Stamping-resistant automobile die

An automobile mold and stamping-resistant technology, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the processing efficiency of automobile molds, poor pressure-resistant use effect, and poor stamping effect, and achieves a simple structure. , The effect of improving hardness and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

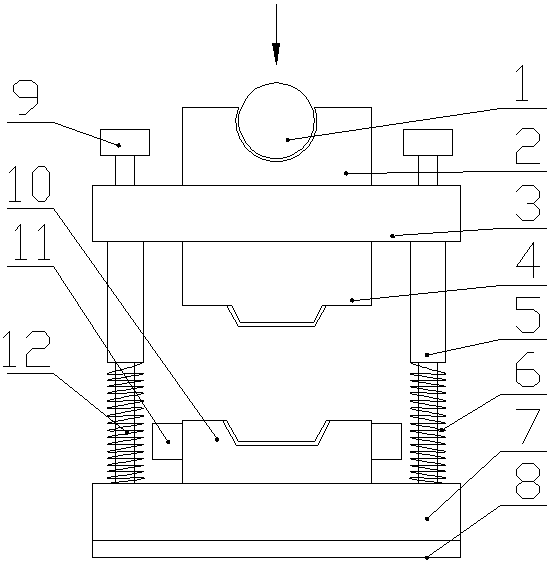

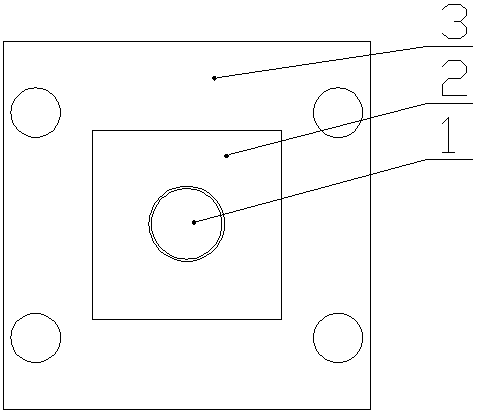

[0015] Such as figure 1 , figure 2 Shown, a kind of stamping-resistant automobile die, it comprises upper mold base 3 and lower mold base 7, the upper end surface of described lower mold base 7 is provided with die 10, and the lower end surface of described lower mold base 7 is provided with There is a rubber pressure-resistant layer 8, the concave die 10 is provided with a stripping plate 11, the four corners of the lower mold base 7 are provided with guide posts 12, and the buffer springs 6 are sleeved on the guide posts 12 , the top of the guide post 12 is provided with a guide post groove 5, the top of the guide post 12 is provided with a limit block 9, and the top of the guide post groove 5 is provided with an upper mold base 3, and the upper The lower end surface of the mold base 3 is provided with a punch 4 corresponding to the die 10, and the upper end surface of the lower mold base 7 is provided with a fixed column 2, and a balance sphere 1 is movably arranged in th...

Embodiment 2

[0018] Such as figure 1 , figure 2 Shown, a kind of stamping-resistant automobile die, it comprises upper mold base 3 and lower mold base 7, the upper end surface of described lower mold base 7 is provided with die 10, and the lower end surface of described lower mold base 7 is provided with There is a rubber pressure-resistant layer 8, the concave die 10 is provided with a stripping plate 11, the four corners of the lower mold base 7 are provided with guide posts 12, and the buffer springs 6 are sleeved on the guide posts 12 , the top of the guide post 12 is provided with a guide post groove 5, the top of the guide post 12 is provided with a limit block 9, and the top of the guide post groove 5 is provided with an upper mold base 3, and the upper The lower end surface of the mold base 3 is provided with a punch 4 corresponding to the die 10, the upper end surface of the lower mold base 7 is provided with a fixed column 2, and a balance sphere 1 is movable in the fixed colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com