Double-seal high temperature and high pressure rotary compensator and manufacturing method thereof

A rotary compensator, high temperature and high pressure technology, used in engine sealing, expansion compensation devices for pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problem of large matching clearance of rotating parts, increased rotational resistance, and poor stability of inner and outer pipes. and other problems, to achieve the effect of reducing the end face gap and pressure area, improving the sealing performance and service life, and preventing direct erosion damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments according to the accompanying drawings.

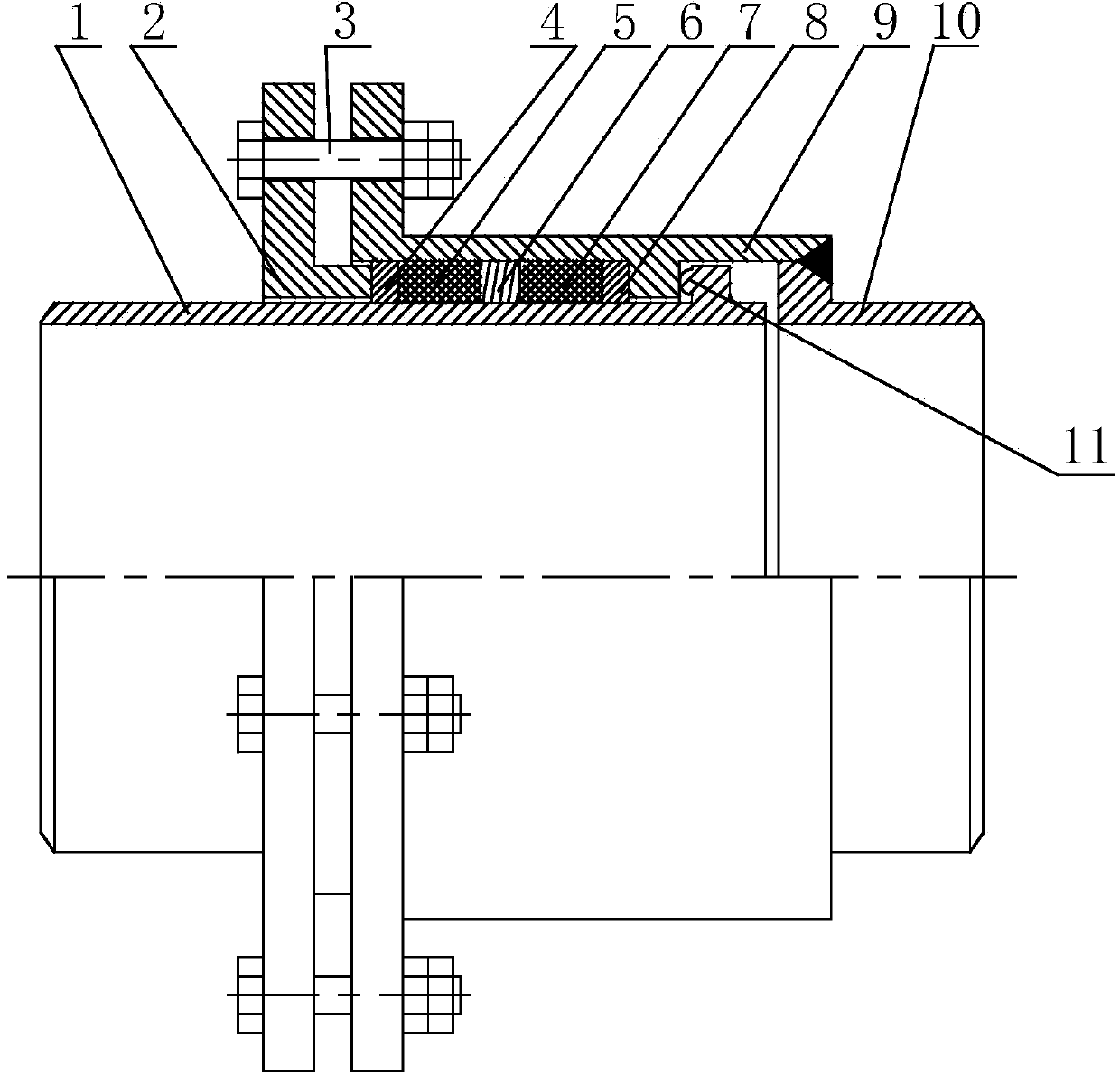

[0018] as attached figure 1 As shown, the high temperature and high pressure pipeline rotary compensator includes inner pipe 1, packing gland 2, bolt assembly 3, left self-lubricating sliding bearing sealing pressure ring 4, left sealing packing 5, sliding bearing centering ring 6, right sealing packing 7 , Right self-lubricating sliding bearing sealing pressure ring 8, outer tube 9 and end tube 10. A double sealing structure is provided between the inner tube 1 and the outer tube 9, specifically, left and right sealing packings 5 and 7 are arranged between the inner tube 1 and the outer tube 9, and the relative parts of the left and right sealing packings 5 and 7 Sliding bearing centering rings 6 are arranged between the ends, and the other ends of the left and right sealing packings 5 and 7 are respectively provided with left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com