U-shaped plate type dielectric-barrier-discharge-based low-temperature plasma reactor and reactive system

A technology of dielectric barrier discharge and low-temperature plasma, which is applied in the direction of plasma and electrical components, can solve the problems of increased operating voltage, easy damage, and irrelevant axial length of the electrode, etc., and achieve the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

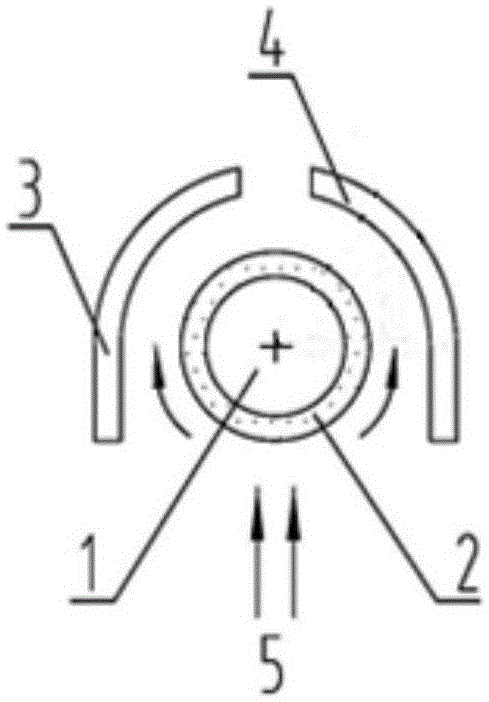

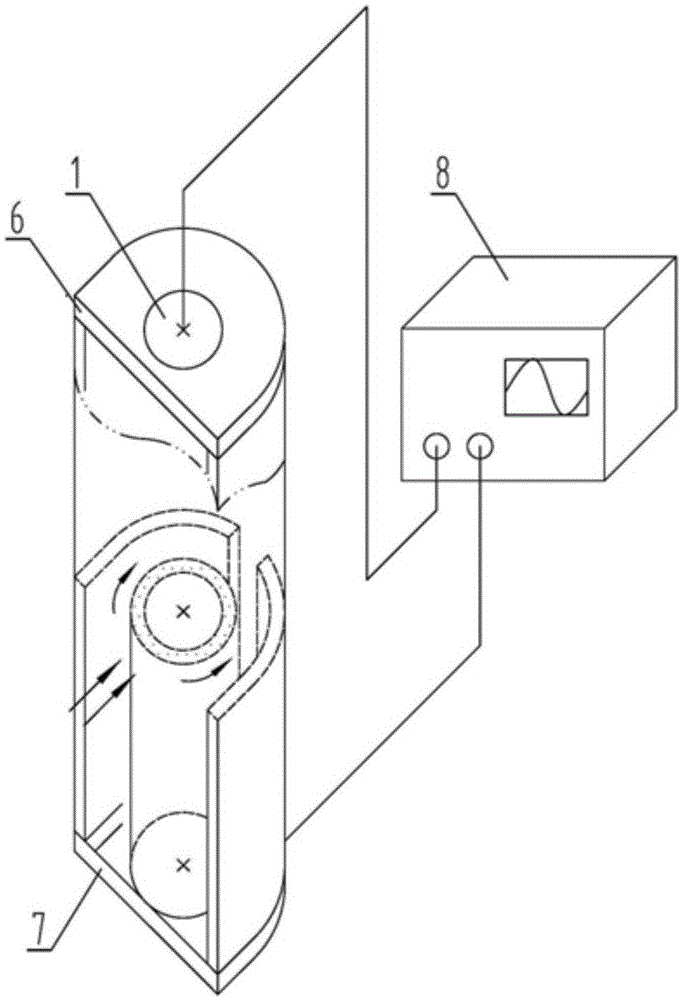

[0044] Such as figure 1 and figure 2 As shown, the core electrode rod 1 and the insulating medium 2 (quartz tube or ceramic tube) are coaxially arranged, and the insulating medium 2 is arranged close to the core electrode rod 1 . The U-shaped plate electrode cover is composed of 1 / 2U-shaped electrode plate a3 and 1 / 2U-shaped electrode plate b4, and each 1 / 2U-shaped electrode plate has a straight plate segment with a length of r and an arc segment with a radius of R. The 1 / 2U-shaped electrode plate a3 and the 1 / 2U-shaped electrode plate b4 are symmetrically arranged around the outside of the insulating medium 2, and there is a certain gap (R-r) between them and the insulating medium 2, which is the DBD gap. The gas 5 to be catalyzed enters the reactor from the U-shaped opening, and the core electrode rod 1 is located in the center of the U-shaped opening, at the front end of the reactor in the direction of gas flow. A gap is set in the middle of the U-shaped bend of the 1 / 2U...

Embodiment 2

[0048] The electrode cover 3 can also be a whole, and a gas outlet channel is provided at the arc of the whole.

Embodiment 3

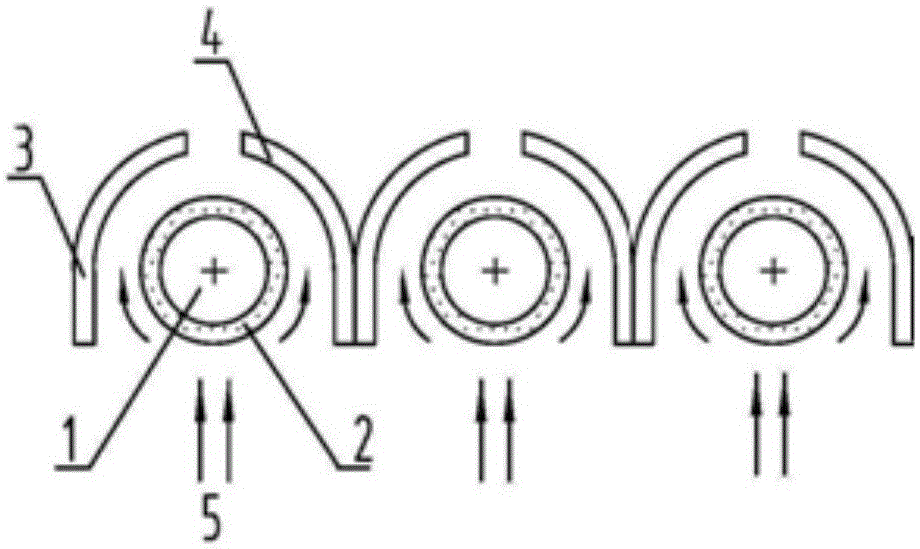

[0050] Such as image 3 and Figure 4 As shown, three reactors are arranged in parallel, and the centerlines of the core electrode rods 1 of each reactor are in the same plane. The driving power supply 8 is connected to all reactors in parallel. There can also be multiple reactors arranged in parallel, such as 3, 4, 5 and more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com