Temperature control heating device used for changing heating and assembly modes of glass hot bending equipment

A heating device and glass technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve the problems of difficult assembly and positioning, difficulty in replacing heating body, short service life, etc. Fast heat, less heat loss and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

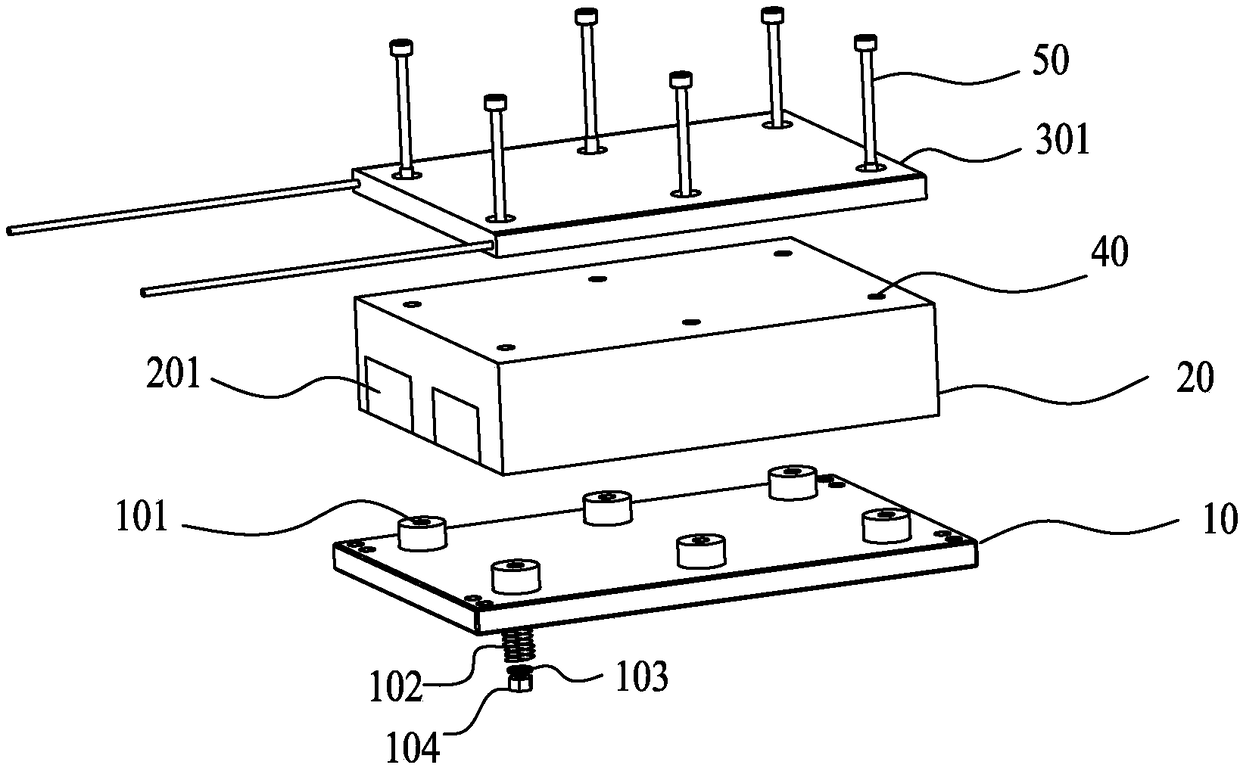

[0021] see figure 1 , the temperature control heating device of the glass hot bending equipment that changes the heating and assembly method includes a support plate 10, a heat insulating plate 20 and a functional ceramic heating body 301, and the functional ceramic heating body 301, the heat insulating plate 20 and the supporting plate 10 are in accordance with The sequence from top to bottom is arranged in turn, and the functional ceramic heating body 301 is heated by electricity. Six through holes 40 are arranged on the support plate 10, the heat insulation plate 20 and the functional ceramic heating body 301. Screws 50 are installed in the through holes 40. The screws 50 from the functional ceramic heating body 301 down through the through hole and locked on the support plate 10 through the nut 104 . The through hole of the support plate 10 is provided with a fixed sleeve 101, and the fixed sleeve 101 is provided with a spring 102 and a washer 103. The screw 50 passes thro...

Embodiment 2

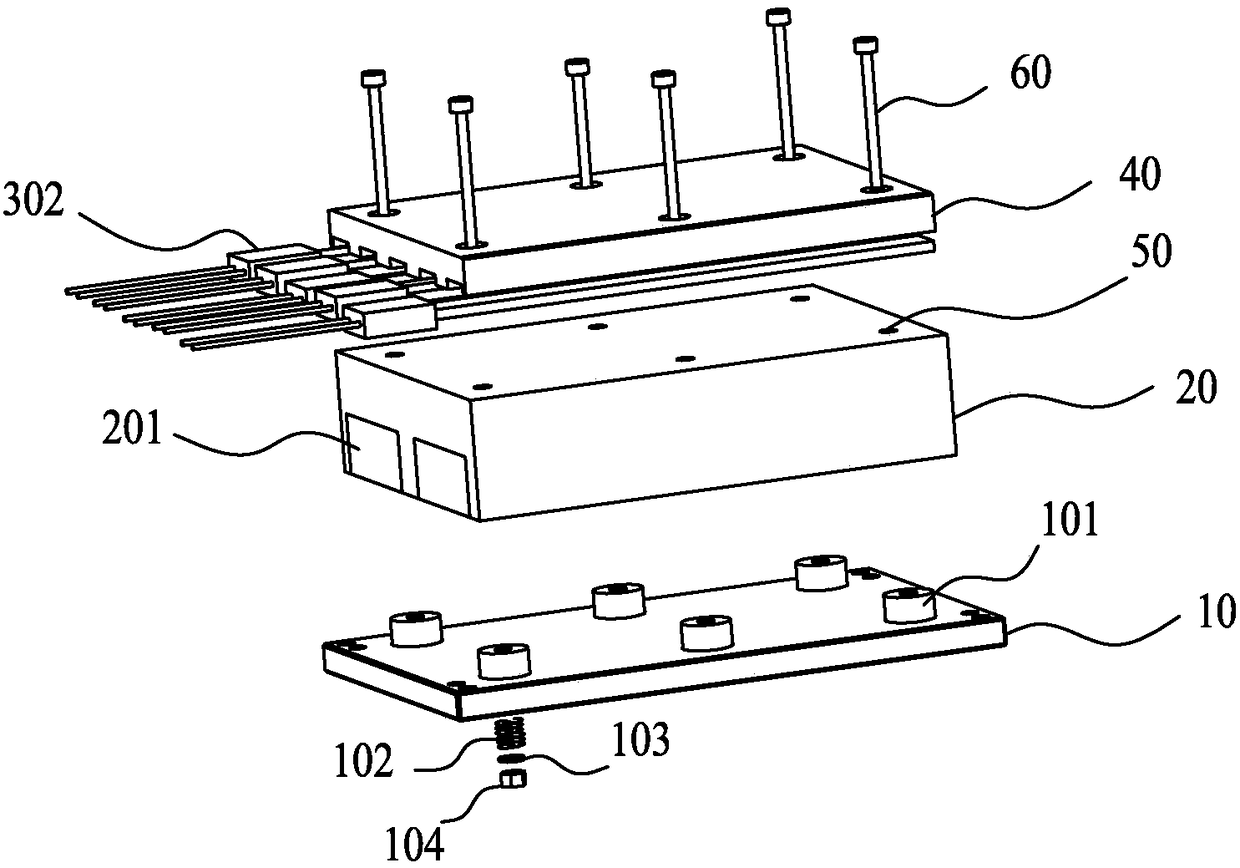

[0024] see figure 2 , the temperature control heating device of the glass hot bending equipment that changes the heating and assembly method, including a support plate 10, a heat insulating plate 20, a heating strip 302 and a heat conducting plate 40, a heat conducting plate 40, five heating strips 302, and a heat insulating plate 20 and the support plate 10 are arranged in sequence from top to bottom, and the heating strip 302 is energized to generate heat. Six through holes 50 are arranged on the support plate 10, the heat insulation plate 20 and the heat conduction plate 40, and screws 60 are installed in the through holes 50. , the screws 60 pass through the through holes 50 from the heat conduction plate 40 downwards and are locked on the support plate 10 by the nuts 104, the heating strip is used to replace the traditional heating pipe, and the functional ceramic heat conduction plate is used to replace the traditional heat conduction plate, which improves the heat condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com