Pressure control structure of pressure cooking appliance

A technology for cooking utensils and cooking containers, which is applied to pressure cookers, cooking utensils, household utensils, etc., can solve the problems of high cost, difficult processing, and inaccurate pressure control accuracy, and achieve low cost, high reliability and feasibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

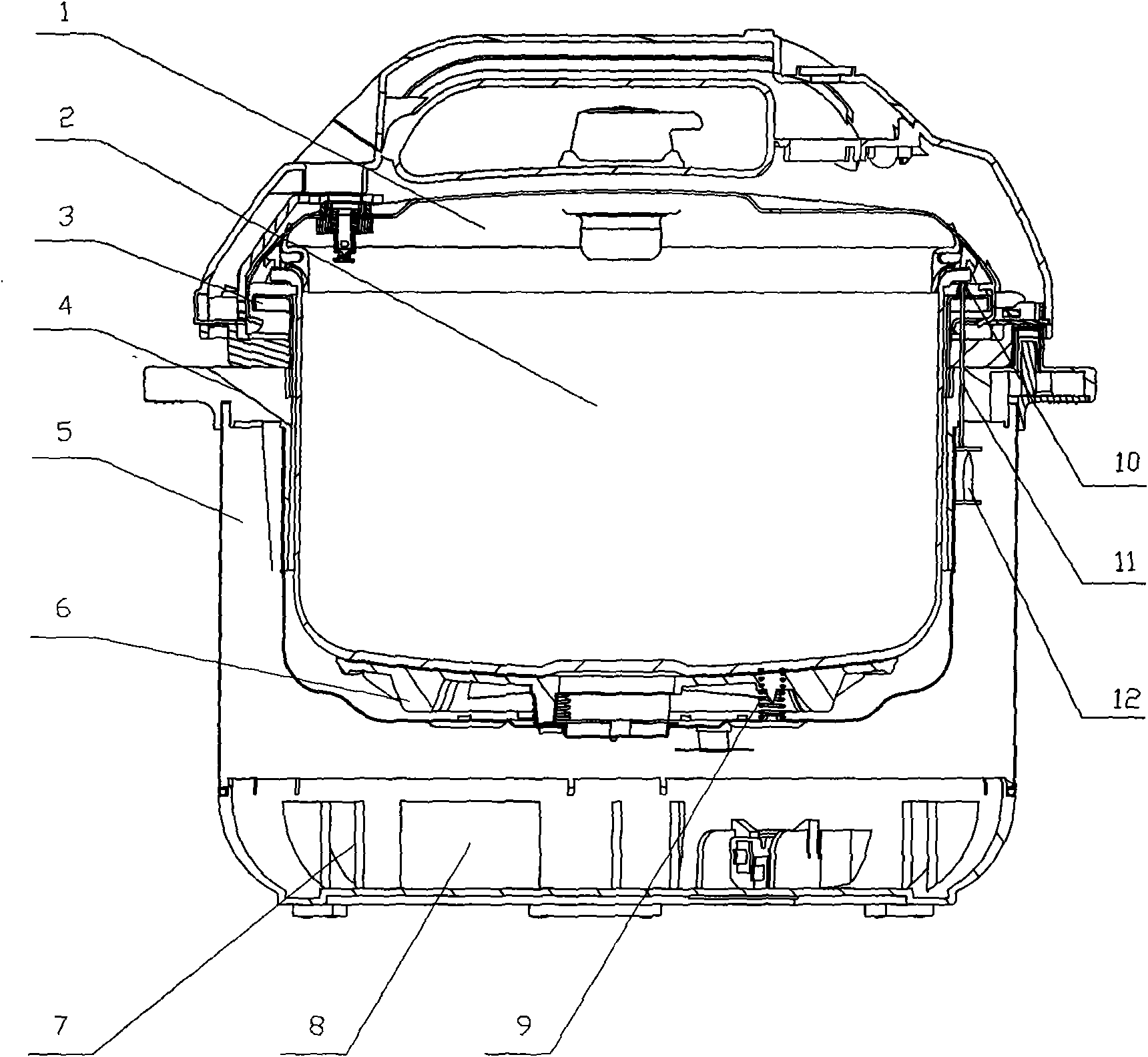

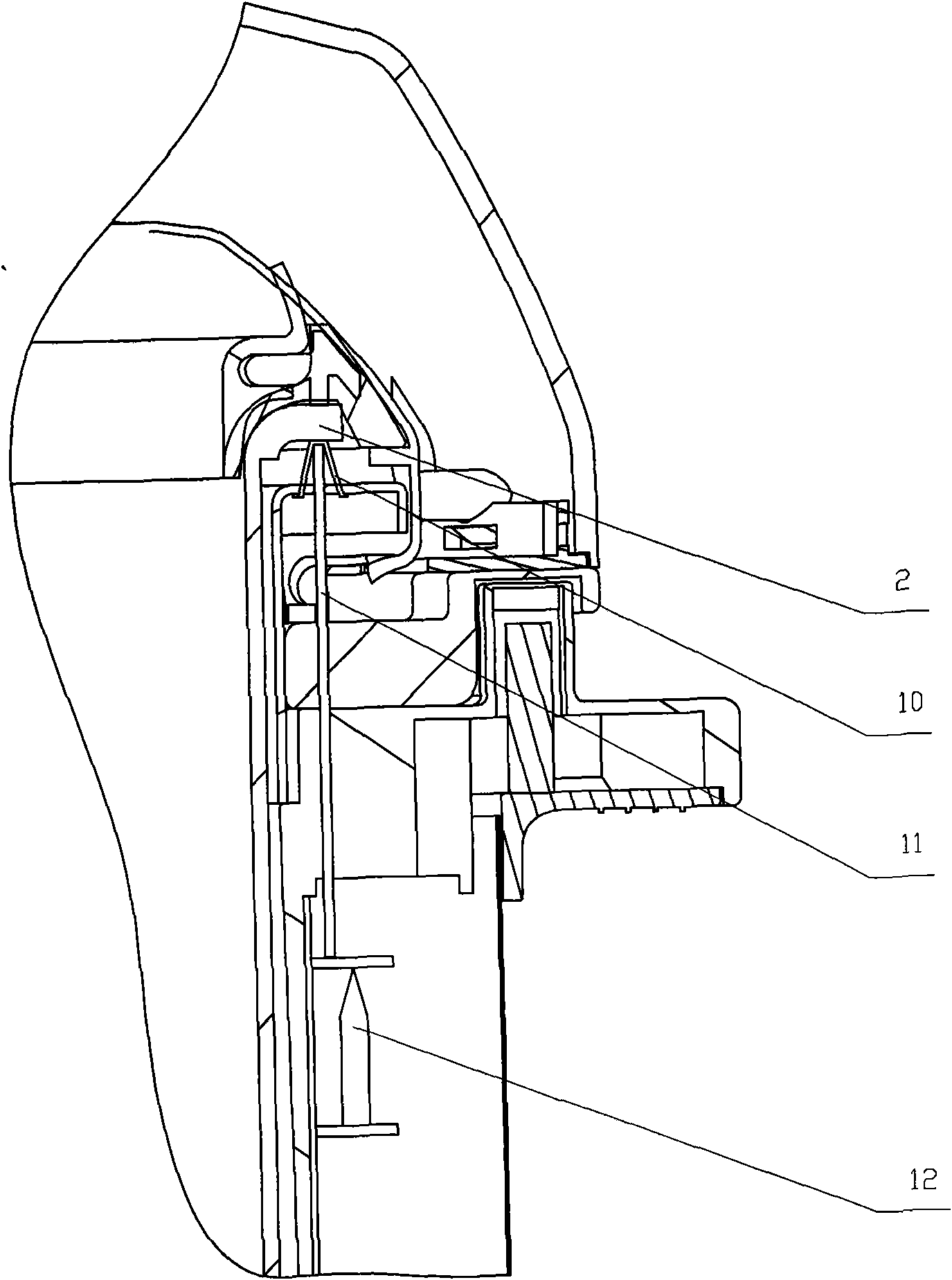

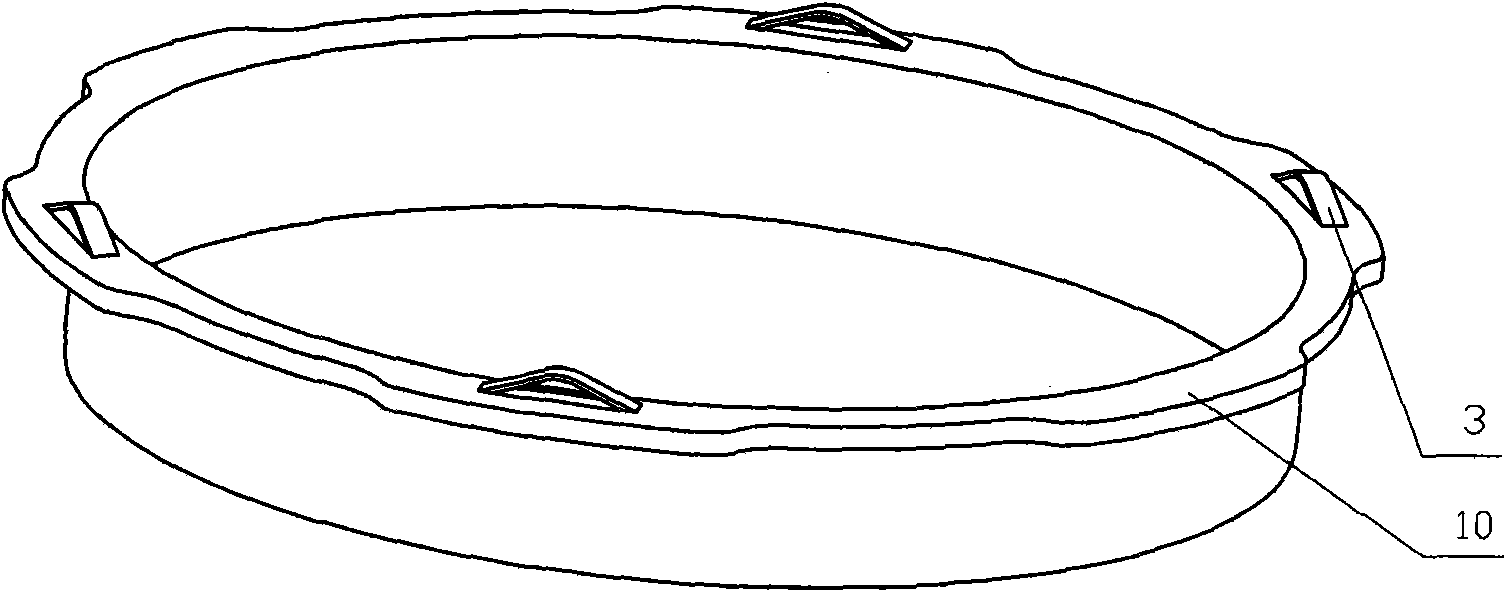

[0031] Embodiment: Taking the control device as a pressure switch as an example, the touch range of the pressure switch is about 0.7-1.5mm, the sealing gap between the inner pot and the lid sealing ring is about 3mm, and 6 elastic reeds are welded and connected at the outer pot button teeth , assuming that the diameter of the inner pot is 220mm, the pressure inside the pot should be controlled at about 50KPa under the condition of considering the thermal upshoot of the electric heating device. When the pressure inside the pot reaches 50KPa, the elastic deformation of each elastic reed should be 1mm About, in order to meet the safety requirements, when the pressure in the pot reaches a maximum of 350KPa, the elastic deformation of each elastic reed should be more than 3mm to meet the pressure relief requirements, and the strength of the outer pot buckle teeth should meet 350KPa (maximum pressure relief pressure ) below can not be deformed and tripped, because the buckle of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com