Permanent-magnet type electricity loss brake electricity-saving control device

A technology of power-loss brake and power-saving control, which is applied to the components of the brake, the type of the brake, the brake actuator, etc., can solve the problems of consumption, the increase of the surface temperature of the brake, and the high power, so as to reduce the internal temperature and have a simple structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

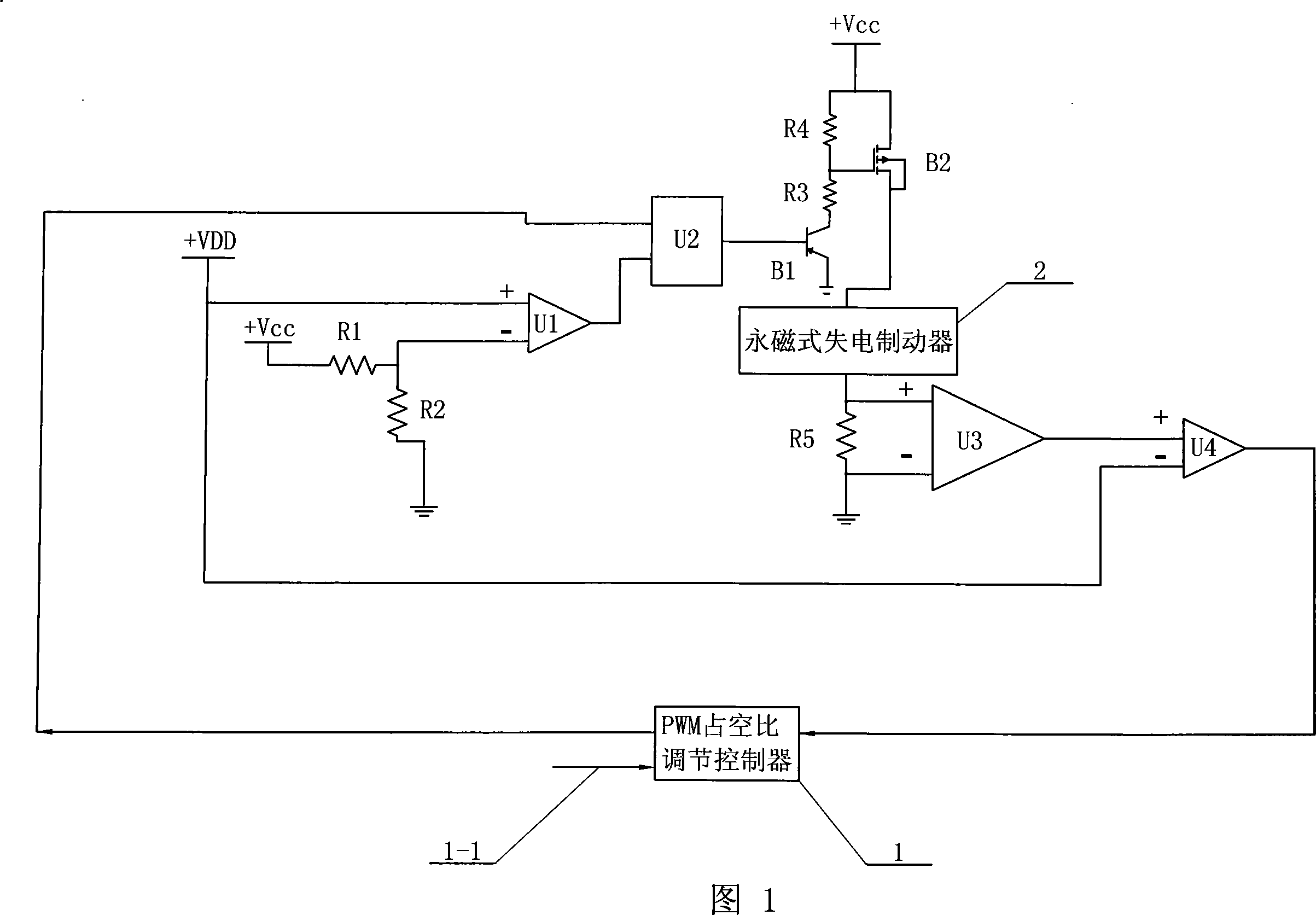

[0016] Specific Embodiment 1: This embodiment is described in conjunction with FIG. 1. This embodiment consists of resistor R1, resistor R2, resistor R3, resistor R4, resistor R5, first operational amplifier comparator U1, two-way AND gate comparator U2, and voltage amplifier U3, the second operational amplifier comparator U4, triode B1, field effect transistor B2, PWM duty ratio adjustment controller 1;

[0017] One end of the resistor R1 is connected to the +Vcc terminal of the power supply, the other end of the resistor R1 and one end of the resistor R2 are connected to the inverting input terminal of the first operational amplifier comparator U1, the other end of the resistor R2 is grounded, and the non-inverting input terminal of the first operational amplifier comparator U1 The input terminal is connected to the inverting input terminal of the second operational amplifier comparator U4 and connected to the reference power +VDD terminal, the output terminal of the first op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com