Leaf vegetable automatic shredding device for agriculture

A vegetable and agricultural technology, applied in the field of automatic shredding devices for leafy vegetables, can solve the problems of vegetable material entering the transmission system, affecting the quality of vegetables, low shredding efficiency, etc., achieving long continuous working time, improving shredding efficiency, reducing The effect of cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

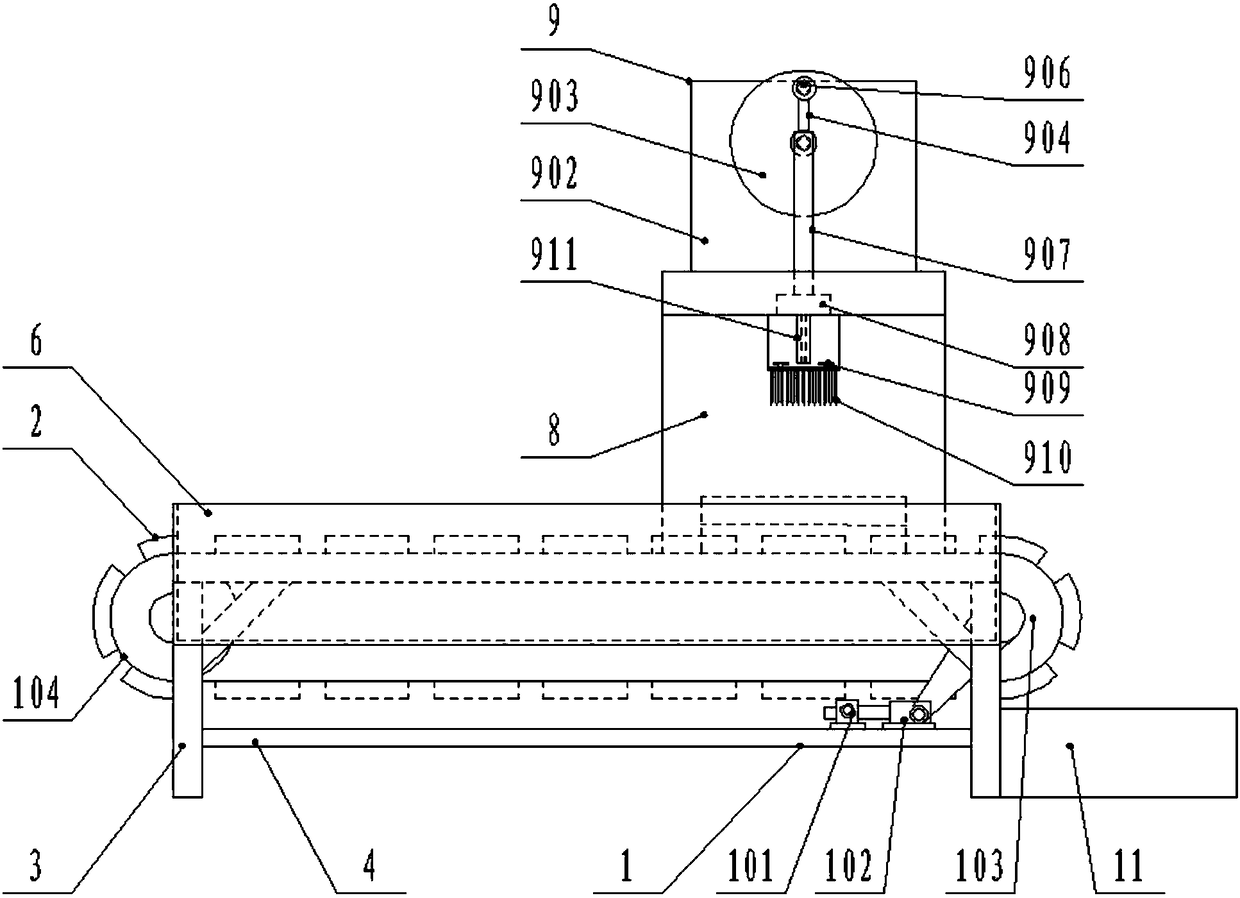

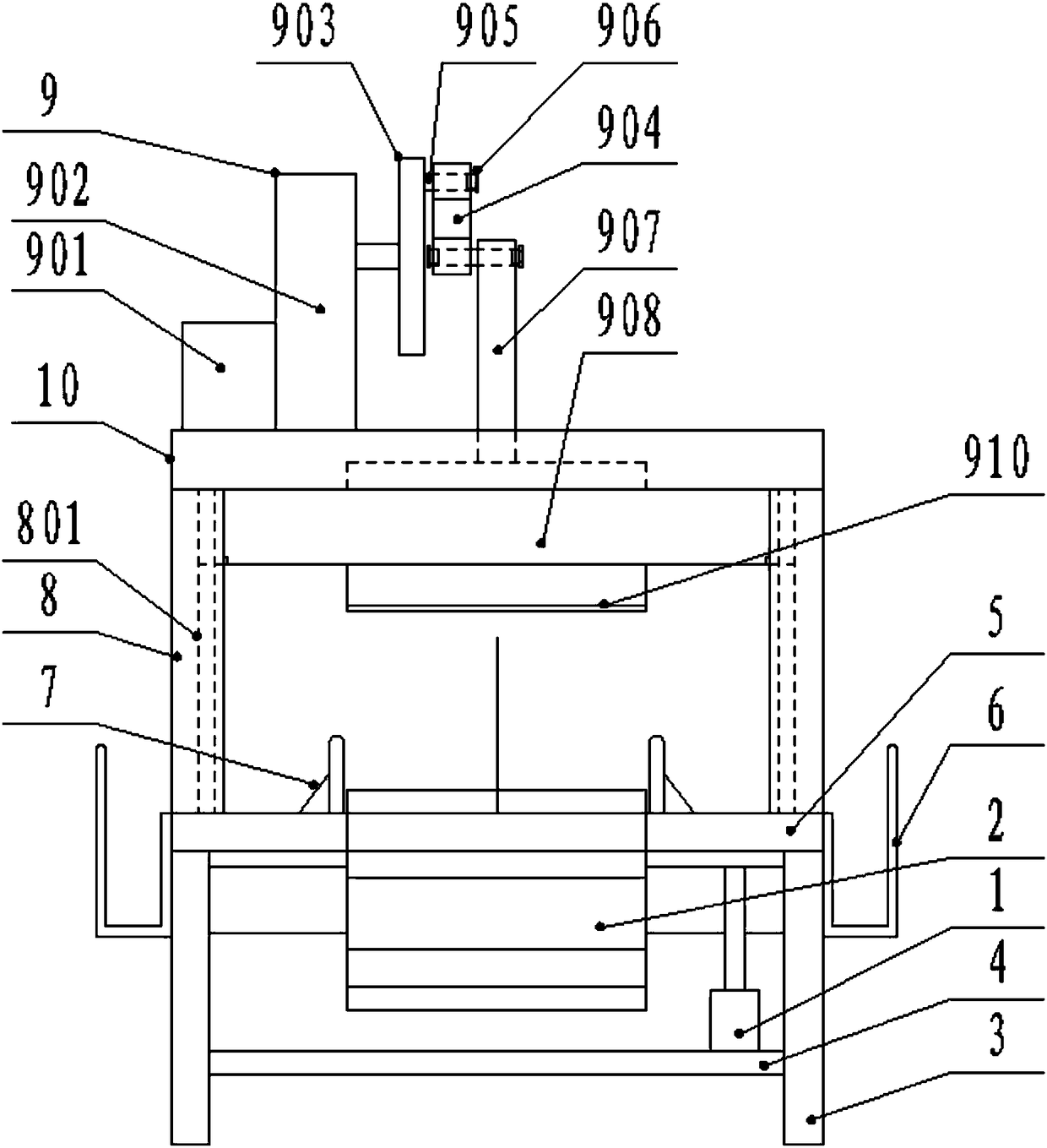

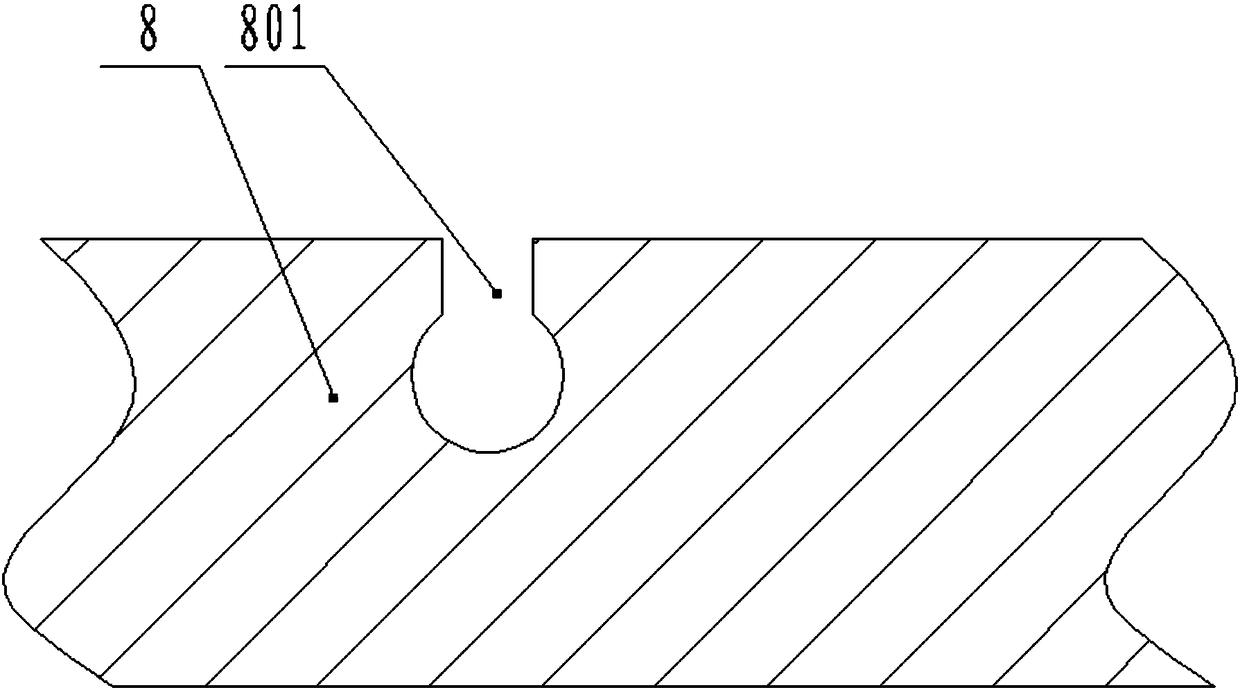

[0034] as attached figure 1 to attach Figure 10Shown: an automatic shredding device for leafy vegetables for agriculture, including a transmission mechanism 1, a turbine motor 101, a continuously variable gearbox 102, a pulley 103, a belt 104, a slot 2, legs 3, and a chassis 4, Cutting table 5, side groove 6, baffle plate 7, side plate 8, guide groove 801, cutting mechanism 9, motor 901, reducer 902, turntable 903, connecting block 904, cylindrical pin 905, plug 906, lifting plate 907, Cutter 908, knife rest 909, cutter 910, guide bar 911, plug 912, top plate 10 and collecting basket 11; Transmission mechanism 1 is made up of turbine motor 101, stepless gearbox 102, pulley 103 and belt 104, based on The device provides the conveying movement of vegetables; the turbine motor 101 is directly connected to the continuously variable gearbox 102, both of which are fixed to the top side of the bottom frame 4 by bolts; there are two pulleys 103, which are respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com