Integrated device for conducting desulfurization and denitrification on marine diesel engine tail gas

A marine diesel engine, desulfurization and denitrification technology, applied in the field of exhaust gas treatment devices of marine diesel engines, can solve the problems of limited treatment effect, temperature limitation, difficult to adapt to complex working conditions, etc., and achieve good effect, prolonged time, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

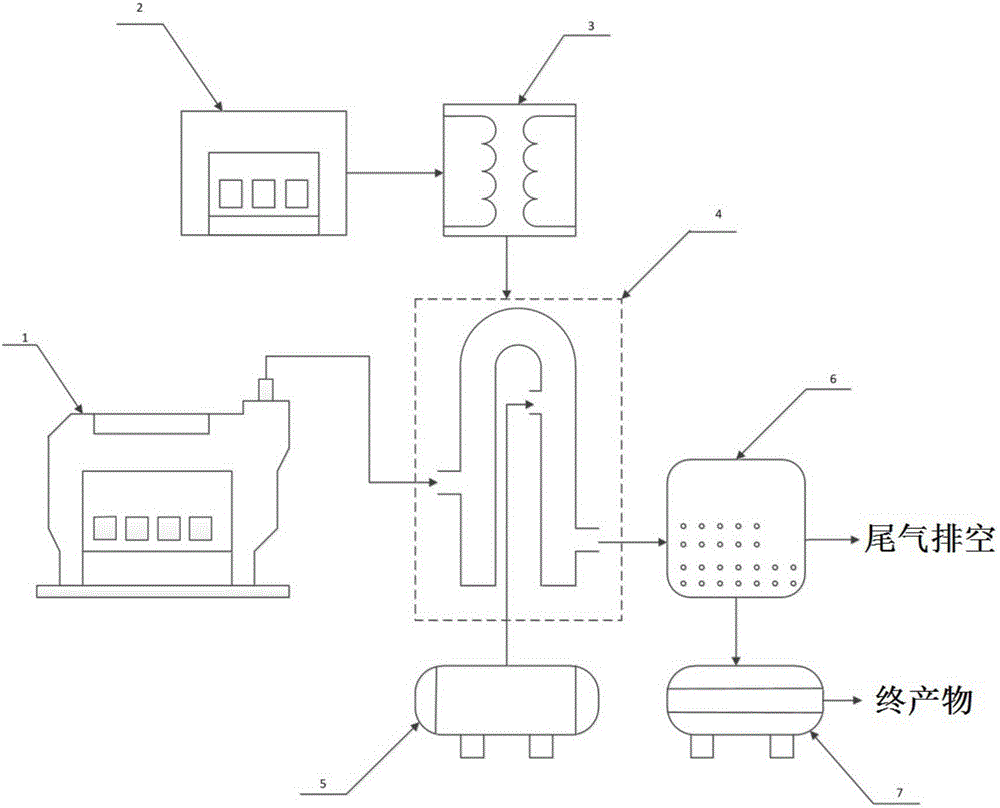

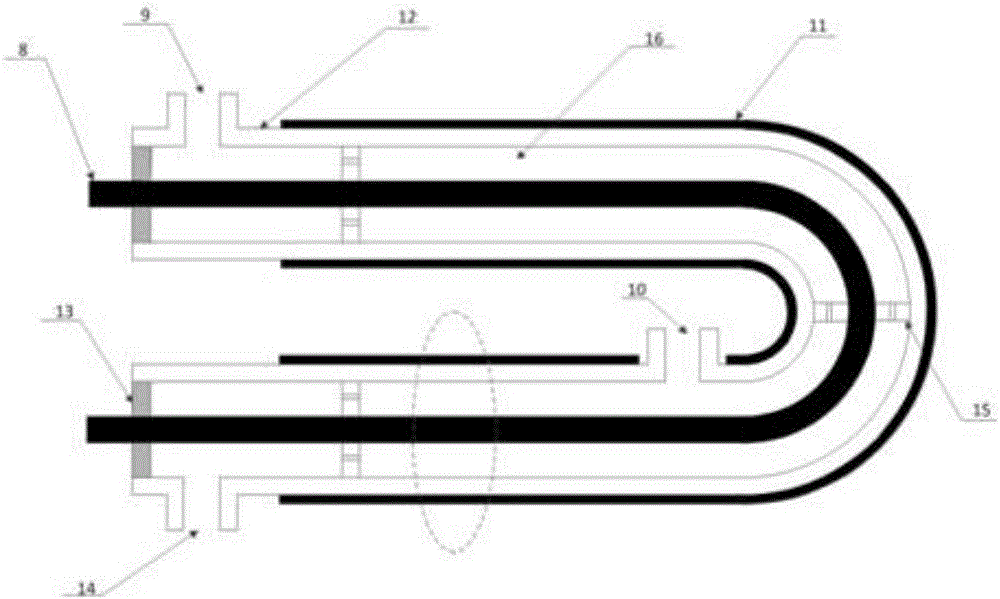

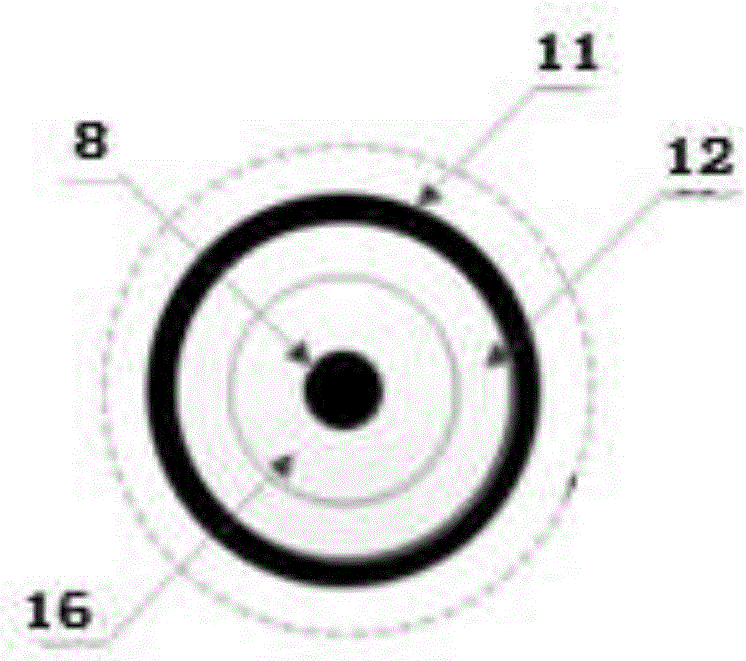

[0022] combine figure 1 ~2. The present invention utilizes the ship power supply device to provide electric energy for generating plasma, changes the layout of the original plasma generator, and adopts a coaxial cylindrical tube-and-tube dielectric barrier discharge plasma generator to generate plasma. Dielectric barrier discharge can generate large space and high density plasma at normal pressure and low temperature, which is suitable for complex working conditions such as ship navigation. At the same time, the internal electrodes of the plasma generator in the present invention adopt a tubular arrangement, which increases the discharge area and plasma generation space, increases the number of active groups, prolongs the interaction time with the tail gas, and fully oxidizes NO and SO2 in the tail gas. Ammonia gas is then introduced to react with the generated H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com