Method for preparing three-dimensional manometer load-type catalyst

A supported catalyst, three-dimensional nanotechnology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as small specific surface area, achieve simple preparation process, large action area, overcome dispersion poor sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Prepare a layer of SiNx thin film on the glass substrate with a chemical vapor deposition method, with a thickness of 200-2000nm;

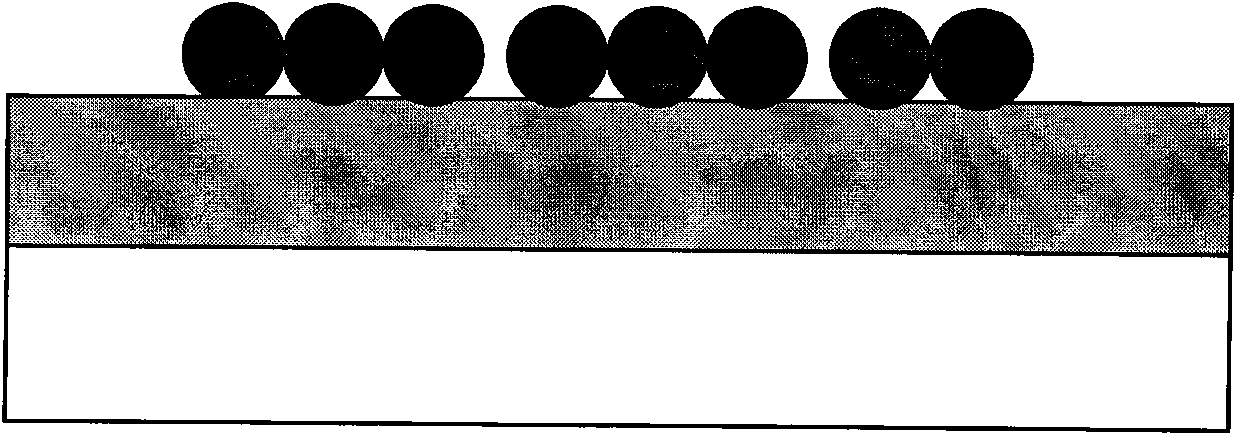

[0034] (2) The configured SiO 2 The nanosphere solution is evenly sprayed onto the glass substrate covered with SiNx film, and dried; ( figure 1 and Figure 4 )

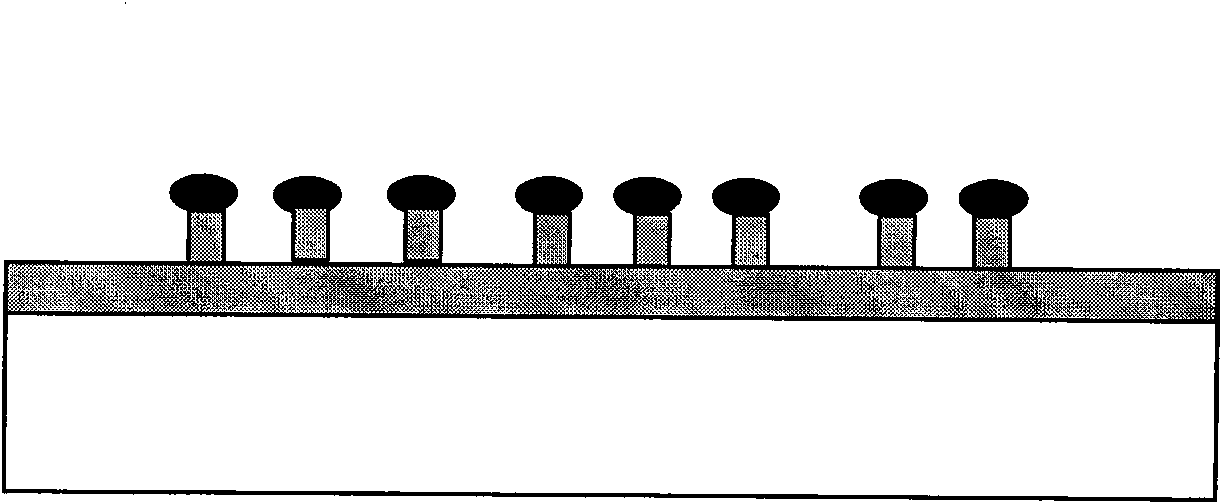

[0035] (3) Using SiO 2 Nanospheres as a mask, through SiNx material and SiO 2 The different etching rates of the material, using the reactive ion etching method to etch out the nano-column; ( figure 2 and Figure 5)

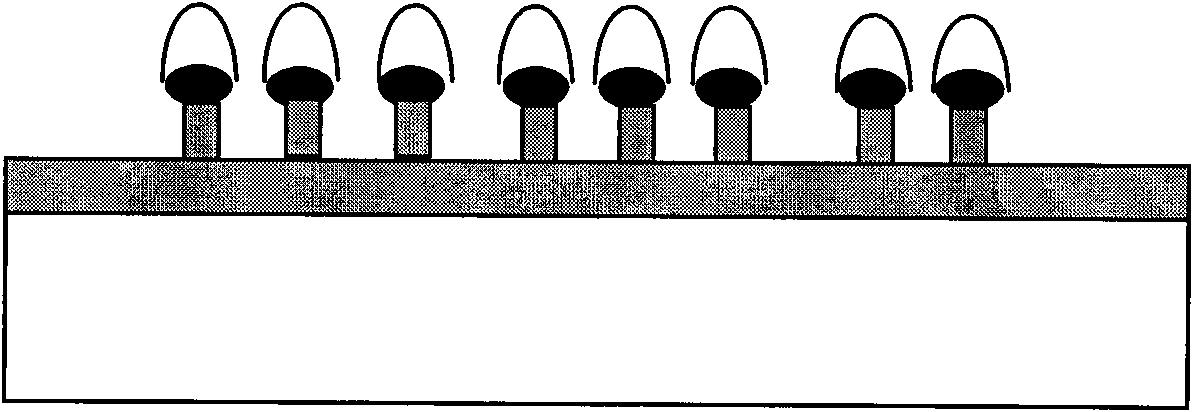

[0036] (4) Preparation of TiO on the etched nanocolumn array by magnetron sputtering technology 2 catalyst;( image 3 and Figure 6 )

[0037] (5) Through the above steps, TiO is formed 2 The catalyst is fixedly supported on SiO 2 Nanocomposite structures on nanospheres and SiNx nanopillars.

Embodiment 2

[0039] (1) Utilize the sol method to prepare a solution containing organic nanospheres, spray it directly onto the glass substrate, and dry to form a uniformly arranged array;

[0040] (2) Using organic nanospheres as a mask, through the different etching rates of the organic nanospheres and the glass substrate, the nanocolumns are etched by the reactive ion etching method;

[0041] (3) Prepare TiO on the etched nanocolumn array by magnetron sputtering technology 2 catalyst;

[0042] (4) Through the above steps, TiO is formed 2 Inorganic-organic composite nanocatalysts in which catalysts are fixedly supported on organic nanospheres.

Embodiment 3

[0044] Step (4) in Example 1: Utilize magnetron sputtering technology to prepare TiO on the etched nano-column array 2 Catalyst, instead: utilize magnetron sputtering technology to prepare metal Ni catalyst on the nano-column array that etch out, other is the same as embodiment one, will form metal Ni catalyst and be fixedly supported on SiO 2 Nanocomposite structures on nanospheres and SiNx nanopillars.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com