Patents

Literature

45results about How to "Reduce popping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

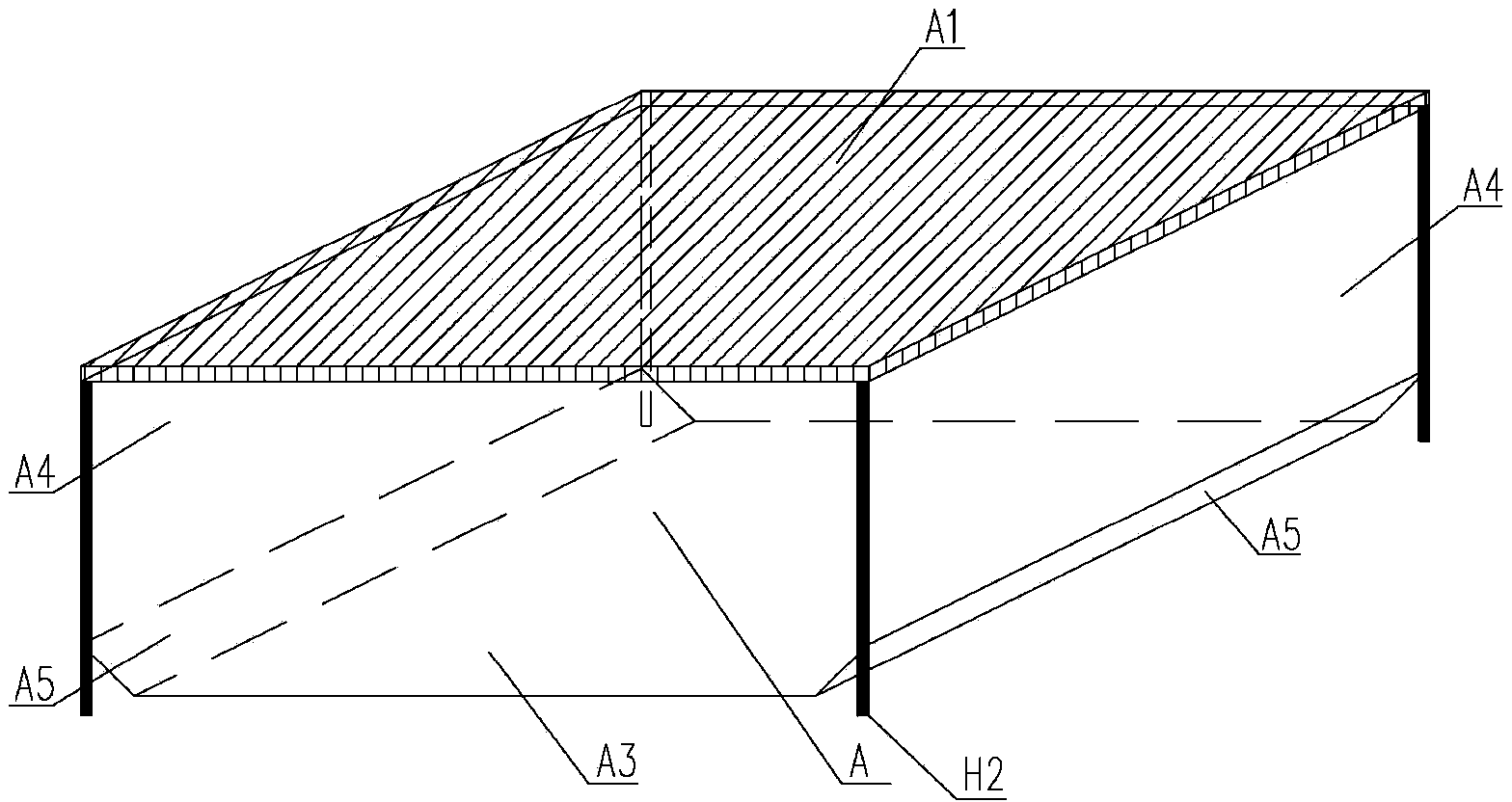

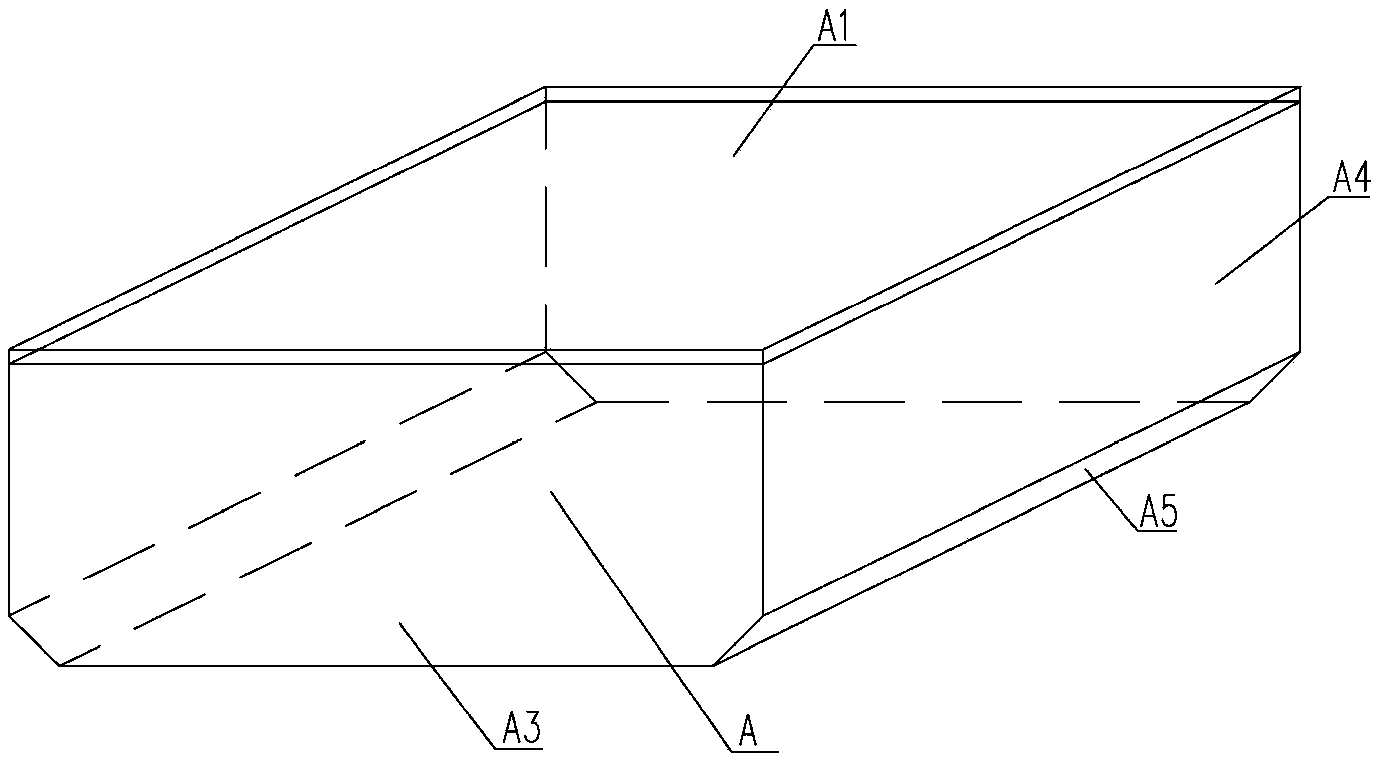

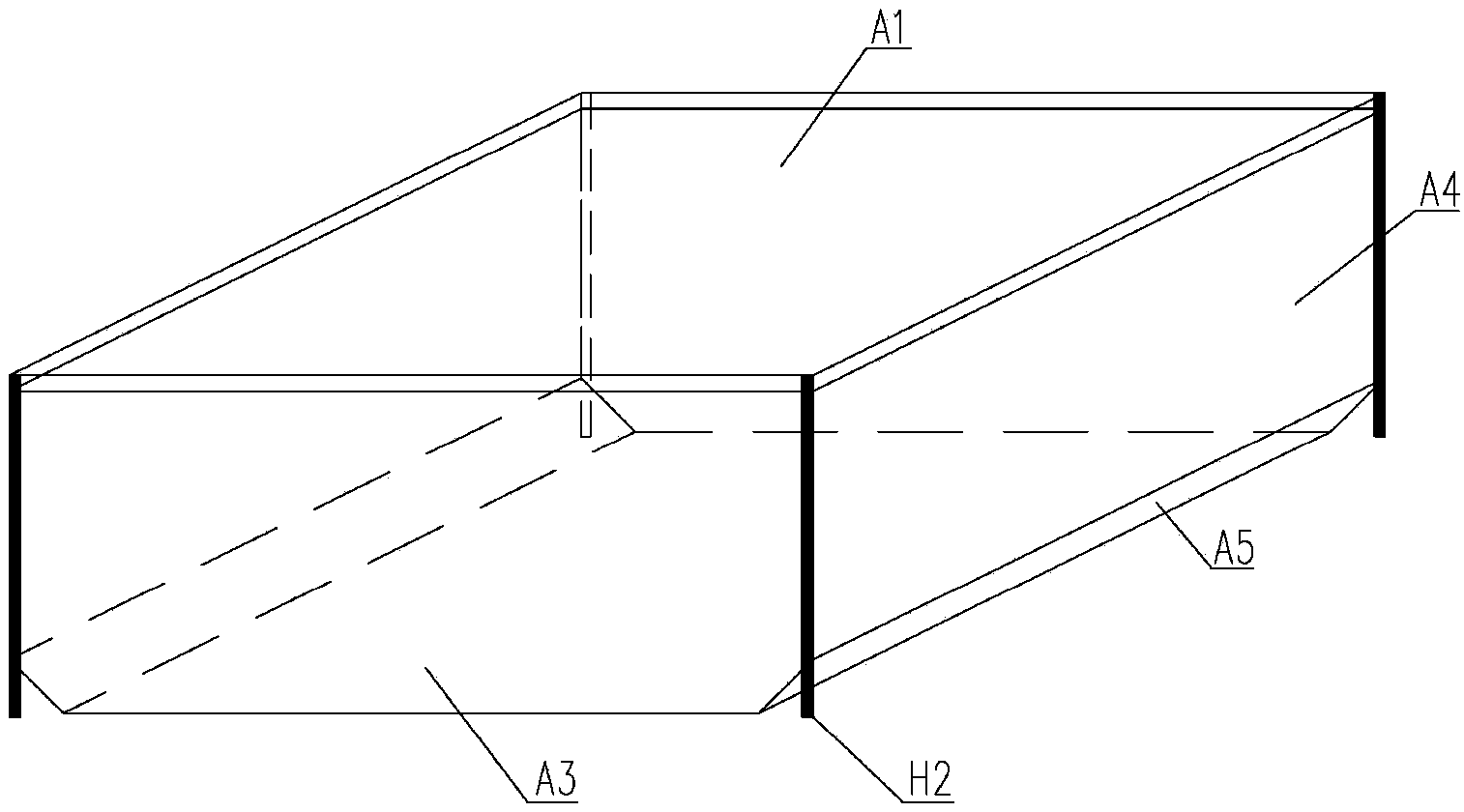

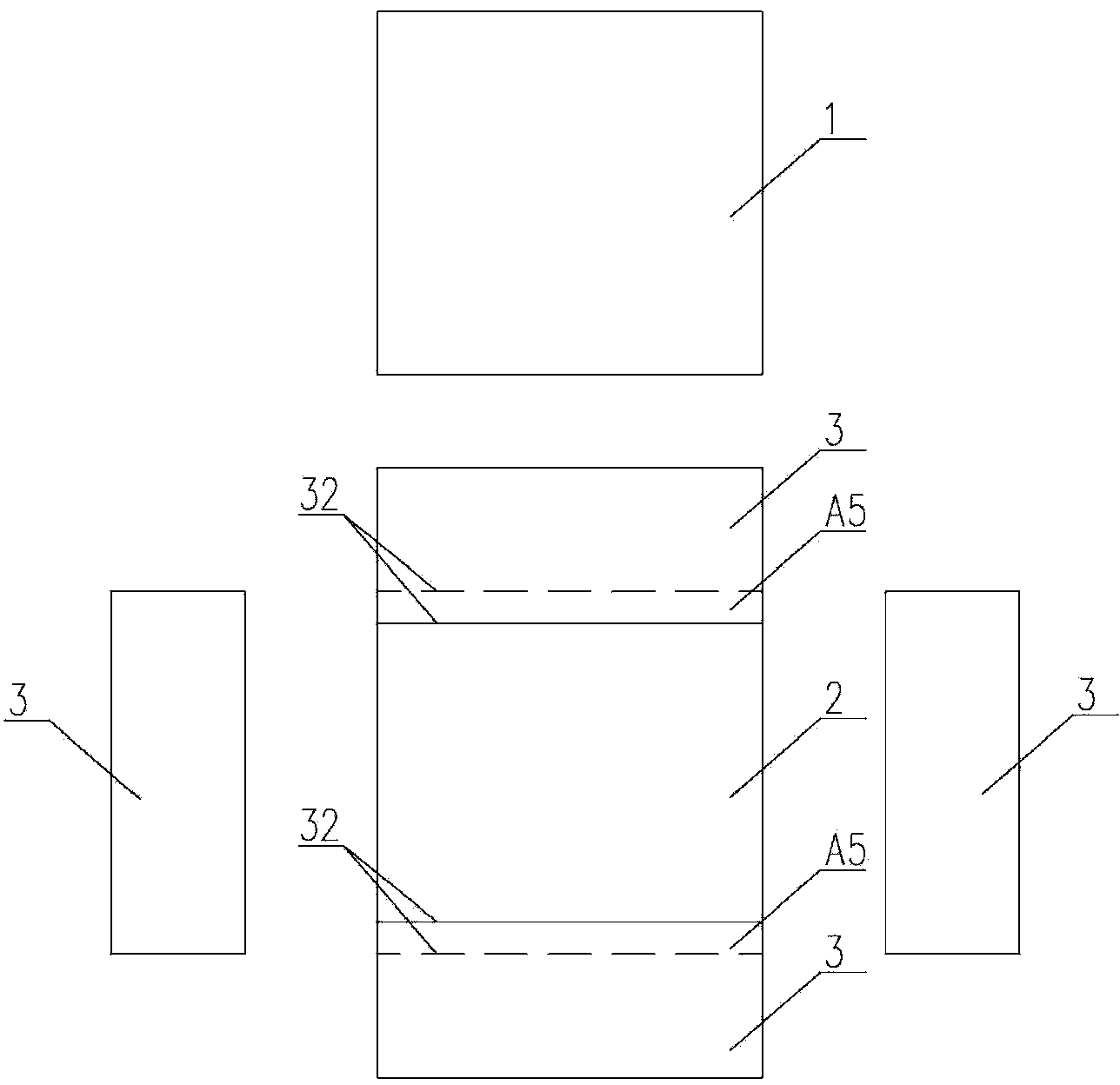

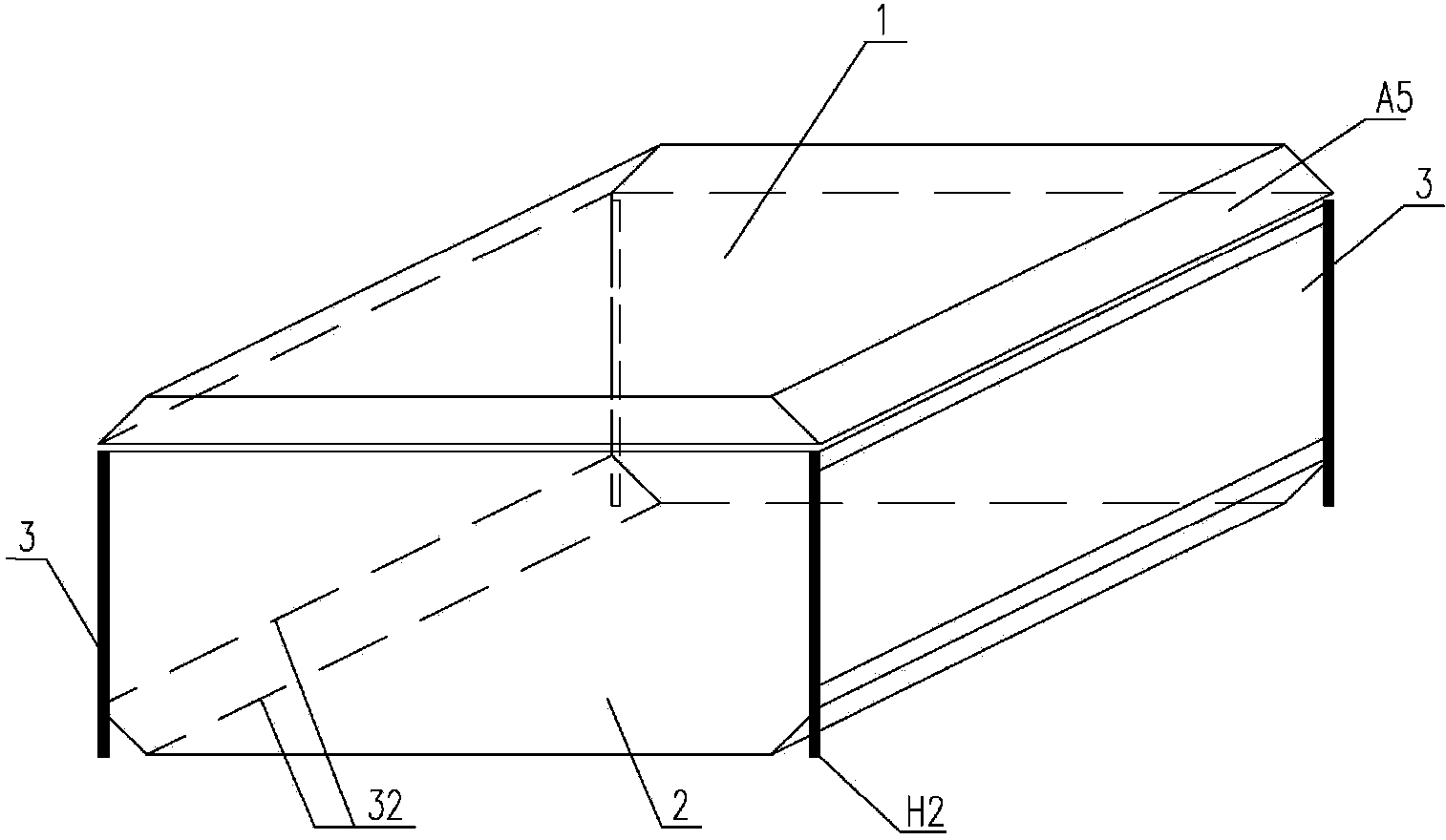

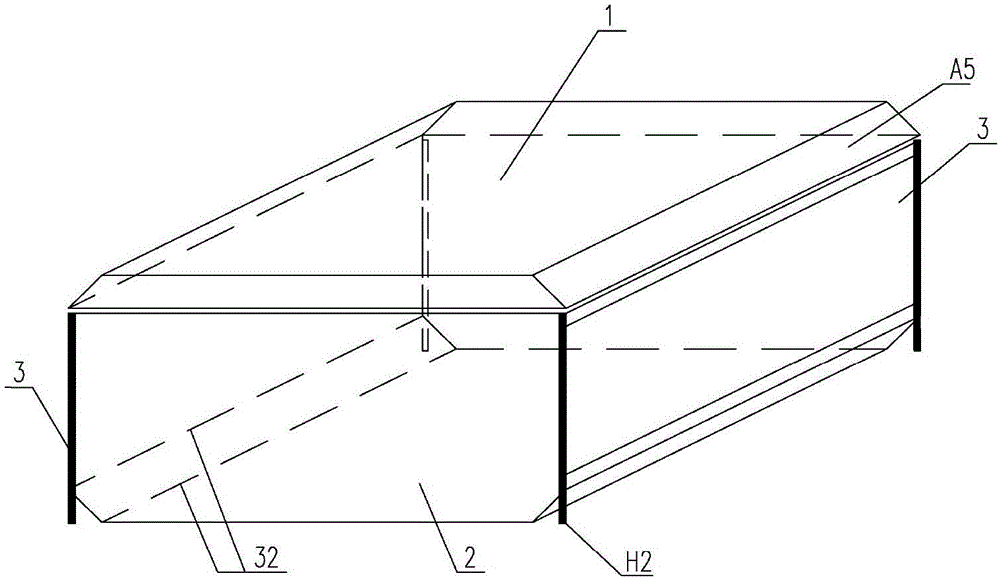

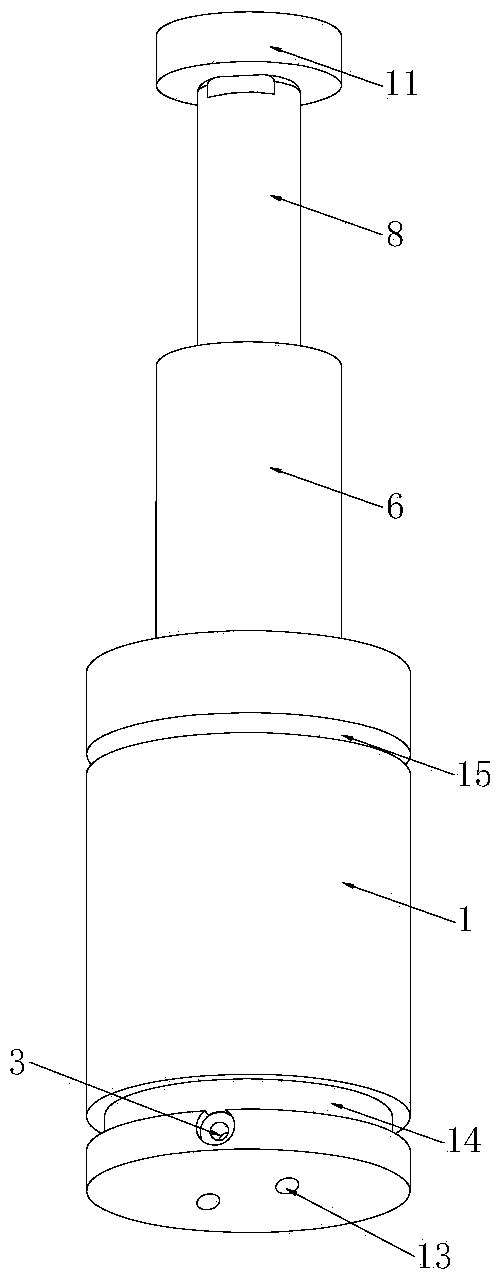

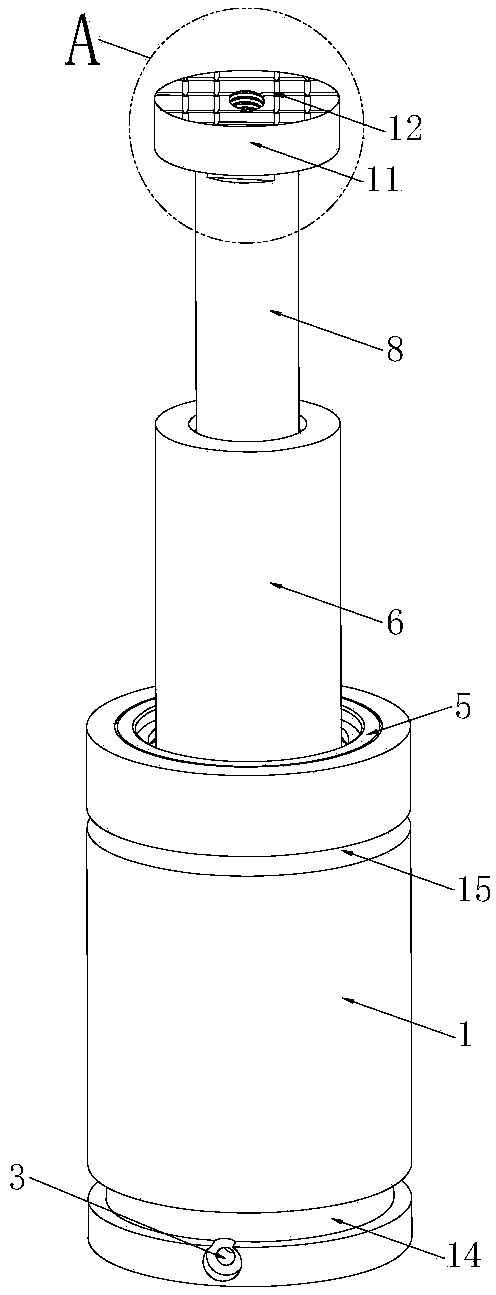

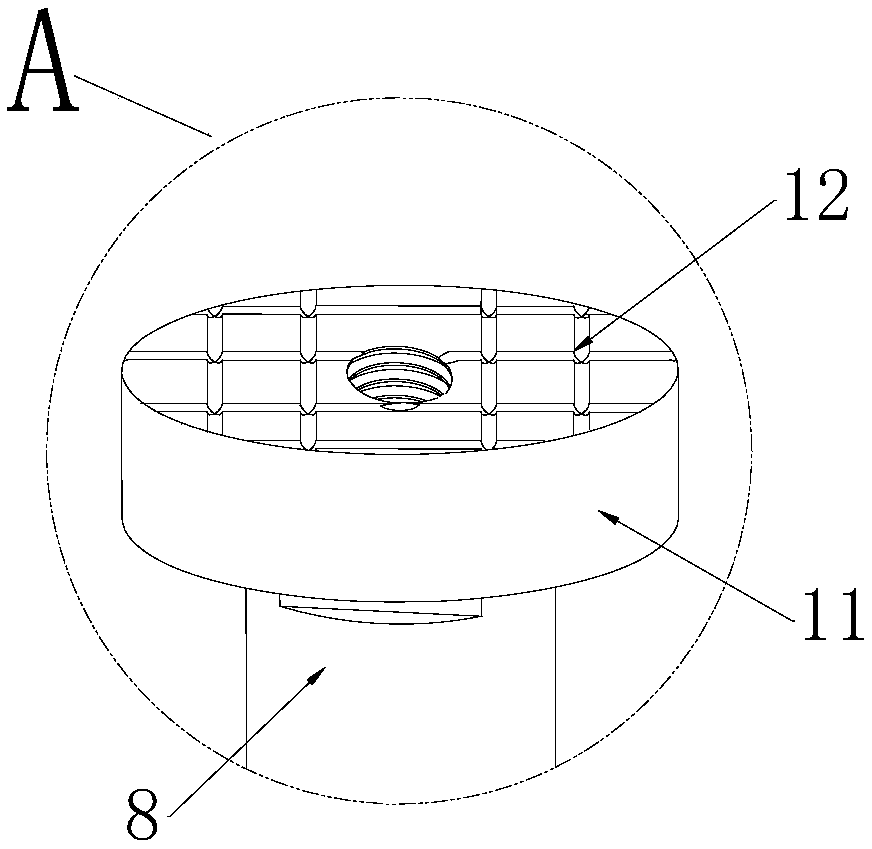

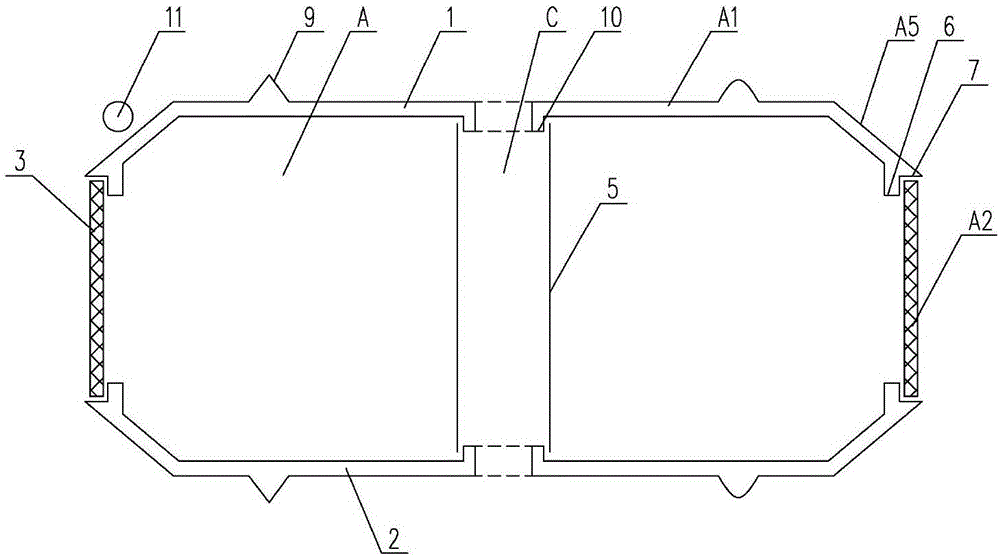

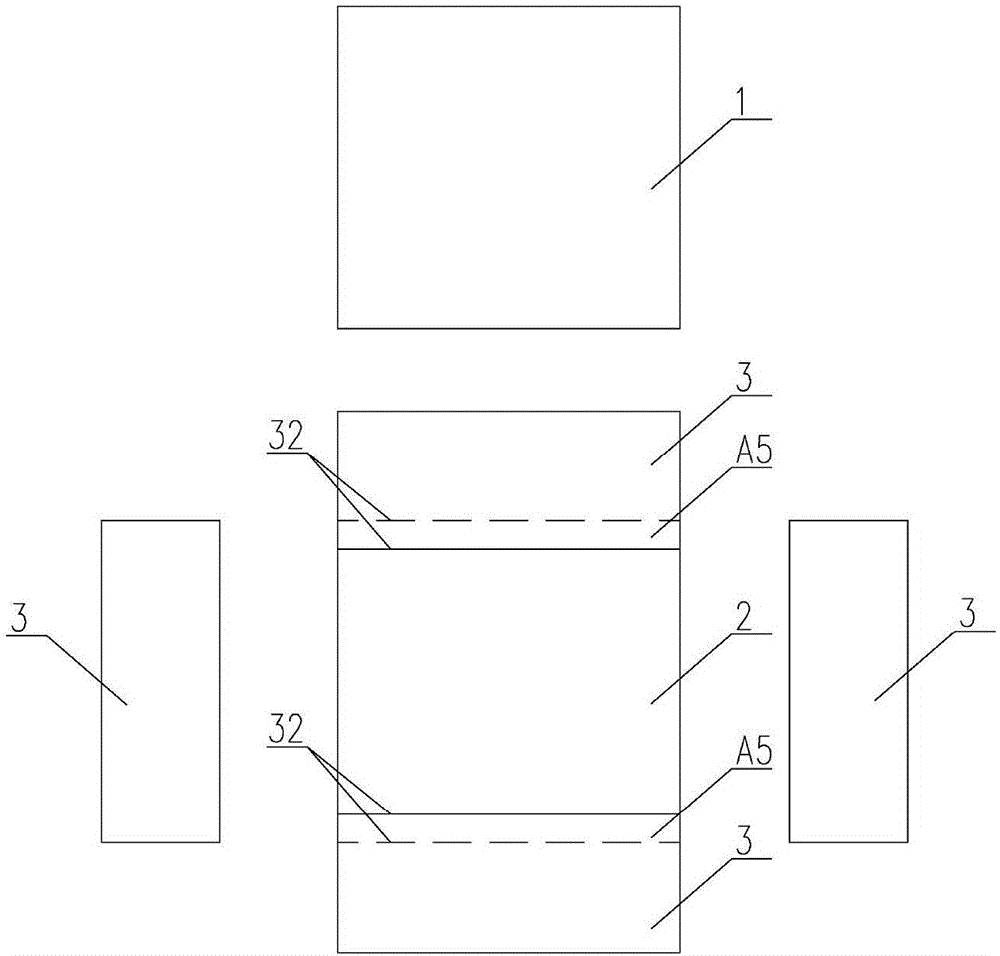

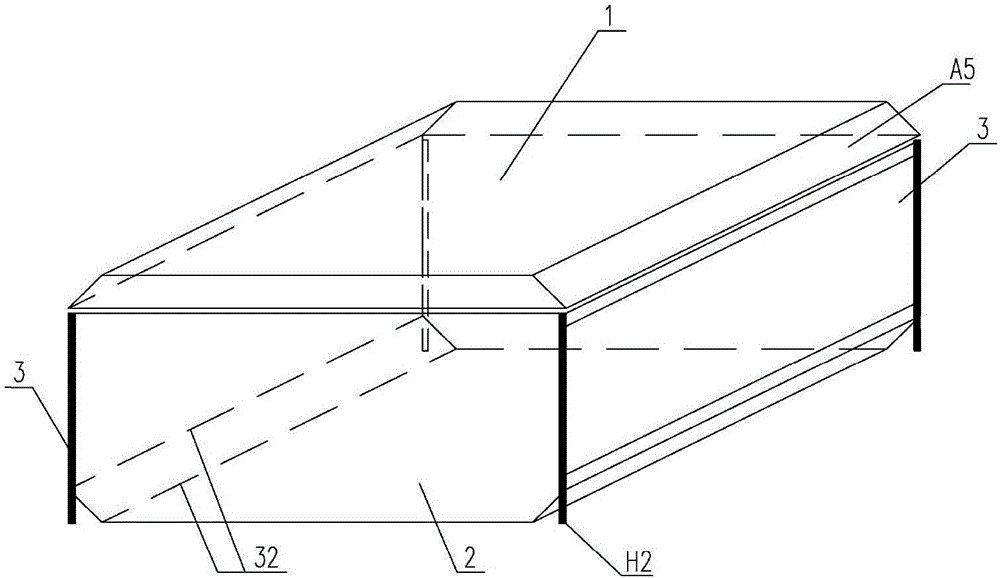

Cast-in-situ hollow floor with pores formed by reticular box-shaped component

The invention provides a cast-in-situ hollow floor with pores formed by a reticular box-shaped component. The cast-in-situ hollow floor comprises a reinforced concrete girder or a profile steel girder, a reinforced concrete ribbed beam, an upper flange plate, a lower flange plate and the reticular box-shaped component, wherein the reticular box-shaped component comprises a box roof, a box body and a box bottom; the box roof is compounded with cement mortar, polyfoam or a panel; the box body and the box bottom are made of reticular bodies; each reticular body comprises a reticular plate, a reinforcing rib and a connecting net, which constitute an integral structure with mutual effect; each of the reinforcing ribs is V-shaped; the reticular box-shaped component comprises at least two reticular bodies; at least two structural slopes are arranged at the corner parts between the box bottom and the box body of the reticular box-shaped component; the reticular bodies of the reticular box-shaped component are made of a steel material or a molding material. The cast-in-situ hollow floor with the pores formed by the reticular box-shaped component adopts the unsealed reticular box-shaped component to substitute the existing fully-sealed hollow fillers and solid fillers as the cast-in-situ hollow floor pore-forming technology. The cast-in-situ hollow floor with the pores formed by the reticular box-shaped component is favorable to realization of building and energy conservation integration and the multifunctional floor.

Owner:HUNAN BDF ENERGY SAVING TECH

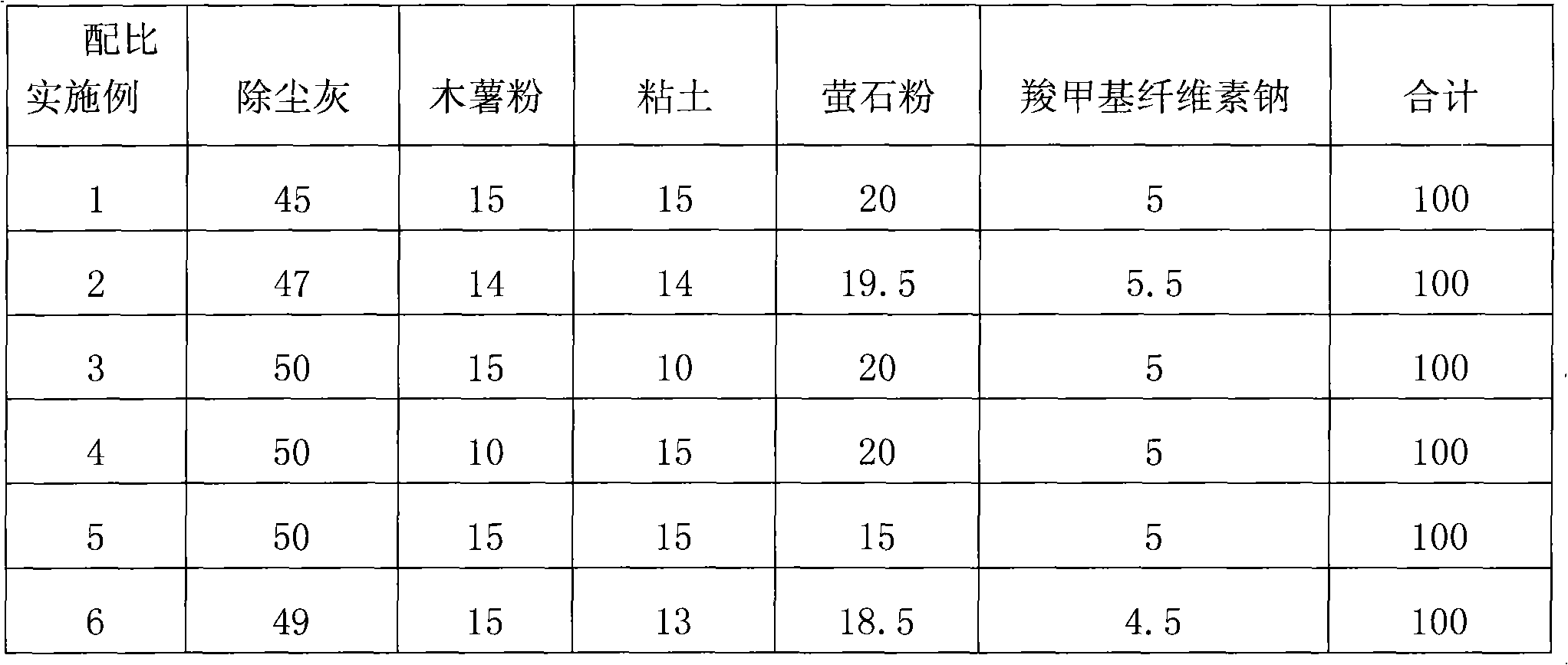

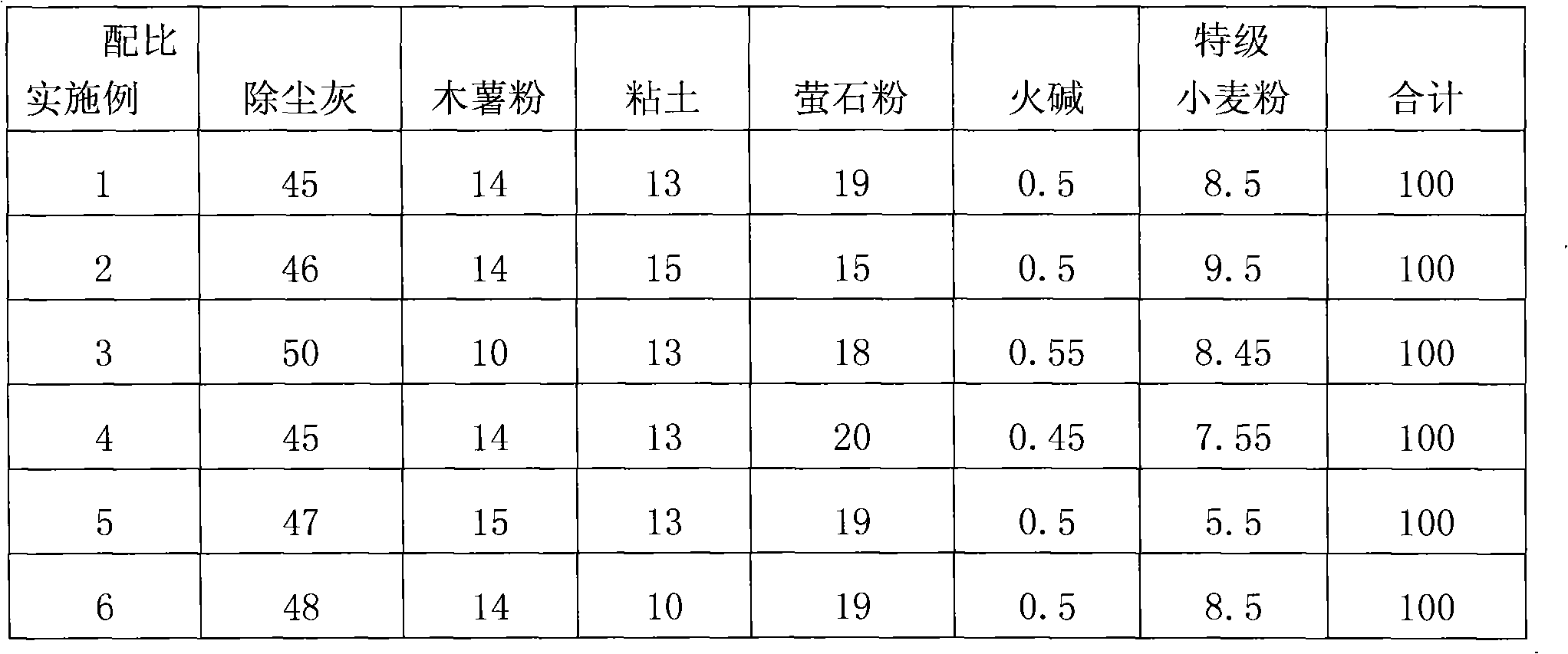

Metallurgical pellet compound binding agent

The invention discloses a metallurgical pellet compound binding agent. The compound binding agent comprises the following components in percentage by weight: 45 to 50 percent of dust generated in blast furnace ironmaking and sintering production processes, wherein the dust is grounded to ensure that more than or equal to 80 percent of the dust has the particle size of 0.043 mm, the TFe in the dust is more than or equal to 60 percent, and montmorillonite in the dust is more than or equal to 20 percent; 10 to 15 percent of cassava meal of which more than or equal to 80 percent has the particle size of 0.043 mm; 10 to 15 percent of clay of which more than or equal to 80 percent has the particle size of 0.043 mm; 15 to 20 percent of fluorspar powder of which more than or equal to 80 percent has the particle size of 0.043 mm; and 4.5 to 5.5 percent of carboxymethylcellulose sodium of which more than or equal to 80 percent has the particle size of 0.043 mm. The carboxymethylcellulose sodium of the compound binding agent can be replaced by caustic soda and special-grade wheat flour. The components are uniformly stirred according to the percentage by weight to prepare the pellet compound binding agent; and during the production of pellets, 0.8 to 1.2 percent of 0.5 percent replaceable bentonite is added, and not only a requirement on pellet production can be meet, but also the used amount of the bentonite is reduced, thereby fulfilling the aims of improving the grade of pellet iron ores and simultaneously improving blast furnace coefficients.

Owner:马鞍山市金鑫建材有限公司

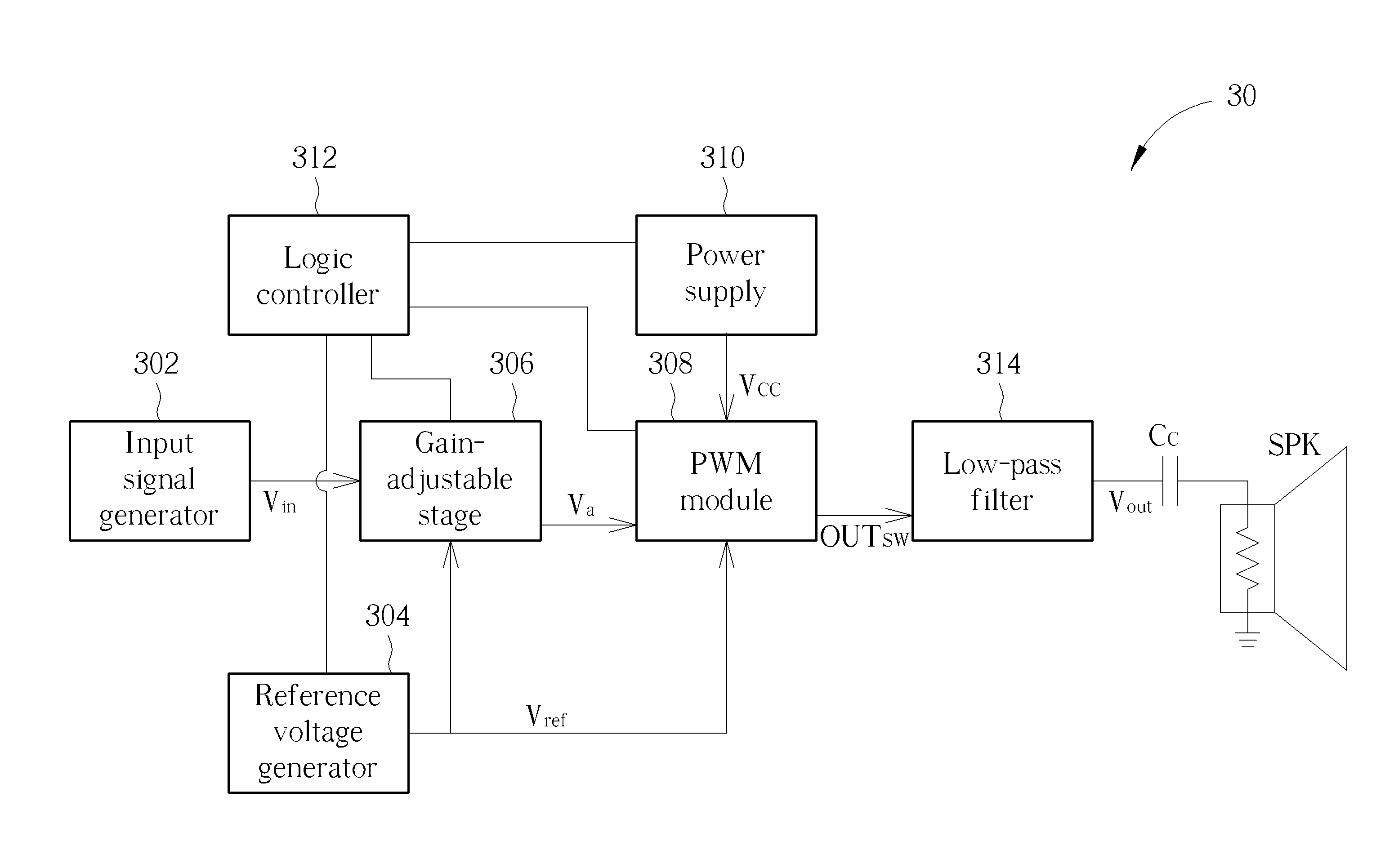

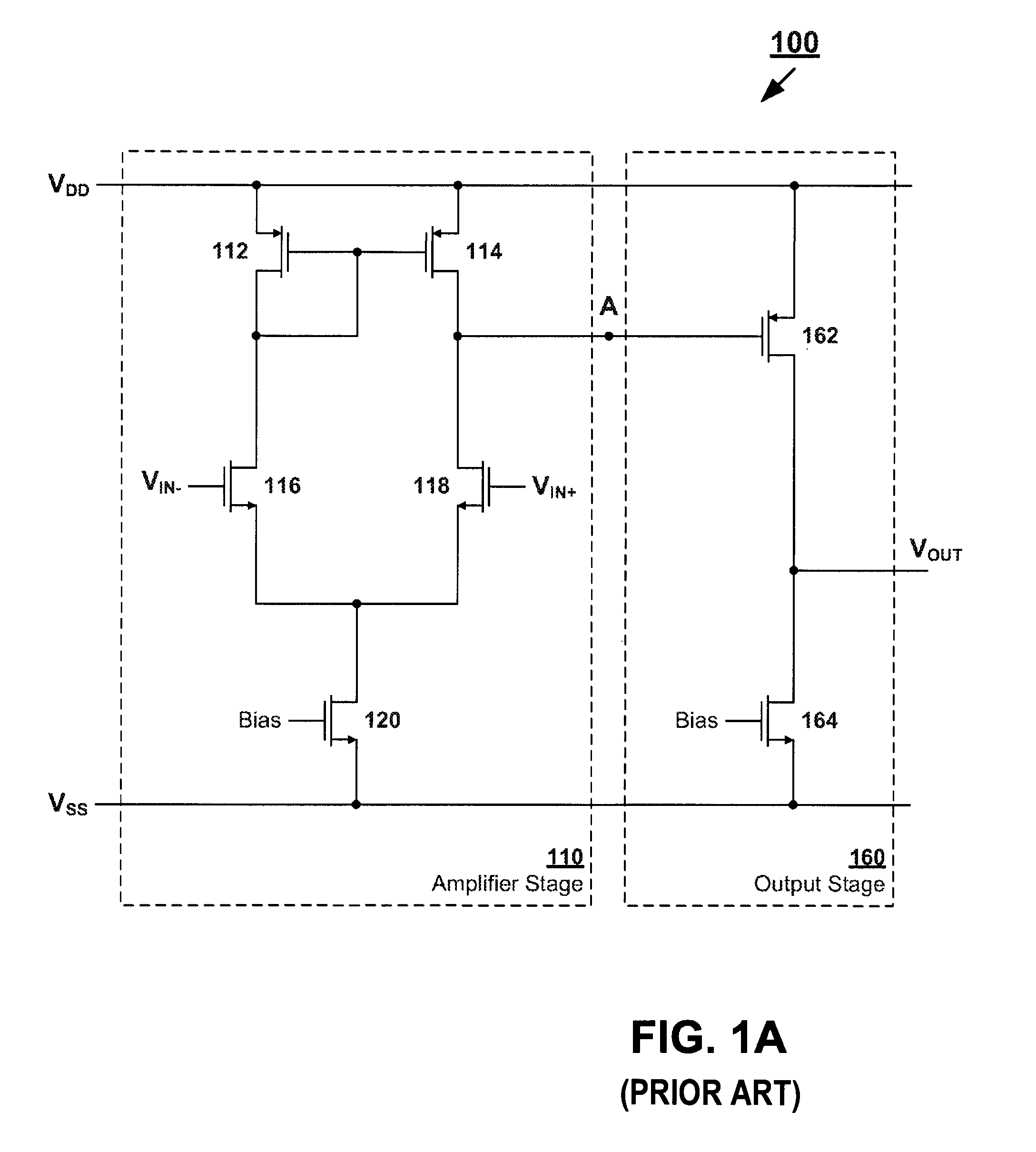

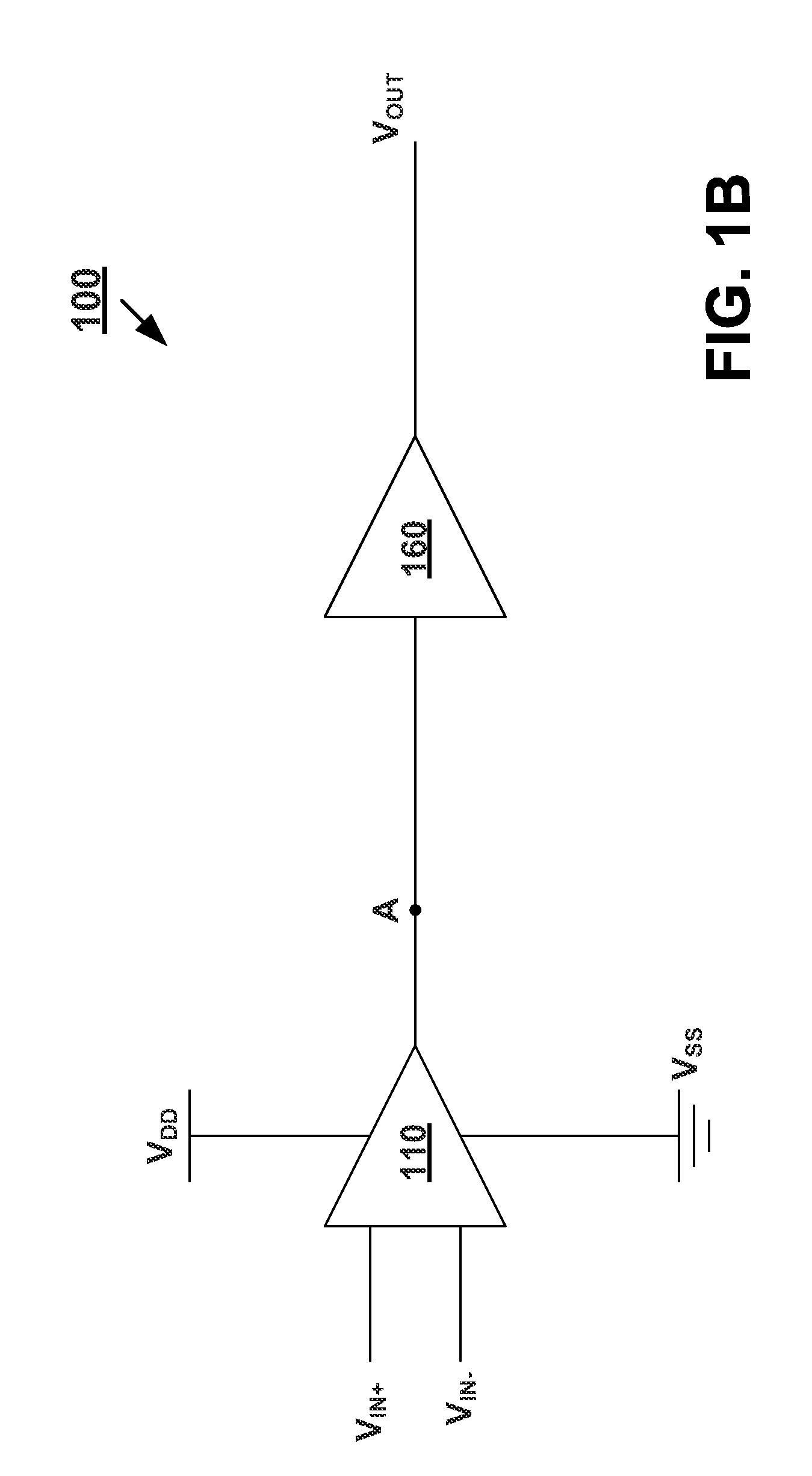

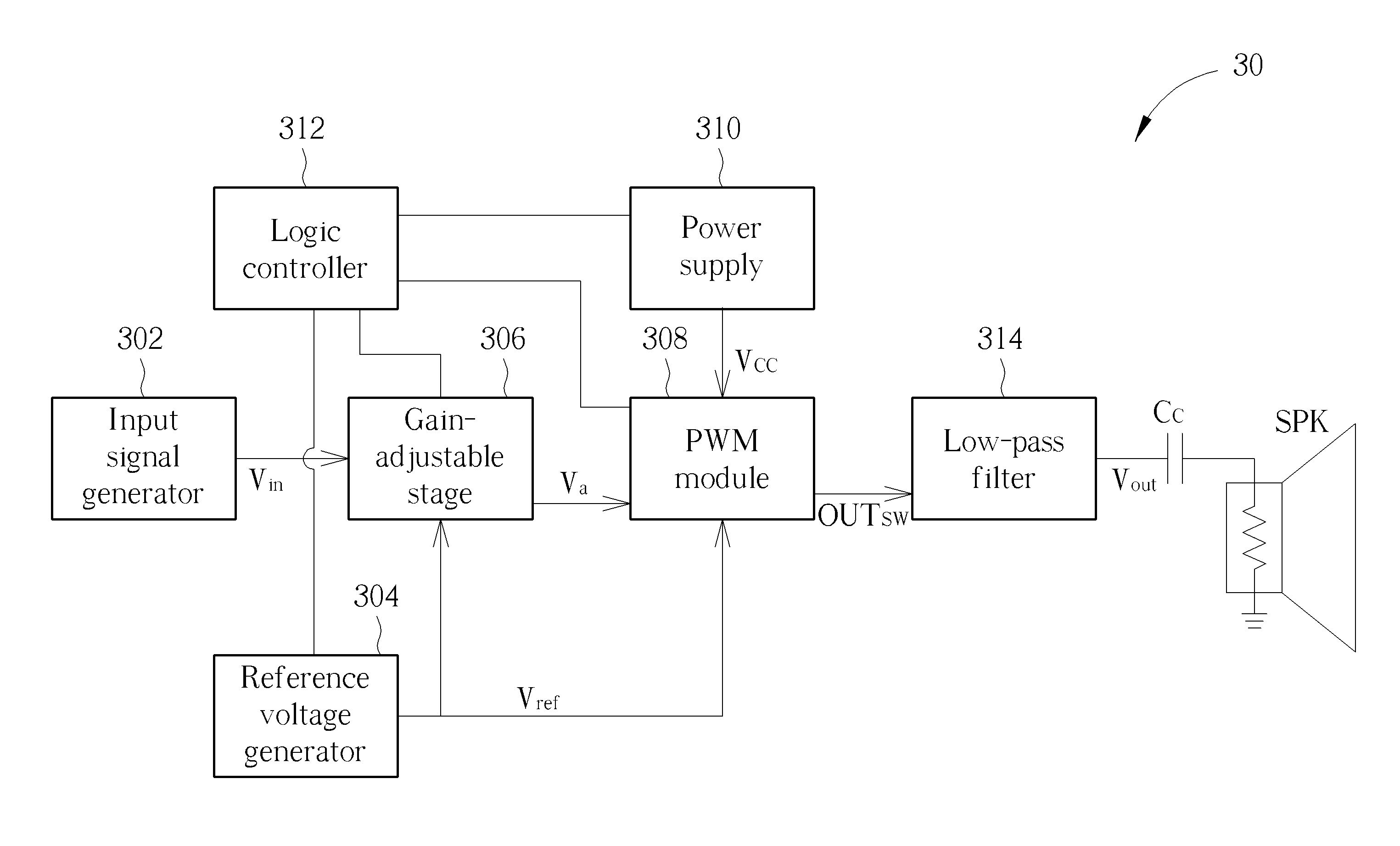

Pop-free single-ended output class-d amplifier

ActiveUS20140062592A1Avoid output voltageReduce a ‘popping’ soundAmplifier with semiconductor-devices/discharge-tubesAmplifier detailsVoltage generatorAudio power amplifier

A pop-free single-ended output class-D amplifier includes: an input signal generator for generating an input signal; a power supply for supplying input power; a reference voltage generator for generating a reference voltage; a gain-adjustable stage for generating an amplified signal according to the reference voltage and adjusting a gain of the single-ended output class-D amplifier; a pulse width modulation module for outputting a pulse width modulation signal according to the reference voltage, the amplified signal, and the input power; a low-pass filter for low-pass filtering the pulse width modulation signal to generate an output voltage; and a logic controller for generating at least one control signal to control the reference voltage generator, the gain-adjustable stage, and the pulse width modulation module according to the input power, the reference voltage, and the pulse width modulation signal.

Owner:ANPEC ELECTRONICS CORPORATION

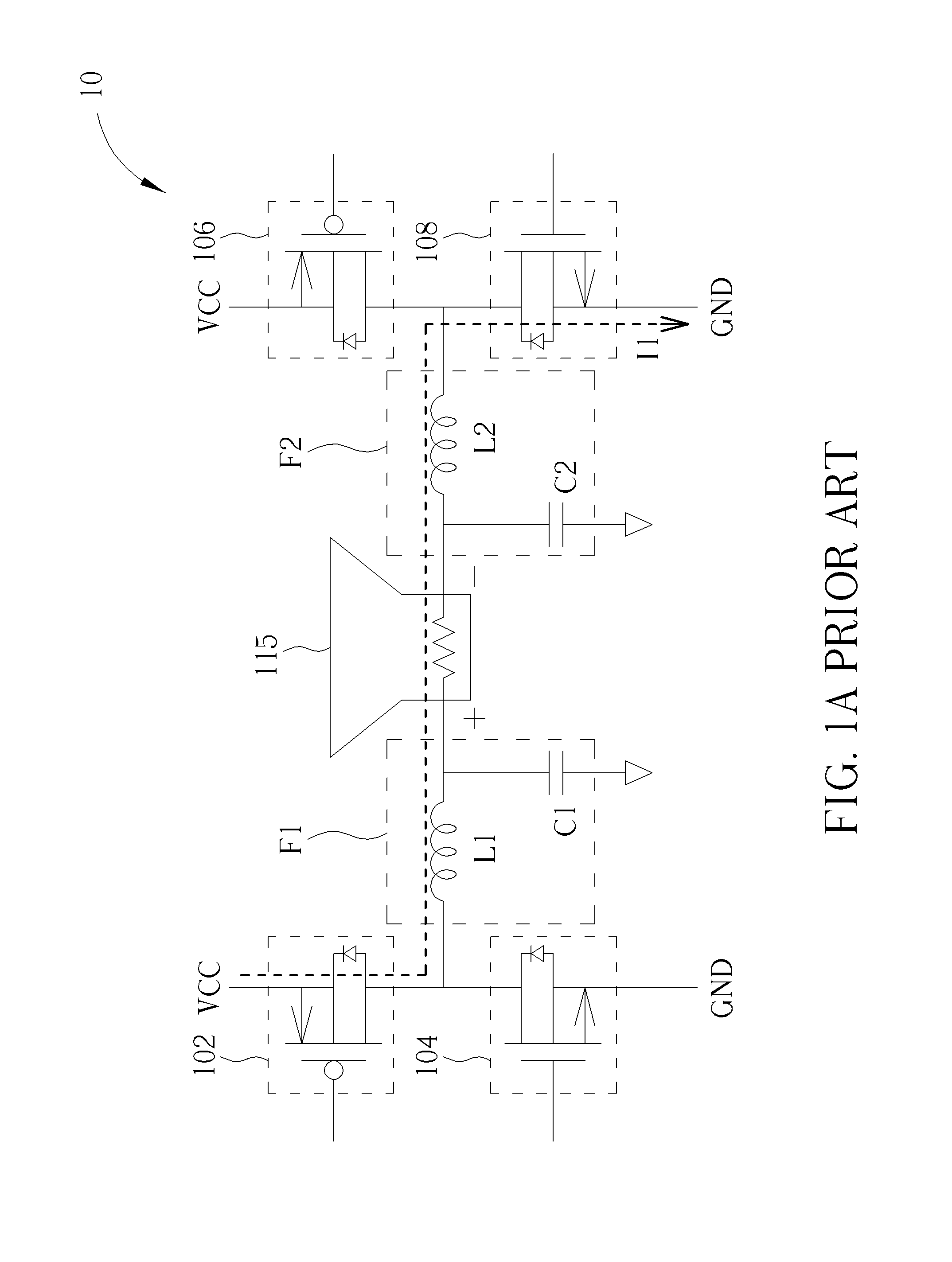

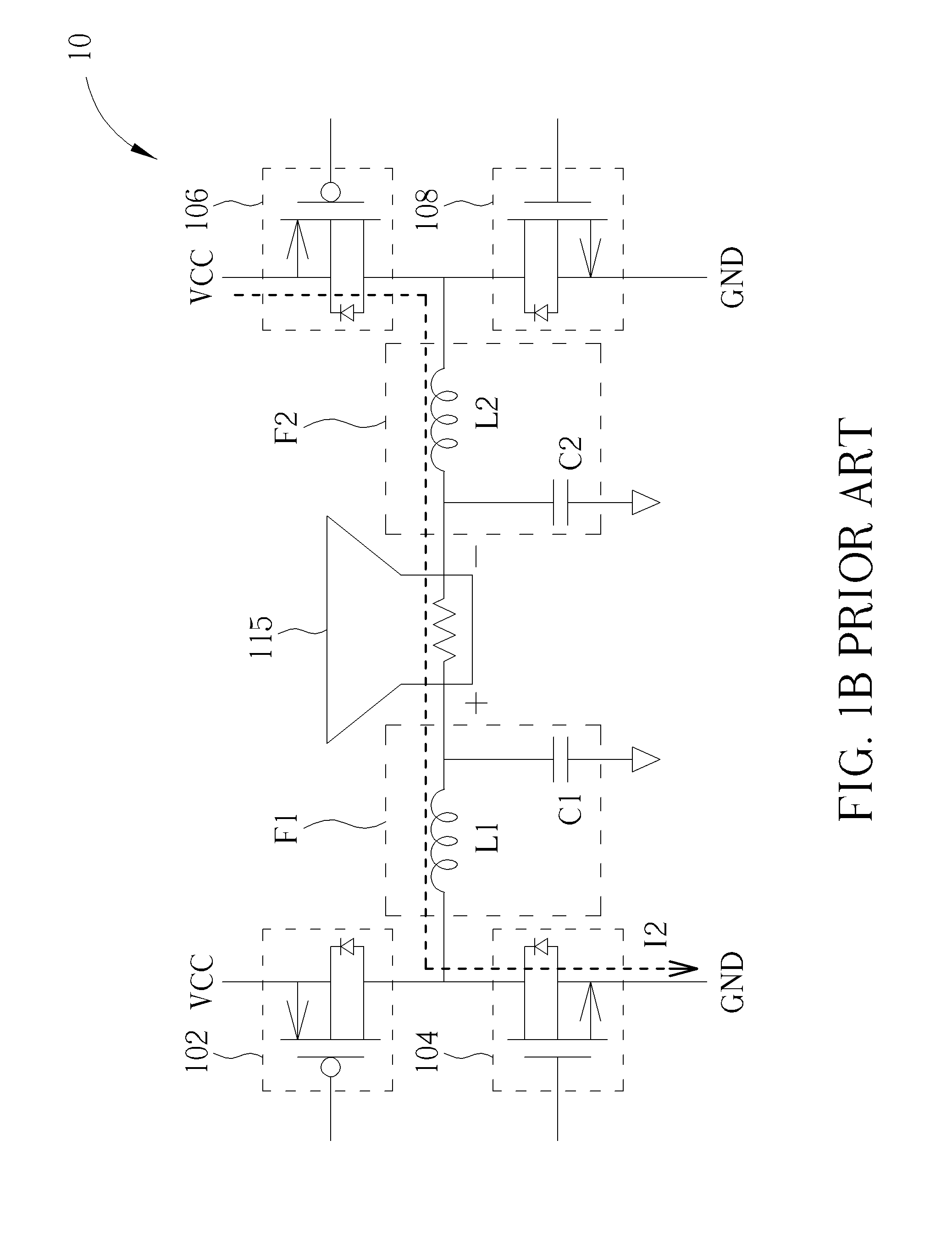

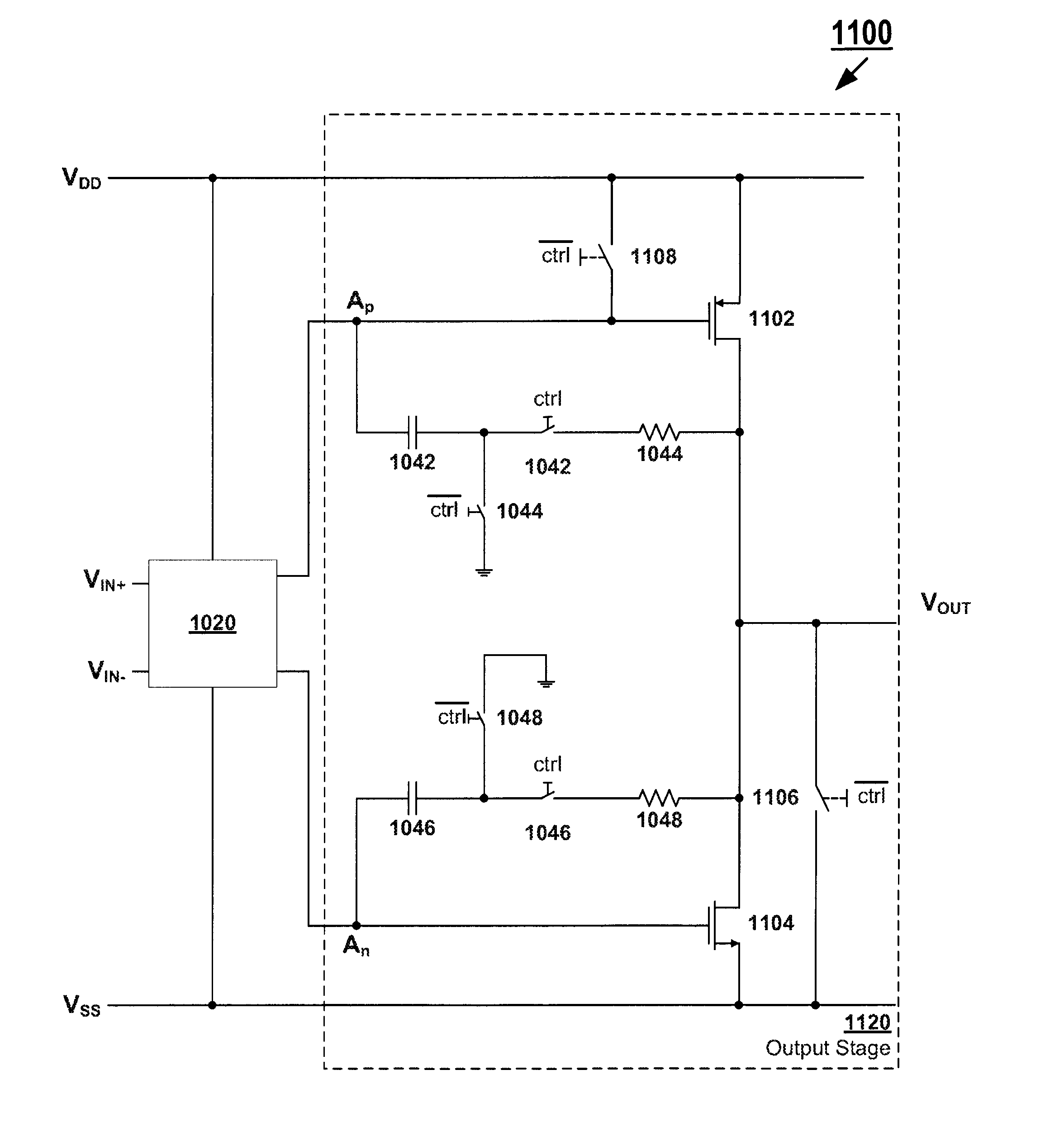

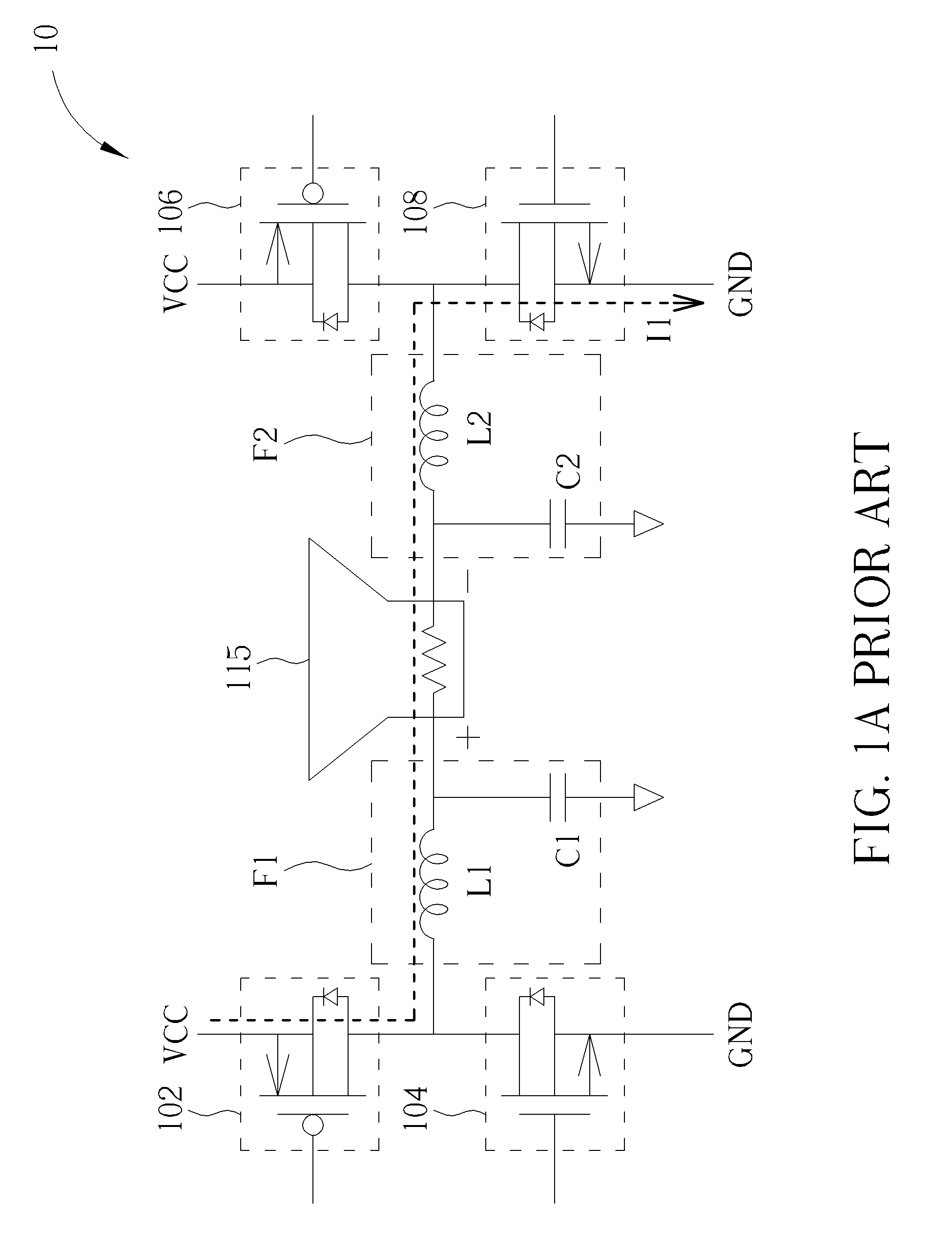

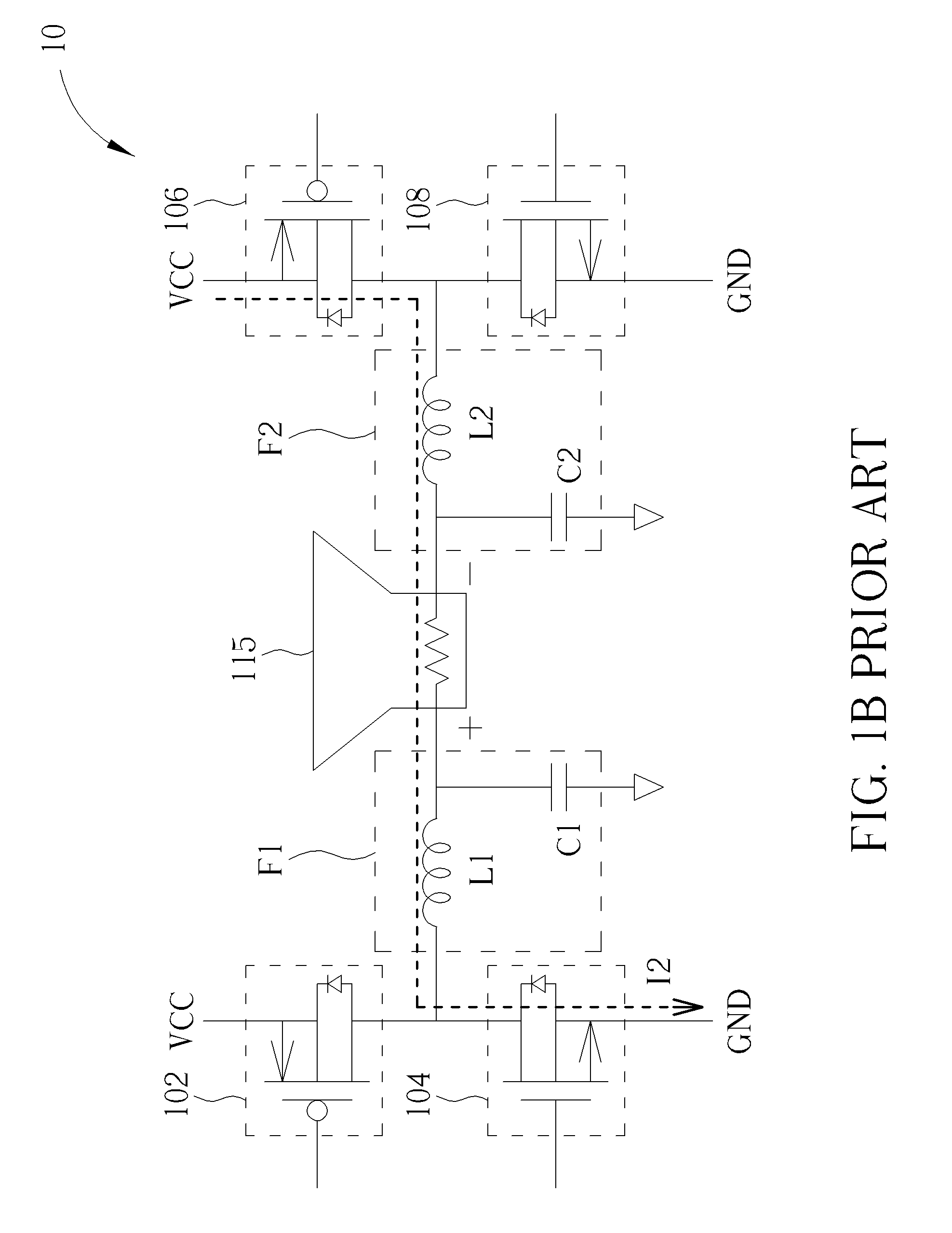

Anti-pop circuit

ActiveUS8063699B2Reduce poppingPush-pull amplifiersNegative-feedback-circuit arrangementsElectricityAudio power amplifier

Presently many audio chips suffer from pop issues, which is especially serious for single ended audio drivers. An audio pop is a disturbance in the output caused by a sudden transition of chip power, particularly when a chip is powered on or powered off. Furthermore, compensation networks included in the amplifiers on audio chips for stability offer a significant path for transmitting power disturbances to the output. Hence, circuitry is developed to suppress pops in the output stages of an amplifier.

Owner:SYNAPTICS INC

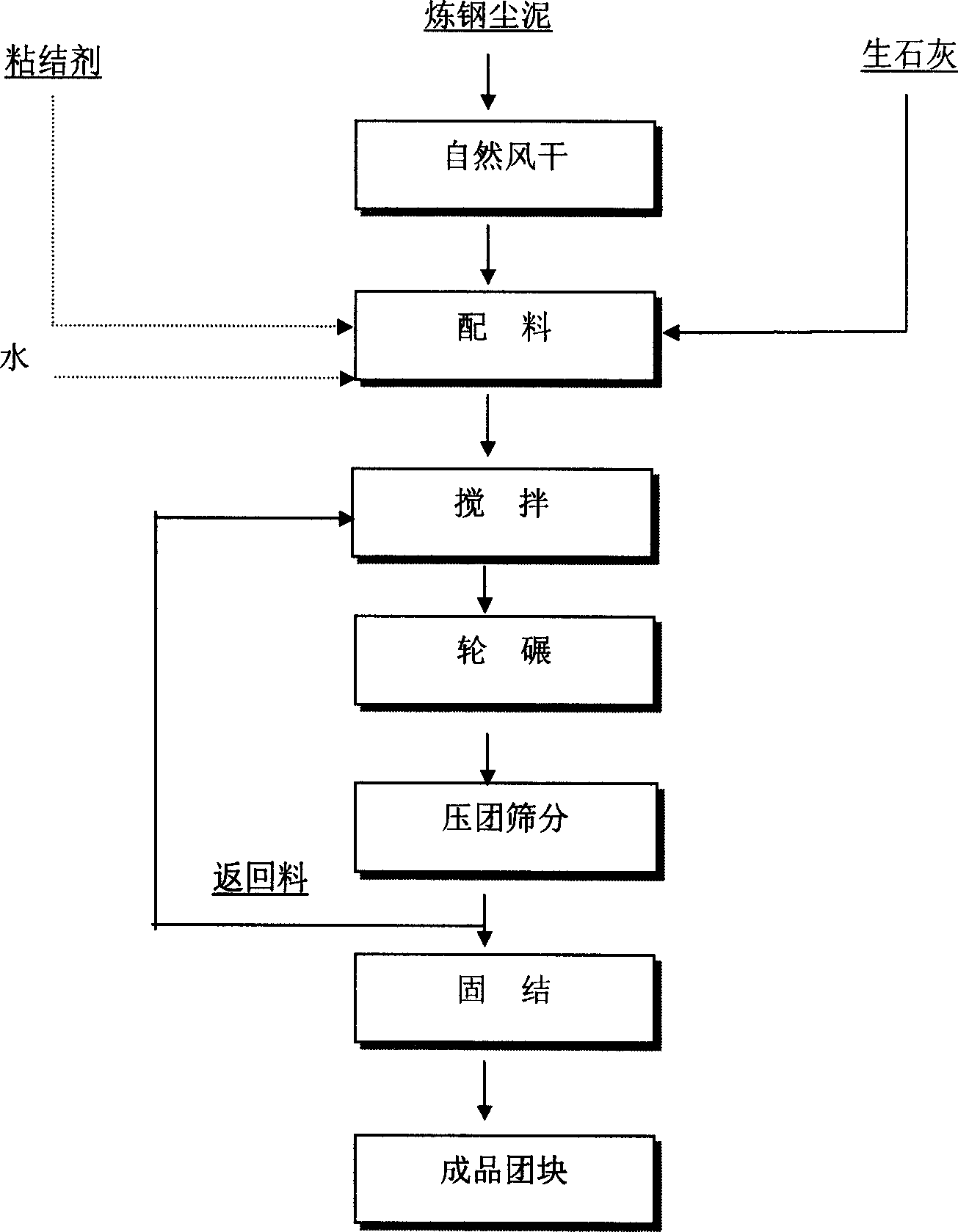

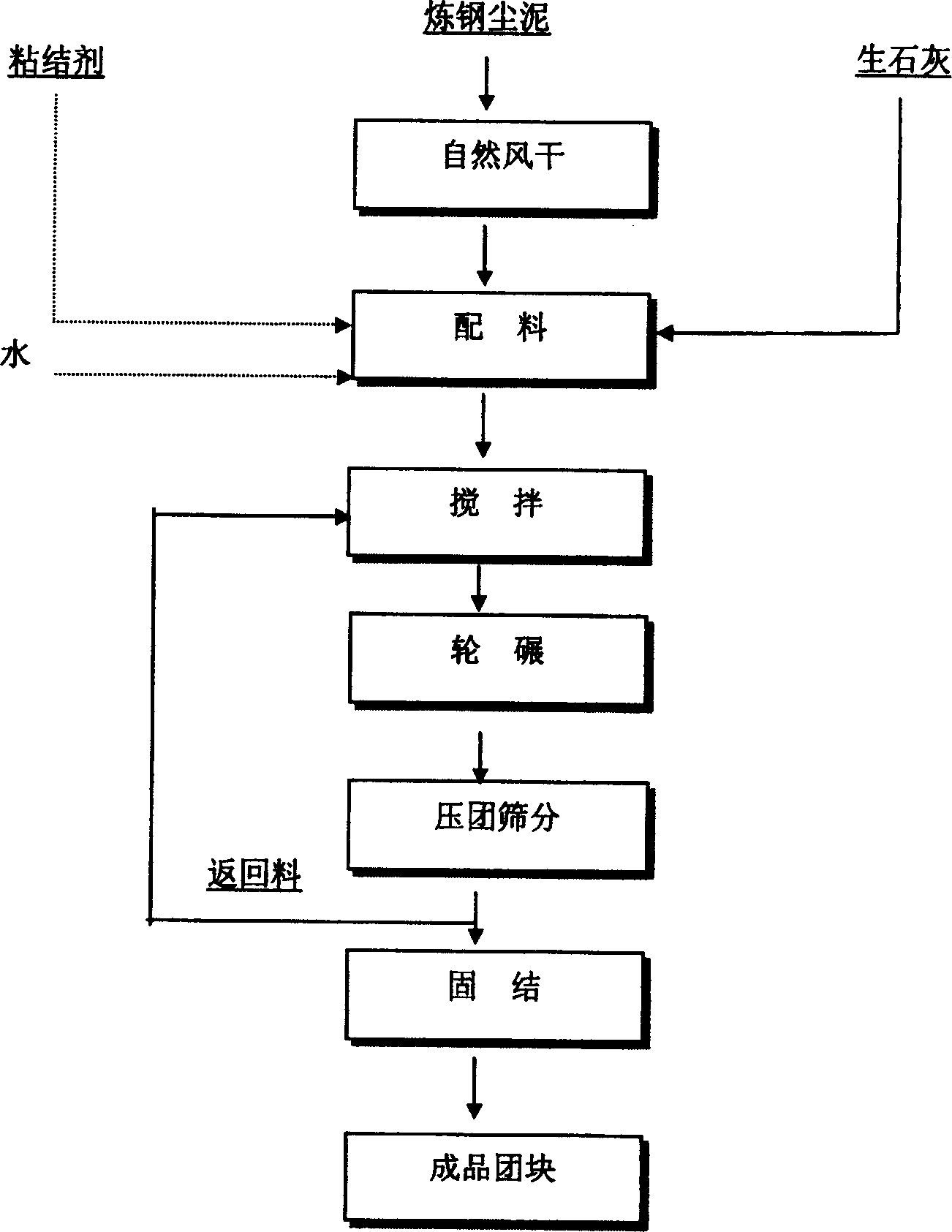

Process for preparing slag by pelletization of steel-making dust slime

InactiveCN1664120AHigh strengthIncreased degree of plastic deformationManufacturing convertersProcess efficiency improvementSteelmaking

The invention relates to a comprehensive utilization method of dust and mud in steelmaking process, which is specifically a spheroiditic slagging agent production process. The invention comprises the following steps: drying dust and mud in the open, adding 2-6% burnt lime and 0.5-1% adhensive to the mud to produce mixture, sending the mixture to agitator to intimate mixing, sending the mixture to roller to be pulverized fully, sending it to pelletizer to produce green-ball of phi20-phi30mm size by roll-type briquetting process in presure of 40-60KN, processing green-ball in jigging screen to get green-ball end product on sifter and sliver as return material under sifter and sending green-ball to tower furnace via charging system to be adglutinate and get end product.

Owner:张清学

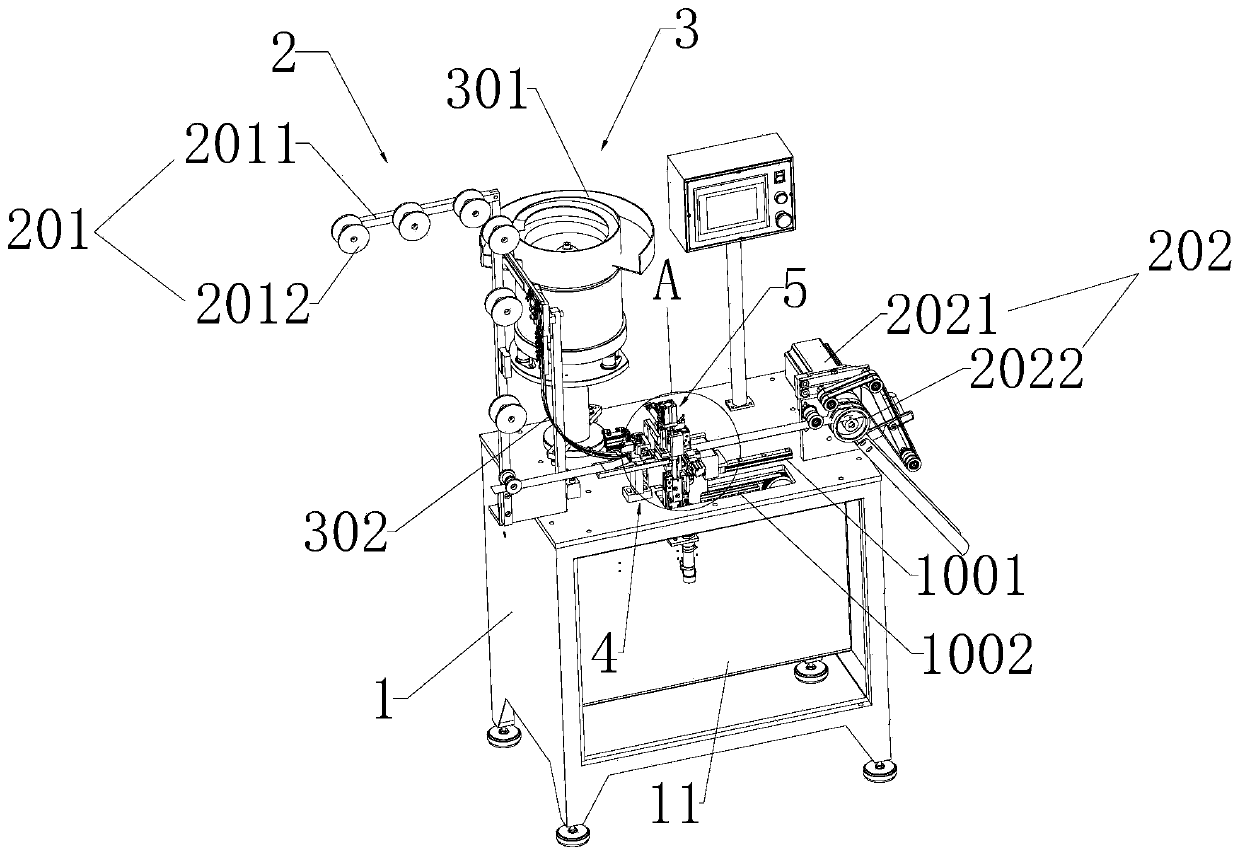

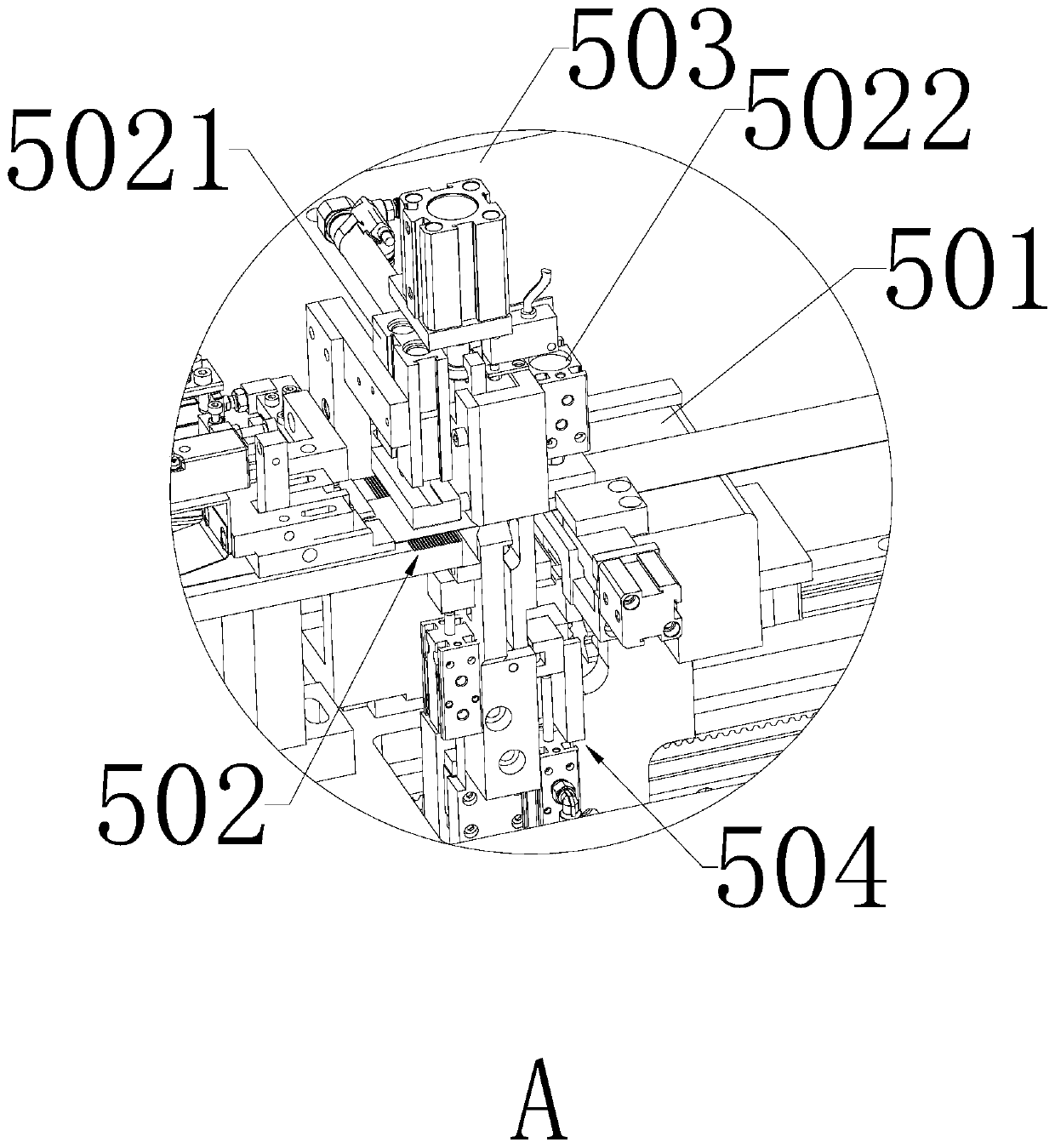

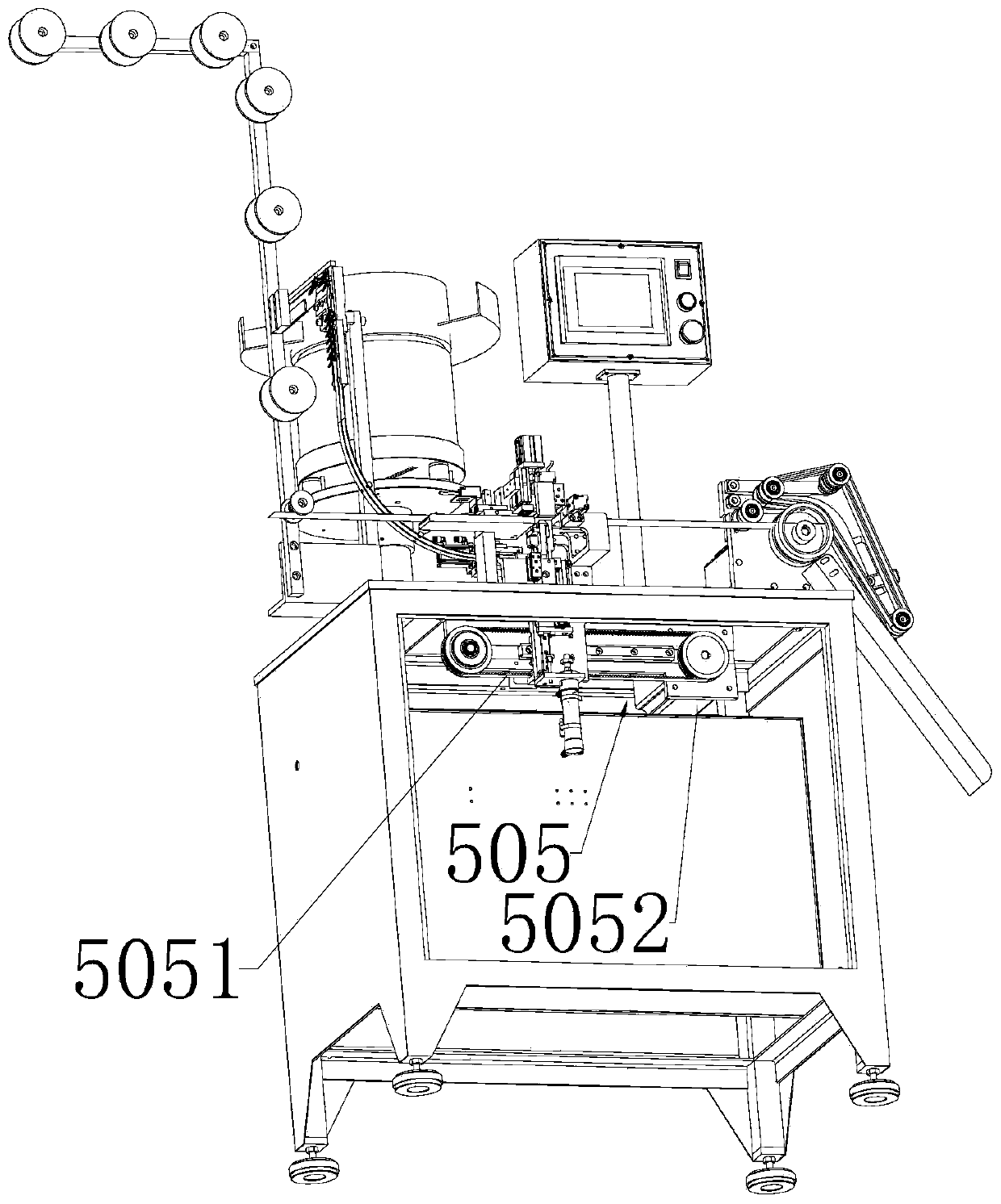

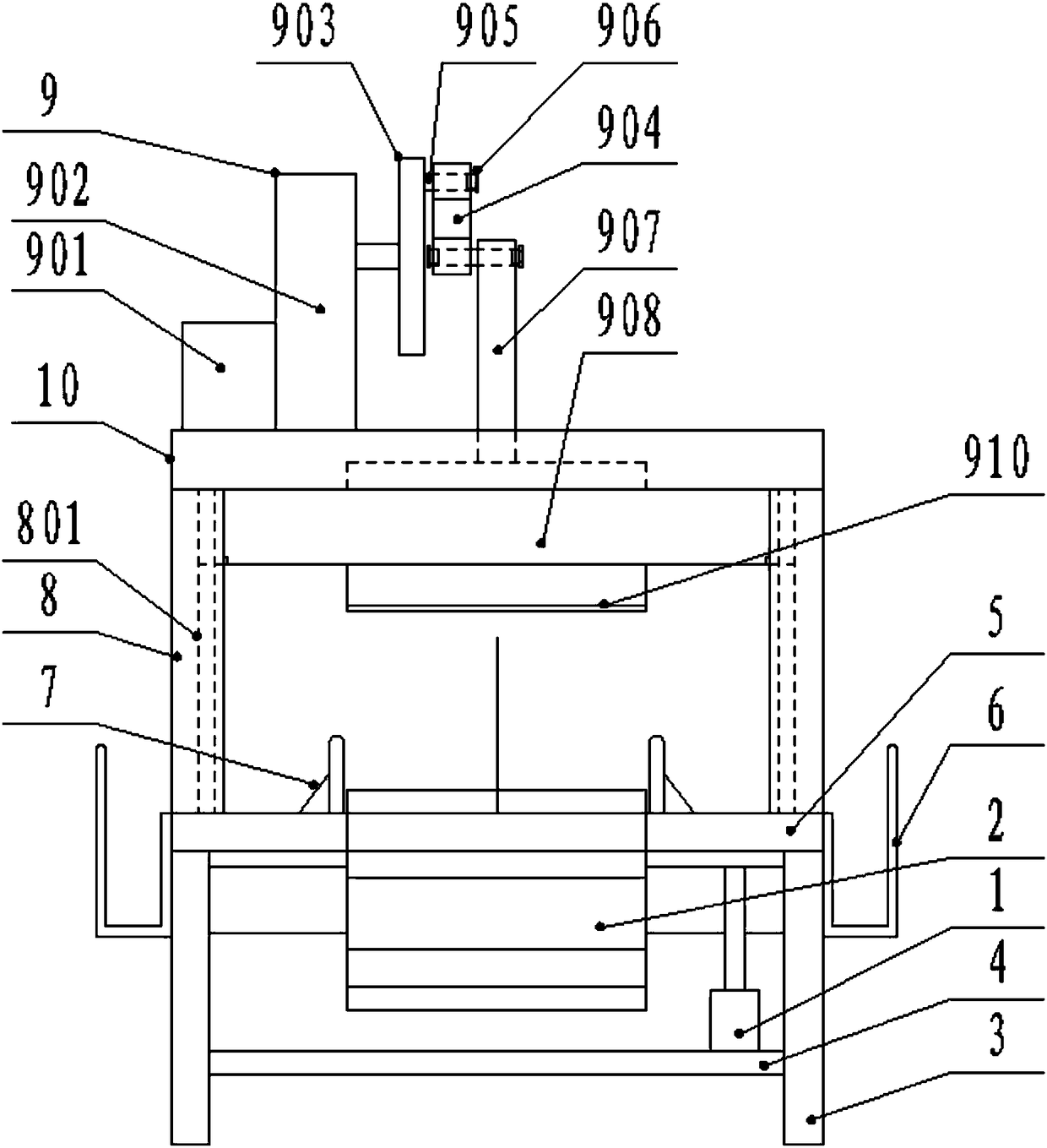

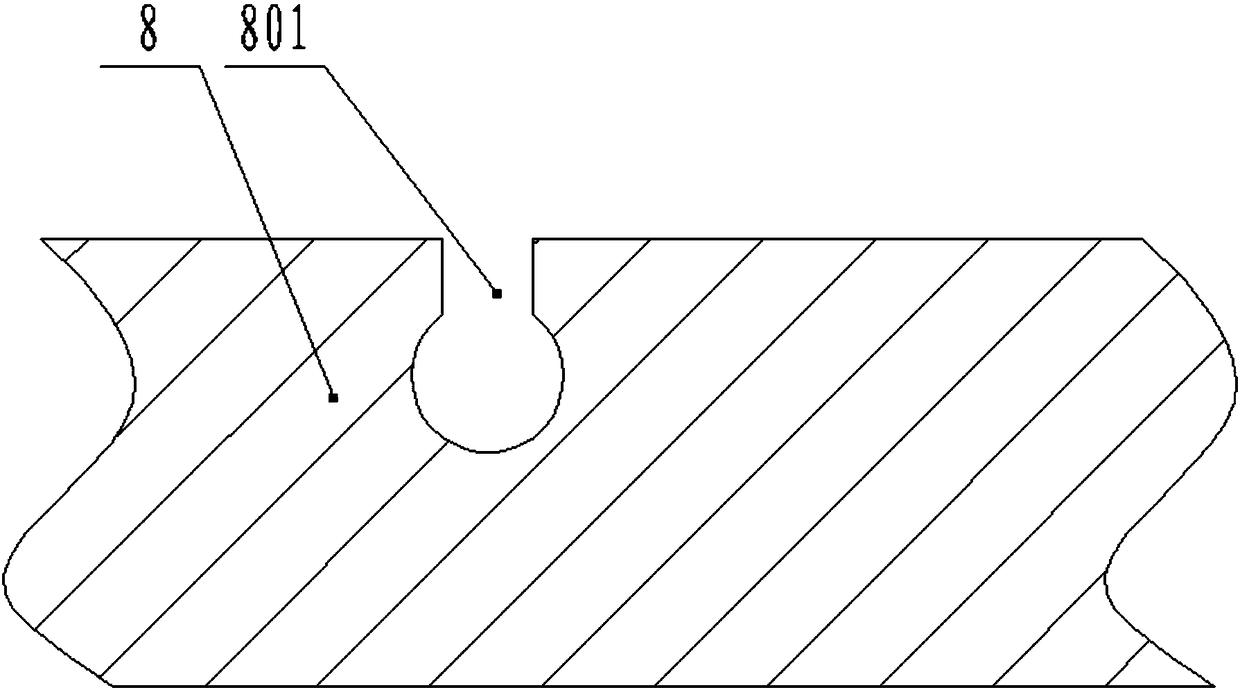

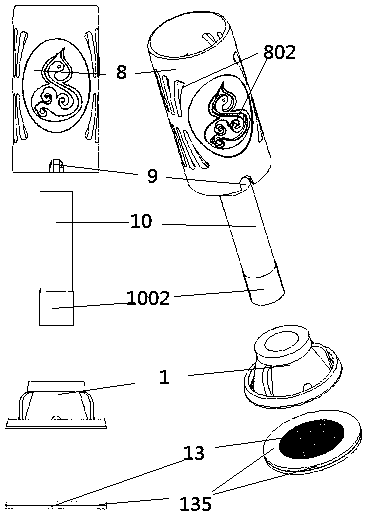

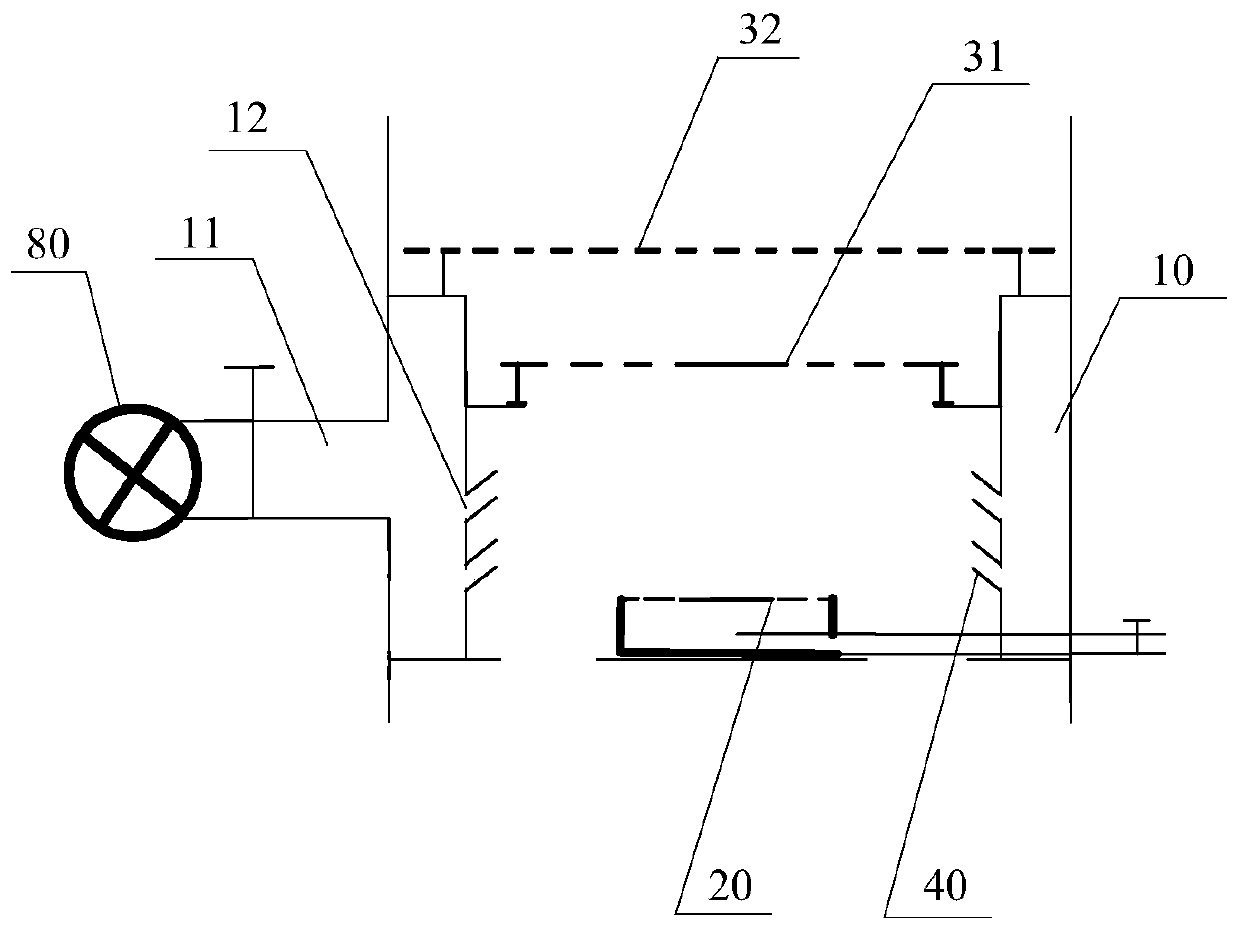

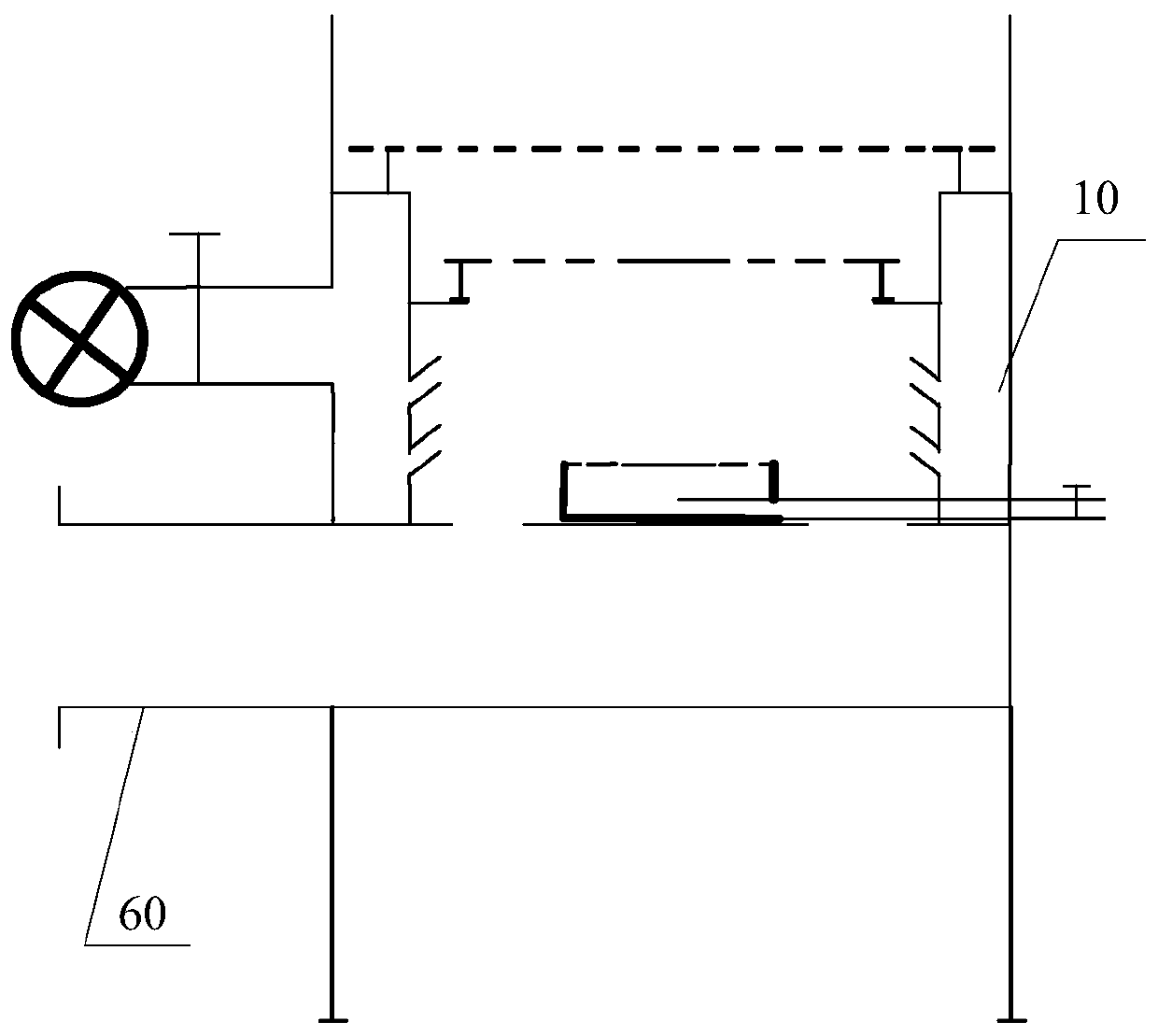

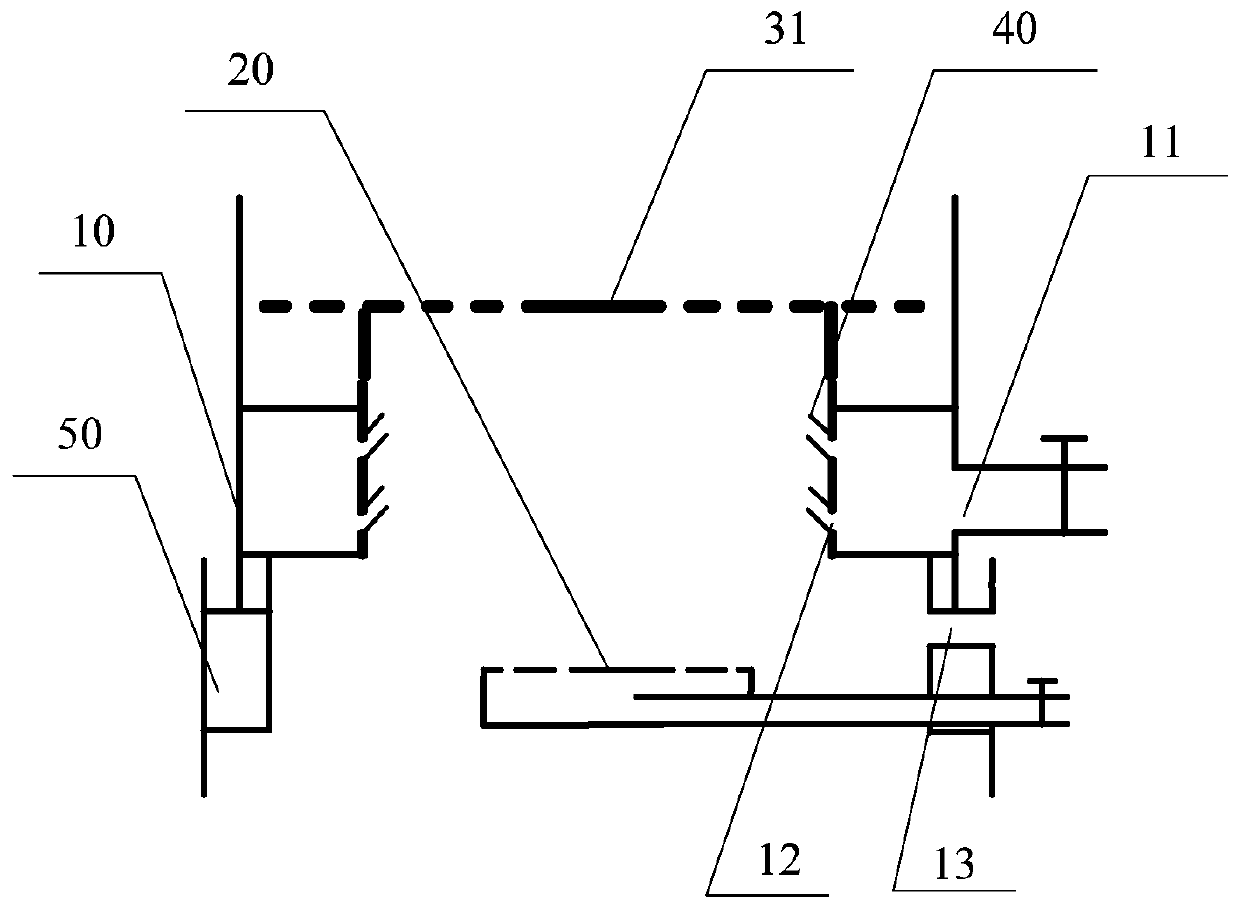

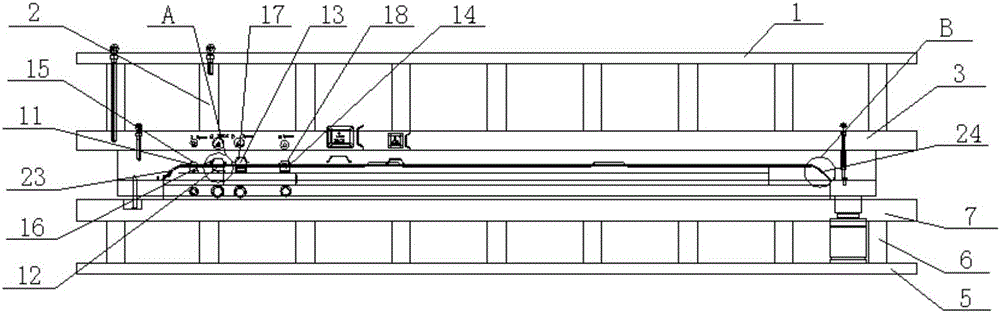

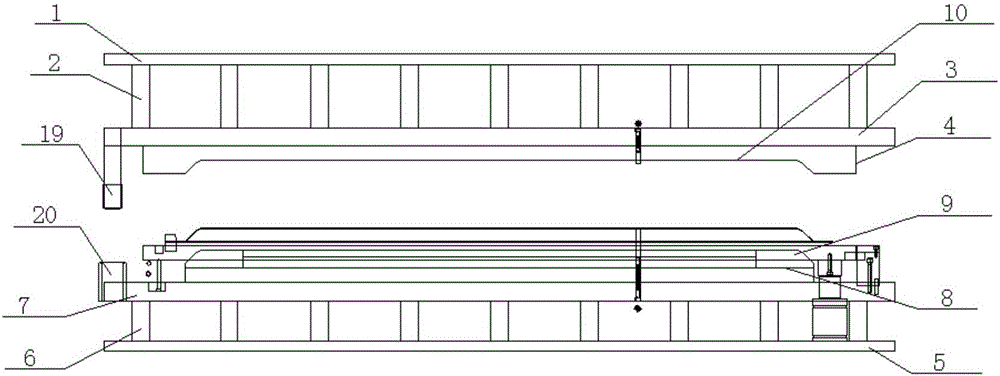

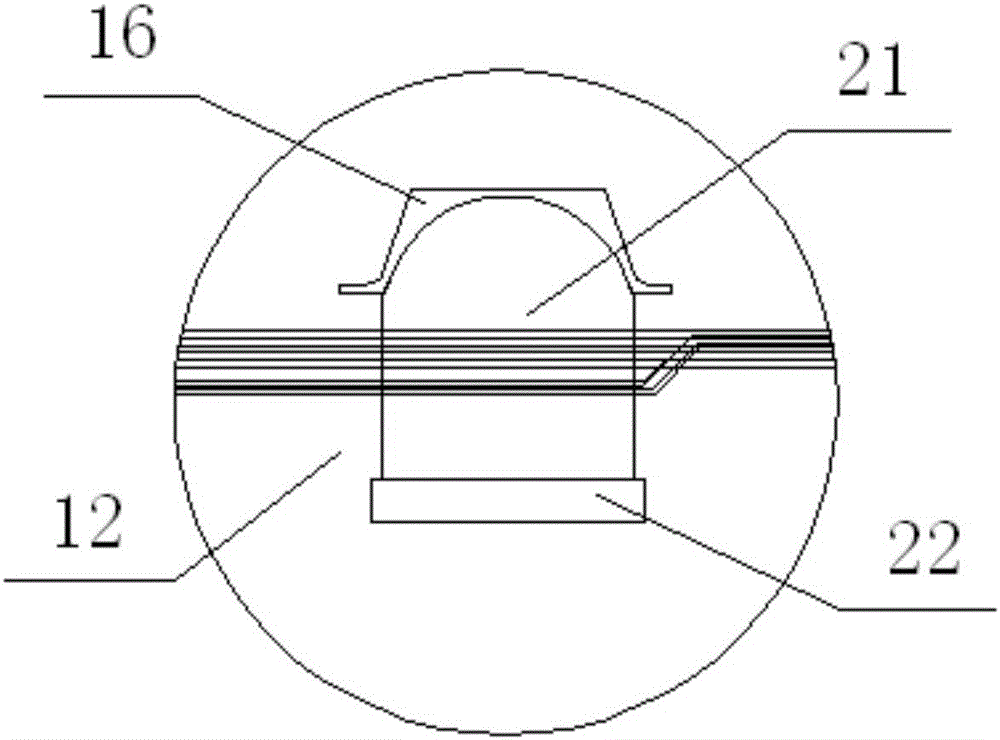

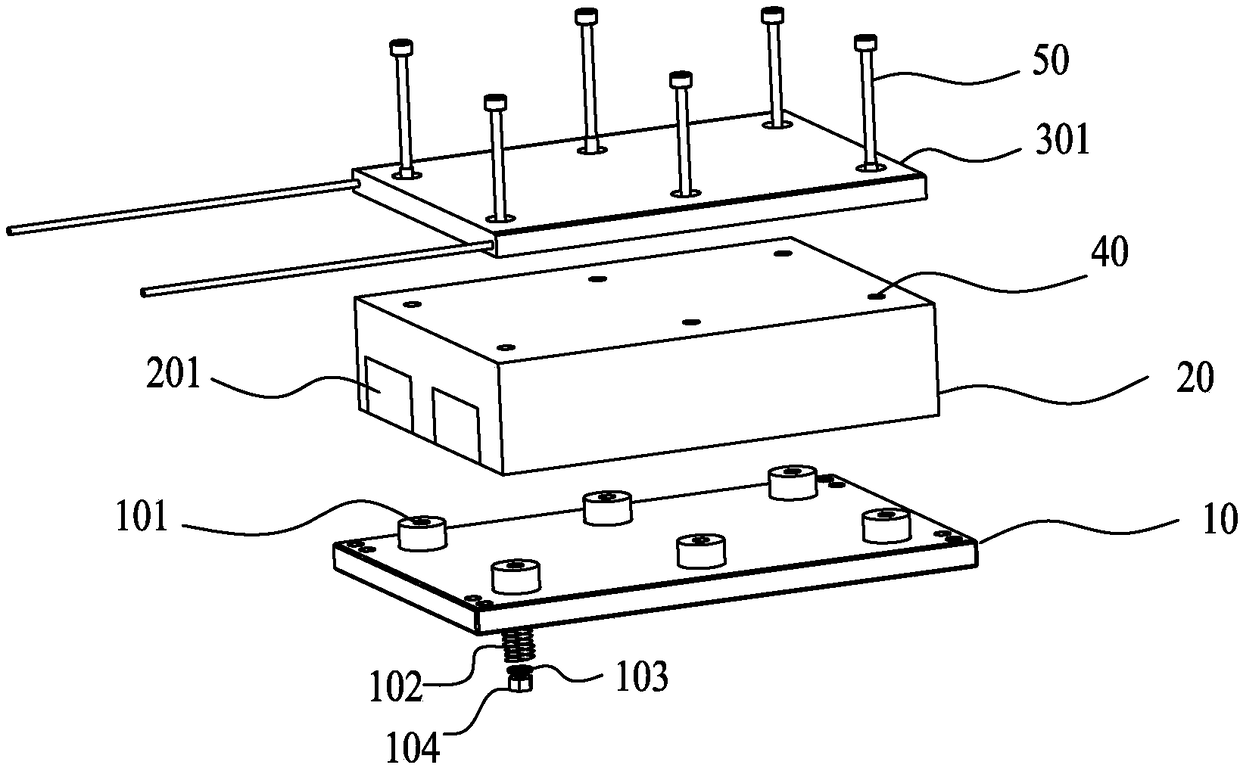

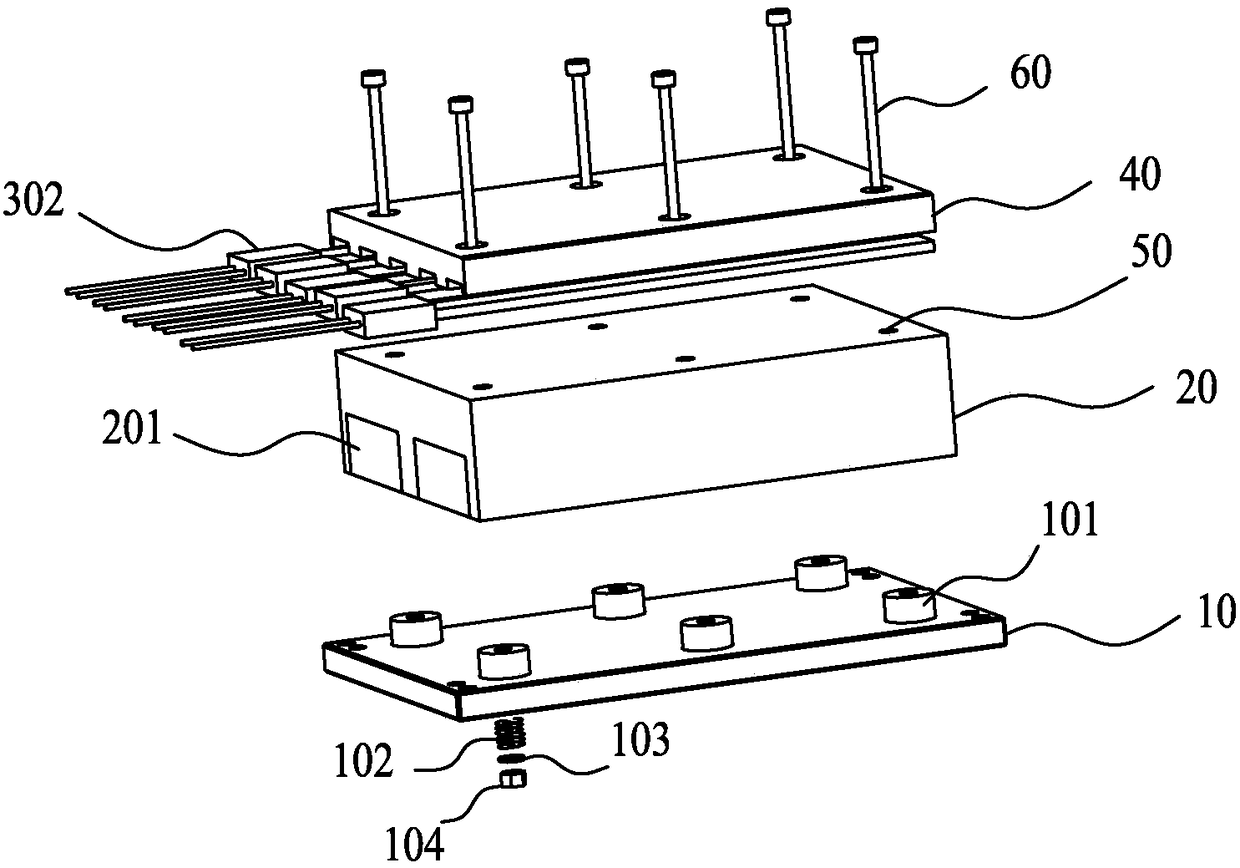

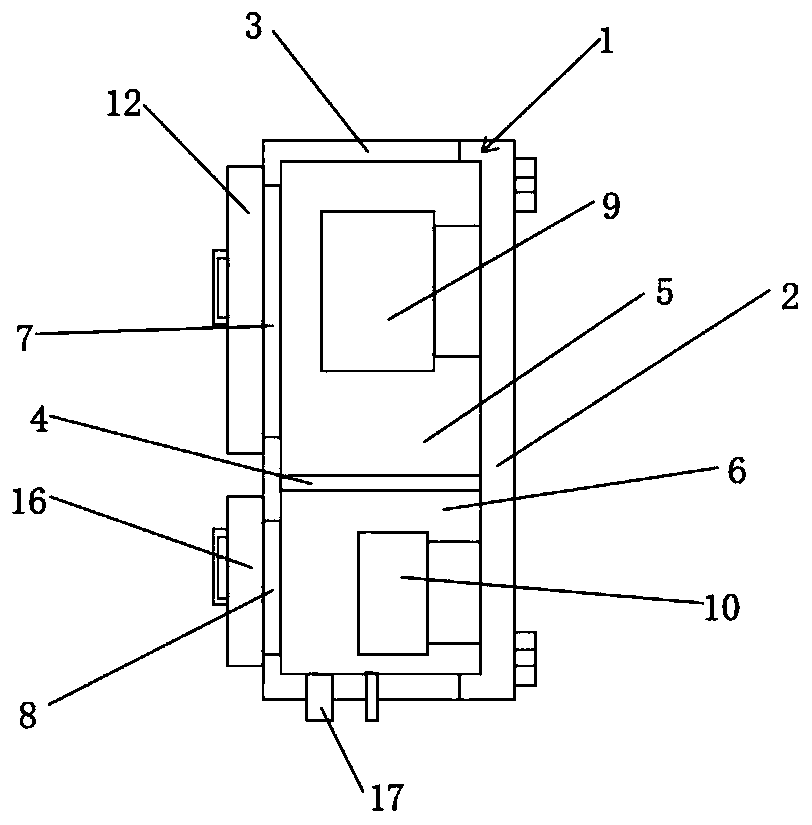

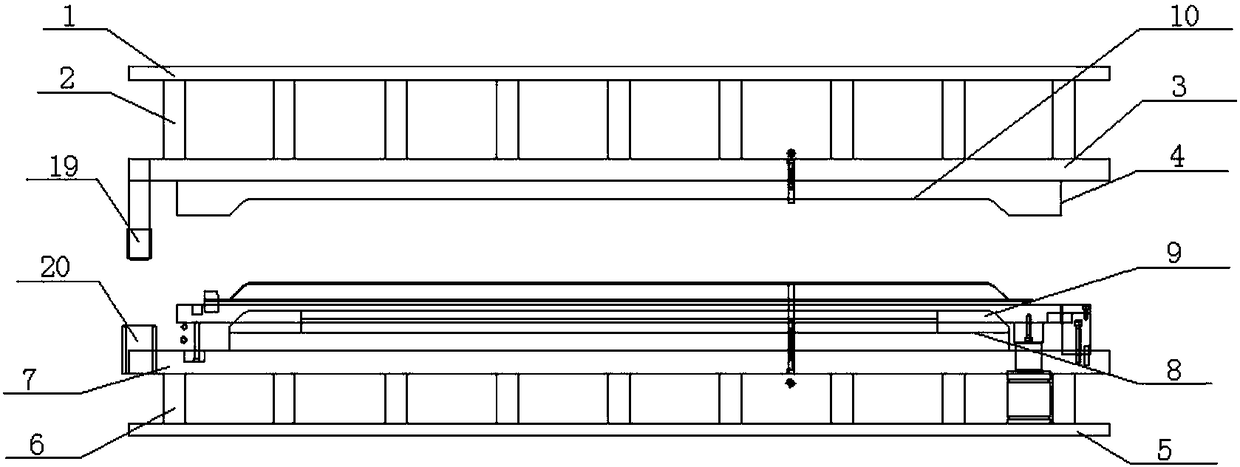

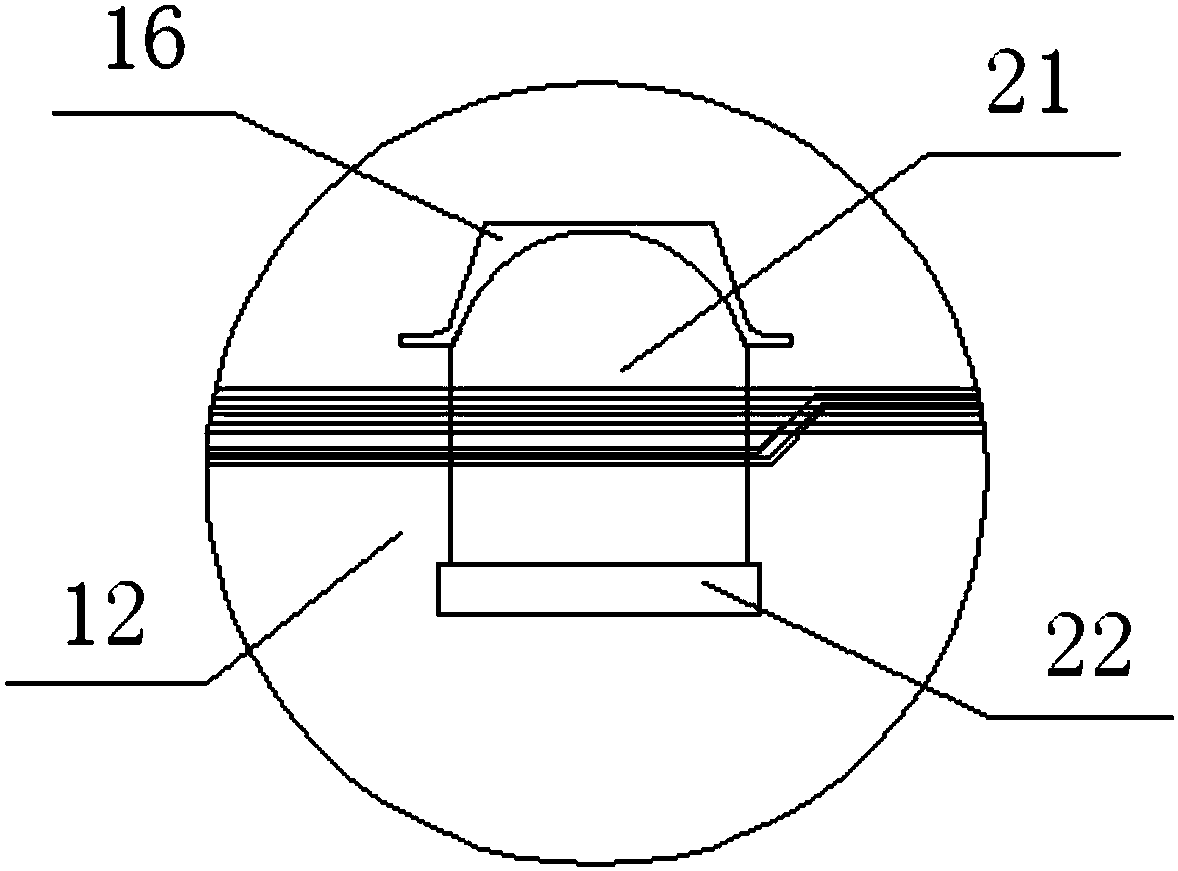

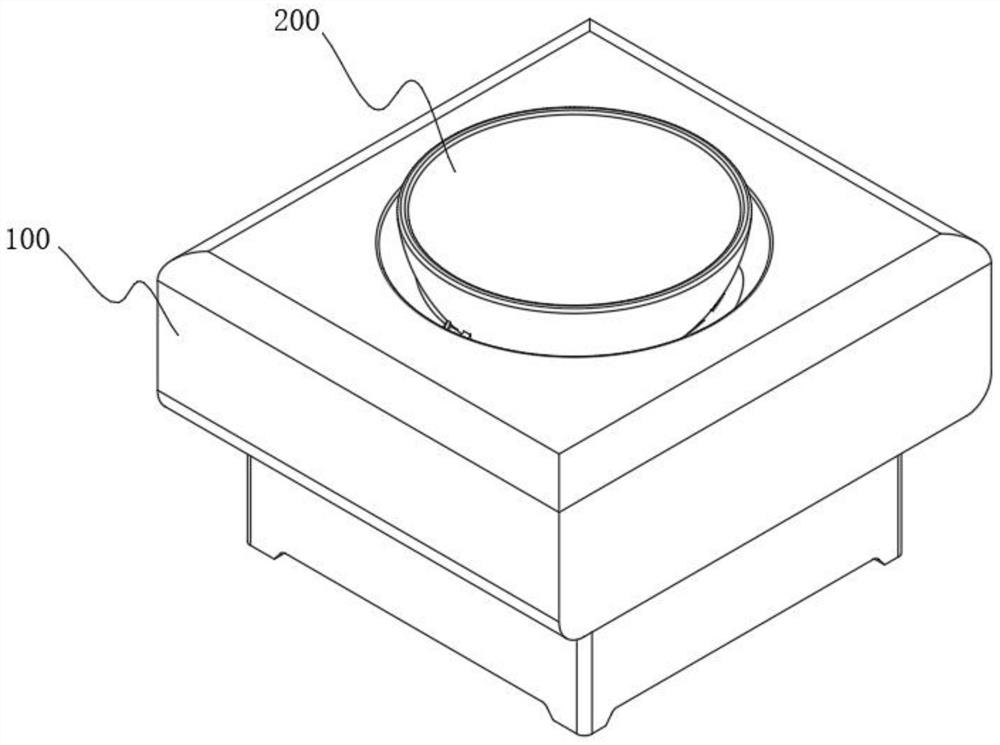

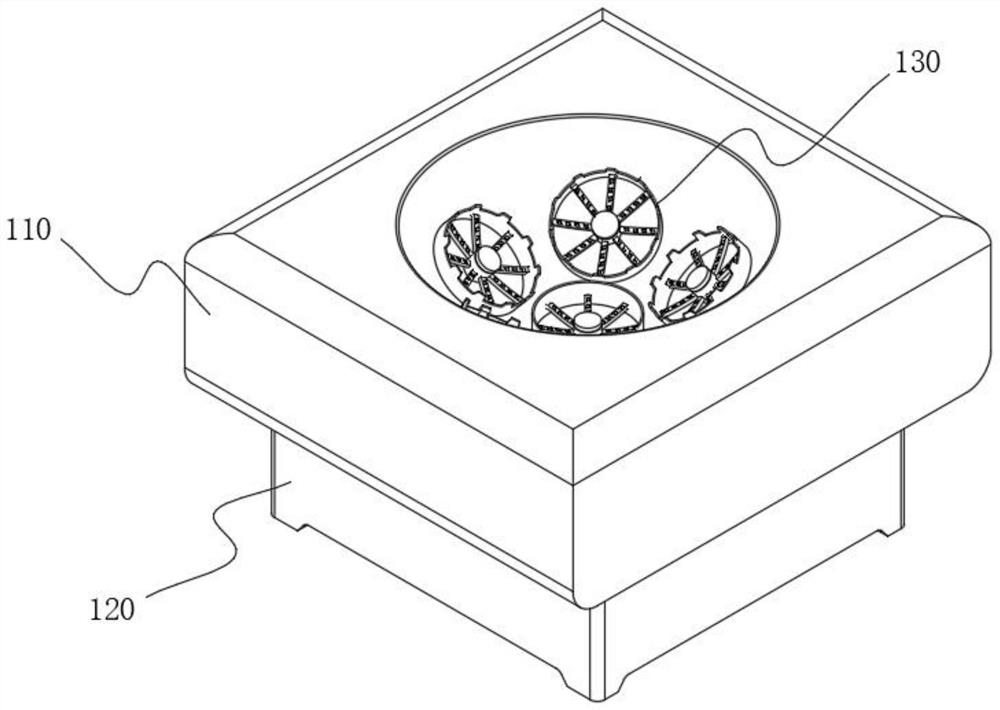

Zipper head passing machine for zippers

ActiveCN109998236ABeneficial technical effectImprove the stability of useSlide fastenersEngineeringPush out

The invention discloses a zipper head passing machine for zippers. The zipper head passing machine for zippers has the scheme that the zipper head passing machine comprises a machine frame, wherein azipper belt conveying assembly, a zipper head conveying assembly, a zipper belt notch detection assembly and a zipper head passing assembly are arranged on the machine frame; the zipper head conveyingassembly comprises a zipper head vibration blanking disc and a zipper head guide slide rail; the tail end of the zipper head guide slide rail is provided with a single zipper head pushing-out assembly; the zipper head passing assembly comprises a horizontal belt guide plate, and also comprises a belt clamping assembly, a zipper belt separating assembly and a zipper head installing assembly; the single zipper head pushing-out assembly is used for conveying the zipper heads to the zipper head installing assembly; the zipper belt conveying assembly drags the zipper belts to be conveyed in the horizontal direction; the horizontal belt guide plate is horizontally and glidingly arranged on the machine frame; the zipper head passing assembly also comprises a horizontal driving assembly; throughthe zipper head passing on the zipper belt in the horizontal direction, the energy consumed in the zipper head passing process is reduced; the efficiency is favorably improved; the influence by gravitational acceleration is reduced; the vibration is reduced; and the use stability of the machine is improved.

Owner:广州市振宇拉链机械有限公司

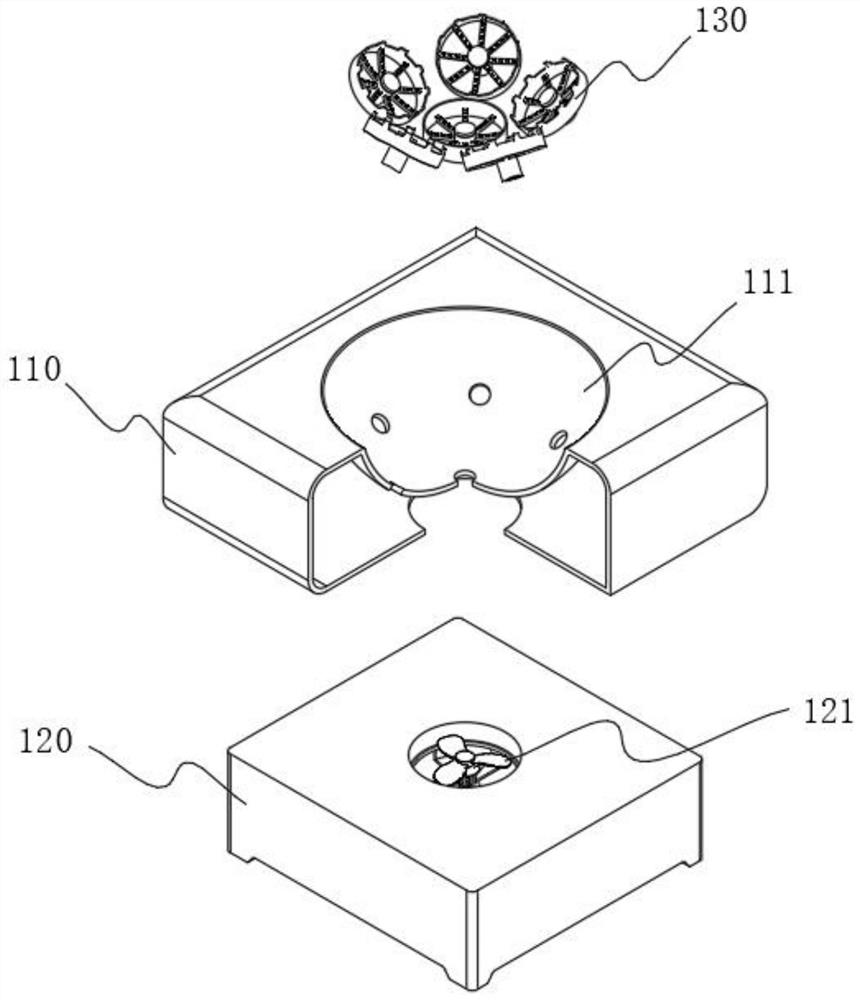

Leaf vegetable automatic shredding device for agriculture

The invention provides a leaf vegetable automatic shredding device for agriculture. The device comprises a top plate. A plug is of a hexagonal bolt structure, and the hexagonal incircle diameter of the end face is larger than the inner circle diameter of a cylinder on a connection block. A cutter is of a long strip shape, a column is fixed to the top, and the cutter is placed in a columnar hole inthe bottom end of a cutter rest. A brake shoe is placed at the front end of the cutter rest, and the top face is provided with a thread hole and fixed through a bolt. The top plate is welded to the top side of a side plate, the middle is provided with a stepped rectangular hole, the periphery size of the small hole end is the same as the periphery size of a lifting plate, and the periphery size of the large hole end is the same as the rectangular periphery size of the top of a cutter disc. The structure is simple, manufacturing is easy, the vegetable spurting phenomenon is reduced through dual-layer protection, the automation degree is high, continuous work time is long, large-batch shredding operation can be achieved, the positions of transmission equipment and cutting equipment will notbe affected by spurted vegetables, the cleaning frequency is reduced, the service life of parts is prolonged, and the shredding efficiency is improved.

Owner:新昌县盈启自动化设备有限公司

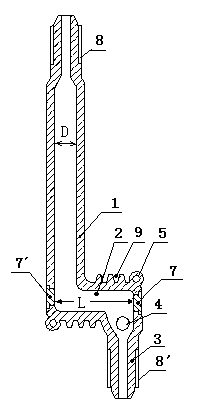

Solution cleaning type air purifier

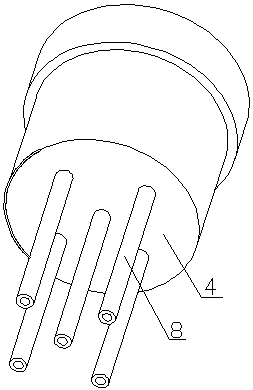

InactiveCN106390668AAchieve sealingReduce areaCombination devicesUsing liquid separation agentParticulatesEngineering

The invention discloses a solution cleaning type air purifier. For the purposes of reducing requirements on a power part and increasing the surface contact area of air with a solution, the solution cleaning type air purifier comprises a machine case, filter screens, a fan, air guide tubes, a mounting frame, the solution and silencing cotton. When being started, the fan sucks the air through a hole net of the mounting frame, and the air is pressed to the bottom of the solution through the air guide tubes after air pressure is generated; as the air guide tubes are densely arranged, the air is divided into a plurality of small bubbles, and the contact area of the air with the solution is increased; and the air passes through the filter screens after being cleaned by the solution, and is further filtered through the filter screens in different types, and as the air cleaned by the solution is cleaner, the requirement on the filter screens is lowered. After the design is used, the air purifier can specially adsorb a target toxic substance, and thus the ability of purifying the air is improved, the concentration of PM2.5 particulate matters is lowered, and the purpose of efficiently cleaning the air in a silencing manner is achieved.

Owner:五河大丁自动化科技有限公司

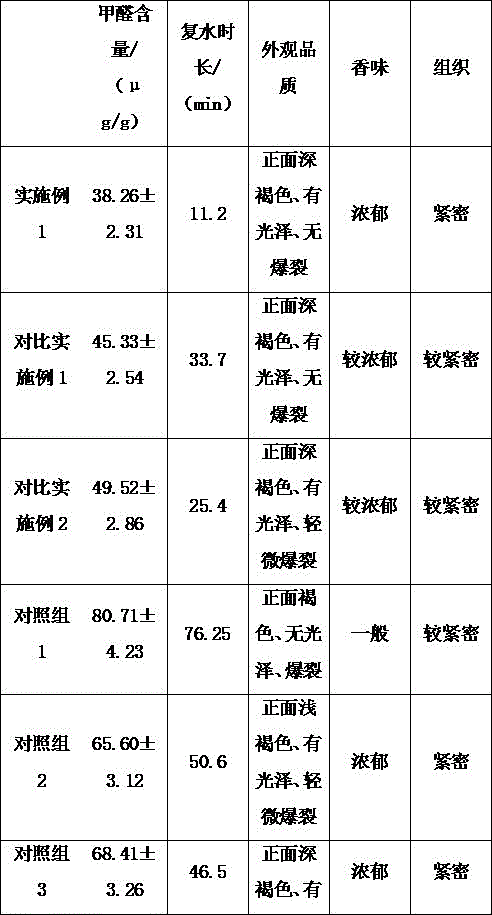

Drying method for lentinus edodes

InactiveCN106359548AImprove permeabilityHigh removal efficiencyFood dryingFood ultrasonic treatmentShiitake mushroomsFlavor

The invention discloses a drying method for lentinus edodes. The drying method comprises the steps of material selection and classification, cleaning for removing impurities and drying treatment for lentinus edodes. According to the drying method, the steps are reasonably matched, and the prepared lentinus edodes is pure in color, strong in flavor and good in appearance and quality. Compared with the existing drying technology, the formaldehyde content of the dried lentinus edodes can be reduced by about 40%, and the reconstitution properties are good, the time for soaking with cold water is only 8-12 minutes, and the mouthfeel is good.

Owner:HEFEI YUANZHENG AFE SCI TECH

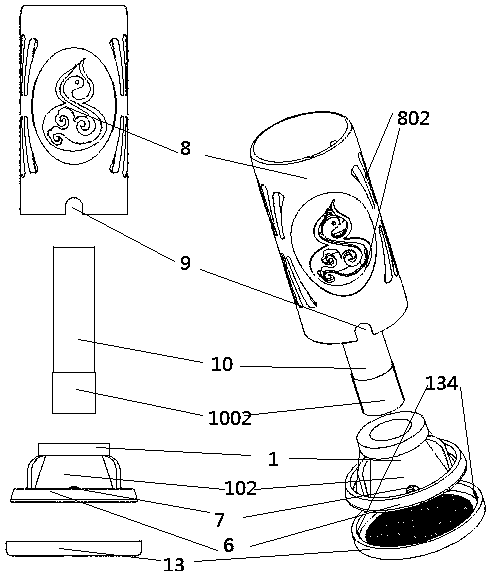

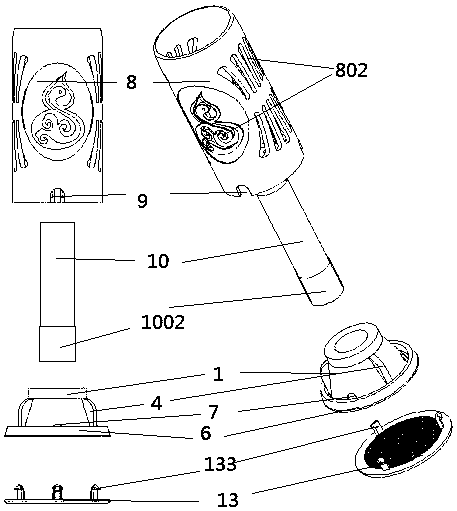

Moxibustion patch with various moxibustion modes and filtering function

InactiveCN107550726ALarge protection areaSolve the incomplete protectionDevices for heating/cooling reflex pointsDispersed particle filtrationPollutionMedicine

The invention relates to a moxibustion product, in particular to a moxibustion patch with various moxibustion modes and a filtering function, and aims to provide a moxibustion patch product which is capable of reducing harms of moxa smoke to human bodies, reducing environment pollution and giving full play to moxibustion efficacies and is convenient to use, low in cost and available to large-scaleproduction and application.

Owner:武汉左点科技有限公司

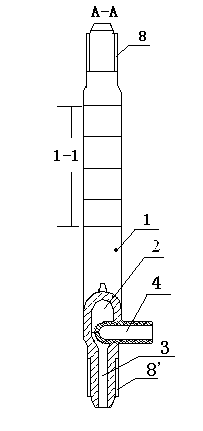

Integrated digestion colorimetric pool

InactiveCN103018169AIncrease volumeImprove pressure resistanceMaterial analysis by optical meansLight irradiationStraight tube

The invention relates to an integrated digestion colorimetric pool used for digestion reaction of a sample and receiving of light rays in spectrum colorimetric analysis. The integrated digestion colorimetric pool is an integrated pipe formed by sequentially connecting and continuously communicating a longitudinal upper pipe, a transverse pipe and a longitudinal lower pipe, wherein the transverse pipe is also used as an optical channel; plane light inlet windows are respectively arranged on the pipe walls at the both ends of the optical channel; a pipe diameter of the integrated pipe is less than the length of the transverse pipe; an upper end opening of the longitudinal upper pipe and a lower end opening of the longitudinal lower pipe are thread ports; and internal diameters of the two longitudinal pipes are reduced at the positions of the ports. Compared with the straight pipe type digestion pool, a total volume of the three digestion colorimetric pools can be obviously reduced; the pressure resistance is high; the trail amount is small; a solution flows inside a pipe inside the pool without residue; the digestion reaction is complete; and the detection precision is high.

Owner:DELIN ENVIRONMENTAL PROTECTION TECH

Preparation method of low-agglomeration and anti-burst fibers for unshaped refractory materials

InactiveCN102924098AAccelerated exclusionShorten drying timeSolid waste managementFiberScreening techniques

The invention discloses a preparation method of low-agglomeration and anti-burst fibers for unshaped refractory materials, which belongs to the field of the refractory materials. The preparation method comprises the following steps: using waste paper (books, newspaper and paperboards and the like), waste hemp articles (hemp bags and hemp ropes and the like) as raw materials; adding a proper amount of an anti-agglomeration additive, placing into an efficient crusher to crush; and then adopting a screening technique to prepare the anti-burst fibers with different length-diameter ratios. The preparation method is simple process and convenient in operation; the obtained product is green and environment-friendly to the environment, the resource is recycled, and the cost performance is high; the internal vapor pressure inside the unshaped refractory materials can be effectively reduced so as to avoid burst; especially in quick-drying unshaped refractory materials with high strength, the anti-burst effect is more obvious.

Owner:TIANJIN POLYTECHNIC UNIV

Pop-free single-ended output class-D amplifier

ActiveUS9041461B2Avoid output voltageReduce a ‘popping’ soundAmplifier modifications to reduce temperature/voltage variationDc amplifiers with modulator-demodulatorVoltage generatorAudio power amplifier

Owner:ANPEC ELECTRONICS CORPORATION

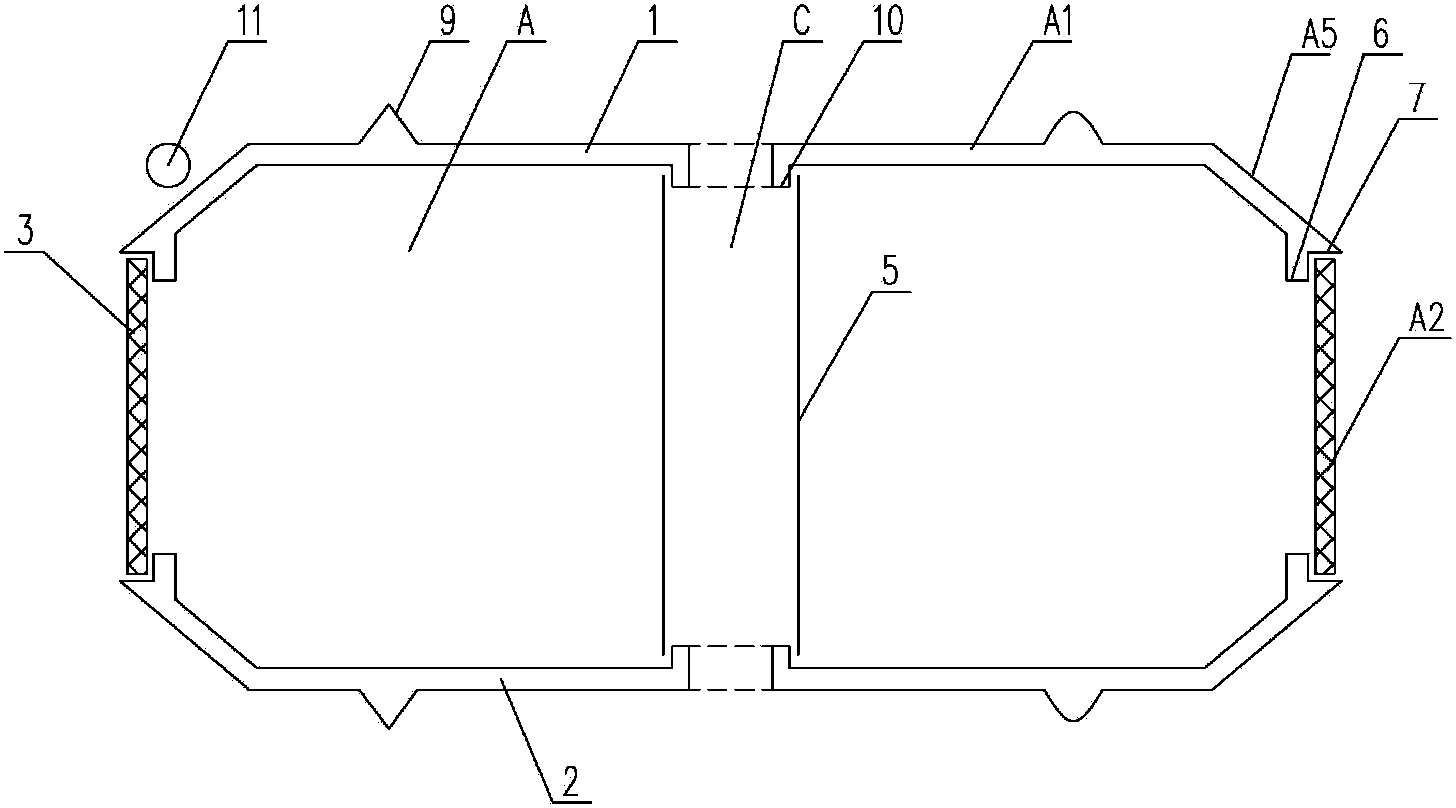

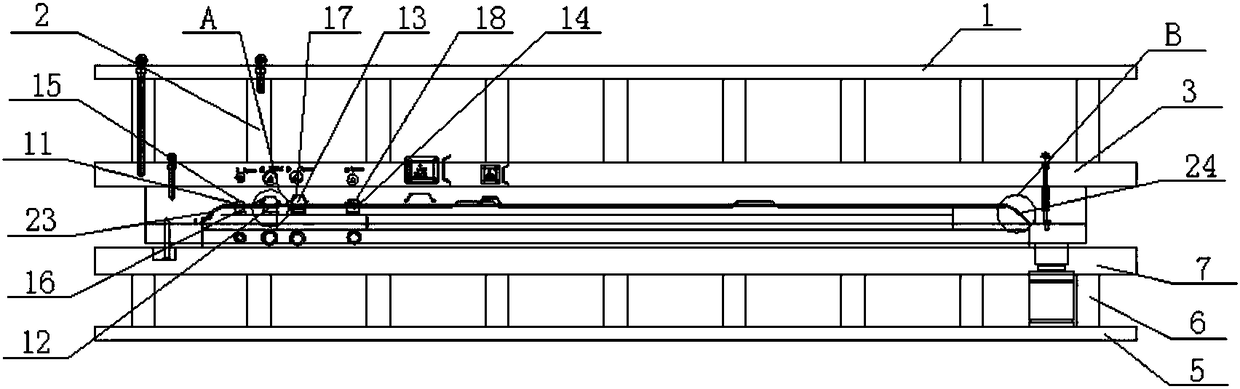

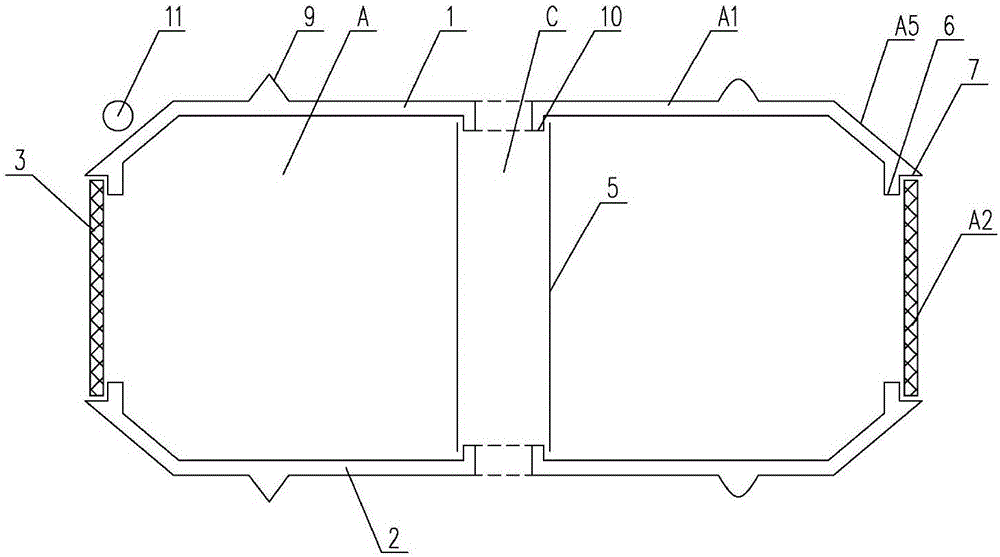

Cast-in-situ hollow floor with pores formed by combined reticular box-shaped component

InactiveCN104314214AHigh degree of mechanizationIncrease productivityFloorsReinforced concreteEngineering

The invention provides a cast-in-situ hollow floor with pores formed by a combined reticular box-shaped component. The cast-in-situ hollow floor comprises a reinforced concrete girder or a profile steel concrete girder, a reinforced concrete ribbed beam, an upper flange plate, a lower flange plate and the combined reticular box-shaped component, wherein the combined reticular box-shaped component comprises a box roof, a box body and a box bottom; the box body and the box bottom are made of reticular bodies; reinforcing ribs of the reticular bodies are vertically placed; each reticular body comprises a reticular plate, the reinforcing rib and a connecting piece, which constitute an integral structure; the lower flange plate is directly compounded with the reticular bodies at the box bottom of the combined reticular box-shaped component. The cast-in-situ hollow floor with the pores formed by the combined reticular box-shaped component adopts the unsealed combined reticular box-shaped component to substitute the existing fully-sealed hollow fillers and solid fillers as the cast-in-situ hollow floor pore-forming technology. The cast-in-situ hollow floor with the pores formed by the combined reticular box-shaped component is beneficial to realization of energy conservation integration of a building and the multifunctional use of hollow floor.

Owner:HUNAN BDF ENERGY SAVING TECH

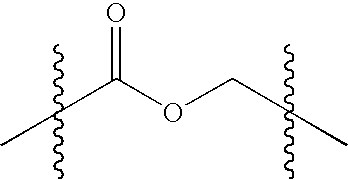

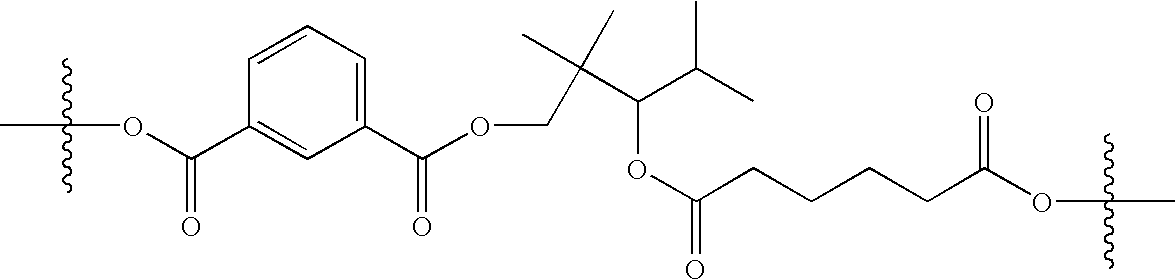

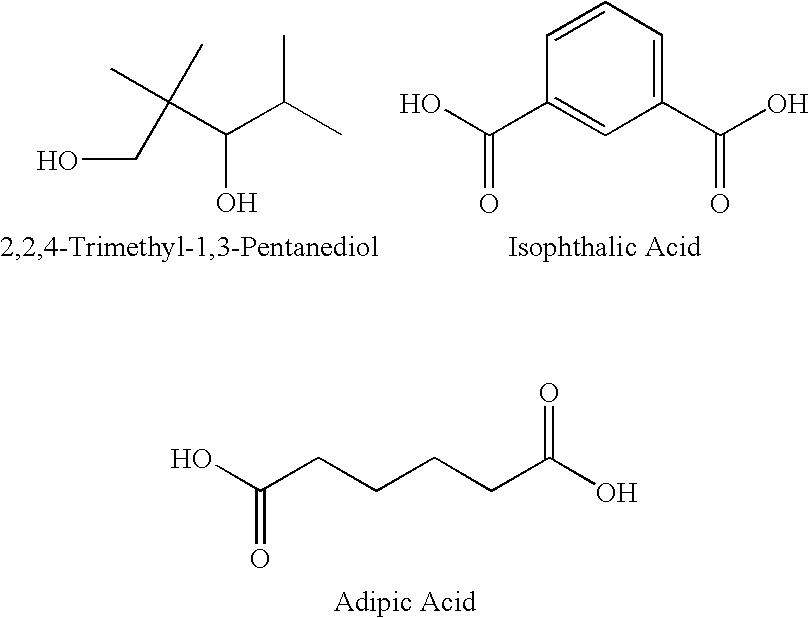

HAPs free coating composition and film thereof

InactiveUS20070260012A1Increase protectionIncrease wrap aroundMixingPolyester coatingsSolventHazardous air pollutants

A coating composition is used to form a film on a substrate. The coating composition includes a polyester, a cross-linking agent reactive with the polyester, and a solvent package substantially free of hazardous air pollutants. The solvent package includes a first solvent, a second solvent, and a third solvent. The first, second, and third solvents in the solvent package have boiling points of less than 300° F., of from 300° F. to 340° F., and of greater than 340° F., respectively. The first, second, and third solvents are also present in amounts of from 10 to 25 parts, of at least 50 parts, and of from 5 to 20 parts, by weight, per 100 parts by weight of the solvent package, respectively. The first, second, and third solvents improve properties of the coating composition and of films formed from the coating composition.

Owner:PPG IND OHIO INC

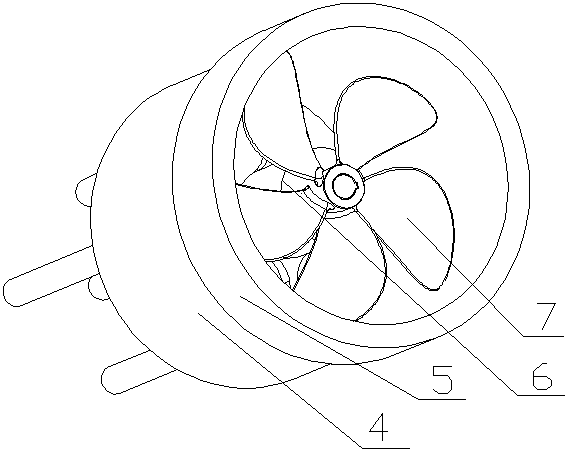

Combustion stove for mating with incinerator

PendingCN110006038ASpeed up the flowReduce poppingIncinerator apparatusGaseous fuel burnerCombustible gasHearth

The invention discloses a combustion stove for mating with an incinerator. A fuel gas supply passage and an air inducing passage are arranged on a stove body, a cavity is formed by the inner circumferential surface and the outer circumferential surface of the stove body, an air inlet hole is formed in the outer circumferential surface of the stove body, a plurality of rings of air distribution holes are formed in the inner circumferential surface of the stove body in the axial direction, the multiple rings of air distribution holes are arranged in a staggered manner, and therefore air flow inthe stove body is accelerated, combustible gas generated by gasification cracking of garbage or fuel gas is sufficiently mixed with air, and further sufficient burning is carried out; in addition, a banking-up disc is arranged at the fire spraying end of the combustion stove, on one hand, smoke emitting is delayed, the burning effect is strengthened, and flowing-out smoke is reduced; and on the other hand, under the condition that the combustion stove is extinguished in the feeding process, since the temperature of a banking-up plate at the fire spraying end is very high, the combustible gas in the incinerator can re-ignite the combustion stove when encountering the banking-up plate, and re-ignition is not needed. The combustion stove can fully combust the combustible gas generated by gasification or cracking of the garbage in the incinerator, smoke and dust are avoided, and the very high promotion value is achieved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH +1

Forming die for large television backplane

The invention discloses a forming die for a large television backplane. The forming die comprises an upper die and a lower die, wherein the upper die comprises an upper cover plate, an upper block, an upper die base and an upper die plate which are fixedly connected in sequence from top to bottom; the lower die comprises a lower supporting plate, a lower block, a lower die base, a lower cushion block and a clamping plate which are fixedly connected in sequence from bottom to top; the centre of the upper die plate is sunken upwards to form a hollow and arc-shaped cavity; the clamping plate is provided with a first raising puncher, a second raising puncher, a third raising puncher and a fourth raising puncher on positions just below the cavity; and parts raised by the first raising puncher, the second raising puncher, the third raising puncher and the fourth raising puncher during die closing, of the backplane, are a first raised bump, a second raised bump, a third raised bump and a fourth raised bump respectively. The forming die disclosed by the invention is capable of reducing a phenomenon of raised bump burst, thus greatly increasing the forming yield of the raised bumps; and moreover, an S-shaped structure with a certain R angle is formed on the bent sectioned surface of the backplane, the bent sectioned surface is not liable to crack during shaping pulling, and the backplane is high in forming quality, low in industrialization cost, and convenient for increasing economic benefits.

Owner:KUNSHAN JIXINCHENG PRECISION MOLD

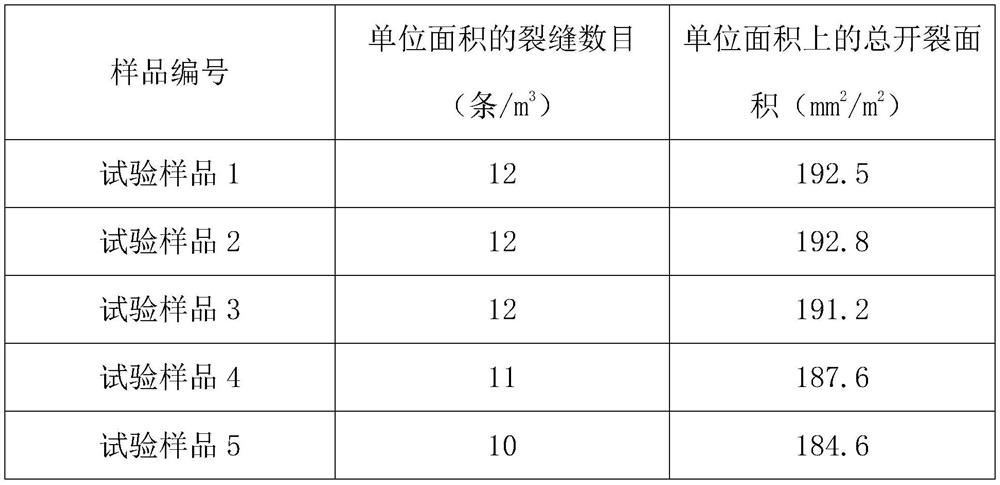

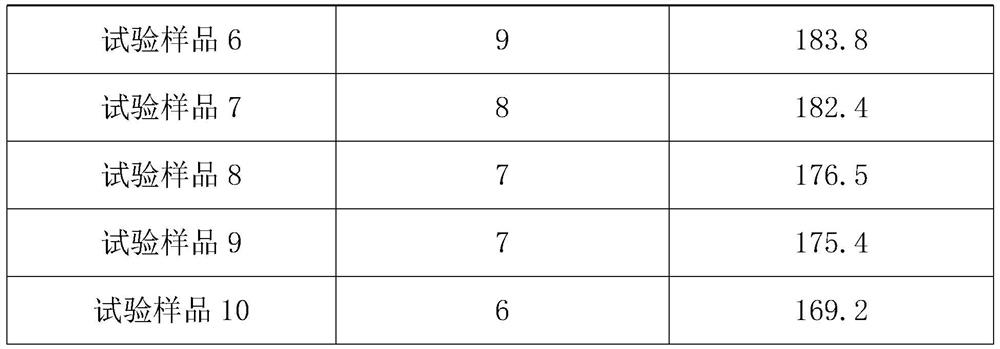

C30 concrete and preparation method thereof

InactiveCN113045274AImprove crack resistanceEasy to separateSolid waste managementKenafWater reducer

The invention relates to the technical field of concrete preparation, and particularly discloses C30 concrete and a preparation method thereof. The C30 concrete is prepared from the following components: cement, fly ash, sand, gravel, water, a water reducing agent, kenaf fibers, a bamboo pulp lignin dispersing agent and rubber powder, wherein the kenaf fibers are subjected to modification treatment; the preparation method comprises the following steps: S1, mixing the cement, the fly ash, the sand, the gravel, the kenaf fiber, the bamboo pulp lignin dispersant, the rubber powder and the water, and stirring for 40-60 seconds to obtain a mixture; and S2, adding water and a water reducing agent into the mixture, and stirring for 60-90 seconds to obtain the C30 concrete. The C30 concrete has the advantage that the anti-cracking performance of the concrete can be enhanced.

Owner:SHAANXI FENGDONG NEW CITY CONCRETE CO LTD

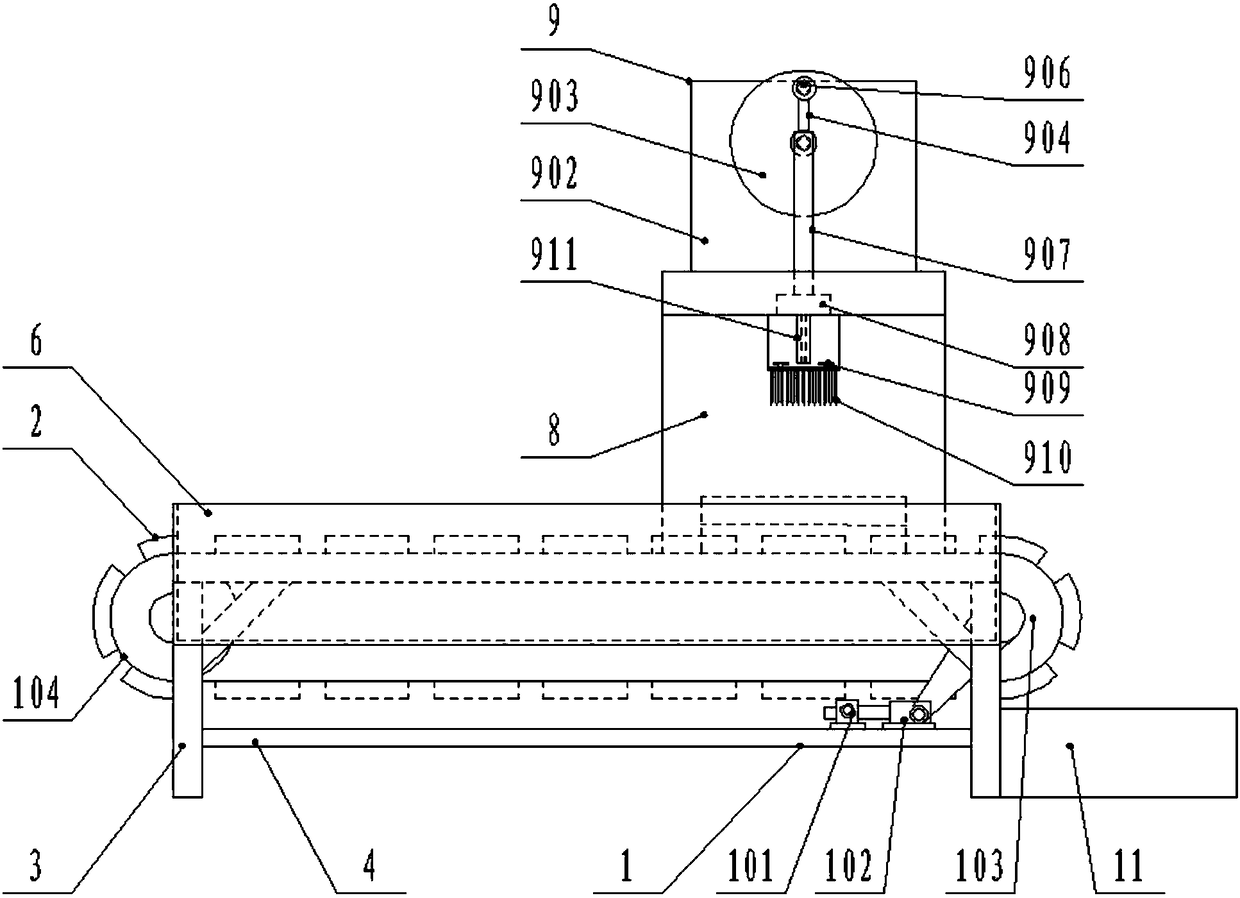

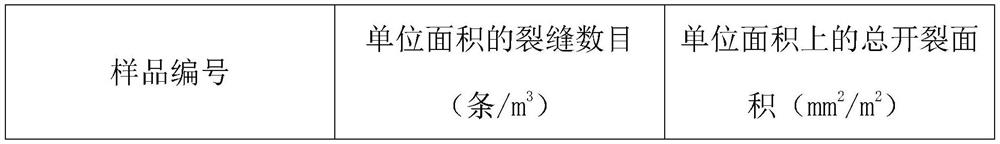

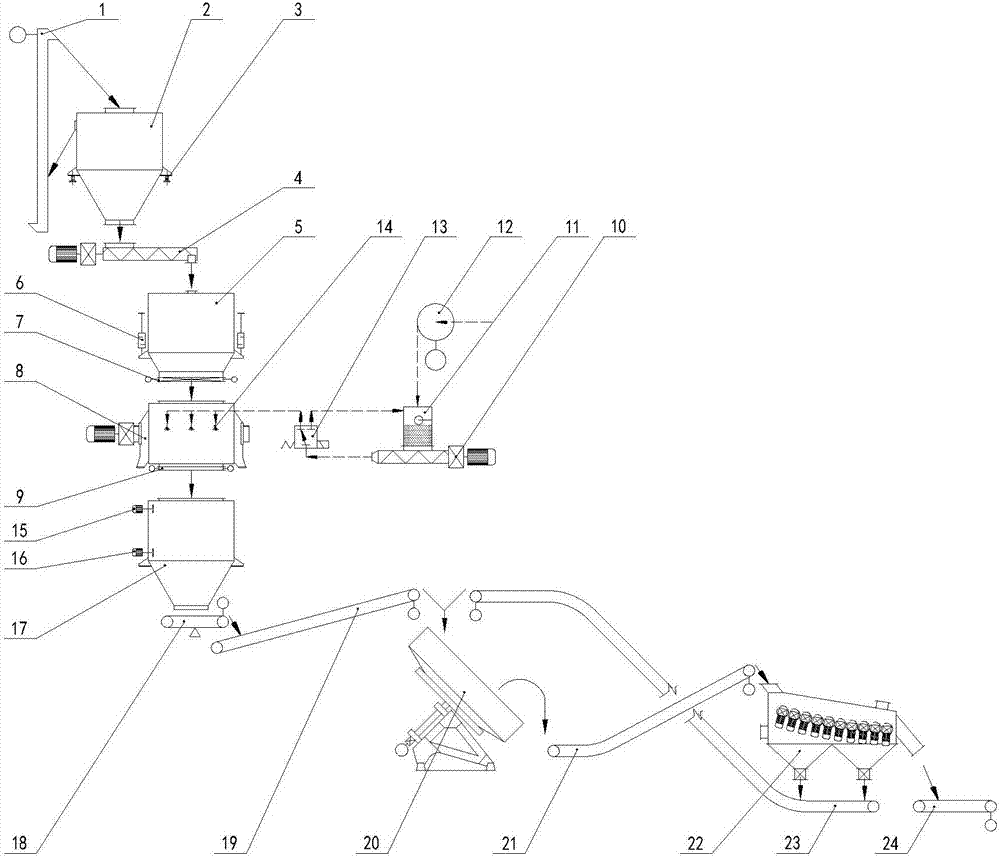

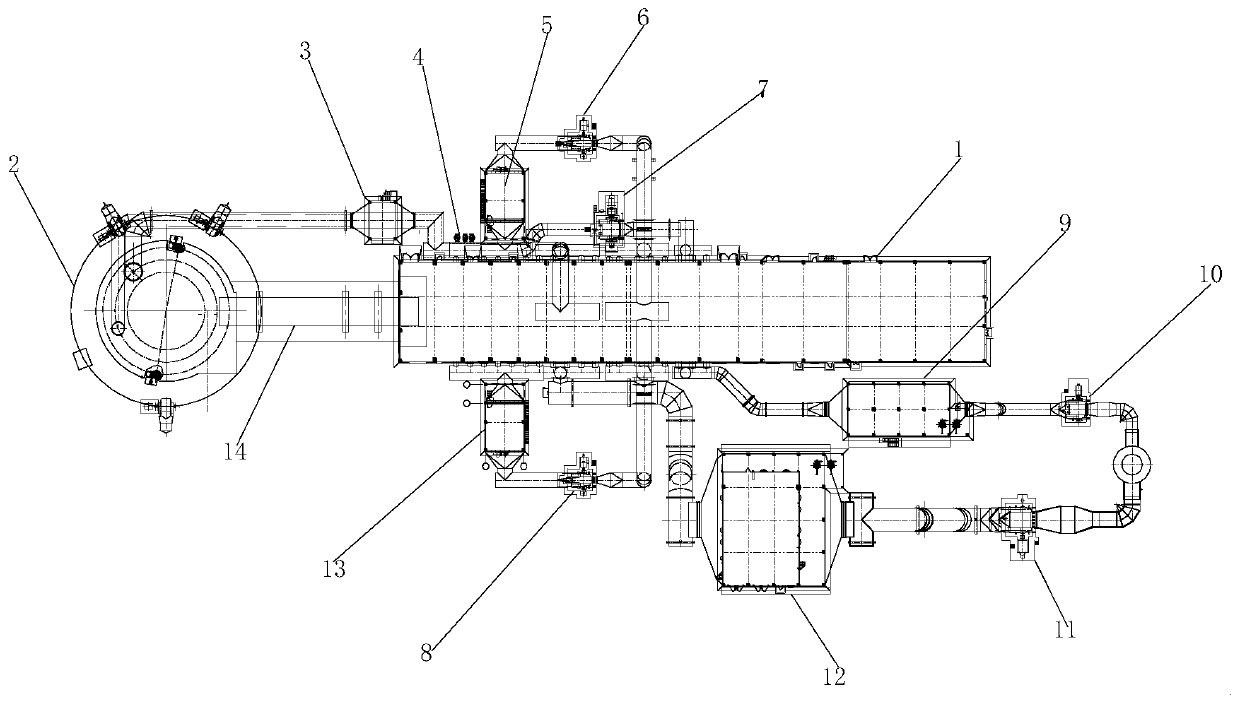

Copper-containing sludge granulating and pre-drying equipment and process method

ActiveCN107055993AReduce moisture content unevennessReduce uniformitySludge treatment by de-watering/drying/thickeningMaterial granulationPorositySludge

The invention discloses copper-containing sludge granulating and pre-drying equipment and a process method. The equipment comprises an elevator, a stabilizing bin, a front stock bin, a pre-watering stirrer, a rear stock bin, a granulator and the like, wherein an integrated stock bin weighing device is arranged on the front stock bin, and a pneumatic valve is arranged at the bottom of the front stock bin; the pre-watering stirrer is capable of realizing stirring and scattering, an atomizing nozzle is arranged above the interior of the pre-watering stirrer and connected with a water supply device so as to realize accurate water distribution, and an upper level gage and a lower level gage are arranged on the rear stock bin; and materials are conveyed among the rear stock bin, the granulator and a drying and screening device through a belt conveyor. The method disclosed by the invention comprises the following steps: accurately distributing water for the mixed powder, fully stirring the materials in a three-dimensional stirring manner, and forming waterborne and uniform wet materials within 3 minutes. Pellets with consistent particles can be prepared, the stacking porosity is improved during sintering, the phenomenon that the pellets are burst due to non-uniform internal and external heating is greatly reduced, the phenomenon of non-uniform kiln section ventilation is greatly reduced, and heat wasted due to evaporation of the moisture can be reduced by 300-400 KJ / kg.

Owner:江苏金圆新材科技有限公司 +1

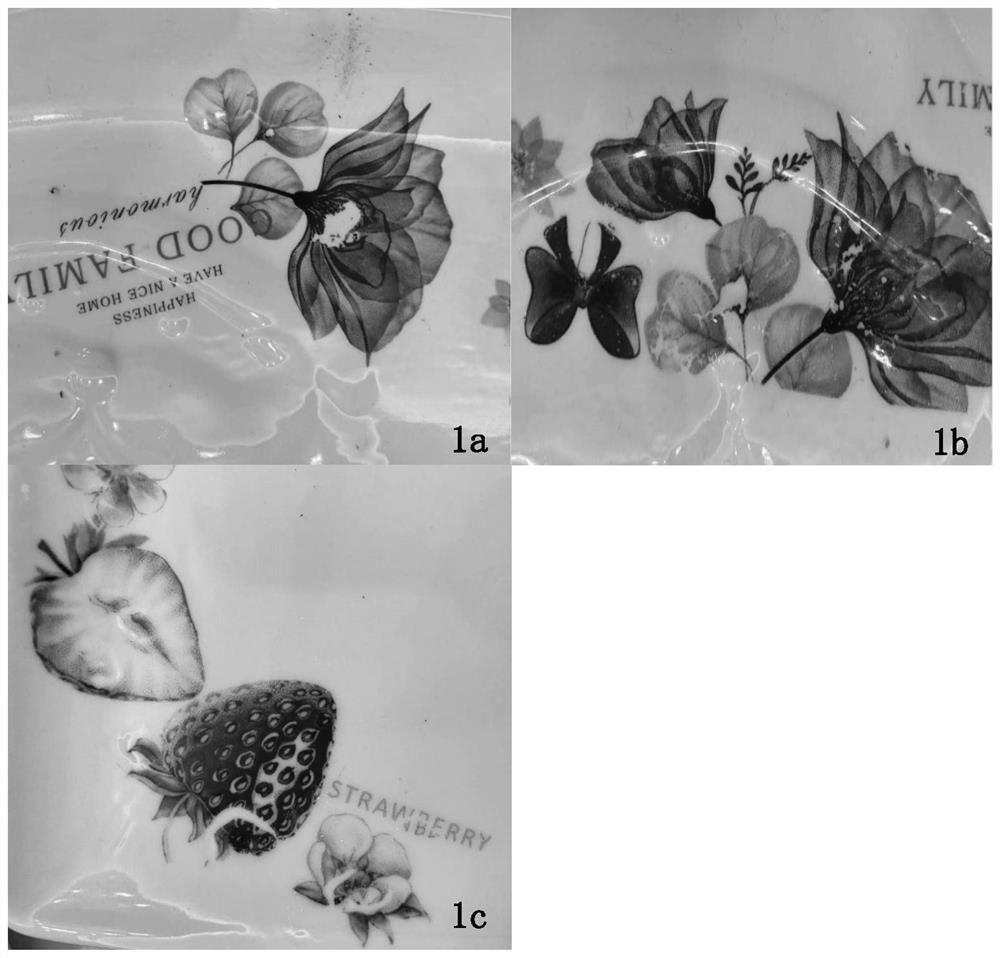

Small film decal paper not prone to cracking as well as preparation method and use method of small film decal paper

The invention relates to the technical field of ceramic decal, in particular to small film decal paper not prone to cracking and as well as a preparation method and use method of the small film decal paper. The small film decal paper comprises backing paper, water-based varnish and alcohol-soluble cover oil printed on the backing paper and further comprises water-based decal glue used in a matched mode, the water-based varnish contains 37%-45% of water-soluble polyacrylate, the alcohol-soluble cover oil contains 20%-30% of alcohol-soluble decal glue, and the water-based decal glue contains 23%-27% of dimethyl silicone oil, 23%-27% of glycerinum, 23%-27% of ethyl alcohol and / or isopropyl alcohol and the like. Through the synergistic effect of the water-based varnish, the alcohol-soluble cover oil and the auxiliary matched water-based decal glue, and through a specific preparation technology and the use method, the decal can be tightly combined with a ceramic clay blank during decal, the probability of cracking in the firing process is reduced to the maximum extent, the cracking rate is reduced to 3% or below, during decal, the decal can be moved and is not prone to wrinkling or blistering, and the components are more environment-friendly.

Owner:潮州市华壹陶瓷花纸有限公司

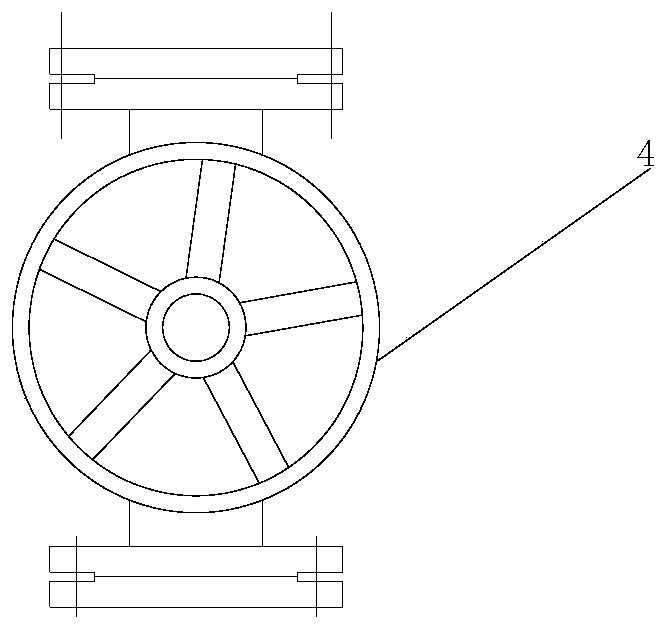

Chain grate machine tail thermal field adjusting device

PendingCN111442648AImprove the state of the environmentReduce poppingMaintainance of heating chambersFurnace typesCold airThermodynamics

The invention relates to the technical field of chain grate machines, and discloses a chain grate machine tail thermal field adjusting device. The chain grate machine tail thermal field adjusting device comprises a chain grate machine chamber, the chain grate machine chamber communicates with a ring cold machine through a rotary kiln, the ring cold machine is connected with a drum-dry dust removerthrough a pipeline, the drum-dry dust remover is connected with a drum-dry draught fan through a drum-dry draught fan hot air pipeline, an adding cold air valve is installed on the drum-dry draught fan hot air pipeline, and the drum-dry draught fan is connected with a first backheating draught fan through a pipeline. According to the chain grate machine tail thermal field adjusting device, the adding cold air valve is additionally arranged on the drum-dry draught fan hot air pipeline, so that the thermotechnical use ratio of a chain grate machine is reasonably distributed and an environmentalstate of the machine tail of the chain grate machine is improved, after the adding cold air valve is installed, a thermotechnical state of a primary operating line is effectively supplied, and the burst phenomenon of pellets is reduced; and the qualification rate of the pellets is improved.

Owner:扬州泰富特种材料有限公司

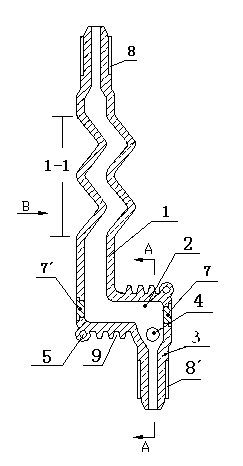

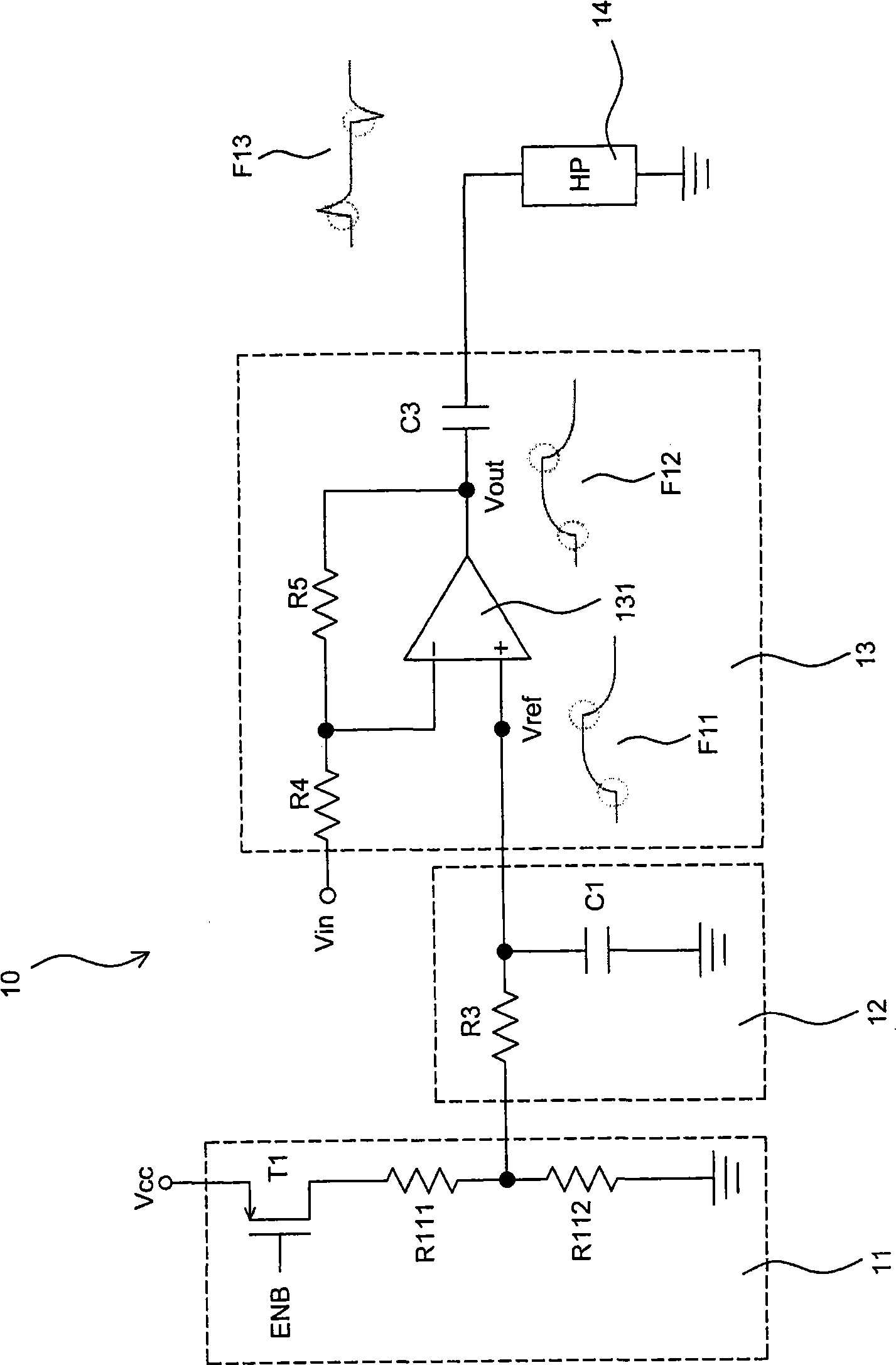

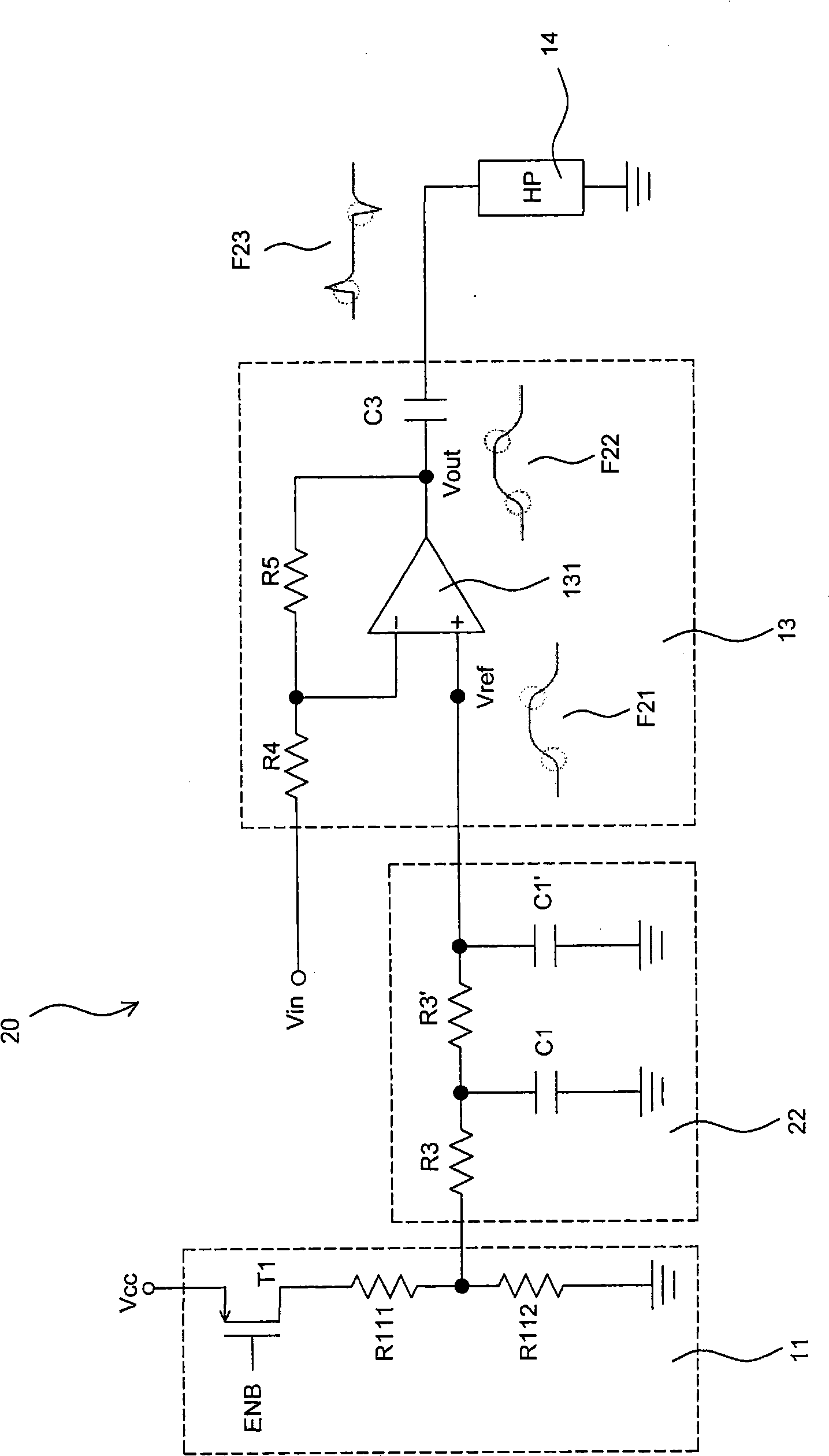

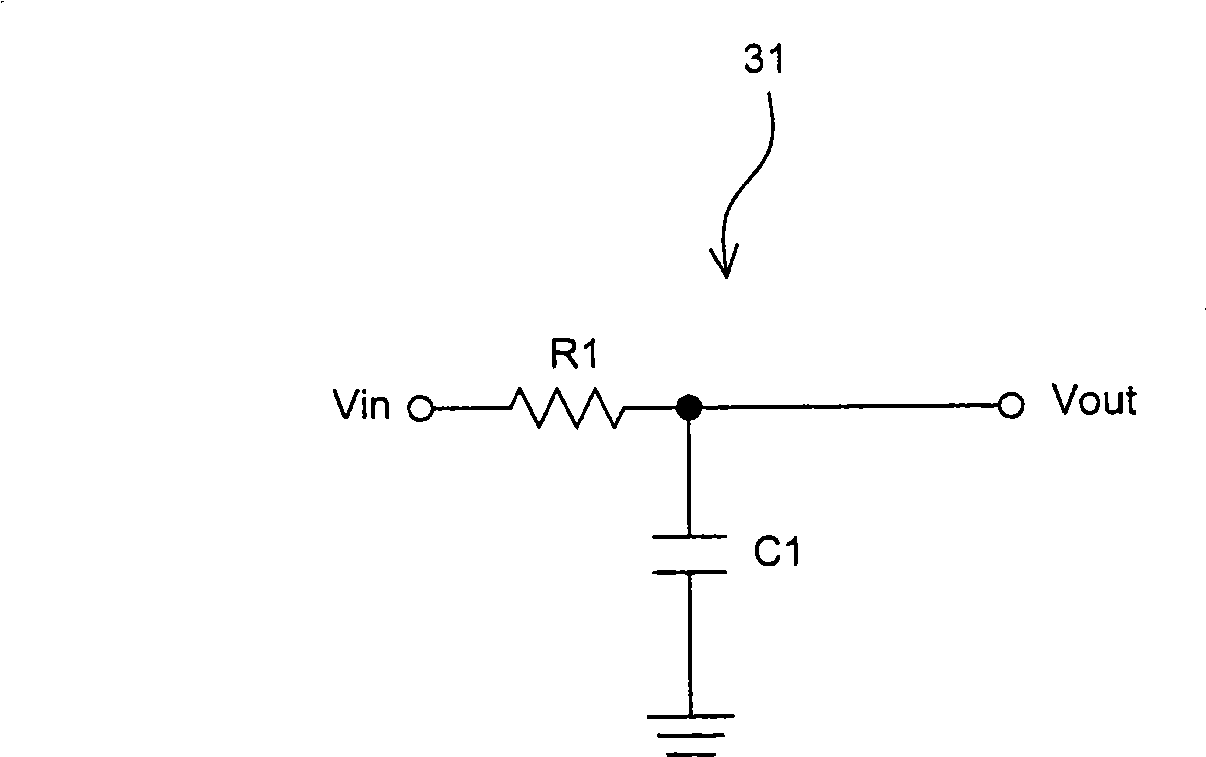

Voice drive circuit for reducing sonic boom when switching on and shutting down

InactiveCN101521488AReduce poppingGain controlAmplifier modifications to reduce temperature/voltage variationVoltage referenceEngineering

The invention provides a voice drive circuit for reducing sonic boom when switching on and shutting down, comprising a reference voltage generating unit, a low-pass filtering unit and a drive unit, wherein the reference voltage generating unit is used for generating a reference voltage; the low-pass filtering unit is a low-pass filter which has at least two stages and is used for generating a filtered reference voltage after receiving the reference voltage; and the drive unit is used for receiving an frequency input signal and the filtered reference voltage, and generating an frequency output signal. The low-pass filter with two stages or more than two stages of the low-pass filtering unit is used for controlling variable quantity of the corresponding reference voltage when switching on and shutting down so as to reduce sonic boom when switching on and shutting down.

Owner:SUNPLUS MMEDIA

Temperature control heating device used for changing heating and assembly modes of glass hot bending equipment

The invention discloses a temperature control heating device used for changing heating and assembly modes of glass hot bending equipment. The device comprises a supporting plate, a heat insulation plate and a heating body, wherein the heat insulation plate and the heating body are sequentially arranged on the supporting plate; the heating body is a ceramic heating body which is electrified and heated, and at least two through holes are formed in the supporting plate, the heat insulation plate and the functional ceramic heating body; screws are arranged in the through holes, and the screws downwards penetrate through the through holes in sequence from the functional ceramic heating body and are locked on the supporting plate through nuts. A traditional heating tube is replaced by the functional ceramic heating body, so that the heat conductivity is improved, the heat transfer speed is high, the heat conduction is uniform, oxidization and dust raising are not likely to happen at high temperature, the service life is prolonged, and the heating body can be replaced conveniently; besides, the heating body and the heat conduction plate can be integrated; the screws penetrate through thewhole plate layers to facilitate assembly and positioning between the plate layers, the plate layers are not easy to loosen, and the occurrence probability of the burst phenomenon of a common heatingbody is reduced.

Owner:深圳雅素达电子科技有限公司

Process for preparing slag by pelletization of steel-making dust slime

InactiveCN1264994CHigh strengthIncreased degree of plastic deformationManufacturing convertersProcess efficiency improvementSteelmaking

The invention relates to a comprehensive utilization method of dust and mud in steelmaking process, which is specifically a spheroiditic slagging agent production process. The invention comprises the following steps: drying dust and mud in the open, adding 2-6% burnt lime and 0.5-1% adhensive to the mud to produce mixture, sending the mixture to agitator to intimate mixing, sending the mixture to roller to be pulverized fully, sending it to pelletizer to produce green-ball of phi20-phi30mm size by roll-type briquetting process in presure of 40-60KN, processing green-ball in jigging screen to get green-ball end product on sifter and sliver as return material under sifter and sending green-ball to tower furnace via charging system to be adglutinate and get end product.

Owner:张清学

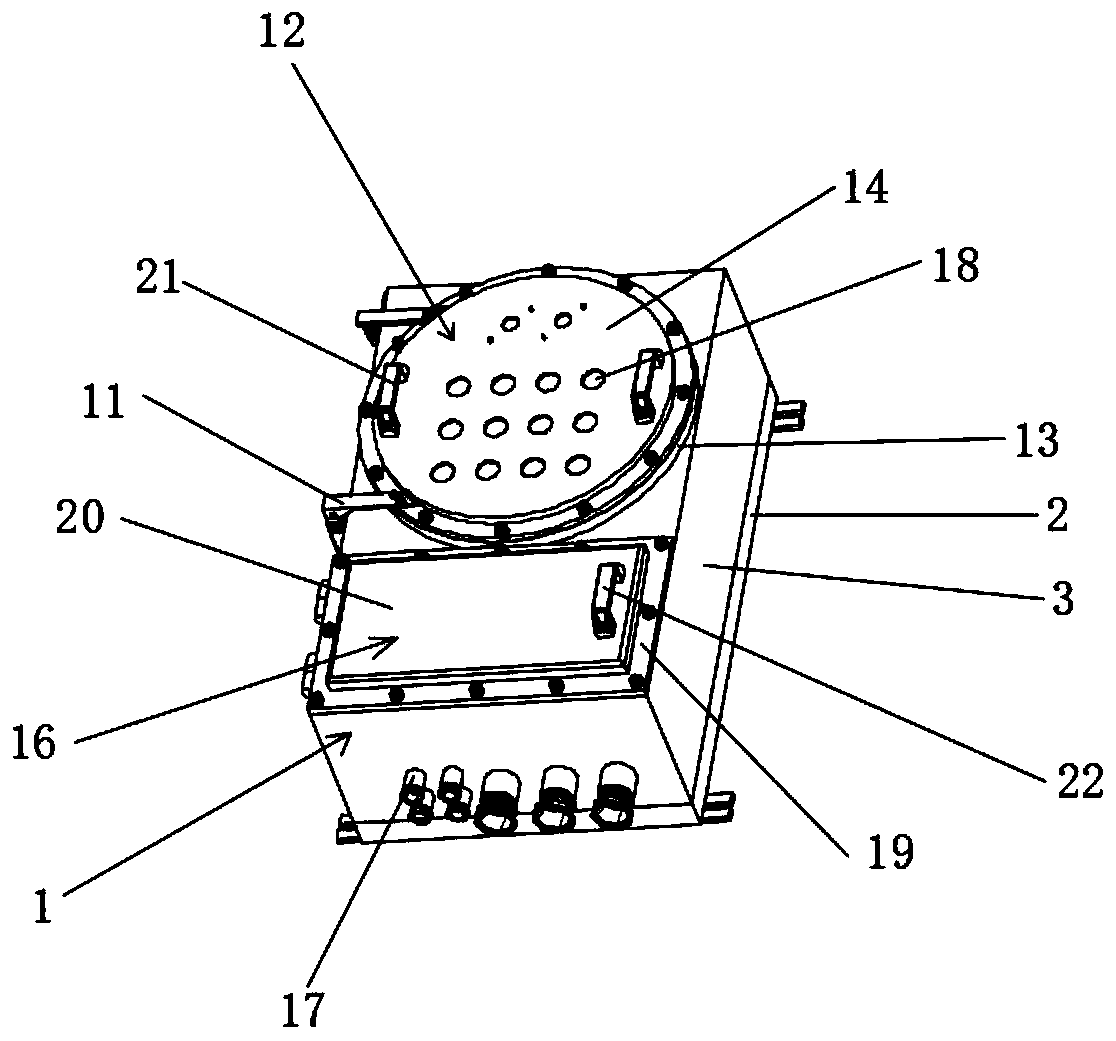

Anti-explosion remote-transmission pressure meter

InactiveCN110132482AReduce disruption and impactPrevent burstFluid pressure measurementHinge angleEngineering

The invention discloses an anti-explosion remote-transmission pressure meter. The anti-explosion remote-transmission pressure meter comprises an anti-explosion box body, wherein the anti-explosion boxbody is formed by combining a bottom plate and a cover plate, a partition plate is arranged on the cover plate, the anti-explosion box body is divided into a first installation cavity and a second installation cavity from top to bottom by the partition plate, a first observation window and a second observation window which are corresponding to the first installation cavity and the second installation cavity are formed in the partition plate, an electronic pressure meter display module is arranged in the first installation cavity, a wireless transmission module connected with the electronic pressure meter display module is arranged in the second installation cavity, a first cover door is arranged on the partition plate by a first hinge piece and is used for covering the first observation window, the first cover door comprises a first door frame, the first door frame is connected with the first hinge piece, a first anti-explosion glass plate is arranged on the first door frame and is transparent, a second cover door is arranged on the partition plate by a second hinge piece and is used for covering the second observation window, and a plurality of through pipes are arranged on the anti-explosion box body. The anti-explosion remote-transmission pressure meter has the characteristic of good anti-explosion performance.

Owner:MAANSHAN HAOYU INSTR

A large TV back panel forming mold

The invention discloses a forming die for a large television backplane. The forming die comprises an upper die and a lower die, wherein the upper die comprises an upper cover plate, an upper block, an upper die base and an upper die plate which are fixedly connected in sequence from top to bottom; the lower die comprises a lower supporting plate, a lower block, a lower die base, a lower cushion block and a clamping plate which are fixedly connected in sequence from bottom to top; the centre of the upper die plate is sunken upwards to form a hollow and arc-shaped cavity; the clamping plate is provided with a first raising puncher, a second raising puncher, a third raising puncher and a fourth raising puncher on positions just below the cavity; and parts raised by the first raising puncher, the second raising puncher, the third raising puncher and the fourth raising puncher during die closing, of the backplane, are a first raised bump, a second raised bump, a third raised bump and a fourth raised bump respectively. The forming die disclosed by the invention is capable of reducing a phenomenon of raised bump burst, thus greatly increasing the forming yield of the raised bumps; and moreover, an S-shaped structure with a certain R angle is formed on the bent sectioned surface of the backplane, the bent sectioned surface is not liable to crack during shaping pulling, and the backplane is high in forming quality, low in industrialization cost, and convenient for increasing economic benefits.

Owner:KUNSHAN JIXINCHENG PRECISION MOLD

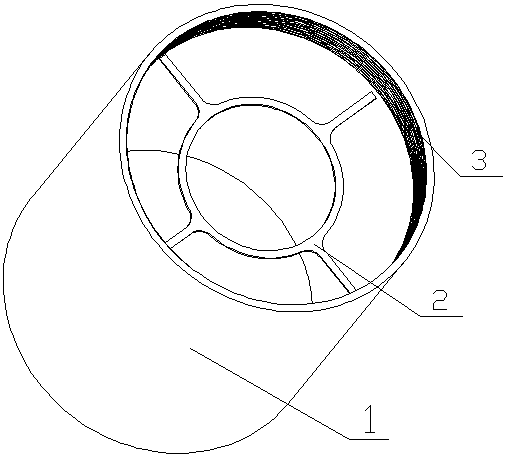

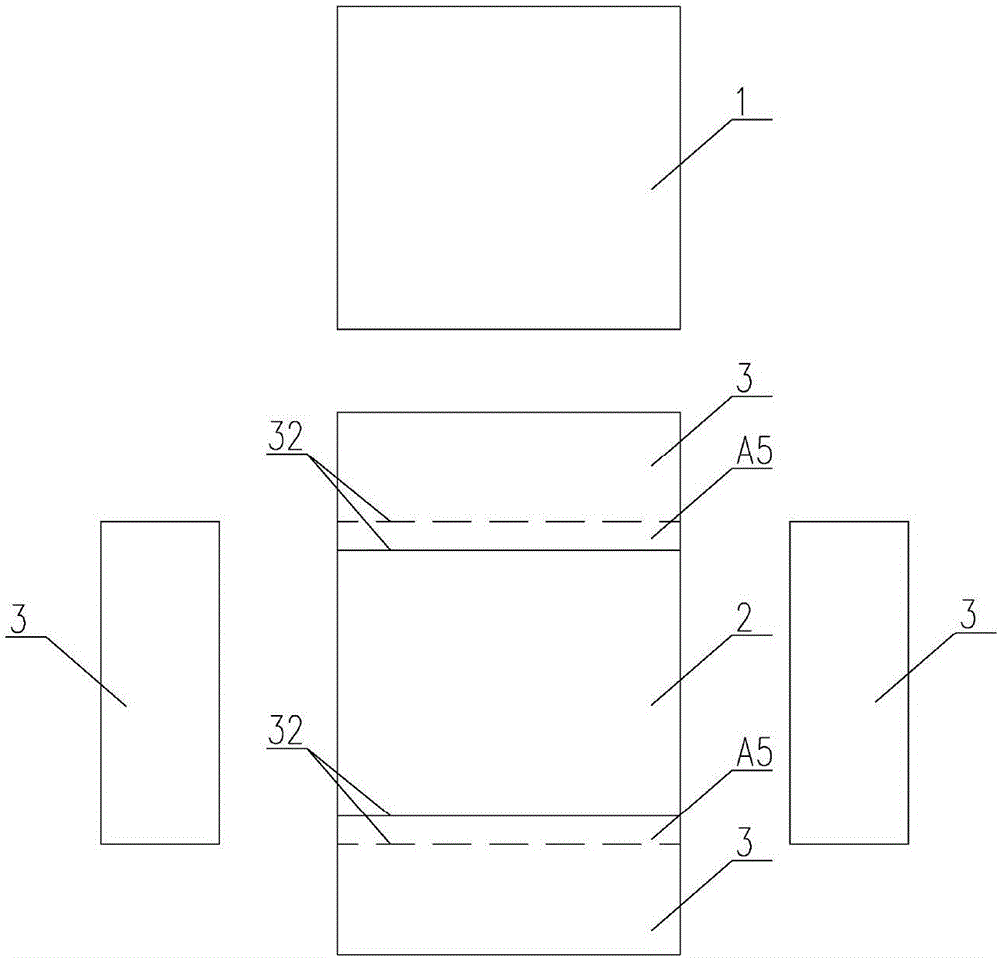

A combined netted box-shaped component for forming holes in cast-in-place hollow floors

The invention provides a combined netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The combined netlike box-shaped component comprises a box roof, a box bottom and a box body, and consists of functional fabricated boards and netlike bodies, wherein the functional fabricated boards are manufactured from concrete mortar and a reinforcing material under the action of a mould or is compounded by superposing adhesive on the netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting sheets; the netlike board, the reinforcing ribs and the connecting sheets form an entirety; the area of a grid in the netlike board is smaller than 120 mm<2>; the netlike bodies are at least applied to the box body of the combined netlike box-shaped component; two structural inclined planes are arranged at corners of the box bottom and the box body. The combined netlike box-shaped component can form holes in the hollow floor; by virtue of surface tension of concrete, the unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the existing cast-in-situ hollow floor, so that integration of building energy conservation and multifunctional utilization of the floor can be easily implemented.

Owner:王本淼 +2

Air flame heat energy stove capable of replacing gas for cooking

InactiveCN113776092AEvenly heatedAvoid temperature riseDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

The invention relates to the technical field of heat energy stoves, in particular to an air flame heat energy stove capable of replacing gas for cooking. The air flame heat energy stove comprises a stove body and a pot body, the stove body comprises a cooking bench and a stove frame arranged at the bottom of the cooking bench, a containing groove is formed in the top of the cooking bench, the pot body is placed in the containing groove when used, and a plurality of flame generating mechanisms are arranged in the containing groove. The plurality of flame generating mechanisms are arranged, and transmission pipes in the flame generating mechanisms are annularly distributed so that flames can be dispersed out, then the flames are sprayed out through a plurality of flame spraying openings and evenly heated at the bottom of the pot body, and therefore the pot body can be evenly heated, the flame diffusion range is controlled through an arranged isolation ring, and overhigh temperature of superposed portions caused by superposition of adjacent flames is avoided.

Owner:惠泽(吉林省)科技开发有限公司

Two-section nitrogen spring with noise reduction and anti-galling function

PendingCN109139767AIncrease the area of actionAvoid stuck phenomenonSpringsGas based dampersNitrogenEngineering

The invention discloses a two-section nitrogen spring with a noise-reduction and anti-galling function, the two-section nitrogen spring comprises a cylinder body, an air inlet hole communicates with ahigh-pressure nitrogen chamber in the cylinder body, the air inlet hole is internally provided with an air charging valve, a liner is arranged in the cylinder body, a buffer chamber is formed at thebottom of the high-pressure nitrogen chamber, a first piston rod is arranged in the liner above the buffer chamber, the first piston rod is of hollow structure, and an annular groove is arranged alongthe bottom of the first piston rod, a second piston rod passes through the first piston rod, a chamber is arranged at the center of the lower part of the second piston rod, a pressure receiving diskis in bolted connection to the upper end of the second piston rod, and a noise reduction groove is formed in the upper surface of the pressure receiving disk. The obvious effects are that: the nitrogen spring travel problem in the current market is solved; the pressure surface is enlarged by the pressure receiving disk, so that the return force of the nitrogen spring is more stable; the contact noise is reduced; and the bottom of the first piston rod is prevented from galling, and thus returning or suddenly jumping of the first piston rod are avoided.

Owner:重庆特力普尔机械设备有限公司

A new steel-concrete composite cast-in-place hollow floor

The invention provides a novel steel-concrete combined cast-in-situ hollow floor. The novel steel-concrete combined cast-in-situ hollow floor consists of a sectional steel column, a sectional steel main beam, a concrete ribbed beam, an upper flange plate, a lower flange plate and a netlike box-shaped component, wherein the lower end of the sectional steel main beam adopts a special steel mould; the netlike box-shaped component is formed by combining a box roof, a box bottom and a box body; the box roof is manufactured from concrete mortar and a reinforcing material under the action of a mould or is formed by compounding the netlike bodies and an adhesive; the box bottom is manufactured from the netlike body; the box body is manufactured from the netlike body; the reinforcing ribs of the netlike bodies are required to be vertically arranged; each netlike body comprises a netlike board, reinforcing ribs and connecting sheets; the netlike board, the reinforcing ribs and the connecting sheets form an entirety; at least two structural inclined planes are arranged at corners of the box bottom and the box body; the netlike body of the box bottom of the netlike box-shaped component is directly compounded in the lower flange plate. By virtue of surface tension of concrete, the unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the steel-concrete combined cast-in-situ hollow floor.

Owner:HUNAN BDF ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com