Power-saving apparatus for hydraulic expanding large retaining-ring by using super high pressure system

A hydraulic bulging and ultra-high pressure technology, which is applied to forming tools, engine seals, engine components, etc., can solve the problems of ultra-high pressure superchargers, such as large space, complicated tooling, and no production, so as to reduce the pressure bearing area and reduce the Excellent forming force and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

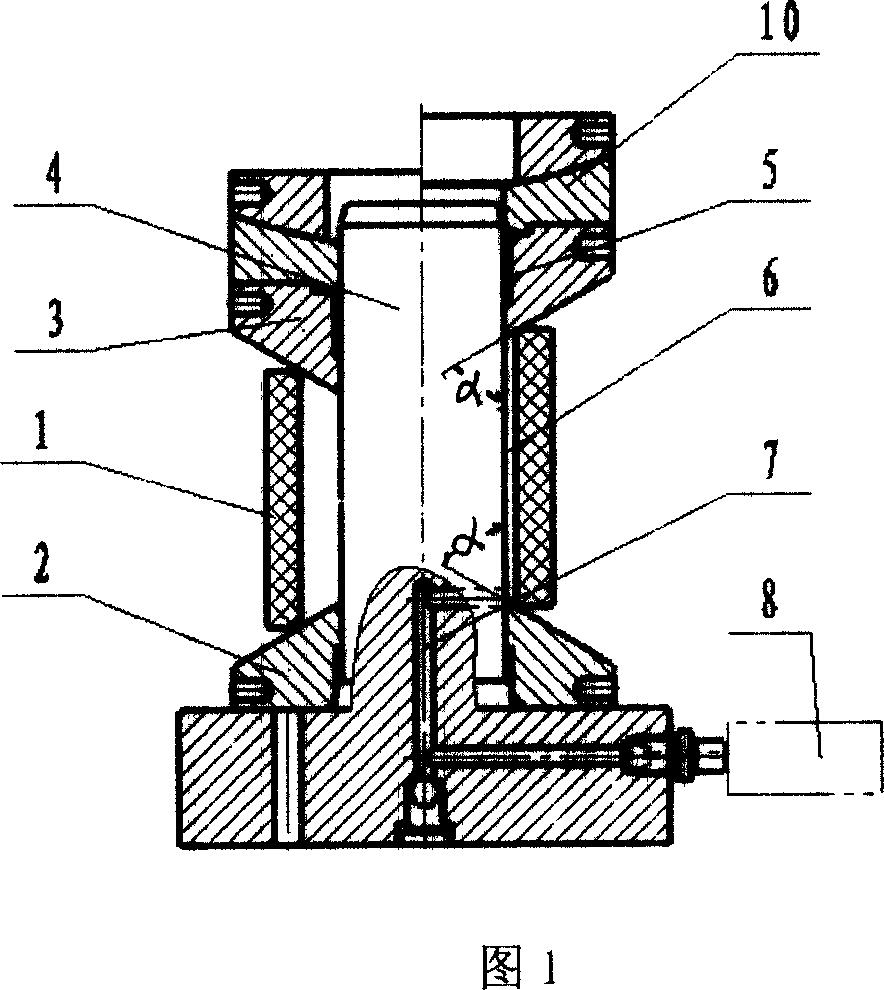

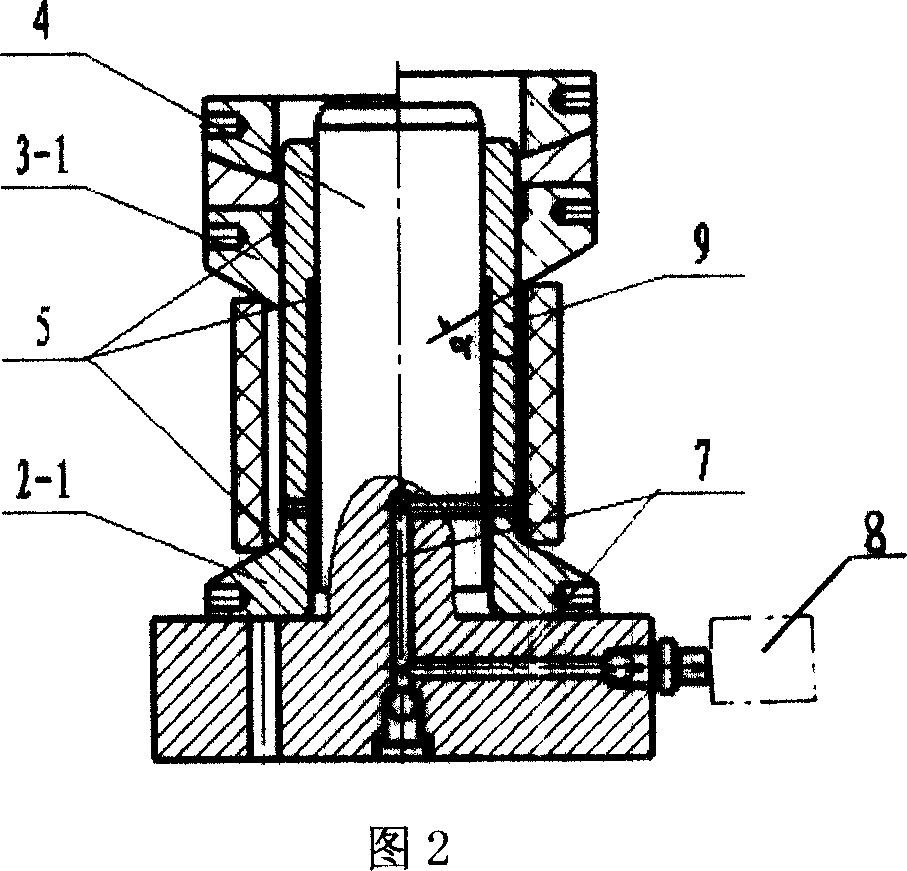

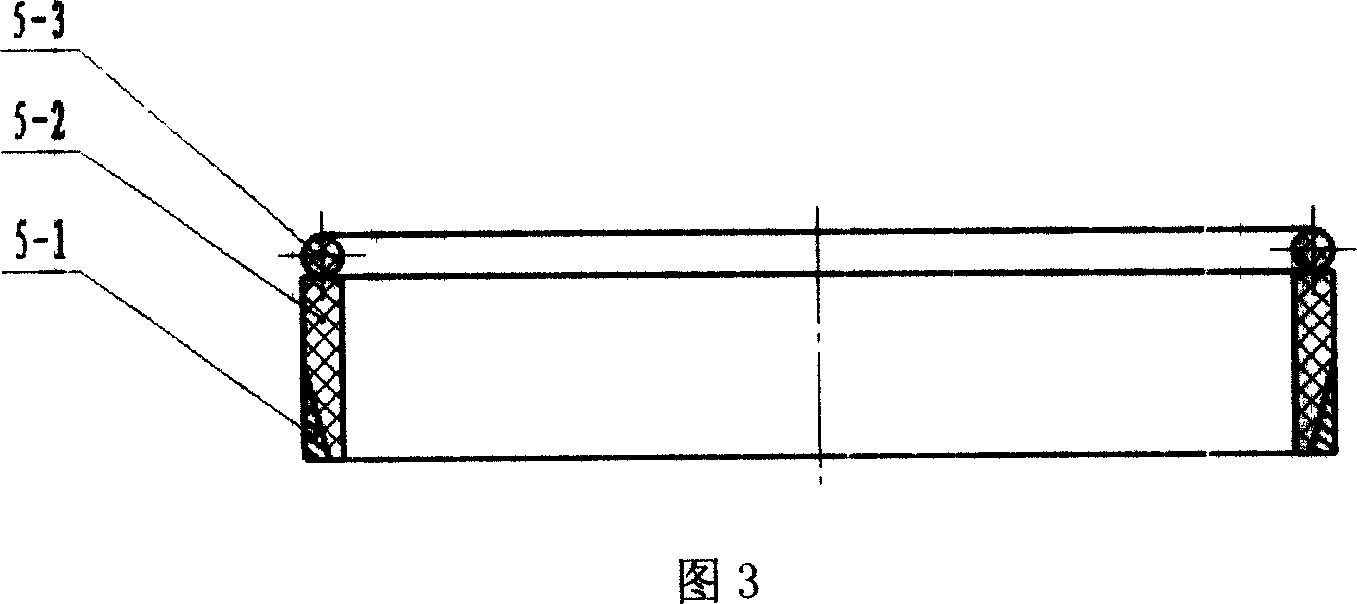

[0014] As shown in Figures 1 and 2, a labor-saving device for hydraulic bulging of a large-scale retaining ring using an ultra-high pressure system is to place a conical hollow lower punch 2 and a conical hollow upper punch at the upper and lower relative positions of the retaining ring blank 1 3. The inner holes of the tapered lower punch and the tapered upper punch are slidably matched with the labor-saving guide post 4, and there is a seal 5. An annular cavity 6 is formed between the guide post and the ring blank, and the inside of the guide post is processed by a The liquid channel 7 communicates with the annular cavity 6 at one end, and connects with the high-pressure system 8 at the other end. The labor-saving device is placed between the working table of the ordinary press and the movable beam. In order to reduce the pressure-bearing area, the labor-saving device has at least Two sets, after the second set, a labor-saving guide sleeve 9 is added outside the labor-saving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com