Oil well wellhead water content automatic test device and test method thereof

An automatic testing device and automatic testing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of increasing the workload and intensity of staff sampling, sending samples and monitoring water cut, failing to grasp the production of oil wells in a timely and accurate manner, and lagging monitoring results and other issues, to achieve the effect of perfecting the level of digital management, reducing labor, and avoiding lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

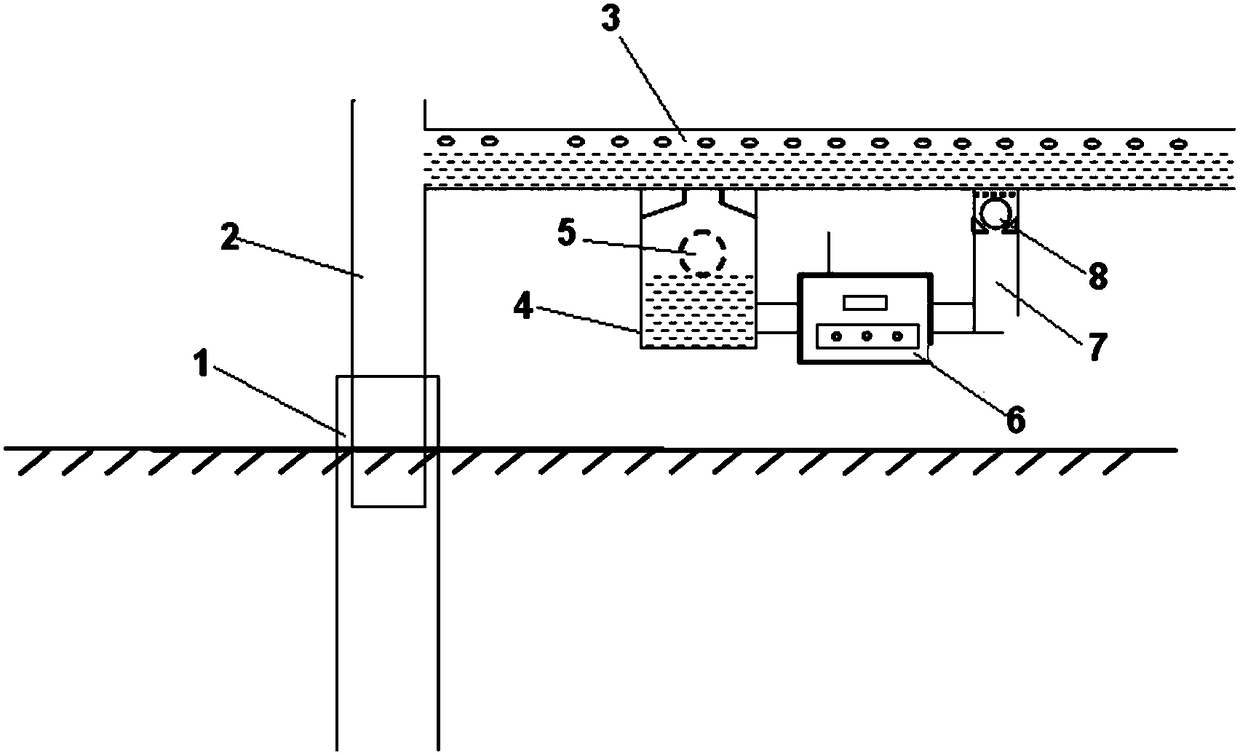

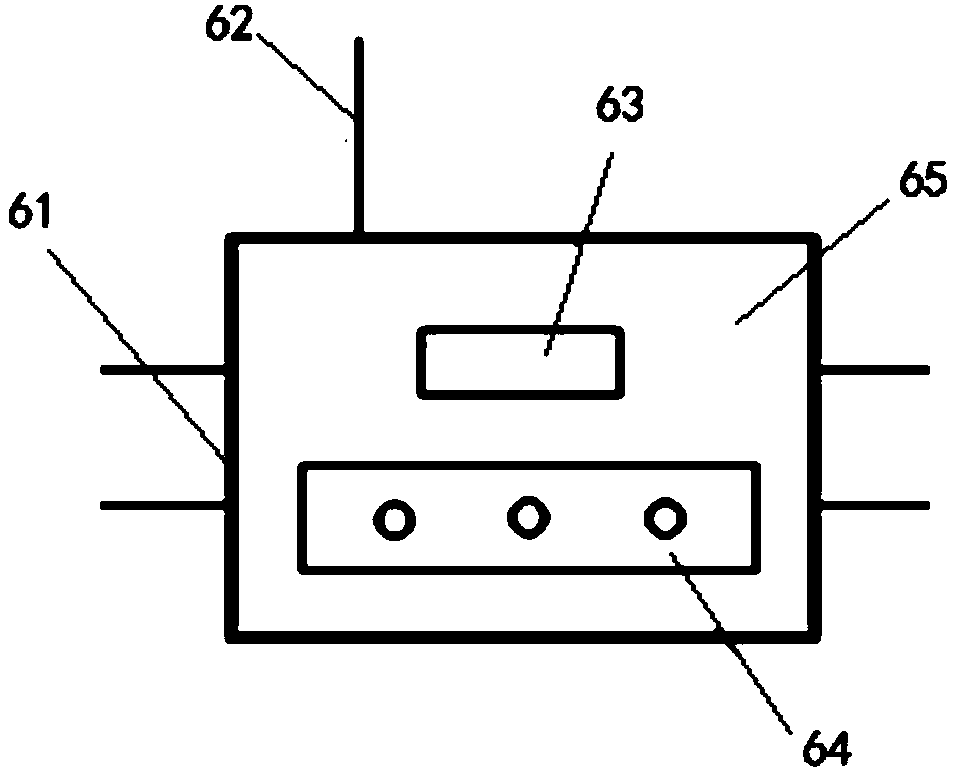

[0032] Such as figure 1 As shown, an automatic test device for water content at the wellhead of an oil well provided by an embodiment of the present invention includes an oil storage tank 4, a floating ball plug 5, a water content tester 6, a return pipe 7 and a check valve 8;

[0033] The oil storage tank 4 is provided with a liquid inlet hole, the liquid inlet hole communicates with the oil well pipeline manifold 3, and the other end communicates with the input end of the water content tester 6, the oil storage tank 4 is located below the oil well pipeline manifold 3, the return pipe 7 and the water content The output end of the tester 6 is connected; the water content tester 6 is provided with a power device, and the power device is used to transport the liquid in the oil storage tank to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com