Sleeving valve type hydraulic breaking hammer

A technology of hydraulic breaker and breaker, which is used in earthmoving machines/shovels, mechanically driven excavators/dredgers, construction, etc. Large, prone to problems such as strain or stuck, achieving the effect of small throttling loss, small pressure bearing area and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

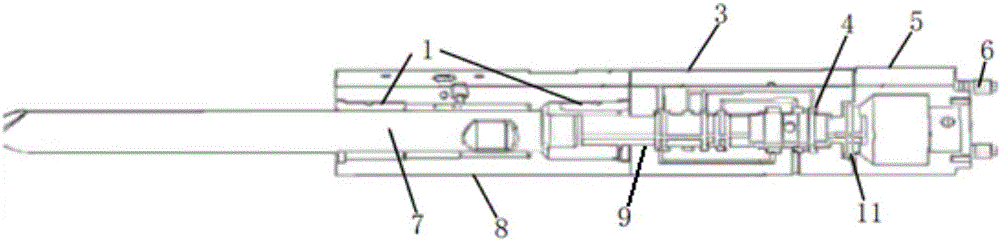

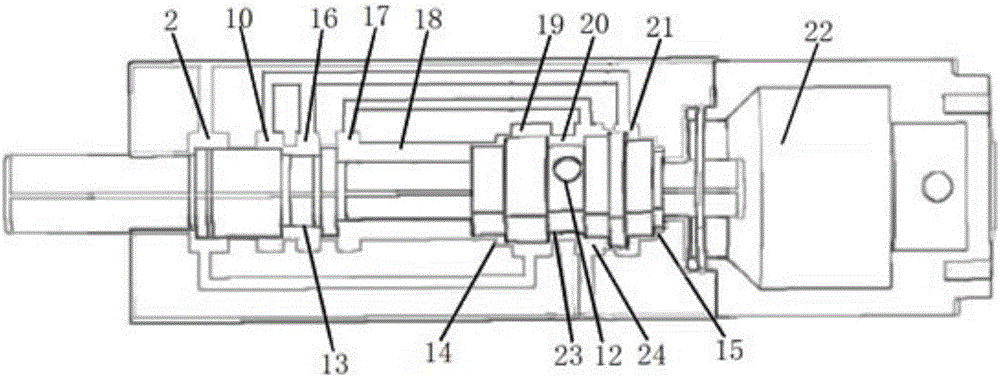

[0040] Such as Figure 1-3 A sleeve valve type hydraulic breaking hammer is shown, which includes a precursor 8, a middle cylinder 3 and a nitrogen chamber 5 arranged in sequence from front to back, and an O-shaped sealing ring 11. The inside of the front body 8 is provided with a drill rod 7 along the axial direction, and a drill rod bushing 1 is arranged between the inner wall of the front body 8 and the drill rod 7, and a device for axially limiting the drill rod 7 is also arranged in the front body 8. Rod plugging. The inside of the middle cylinder 3 is provided with a piston 9 connected to the drill rod 7, a sleeve valve 4 sleeved outside the piston 9 and adapted to the inner wall of the middle cylinder 3, and a drive piston 9 and the sleeve valve 4 along the middle cylinder. 3. A hydraulic oil circuit system with axial reciprocating movement. The inner wall of the middle cylinder body 3 is provided with a front stop surface 14 of the sleeve valve and a rear stop surfac...

Embodiment 2

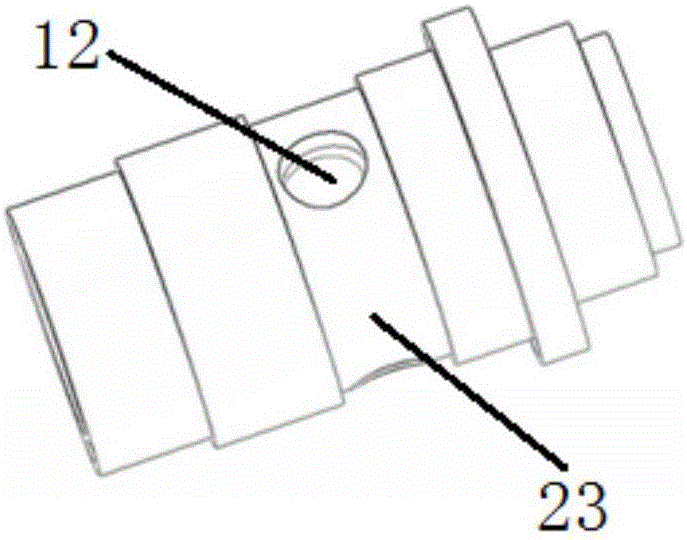

[0047] In this embodiment, five through-holes 12 communicating with the pressure-transforming chamber 18 are evenly opened on the bottom surface of the sleeve valve groove 23 , and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com