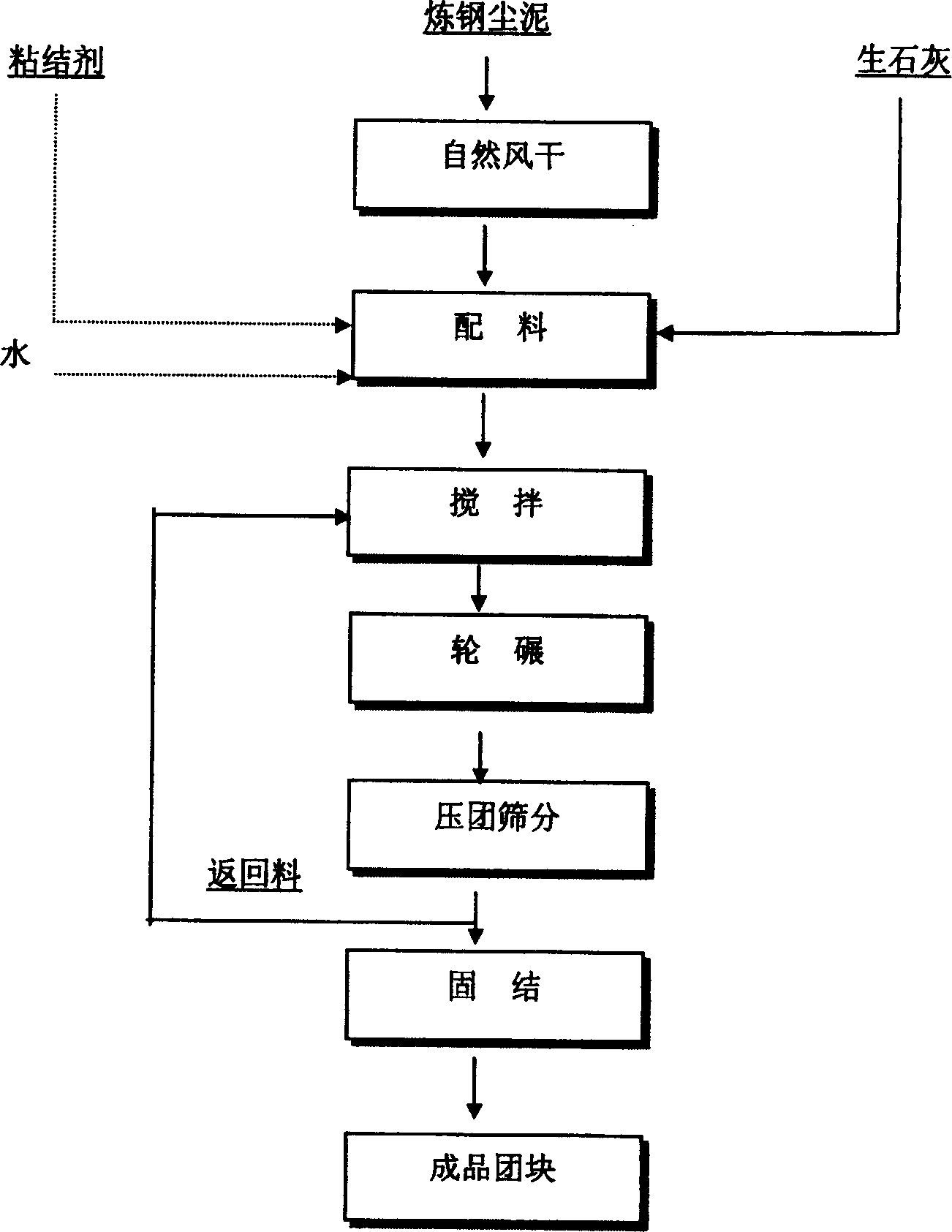

Process for preparing slag by pelletization of steel-making dust slime

A manufacturing process and technology of dust sludge, which is applied in the field of comprehensive utilization of steelmaking dust sludge, can solve the problems of difficult guarantee of thermal strength, large site maintenance, high cost of binder, etc., to reduce bursting phenomenon, ensure strength, and reduce cracking and fault effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A batch of raw materials of steelmaking dust and mud after natural air drying is mixed with 5% quicklime and 0.7% binder to make a primary mixture; the primary mixture is mixed with the returned material for the second time, and 4 tons of secondary mixture are taken Send to the spiral mixer through the belt conveyor for stirring for 5 minutes, then send it to the wheel mill for wheel milling through the belt conveyor, and then send it to the double-roller pelletizing machine for pelletizing through the belt conveyor after 10 minutes of wheel milling; when pelletizing, mix The moisture content of the material is controlled at 10%, and the pressure is controlled at 50KN; the green pellets produced are passed through a vibrating screen, and the green pellets on the screen are loaded into the hopper through the feeding system and sent to the shaft furnace for consolidation, and the crushed material under the screen is returned to the mixer as return material Reuse: After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com