Sealing and connecting structure of flange

A connection structure and flange technology, which is used in flange connection, engine sealing, pipe/pipe joint/pipe fittings, etc., can solve the problems of large flange volume, increased manufacturing cost, large space, etc. The effect of reducing the pressure area and reducing the cost of manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

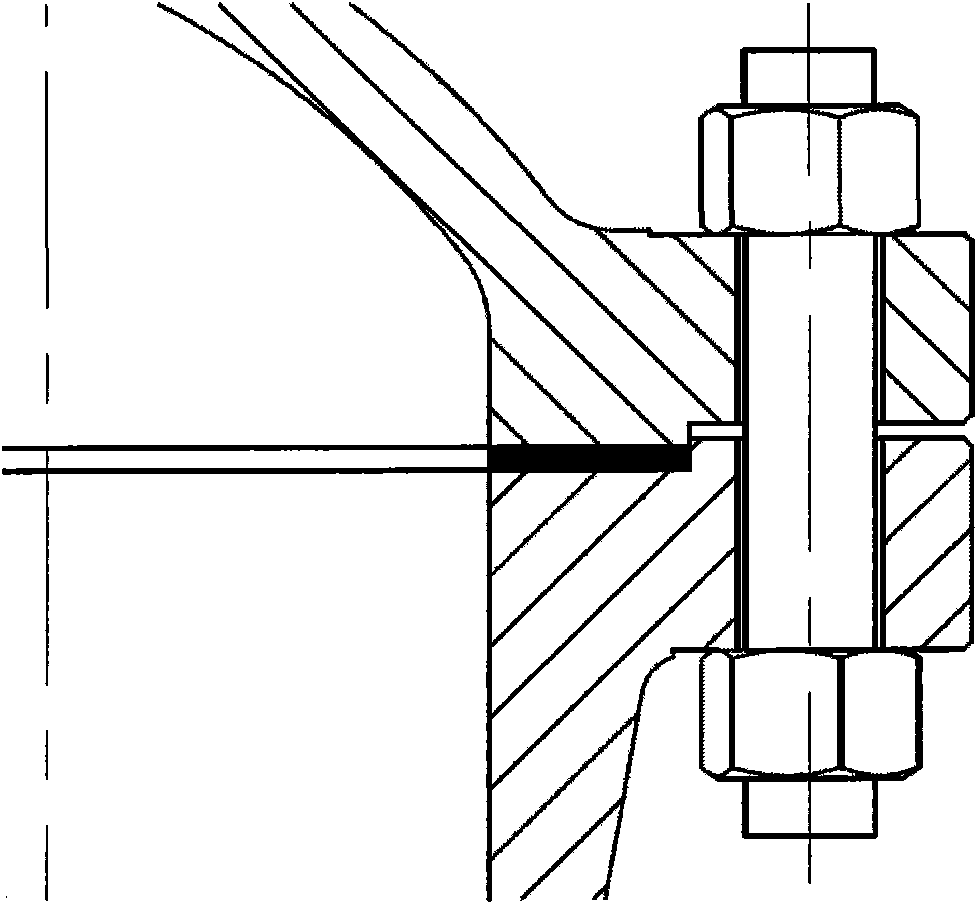

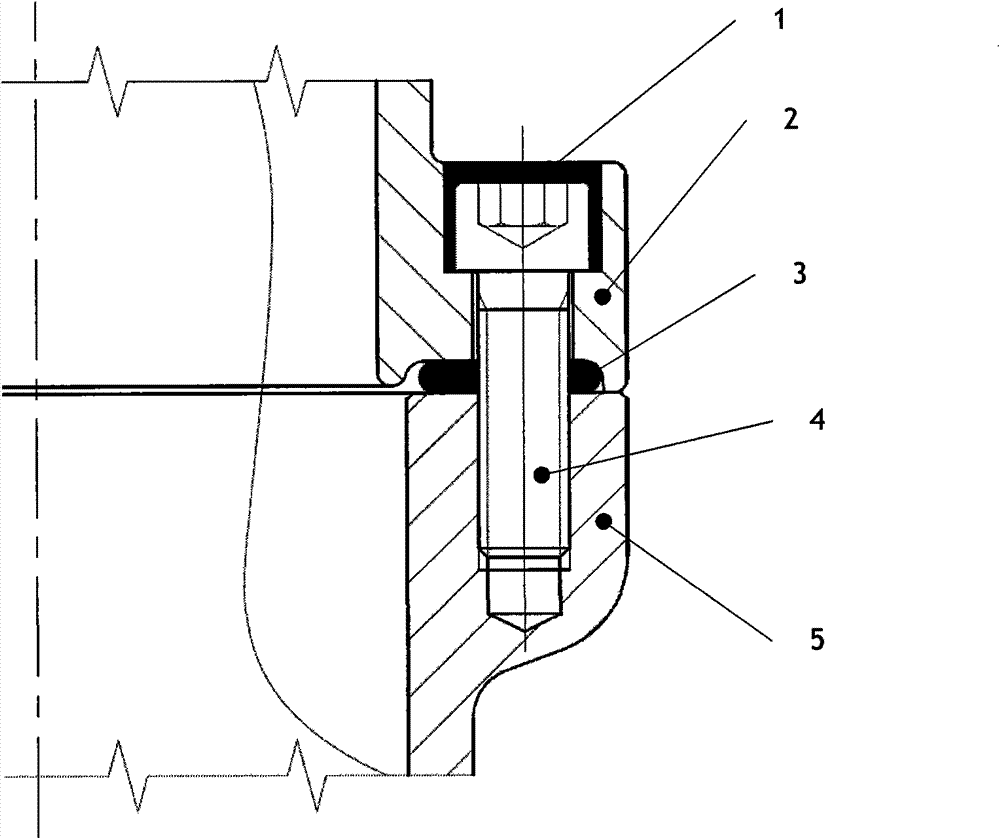

[0016] Such as figure 2 As shown, the flange sealing connection structure provided by the present invention includes an upper flange 2 , a lower flange 5 , screws 4 , rubber plugs 1 , and rubber rings 3 .

[0017] On the flange of the upper flange 2, there are evenly distributed cylindrical countersunk screw holes, and the screws 4 are hidden in them. At the same time, the distribution position of the screws 4 is the shortest from the inner cavity of the flange, and the pressure-bearing area of the flange is reduced, reducing the number of screws. diameter and dimensions. The bottom of the upper flange 2 is cast into a ring of sealing grooves, which does not require precision machining and reduces the requirements for machining and assembly. A threaded blind hole is provided on the flange of the lower flange 5, and the bottom of the screw is isolated from the external environment. The screw 4 is a hexagon socket head screw, one end of which is a cylindrical countersunk he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com