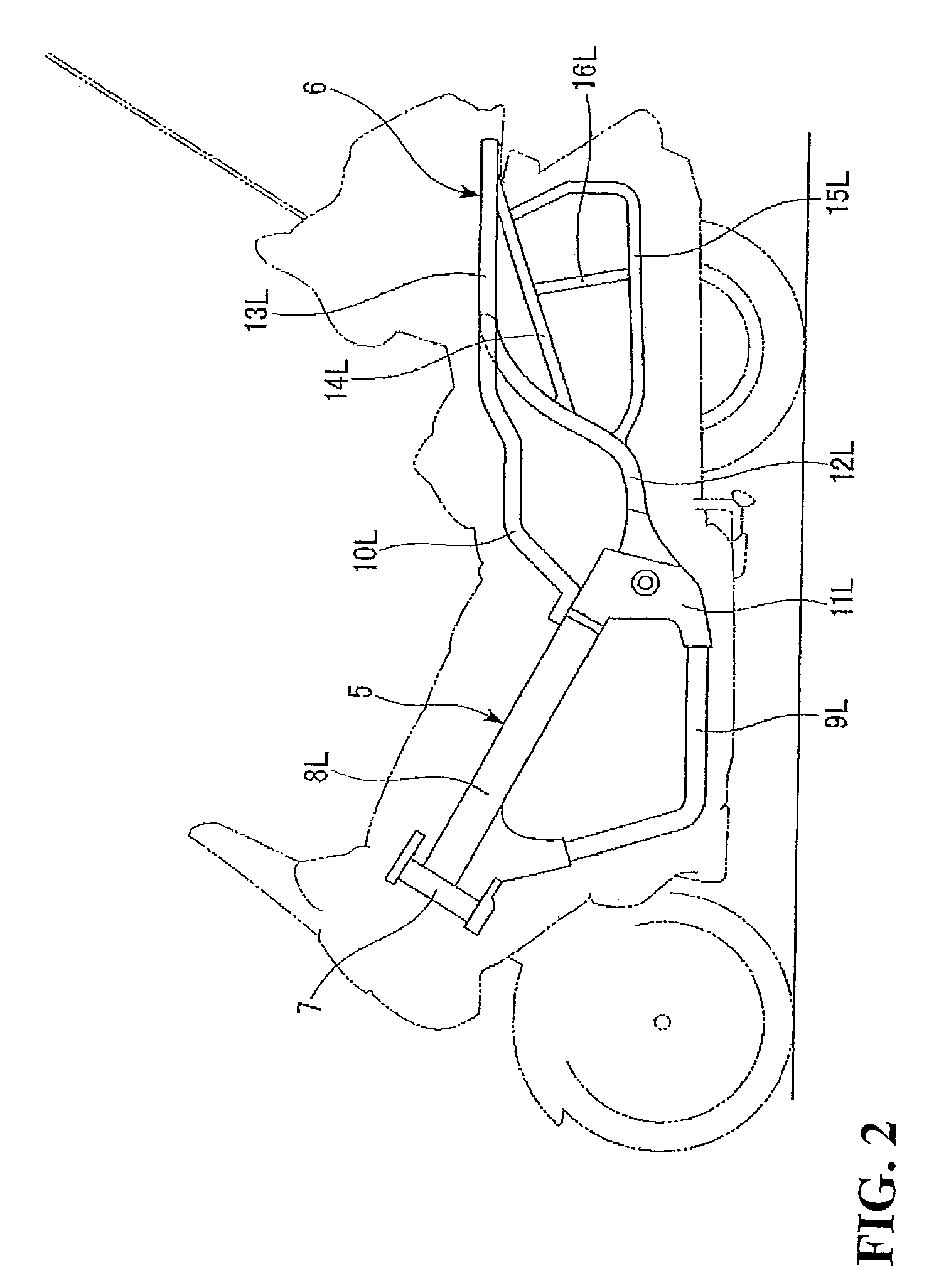

Rear structure of straddle-ride type vehicle

ActiveUS8465083B2Reduce the negative pressure areaIncrease loadVehicle seatsVehicle body stabilisationAutomotive engineering

In a vehicle whose tire is wholly covered from the left, right and back, a negative pressure area to the rear of the vehicle is reduced. In a vehicle including a left trunk and a right trunk in a rear portion of the vehicle, a rear fender continuous with respective rear faces of the left and right trunks is provided, and a plane formed of the respective rear faces of the left and right trunks and the rear fender is provided with negative pressure correction holes.

Owner:HONDA MOTOR CO LTD

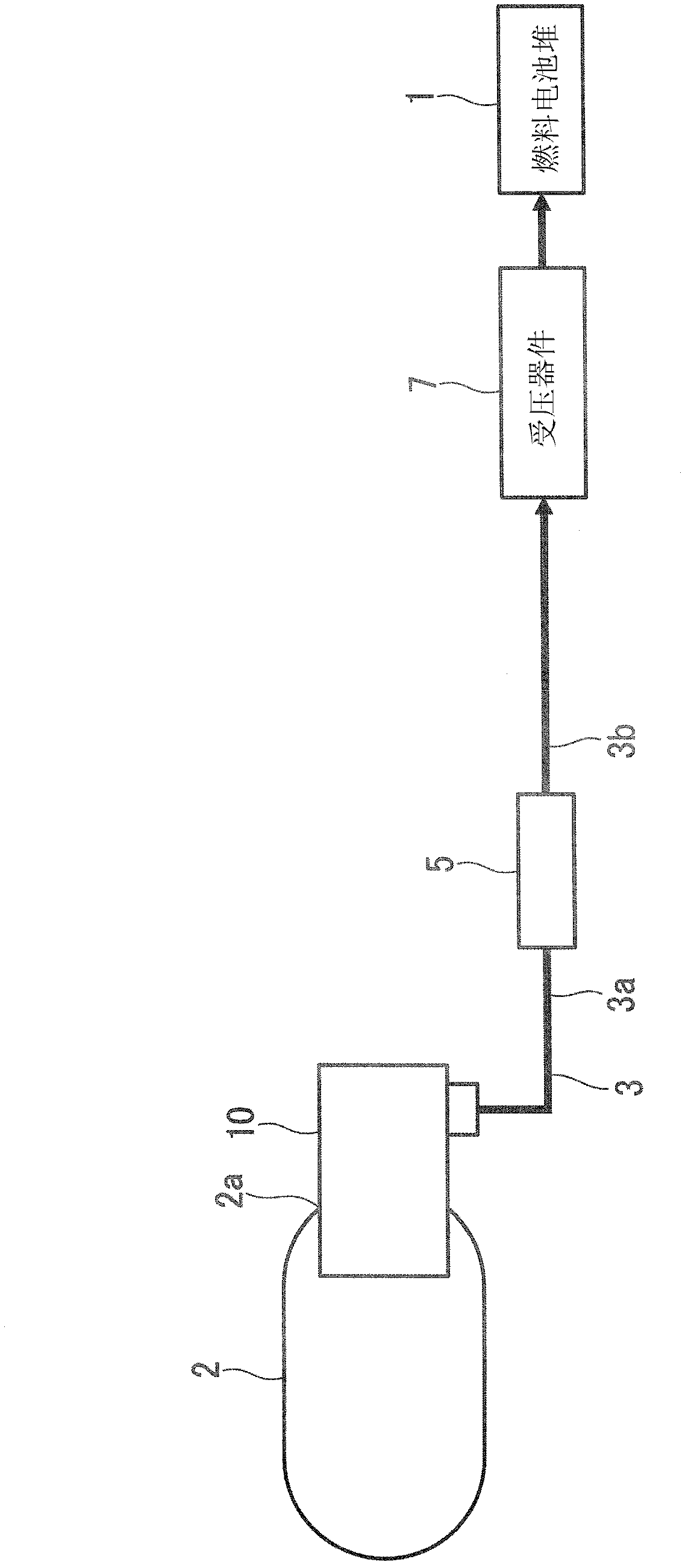

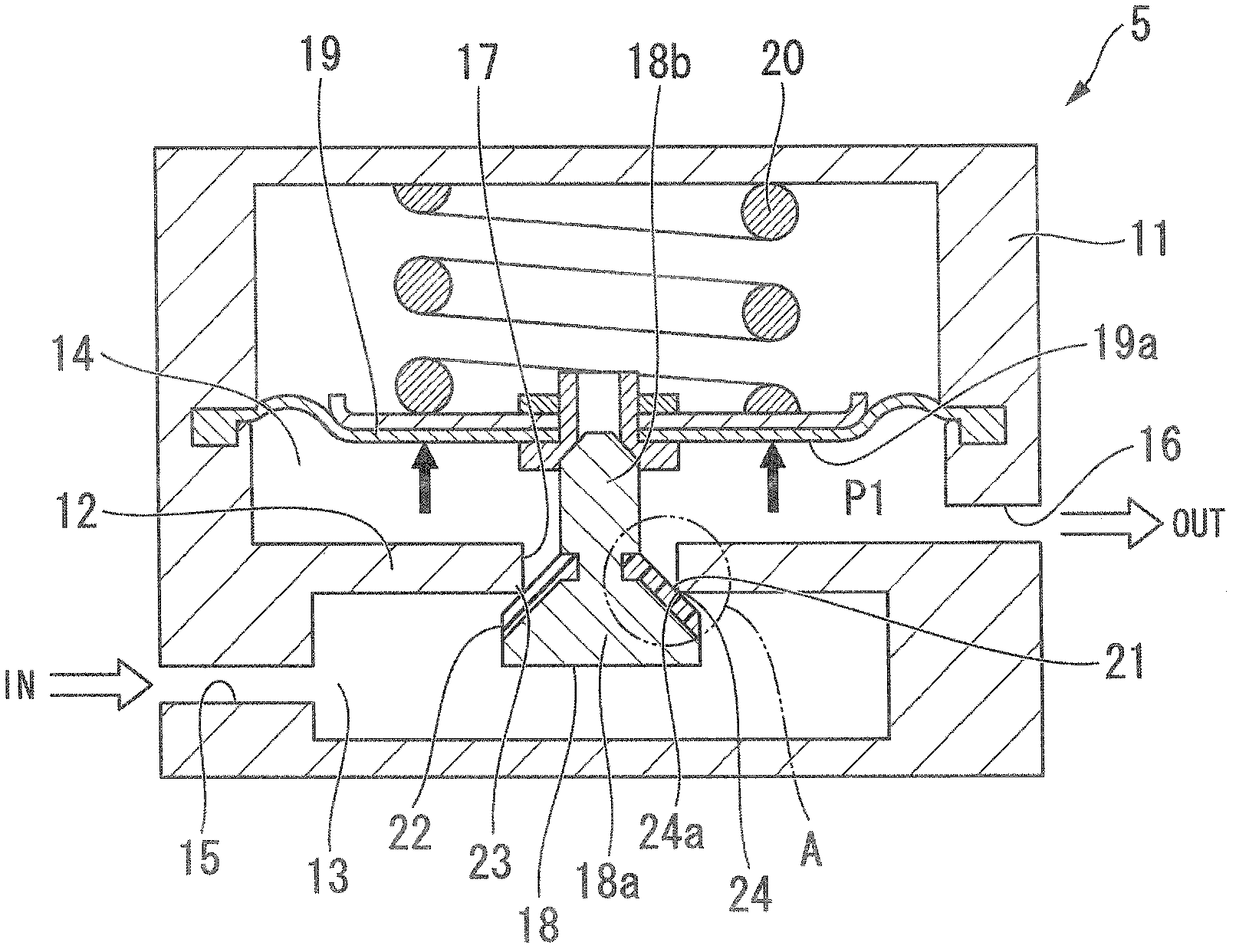

Pressure reducing valve having shutoff mechanism

InactiveCN102734515APrevent leakageInhibit deteriorationEqualizing valvesSafety valvesHigh pressureMaximum pressure

A high-pressure side primary pressure chamber communicates with a secondary pressure chamber on the side of a pressure receiving device through a communication hole. A diaphragm which receives the pressure in the secondary pressure chamber is provided, and a valve body is connected to the diaphragm. The diaphragm is biased by a spring in a valve opening direction. The area S (mm2) of the pressure receiving surface of the diaphragm and the spring constant k (N / mm) of the spring are set so as to satisfy the following equations (1) and (2). P1S-k[Delta]L>C (1) P1<P2 (2) where P1 denotes the pressure (MPa or N / mm2) of the secondary pressure chamber, [Delta]L denotes the displacement (mm) of the spring, C denotes the minimum closing load (N) of the valve body, and P2 denotes the allowable maximum pressure (MPa or N / mm2) of the pressure receiving device.

Owner:HONDA MOTOR CO LTD

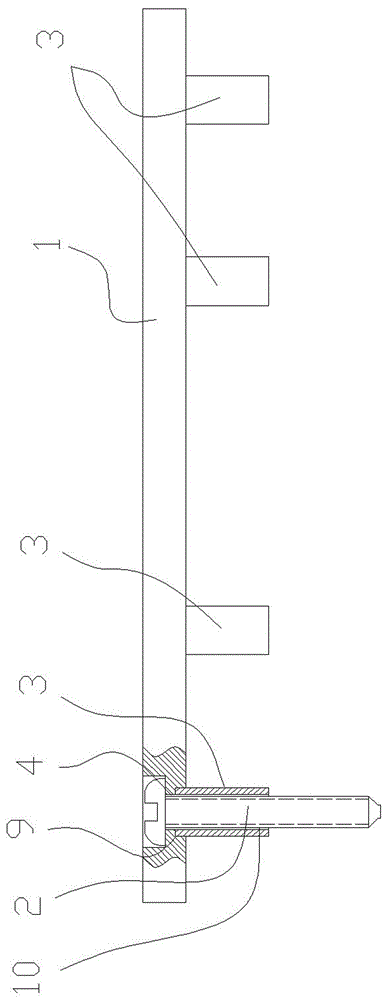

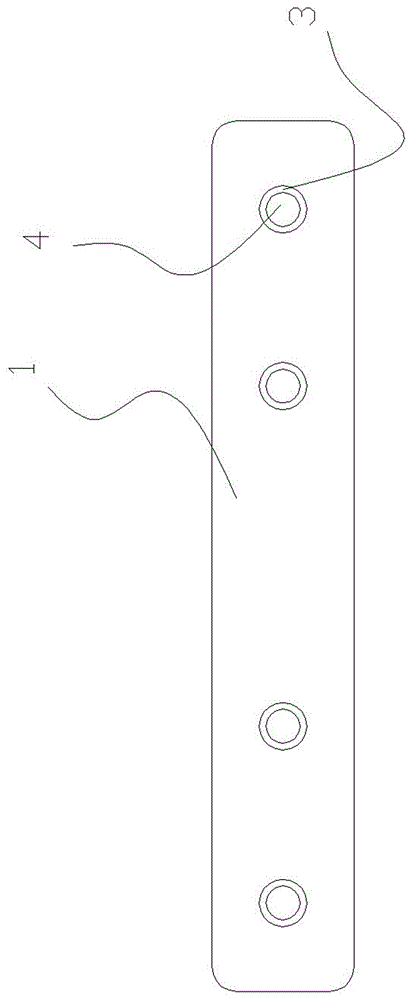

Novel bone fracture plate

InactiveCN105662568AProtect blood supplyReduce pressure areaFastenersBone platesBone CortexIliac screw

The invention relates to a novel bone fracture plate which comprises a bone fracture plate body and a screw. The novel bone fracture plate is characterized in that one of the surfaces of the bone fracture plate stretches across the two sides of a bone fracture line; at least two supporting columns are arranged on each side of one of the surfaces of the bone fracture plate; a screw hole is formed in the bone fracture plate body; the screw is inserted into the screw hole from the other side of the bone fracture plate, passes through the supporting columns and finally enters a cortical bone to complete bone fracture fixation; or the two adjacent supporting columns are fixedly connected with the bone fracture plate body on the two sides of the screw hole; the screw directly enters the cortical bone to complete bone fracture fixation after being inserted into the screw hole from the other side of the bone fracture plate body. Compared with the prior art, the novel bone fracture plate provided by the invention has the advantages that the damage caused by regular operation to blood supply for a bone fracture segment can be avoided, so that bone fracture healing is facilitated; 'inner fixation' is not needed to be taken through operation in the second-time hospitalization, so that the hospitalization expense can be effectively reduced.

Owner:赖金平 +3

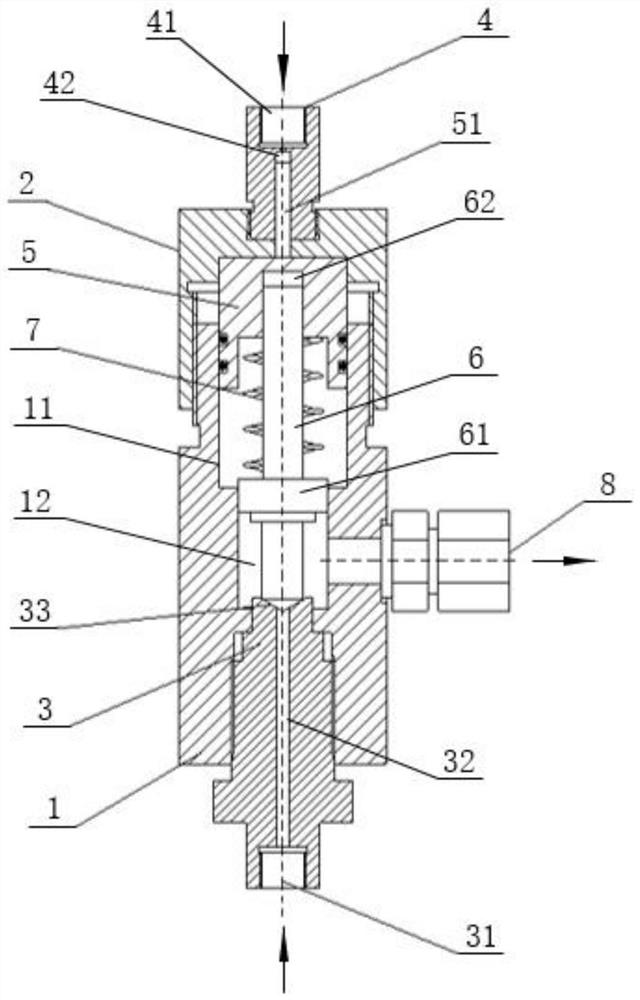

Diaphragm compressor follow-up valve and using method thereof

PendingCN111911674AReduce pressure areaReduce weightPositive displacement pump componentsFlexible member pumpsEngineeringDischarge pressure

The invention discloses a diaphragm compressor follow-up valve and a using method thereof, and belongs to the technical field of diaphragm compressor structures. The diaphragm compressor follow-up valve comprises a valve body and a valve deck which are fixedly connected. A work cavity is formed between the valve body and the valve deck, and a valve needle is arranged in the work cavity. The valvebody is provided with an oil cavity connecting end; the oil cavity connecting end communicates with an oil channel, and the oil channel is in separable sealed contact with the valve needle; the valvedeck is provided with an exhaust pressure connecting end; the exhaust pressure connecting end communicates with an air channel, and a piston rod is slidably arranged in the air channel and fixedly connected with a spring seat; and the outer side of the valve needle is sleeved with a spring, and the spring is positioned between an oil baffle block and the spring seat. The device adopts a valve needle structure, so that the pressure bearing area is small, the overall size of the follow-up valve is correspondingly reduced, the weight is light, and the burden on a follow-up valve connecting piececan be reduced at the same time on the occasion with large vibration. The oil discharge pressure is also only related to the exhaust pressure of a compressor and the pre-compression amount of the spring, the oil discharge pressure can be adjusted by replacing the spring or adding a spring adjusting pad, the use is flexible, and the controllability is also greatly enhanced.

Owner:SHENYANG YUANDA COMPRESSOR

Clean out sub

A clean out sub for use in a drill string having a tool body with a cavity for passage of drilling fluid and annular fluid circulation ports extending through the tool body, a valve spool is positioned within the tool body cavity having a reduced diameter orifice, a compression spring is located within the tool body cavity adjacent the valve spool, wherein a drop in fluid pressure created by the orifice imparts a downhole force on the valve spool and at a predetermined force overcomes a set resistive force of the compression spring thereby moving the valve spool to open the annular fluid circulation ports.

Owner:WWT NORTH AMERICA HLDG

Method for processing high-temperature alloy die forging piece with central hole

The invention discloses a method of processing a high-temperature alloy forging part with a center hole. The invention is characterized in that the center hole of the high-temperature alloy forging part is made before forging to remove the metal of inferior structure positioned at the center; and then forging is processed. Useful life of the mould can be prolonged and quality of the mould can be guaranteed by adopting the method.

Owner:SOUTHWEST ALUMINUM GRP

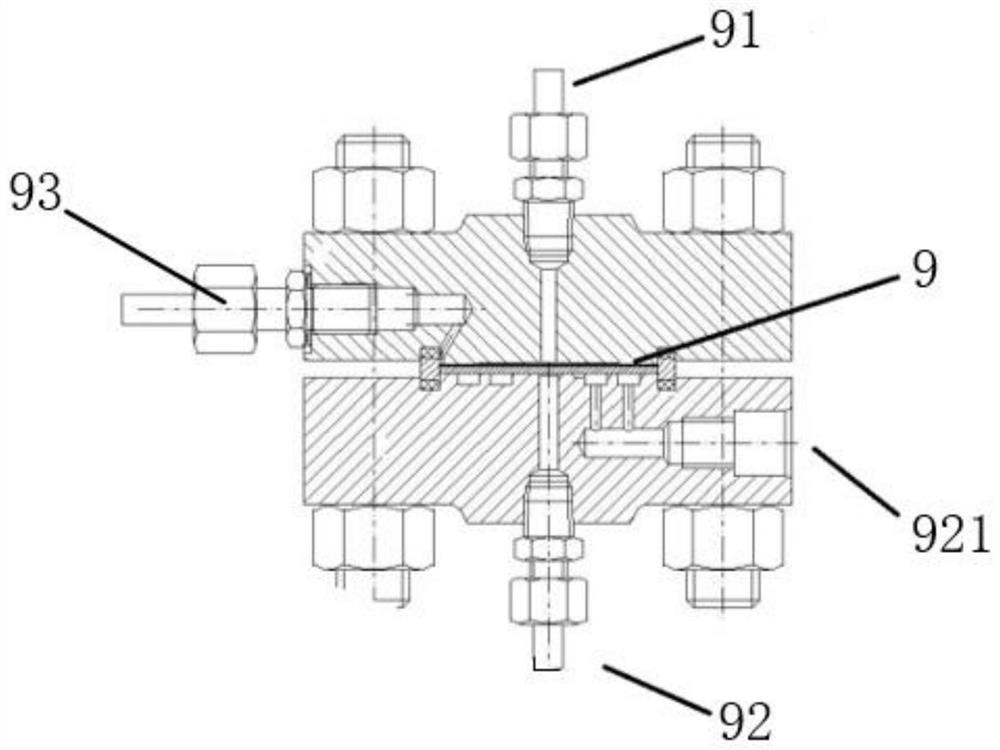

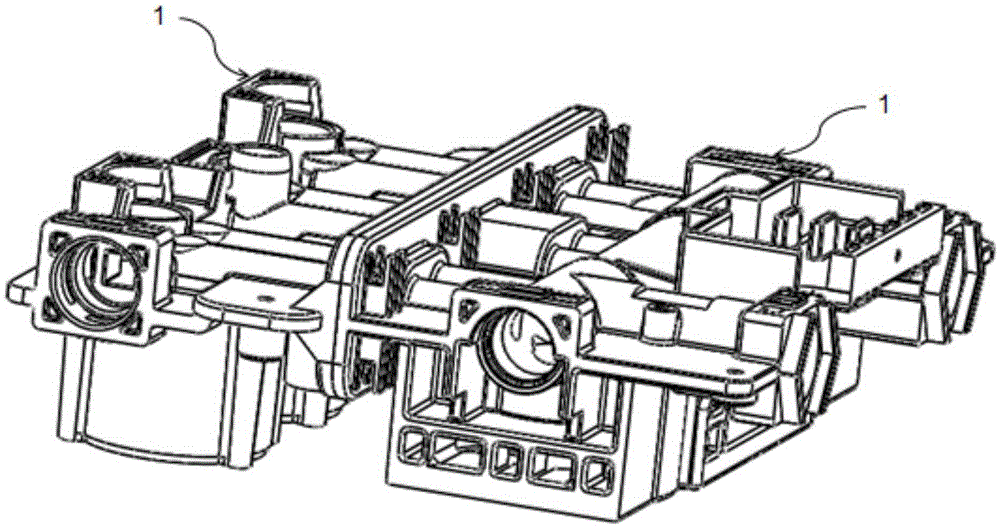

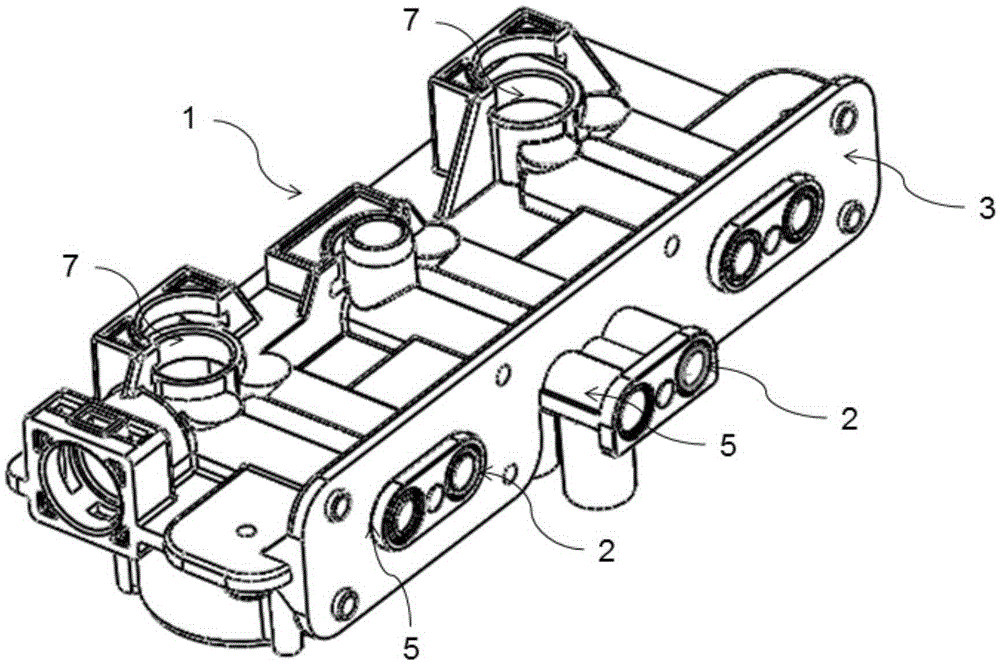

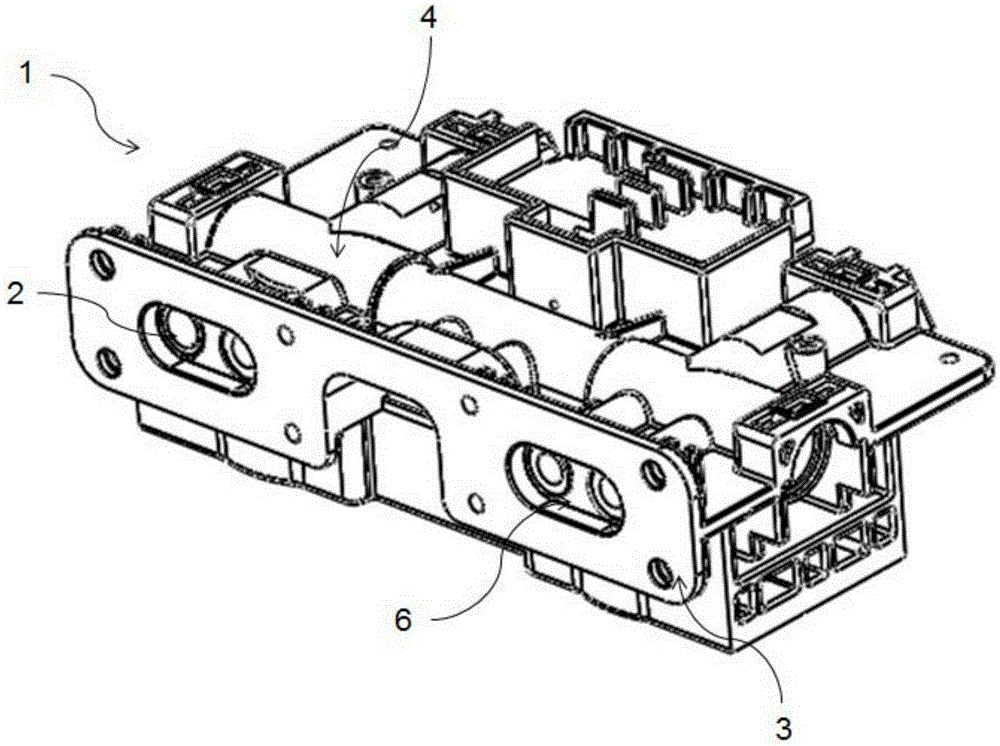

Integrated waterway module and water softener

ActiveCN105299368AReduce the risk of water leakageReduce pressure areaTreatment involving filtrationWater/sewage treatment by ion-exchangeWater leakageComputer module

The invention discloses an integrated waterway module of a water processing device. The integrated waterway module comprises at least two independently-formed waterway units. Each waterway unit is internally provided with a plurality of parallel interface runners, and every two adjacent waterway units can be jointed to enable the corresponding interface runners to be communicated. According to the integrated waterway module, at least two independently-formed waterway units are arranged, and a preset angle is formed between the jointed face of every two waterway units and the parallel interface runners. Thus, the pressure bearing area of a sealing face is greatly reduced, the water pressure, only borne by the jointed faces, of the interface runners is greatly reduced, and the risk of water leakage between every two connected waterway units in the integrated waterway module is lowered.

Owner:A O SMITH CHINA WATER HEATER CO LTD

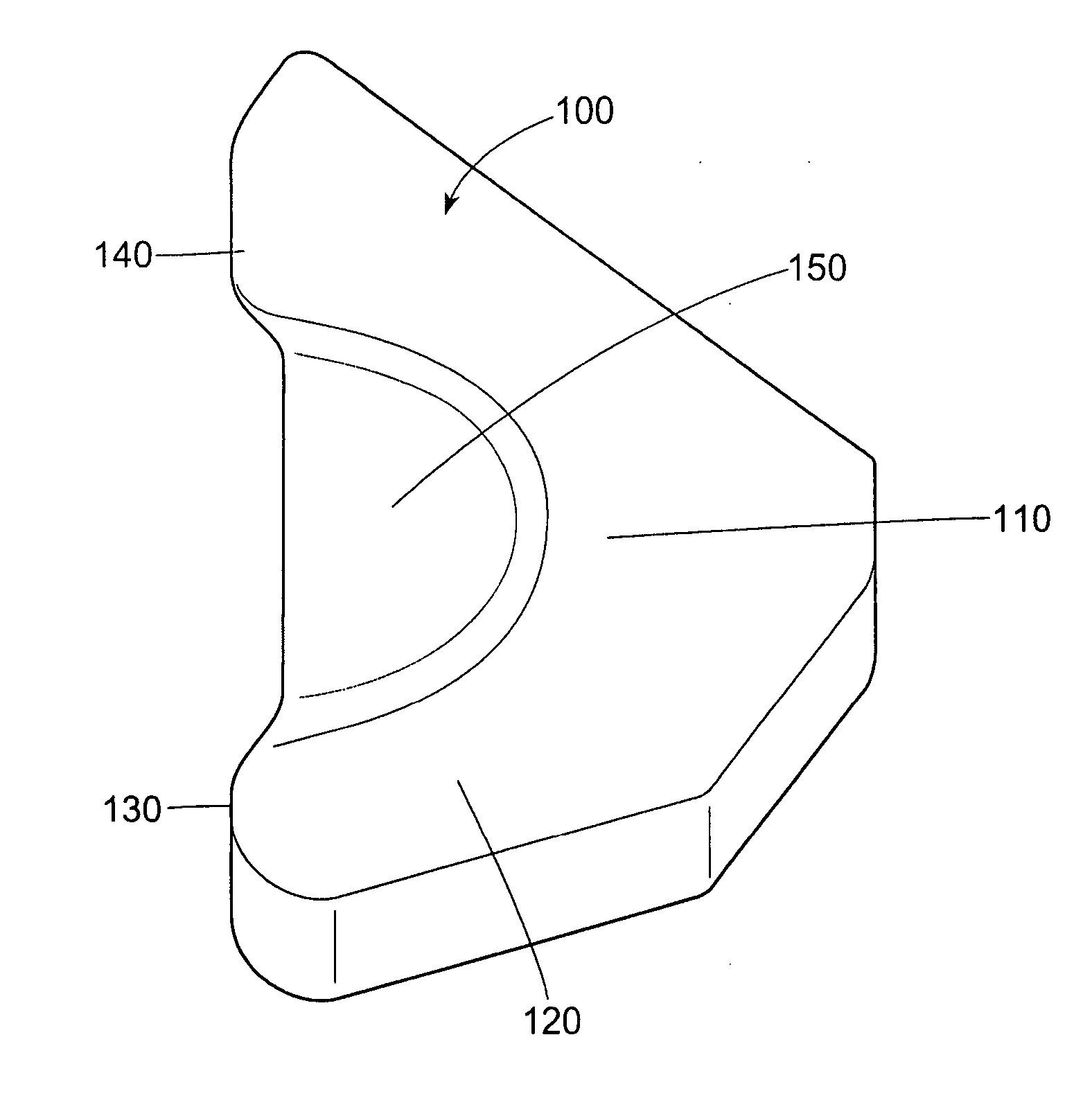

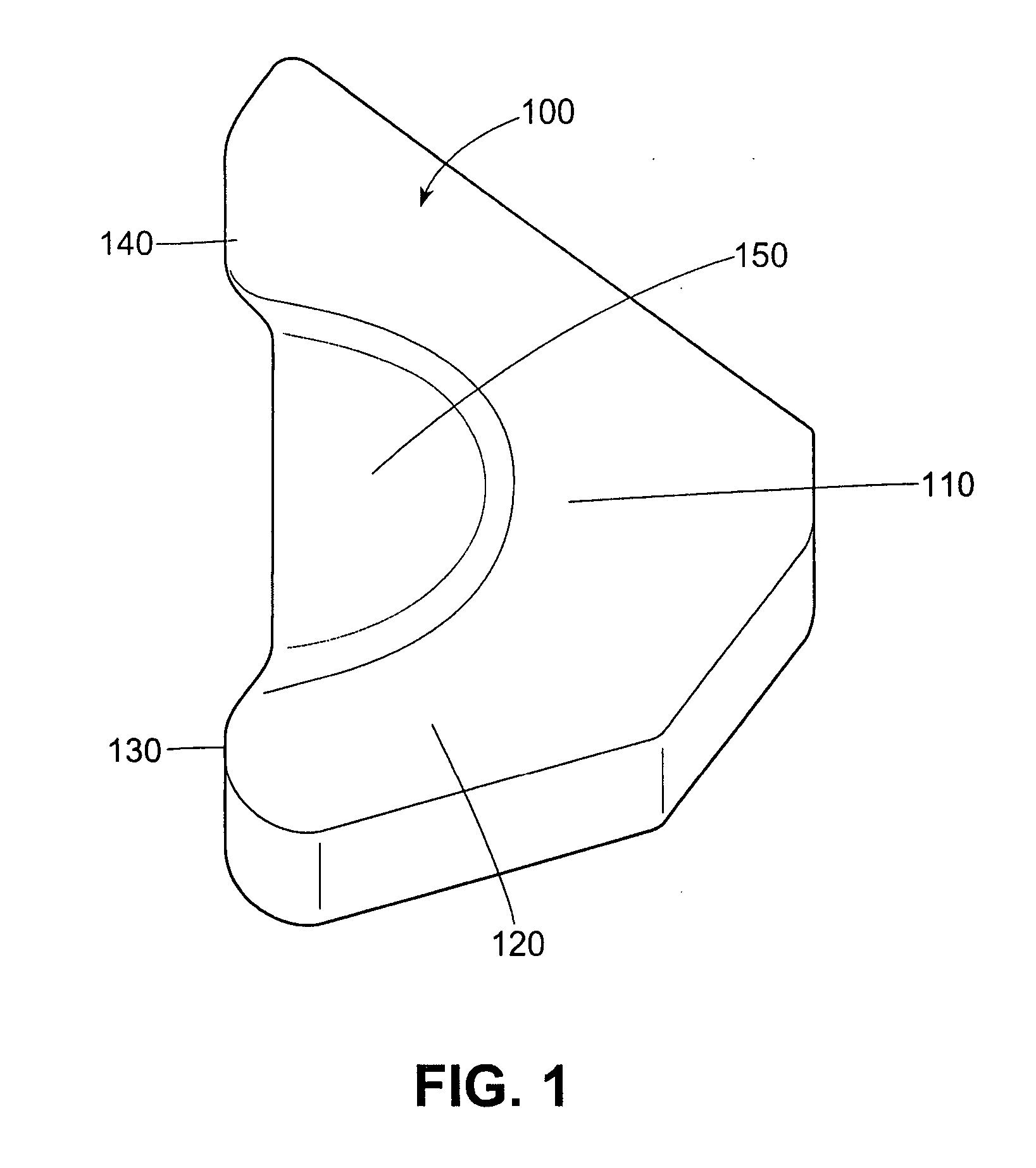

Ventilation mask

InactiveUS20170014590A1Reduce pressure areaSimpler and effective attachmentRespiratory masksMedical devicesPositive pressureEngineering

A mask for the delivery of a medical gas under positive pressure, the mask including a single shell forming a chamber having an outlet, a first passage connecting the chamber to the exterior of the mask, a sealing recess isolated from the chamber and open to allow engagement with the face of a user, and extending around the periphery of the outlet, and a second passage connecting the sealing recess to the exterior of the mask, the arrangement being such that operatively the mask may be placed on a user so as to cover the airway, suction may be connected to the second passage so that the sealing recess seals the mask against the face of the user, and a medical gas may be supplied to the first passage for delivery through the outlet to the airway of the user.

Owner:INT HEALTH GRP PTY LTD

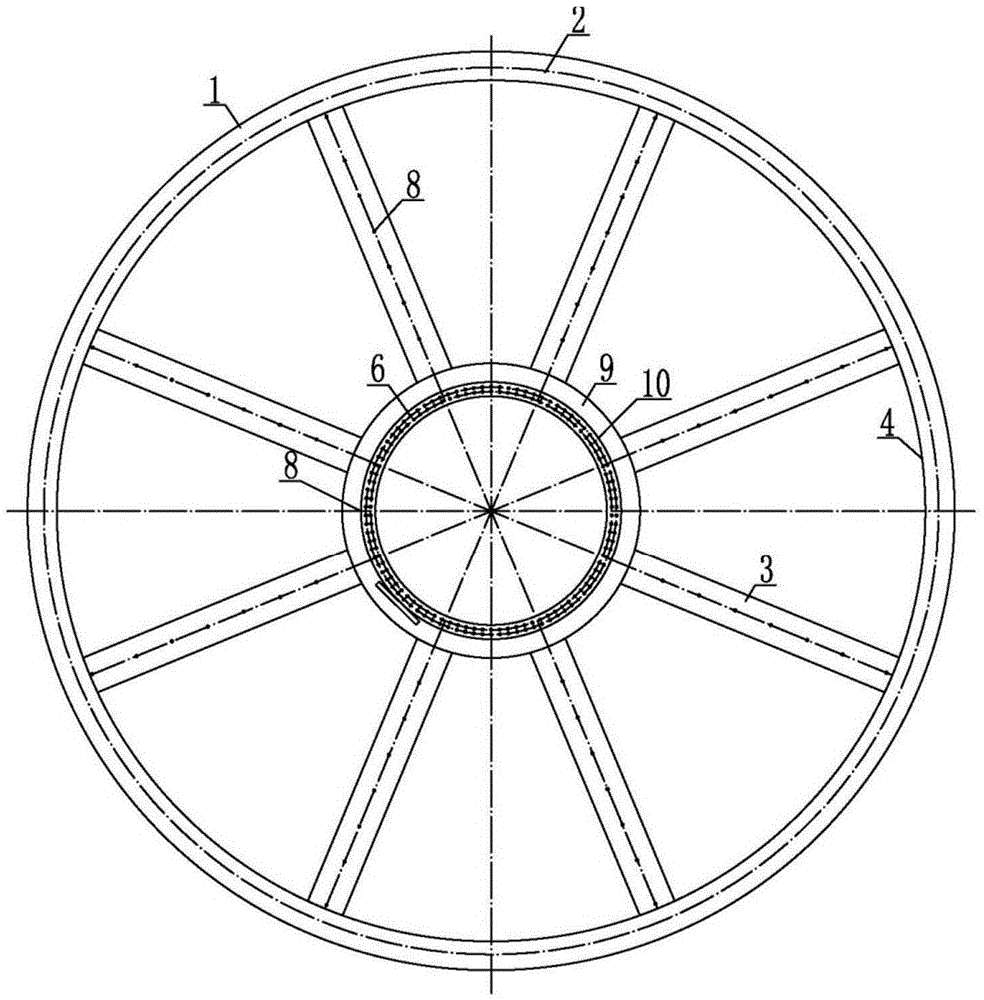

Wind power generation tower foundation with prefabricated foundation prestressed beams and slab

InactiveCN105544593AReduce pressure areaSmall amount of workFoundation engineeringPre stressEngineering

The invention discloses a wind power generation tower foundation with prefabricated foundation prestressed beams and slab. The wind power generation tower foundation with prefabricated foundation prestressed beams and slab comprises a concrete cushion on which a concrete foundation slab is arranged; a circular-arc-shaped concrete column pier is arranged in the middle of the concrete foundation slab; edge small beams are arranged on parts, close to edges, of the concrete foundation slab, and the circular-arc-shaped concrete column pier and the edge small beams, and two adjacent edge small beams are connected by means of prefabricated cantilever beams; prestressed anchor bolts are uniformly buried in the concrete column pier, and one end of each prestressed anchor bolt is connected with a lower foundation anchor plate, while the other end of the same is connected with a tower tube; voids are uniformly formed in the prefabricated cantilever beam, and the prefabricated cantilever beams are in prestressed connection with the concrete foundation slab by using prestressed bolts in the voids. Rigid connection of the tower tube with the foundation is guaranteed, the amount of the steel utilized is reduced, and the construction of such a part is also simplified simultaneously.

Owner:HUIHONG ENG TECH CO LTD

Pretensioning device for a safety belt

ActiveUS8684413B2Reduce pressure areaReduce pressureBelt retractorsSafety beltsEngineeringBelt safety

A pretensioning device (10) for a safety belt, of a motor vehicle, having a gas generator (17), a piston (21) guided in a tube (16), which closes a pressure area (20) in the tube (16) that is pressurized by the gas generator (17) whereupon the piston (21) is able to move in a pretensioning movement which is able to be conveyed to the safety belt by means of an inertia body (19a) resting on a front face (9) of the piston (21). The piston (21) forms a pass-through opening (1) releasable upon exceeding of a predetermined pressure and a recess (26) is provided in the front face (9) with an inertia body (19a) resting thereon, so that a flow connection is created from the pass-through opening (1) to the area (25) located behind the piston (21) in the direction of the pretensioning movement (S).

Owner:AUTOLIV DEV AB

Sleeving valve type hydraulic breaking hammer

InactiveCN106120925ASimple structureCompact structureMechanical machines/dredgersReciprocating motionSleeve valve

The invention relates to a sleeving valve type hydraulic breaking hammer. The sleeving valve type hydraulic breaking hammer comprises a front body, a middle cylinder and a nitrogen chamber which are sequentially arranged from front to back. A drill rod is arranged inside the front body in the axial direction. The middle cylinder is internally provided with a piston, a sleeving valve and a hydraulic oil path system, wherein the piston is in transmission connection with the drill rod; the sleeving valve is arranged outside the piston in a sleeving mode and matched with the inner wall of the middle cylinder; and the hydraulic oil path system drives the piston and the sleeving valve to move back and forth in the axial direction of the middle cylinder. In the working state, the piston drives the drill rod to move back and forth in the axial direction of the middle cylinder under driving of the hydraulic oil path system, and accordingly hard objects are broken. Compared with the prior art, the sleeving valve type hydraulic breaking hammer is simple in structure, the sleeving valve is directly arranged on the piston in the sleeving mode, a valve element is omitted, the structure is more compact, and structure manufacturability is good; and since the travel stroke of the sleeving valve is short, the working efficiency is remarkably improved, and the demands of engineering application can be met.

Owner:SHANGHAI UNIV OF ENG SCI

Method for alleviating or diverting pressure, treating or preventing the formation of sleep lines or decreasing their rate of formation, decreasing the rate of scar formation or facilitating the overall healing of a target area of a subjects's body

InactiveUS20080041395A1Decrease rate of formationDecreased pressureOperating chairsDental chairsPhysical medicine and rehabilitationScars

Owner:TYTEL JUDITH E +1

Sealing and connecting structure of flange

ActiveCN102022596BReduce pressure areaReduce processing requirementsEngine sealsFlanged jointsRubber ringEngineering

The invention relates to a sealing and connecting structure of a flange, which comprises a rubber stopper, an upper flange, a rubber ring, a screw and a lower flange, wherein the rubber ring is arranged between the upper flange and the lower flange, the screw is embedded in the upper flange and connected with the lower flange after penetrating the rubber ring, and the rubber ring is arranged at the top of the screw on a lug of the upper flange. Compared with the prior art, the invention has the advantages of rust and corrosion prevention, repeated use, low manufacture and maintenance cost, small appearance size and the like.

Owner:SHANGHAI KARON VALVES MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com