Two-section nitrogen spring with noise reduction and anti-galling function

A nitrogen spring, two-stage technology, applied in the direction of springs, spring/shock absorbers, gas shock absorbers, etc., can solve the problems of weak initial return, noise pollution in the production environment, stuck at the bottom, etc., to increase the impact Small force area, compact structure, and the effect of reducing contact noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

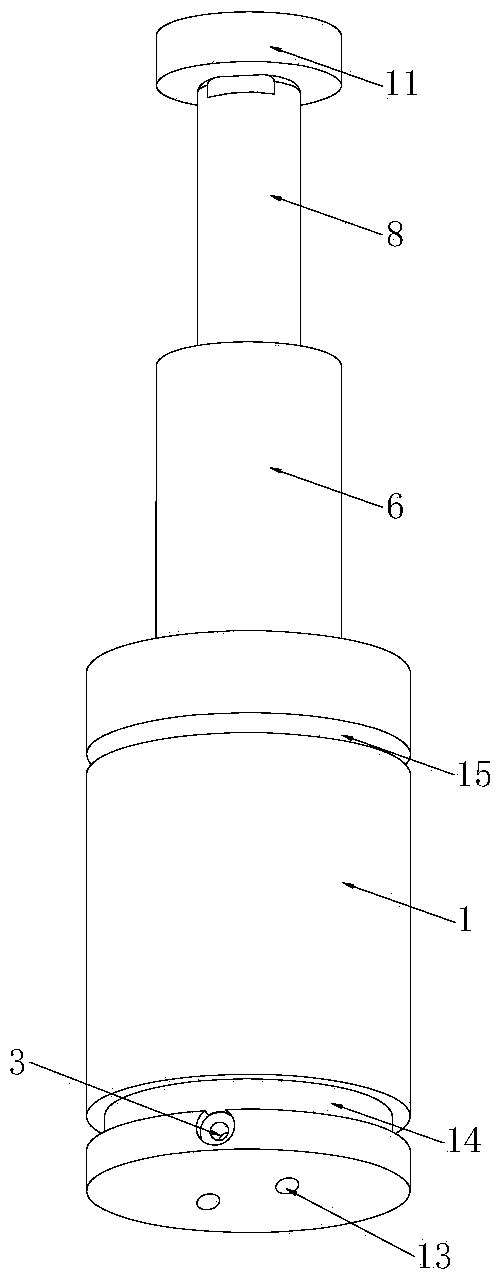

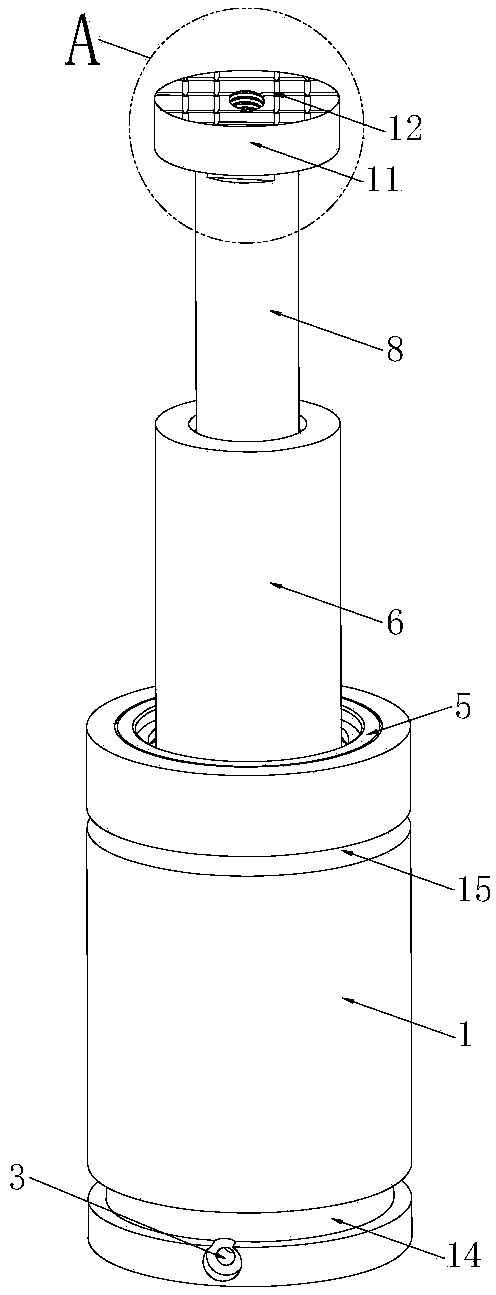

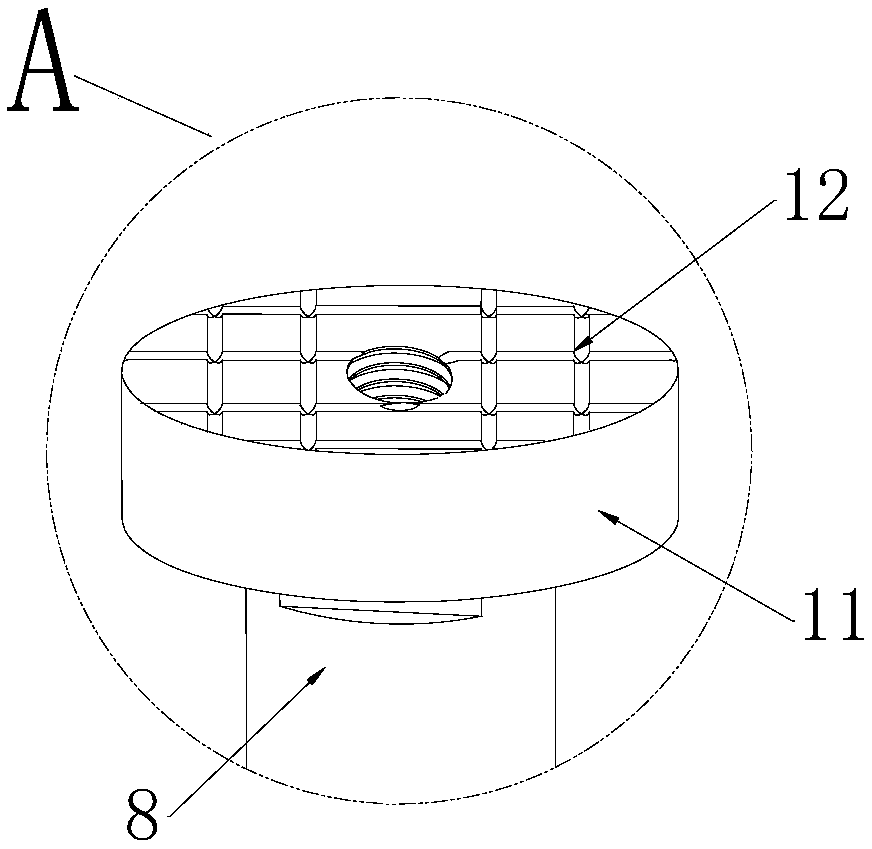

[0027] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1 to Figure 6 As shown, a two-stage nitrogen gas spring with noise reduction and anti-seizure functions includes a cylinder body 1, and an air inlet 3 communicating with a high-pressure nitrogen chamber 2 in the cylinder body 1 is provided at the bottom of the cylinder body 1, The air inlet 3 is provided with a charging valve, a buffer chamber 4 is formed at the bottom of the high-pressure nitrogen chamber 2, a bushing 5 is installed on the upper part of the cylinder body 1, and a second bushing is arranged in the bushing 5. A piston rod 6, the first piston rod 6 is a hollow structure, an annular groove 7 is provided along the bottom of the first piston rod, and the area ratio of the annular groove 7 to the bottom end surface of the first piston rod 6 is not less than 1 / 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com