Liquefied gas carrying ship

A technology for transport ships and liquefied gas, applied in the field of natural gas (LNG) LNG ships, can solve the problems of increased pressure area, increased wind pressure resistance, and increased position of the center of gravity of the ship, so as to reduce the pressure area and reduce the Wind pressure resistance, the effect of lowering the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

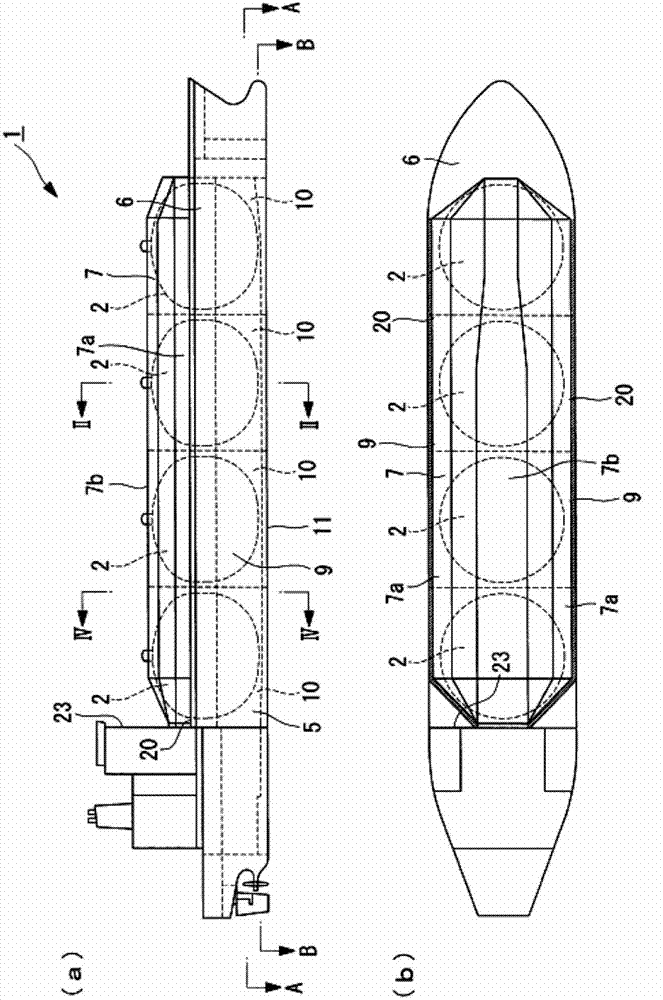

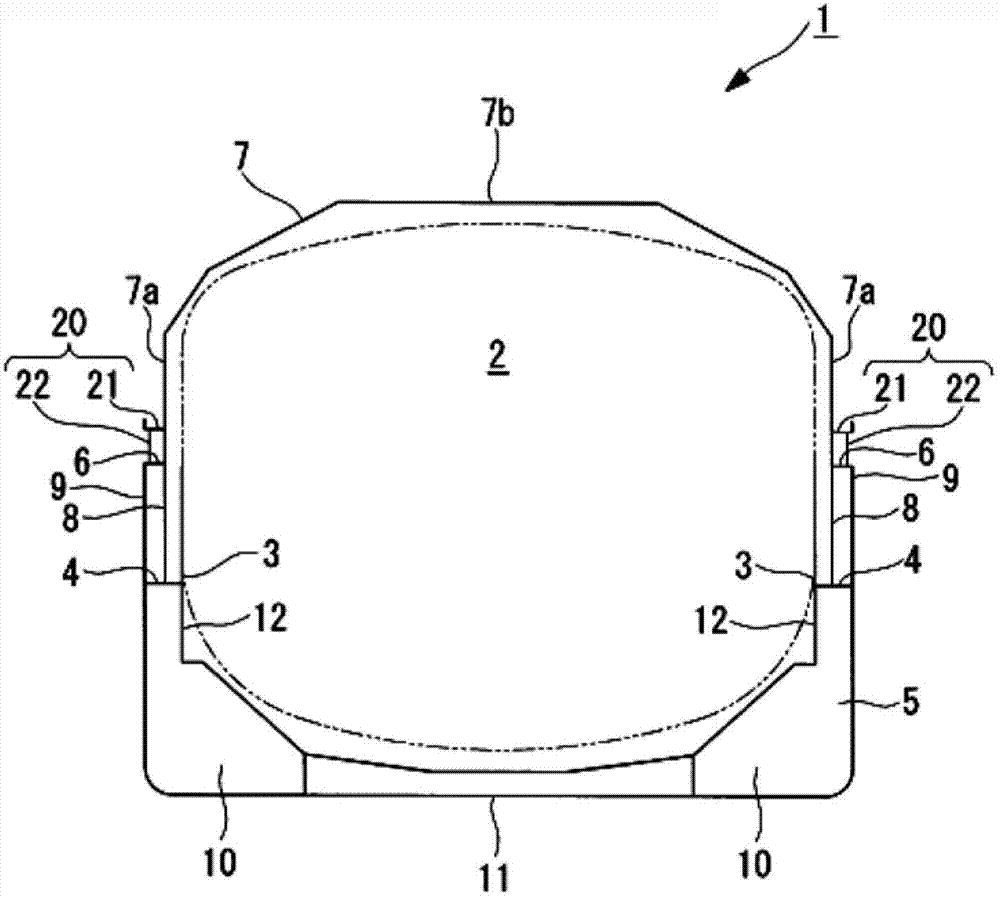

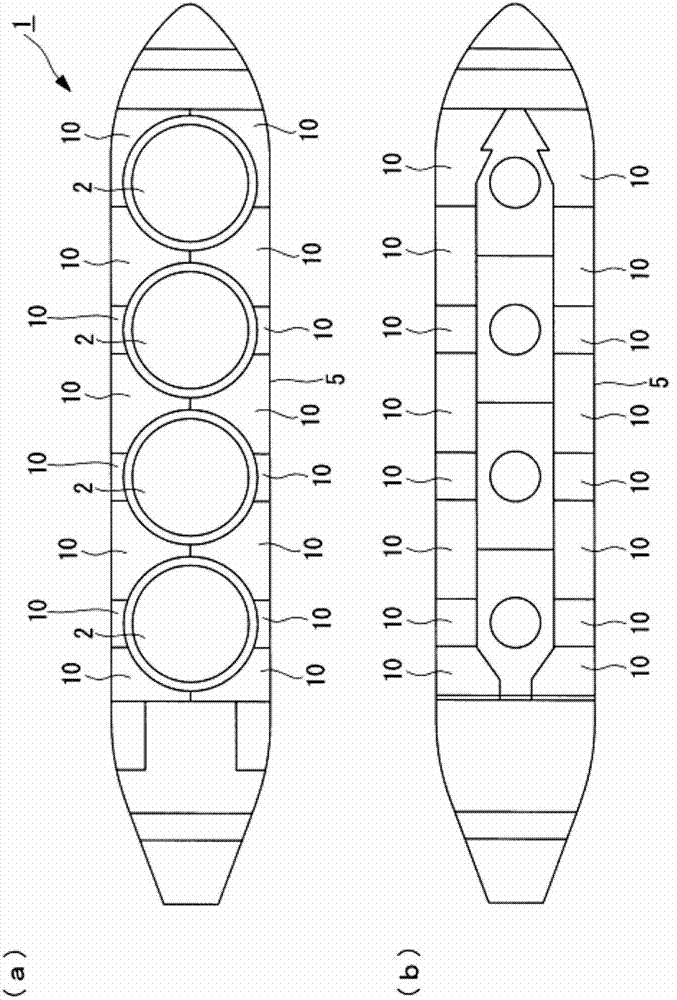

[0045] Below, refer to Figure 1 to Figure 5 One embodiment of the liquefied gas carrier of the present invention will be described.

[0046] figure 1 It is a figure of the liquefied gas carrier ship of this embodiment, (a) is a right side view, (b) is a plan view, figure 2 yes figure 1 (a) II-II arrow sectional view, image 3 It is a figure of the liquefied gas carrier of this embodiment, (a) is figure 1 (a) A-A sectional view, (b) is figure 1 (b) The BB arrow section view, Figure 4 yes figure 1 (a) IV-IV section view, Figure 5 yes Figure 1 ~ Figure 3 (a) Side view of the flattened spherical vessel shown.

[0047] Such as figure 1 (a), figure 1 (b), and image 3 As shown in (a), the liquefied gas carrier ("LNG ship" in this embodiment) 1 of this embodiment is equipped with, for example, four flat spherical containers made of aluminum (also called "non-true spherical containers") 2 These aluminum-made flattened spherical containers 2 are configured so that liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com