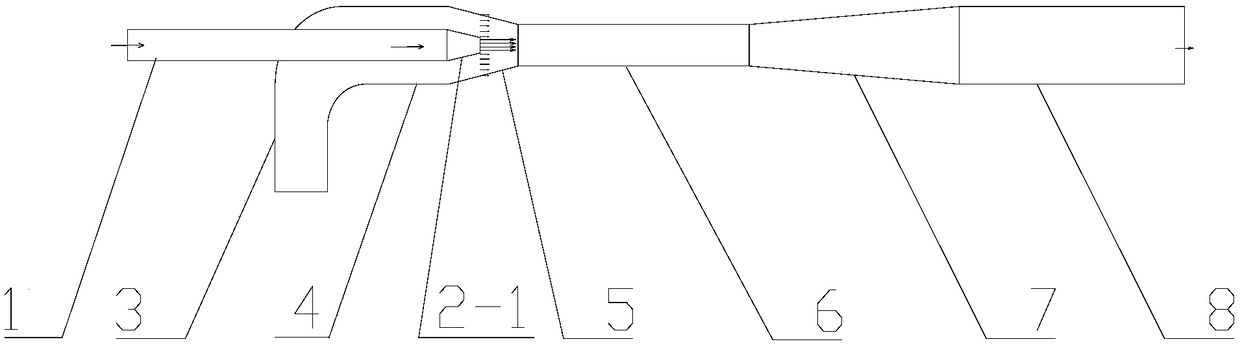

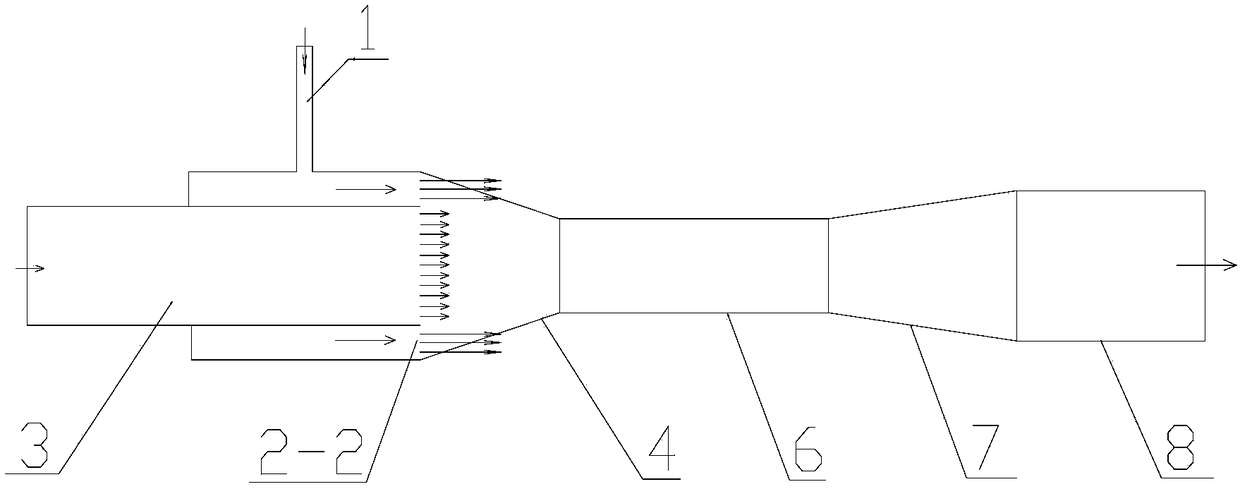

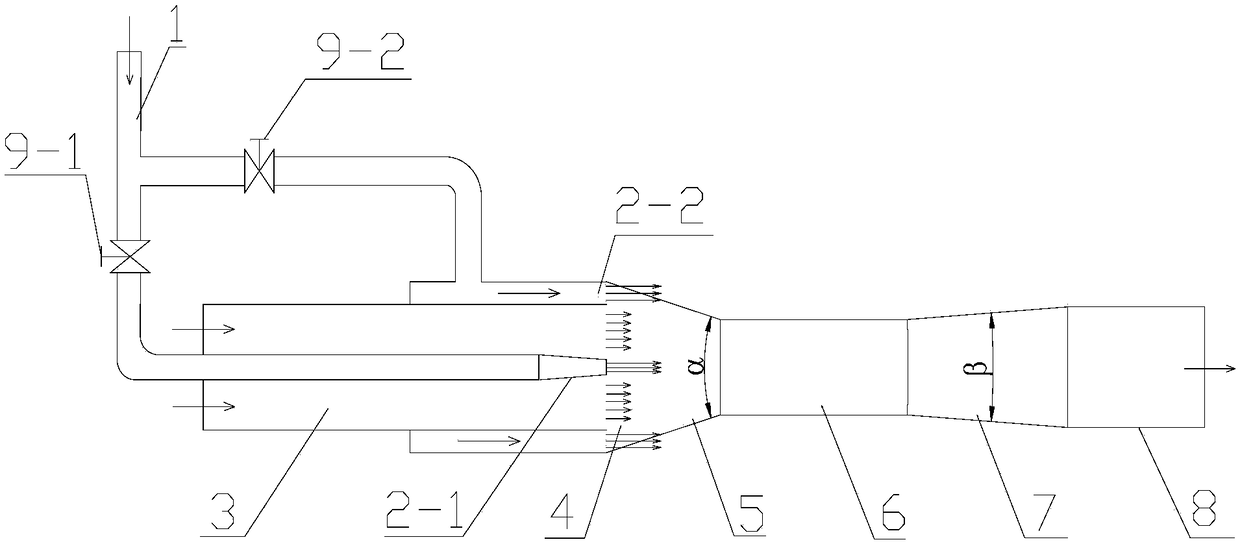

Compound jet pump based on combination of center jet flow and annular jet flow

A technology of annular jet and center jet, which is applied in jet pumps, pumps, non-volume pumps, etc., can solve the problems of poor performance and low efficiency of jet pumps, and achieve improved efficiency, easy processing, and increased action area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] When the present embodiment adopts the composite jet pump based on the combination of central jet and annular jet to work, the center area ratio of the composite jet pump, that is, the ratio of the area of the throat 6 to the outlet area of the central nozzle 2-1 is 25, so The annular area ratio of the composite jet pump is that the ratio of the area of the throat 6 to the outlet area of the annular nozzle 2-2 is 3.05, and the area ratio of the composite jet pump is the area of the throat 6 to the outlet of the central nozzle 2-1 and the area of the annular nozzle 2-2. 2 The ratio of the sum of the outlet areas is 2.72; the length-to-diameter ratio of the throat pipe 6, that is, the ratio of the length of the throat pipe 6 to the diameter of the throat pipe 6 is 2.5; 20°; the throat 6 is in the form of a cylindrical throat; the diffuser 7 is in the form of uniform diffusion, and its diffusion angle β=6°.

[0024] The working process of the compound jet pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com