A new steel-concrete composite cast-in-place hollow floor

A hollow floor and cast-in-place technology, which is applied to floors, building components, buildings, etc., can solve the problems of increased self-weight of high-rise buildings, large buoyancy of holes, and unfavorable earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be further described below in conjunction with the accompanying drawings.

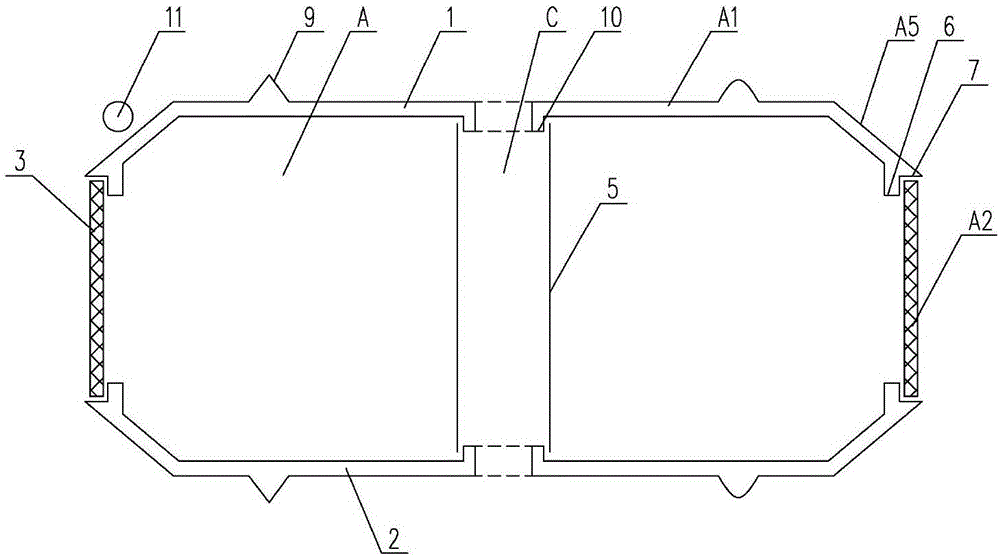

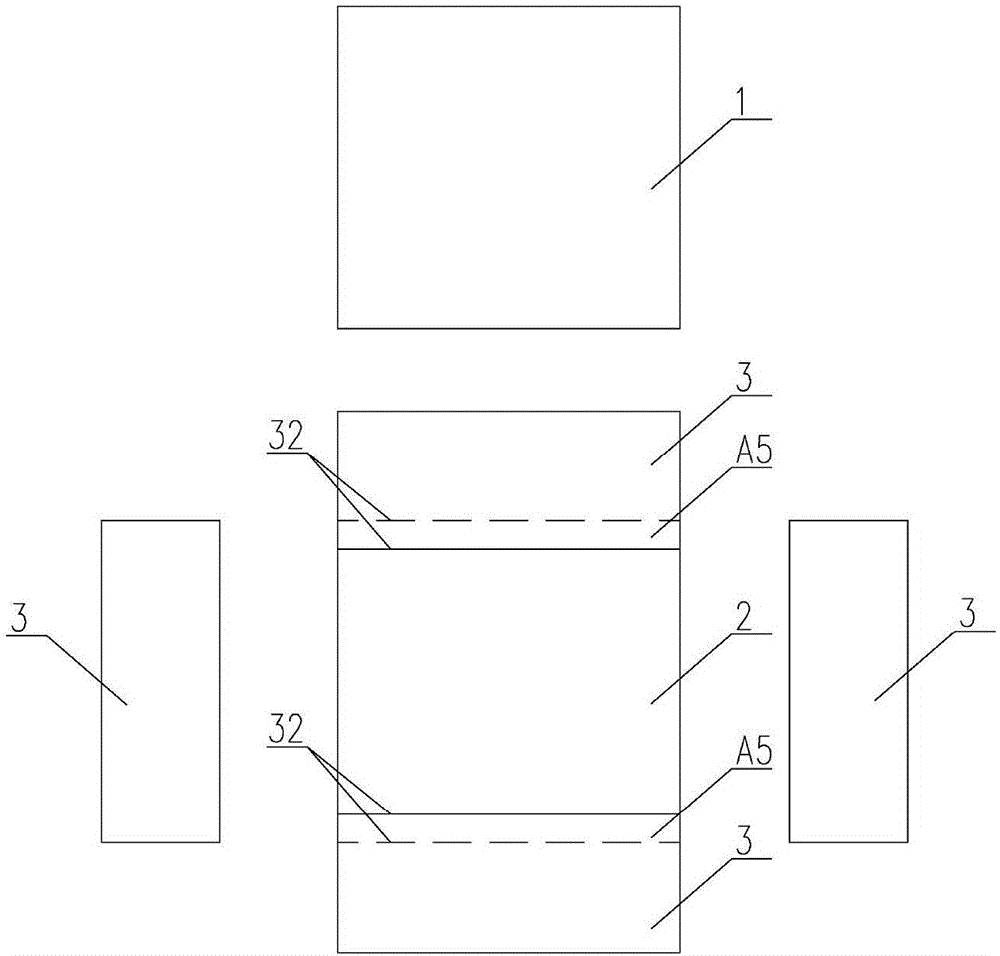

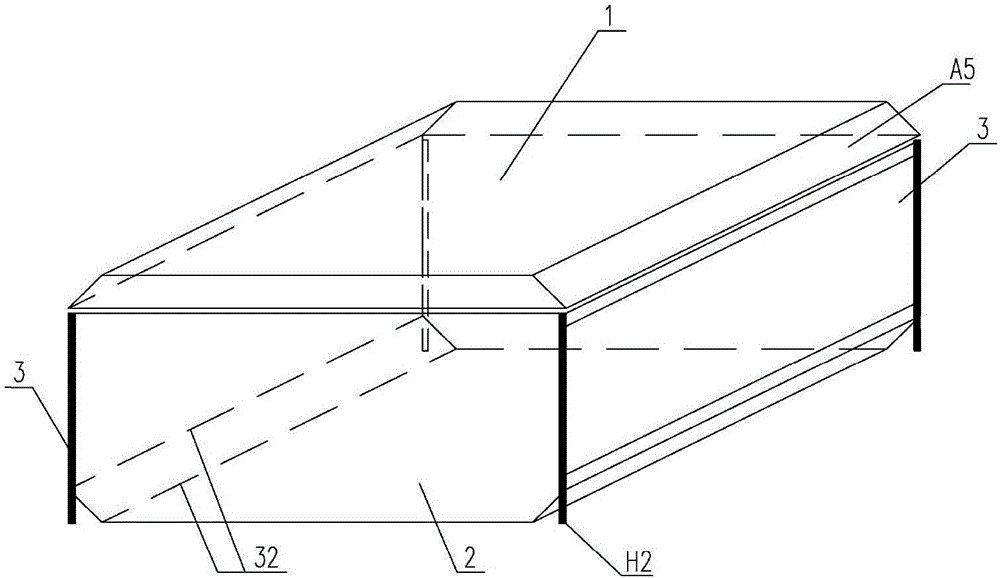

[0027] figure 1 It is a cross-sectional view of the mesh box-shaped member of the first embodiment of the present invention, as figure 1As shown, the reticulated box-shaped member is composed of a composite plate A1 and a reticulated body A2. Among them, the reticulated box-shaped component A includes box top 1, box bottom 2 and box body 3. Box top 1 and box bottom 2 are composite panels A1 made of concrete mortar and reinforcing materials under the action of mechanical molds. According to the needs of architectural design, select Composite panels A1 in different shapes and sizes. The mesh body A2 is made of thin steel plates, and the thin steel plates form the mesh body A2 under the modulation of special mechanical equipment. The mesh body A2 includes the mesh plate A21, the reinforcing ribs A22 and the connecting pieces A23, and the mesh body A2 is connected into a Cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com