Wellhead oil-gas-water three-phase flow impedance-capacitance type water content measuring device and method

A capacitance water content and measuring device technology, which is applied in the direction of measurement, mining fluid, earthwork drilling, etc., can solve the problems of inability to realize automatic measurement, large difference in accuracy, poor measurement effect, etc., and achieve real-time online measurement, safety High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

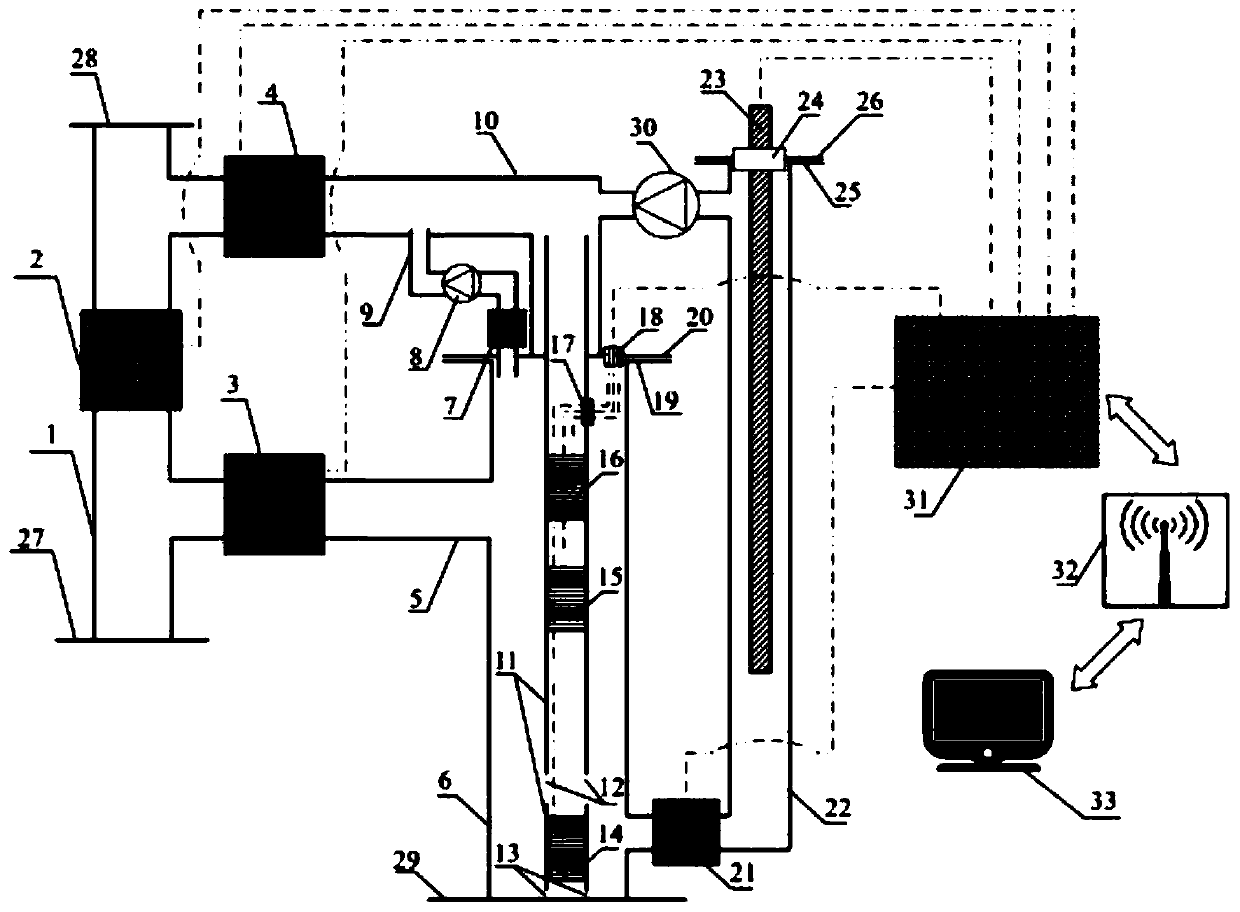

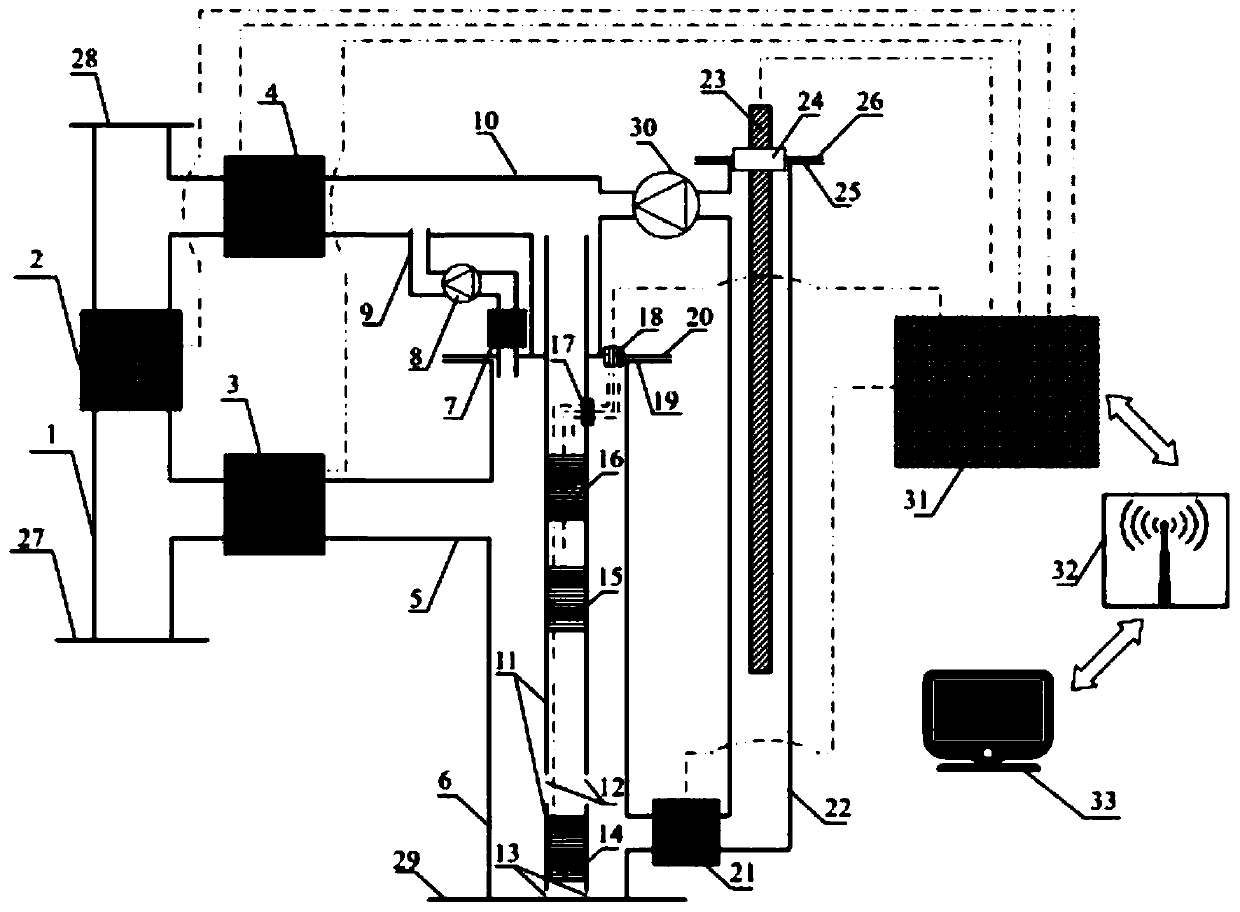

[0043] A wellhead oil-gas-water three-phase flow impedance capacitance water cut measurement device and method, such as figure 1 As shown, the water cut measurement device includes a wellhead installation module, a gas-liquid separation system, a dynamic water cut measurement system, a static water cut measurement system, a control valve group and a data processing system. Wherein, the wellhead installation module includes an installation pipeline 1, an installation pipeline inlet flange 27, an installation pipeline outlet flange 28, and the installation pipeline inlet flange 27 and the installation pipeline outlet flange 28 are respectively welded to both ends of the installation pipeline 1;

[0044] The gas-liquid separation system includes a mixed-phase inlet pipeline 5, a gas-liquid separation tank 6, a gas-liquid separation tank base 29, a first flange 19 on the top of the gas-liquid separation tank, a second flange 20 on the top of the gas-liquid separation tank, a connec...

Embodiment 2

[0050] In the wellhead installation module, the first control valve 2 is sealed and installed in the middle of the installation pipeline 1, and the liquid inlet of the second control valve 3 is sealed and connected between the first control valve 2 and the inlet flange 27 of the installation pipeline through the pipeline. A control valve 2 and the outlet flange 28 of the installation pipeline are sealed and connected to the liquid outlet of the third control valve 4 through a pipeline.

[0051] In the gas-liquid separation module, one end of the mixed-phase inlet pipe 5 is sealed and connected with the liquid outlet of the second control valve 3, and the other end is sealed and connected with the gas-liquid separation tank 6; one end of the mixed-phase outlet pipe 10 is sealed and connected with the liquid inlet of the third control valve 4 , the other end of the mixed-phase outlet pipe 10 is welded on the second flange 20 on the top of the gas-liquid separation tank; one end o...

Embodiment 3

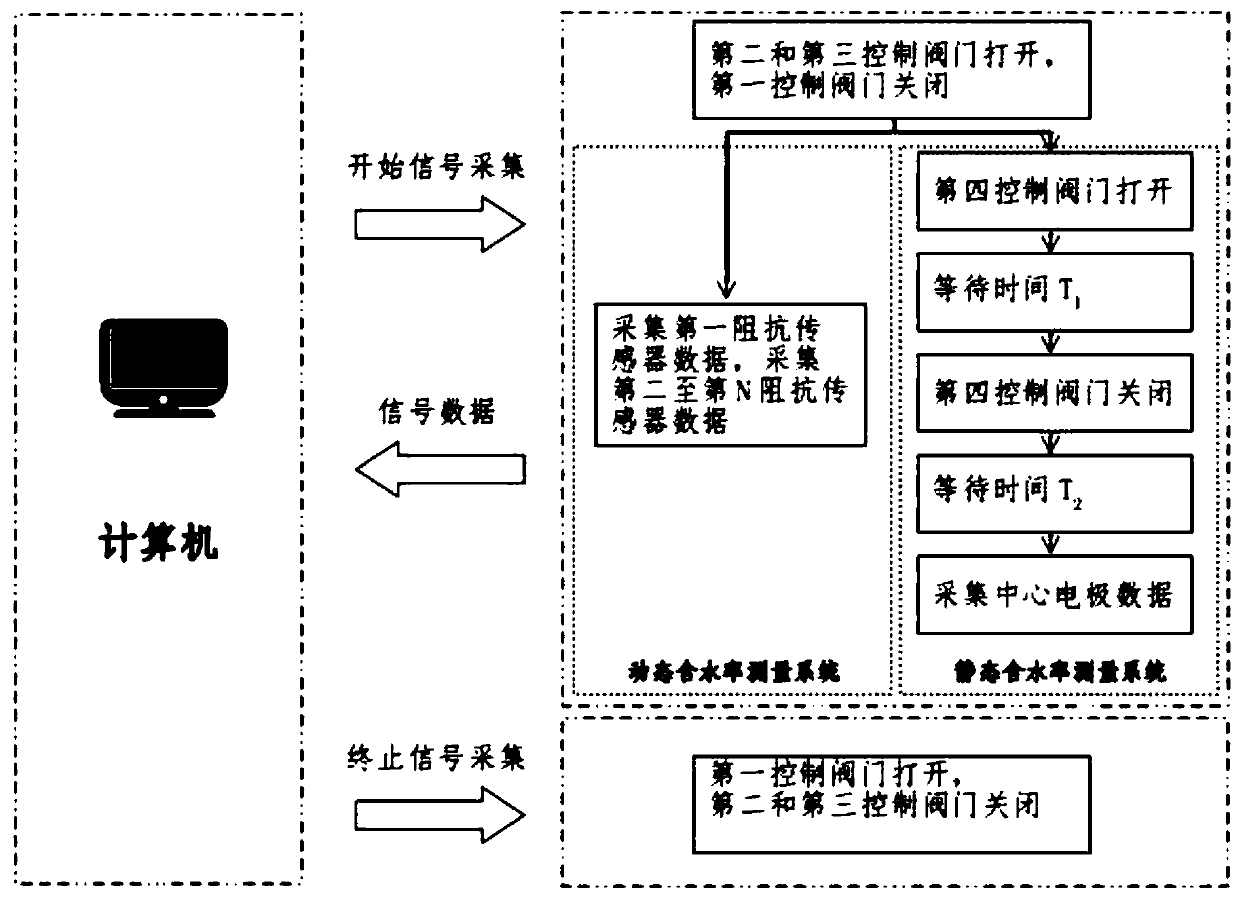

[0055] A control method of a wellhead oil-gas-water three-phase flow impedance capacitance water content measuring device, manually send out start signal acquisition and termination signal acquisition instructions through a computer 33, the wellhead circuit system 31 receives the instructions from the computer 33 from a wireless base station 32, and controls the Control the on-off of the valve group to control the internal fluid flow of the measuring device, and perform signal collection and transmission; the control method includes:

[0056] like figure 2 As shown, when the wellhead circuit system 31 receives the instruction to start signal collection from the computer 33, the wellhead circuit system 31 controls the opening of the second control valve 3, the third control valve 4, and the fourth control valve 21, and the first control valve 2 Close; the oil-gas-water multiphase fluid flows through the installation pipeline inlet flange 27, the second control valve 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com