Large size ceramic sheet shaping apparatus and method

A technology for forming equipment and ceramic thin plates, which is applied in the field of forming equipment for large-scale ceramic thin plates, can solve the problems of large tonnage, difficult production, high cost, etc., and achieve the effects of reducing production costs, increasing production, production difficulty and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the present invention will be further described:

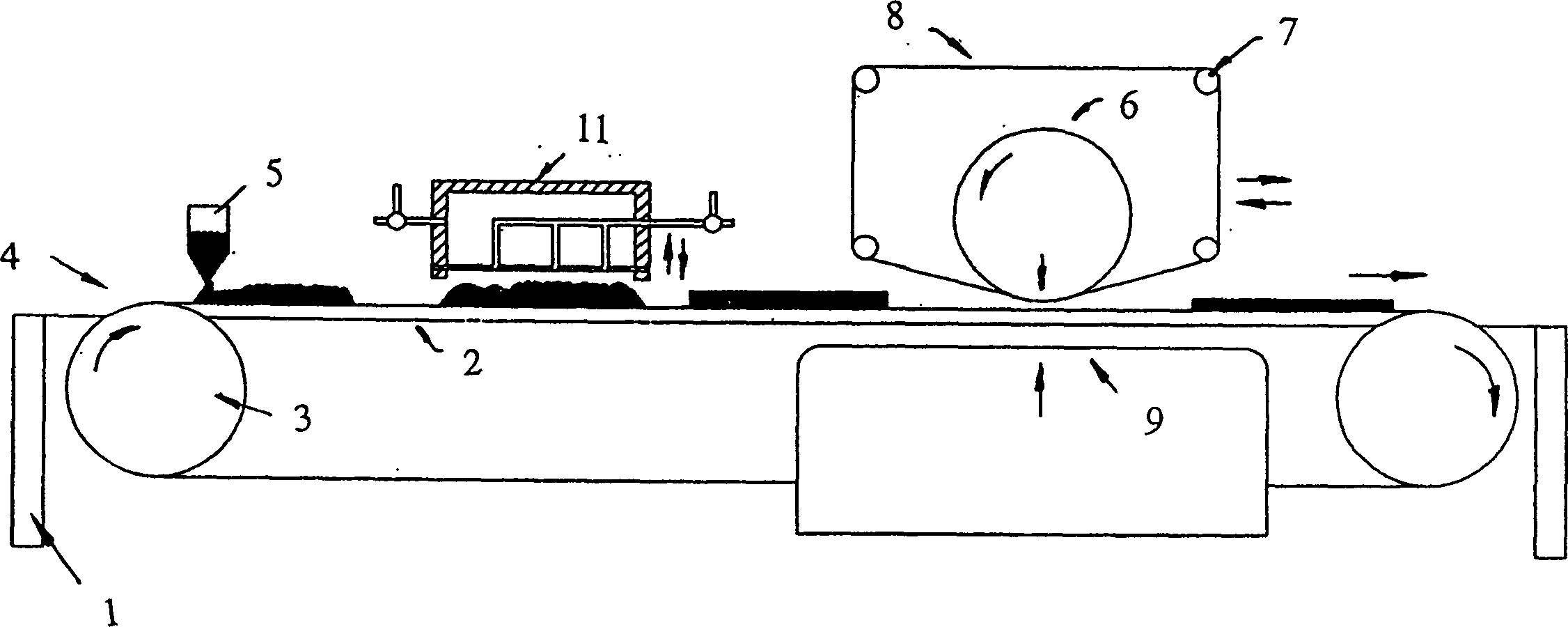

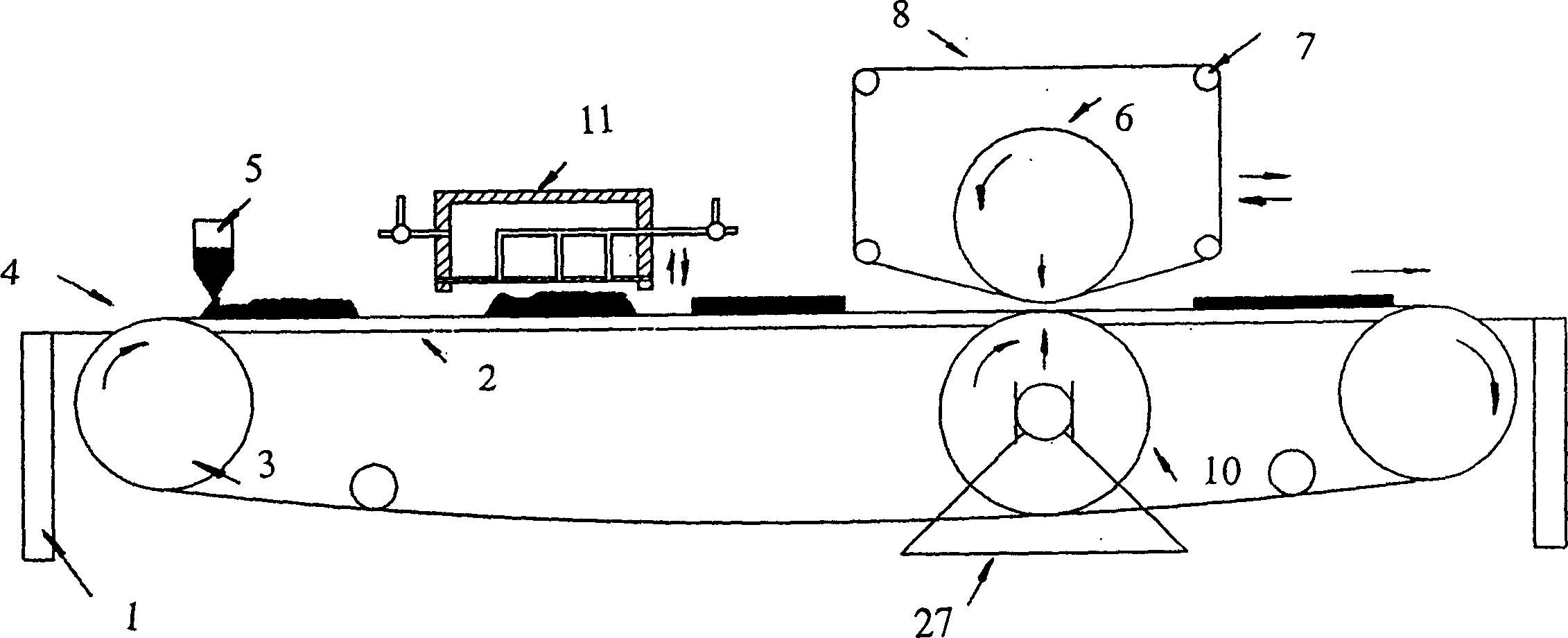

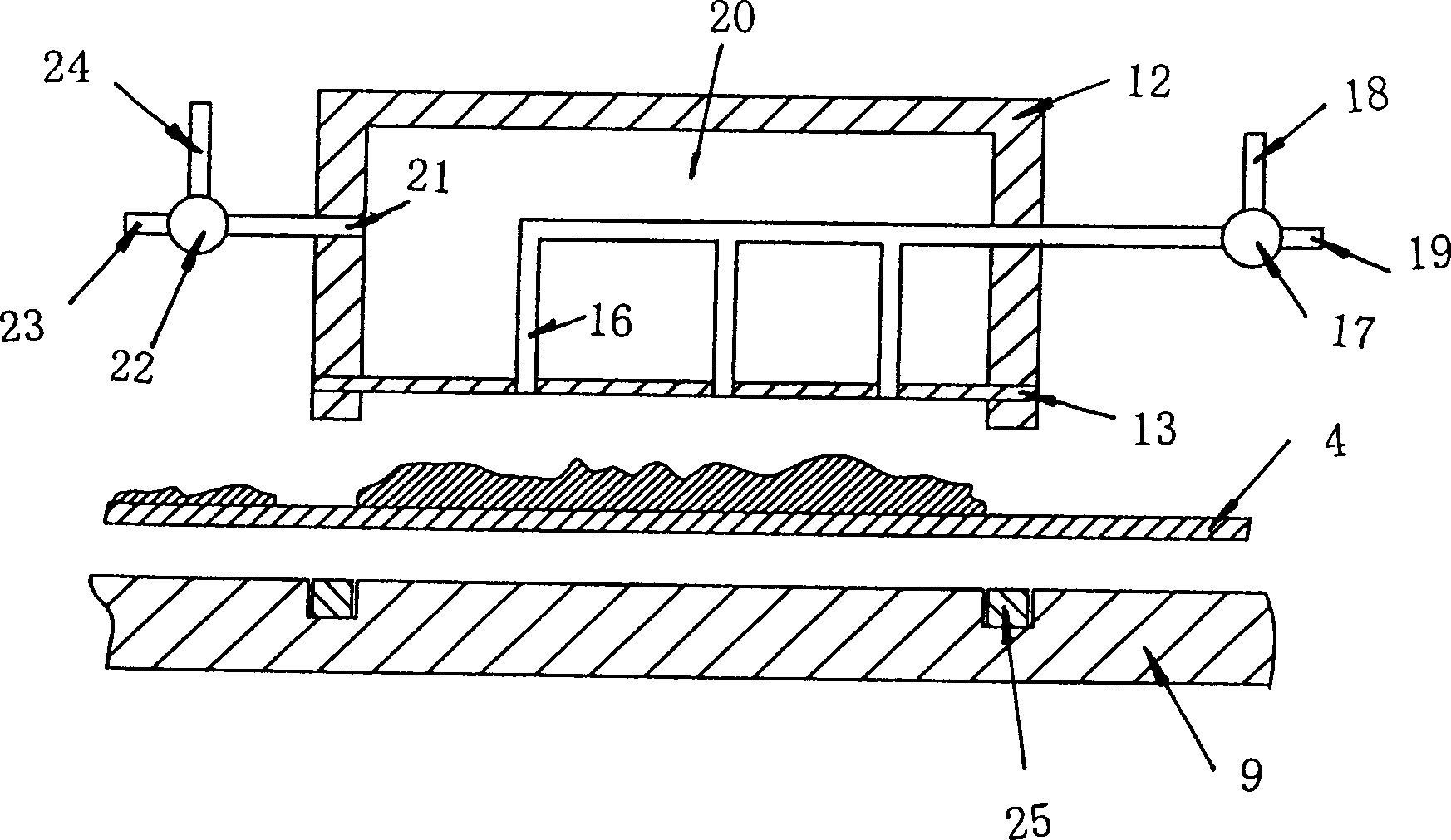

[0049] like figure 1 The shown large-scale ceramic thin plate forming equipment of the present invention has a frame 1, a supporting plate 2 is provided on the frame 1, a transmission wheel 3 is housed on the frame 1, and the transmission wheel 3 drives the lower belt 4, and the lower belt 4 top is provided with upper pressure roller 6, is provided with upper belt 8 on the peripheral surface of upper pressure roller 6, and this upper belt 8 both can be by establishing four belt guide shafts 7 at the four jiaos of upper pressure roller 6, and be enclosed within four The outer side of root guide shaft 7 is close to last pinch roller 6 bottoms, also can directly wrap on the surface of last pinch roller 6. A base 9 corresponding to the upper pinch wheel 6 is disposed perpendicular to the lower frame at the last pinch wheel 6 , and the last pinch wheel 6 can roll on the base 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com