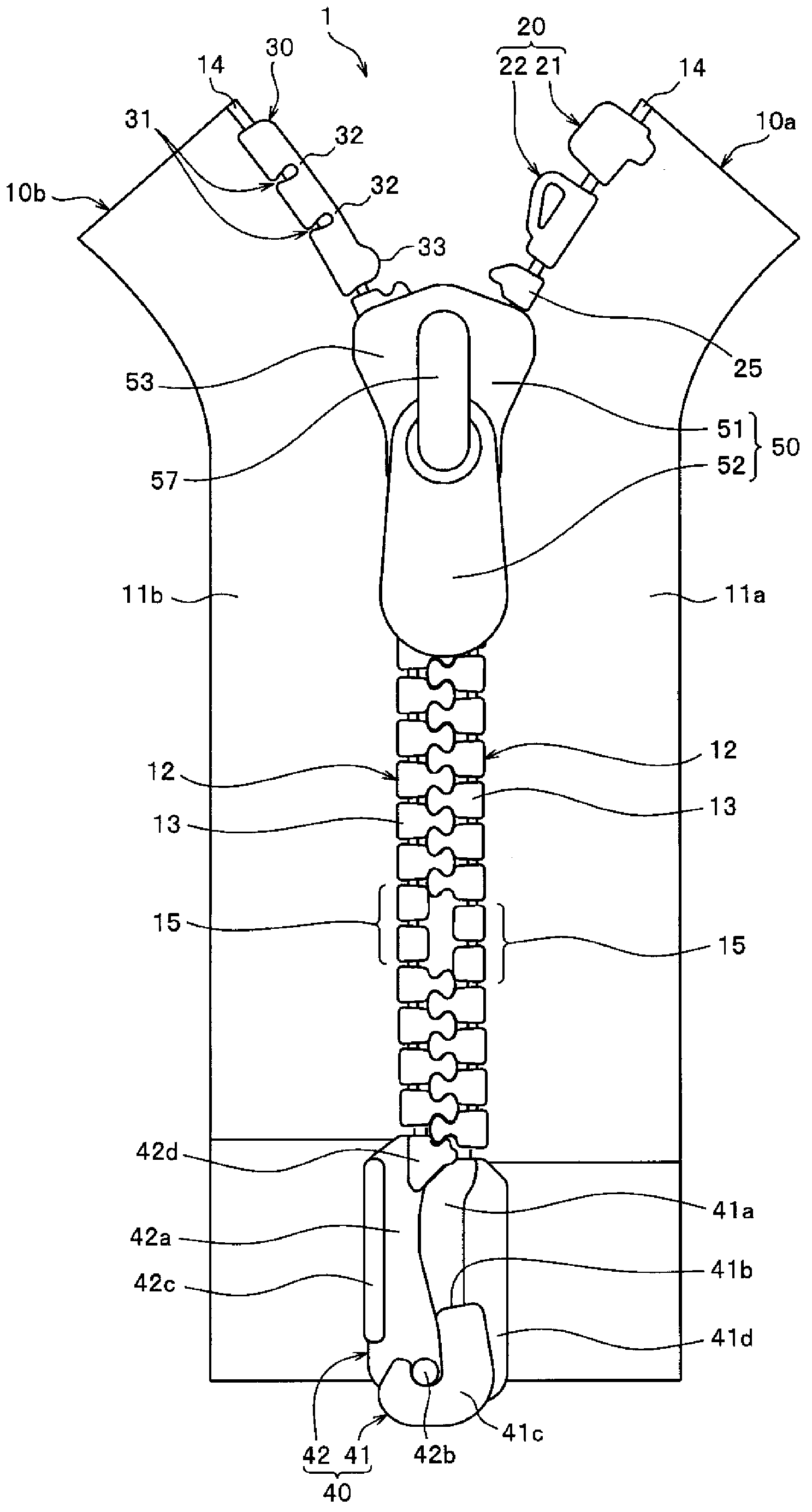

Slide fastener

A technology of zipper and zipper teeth, applied in the field of zipper, can solve the problems such as low fixing strength of the front-end chain teeth chain 92, falling off of the front-end chain teeth 93a, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

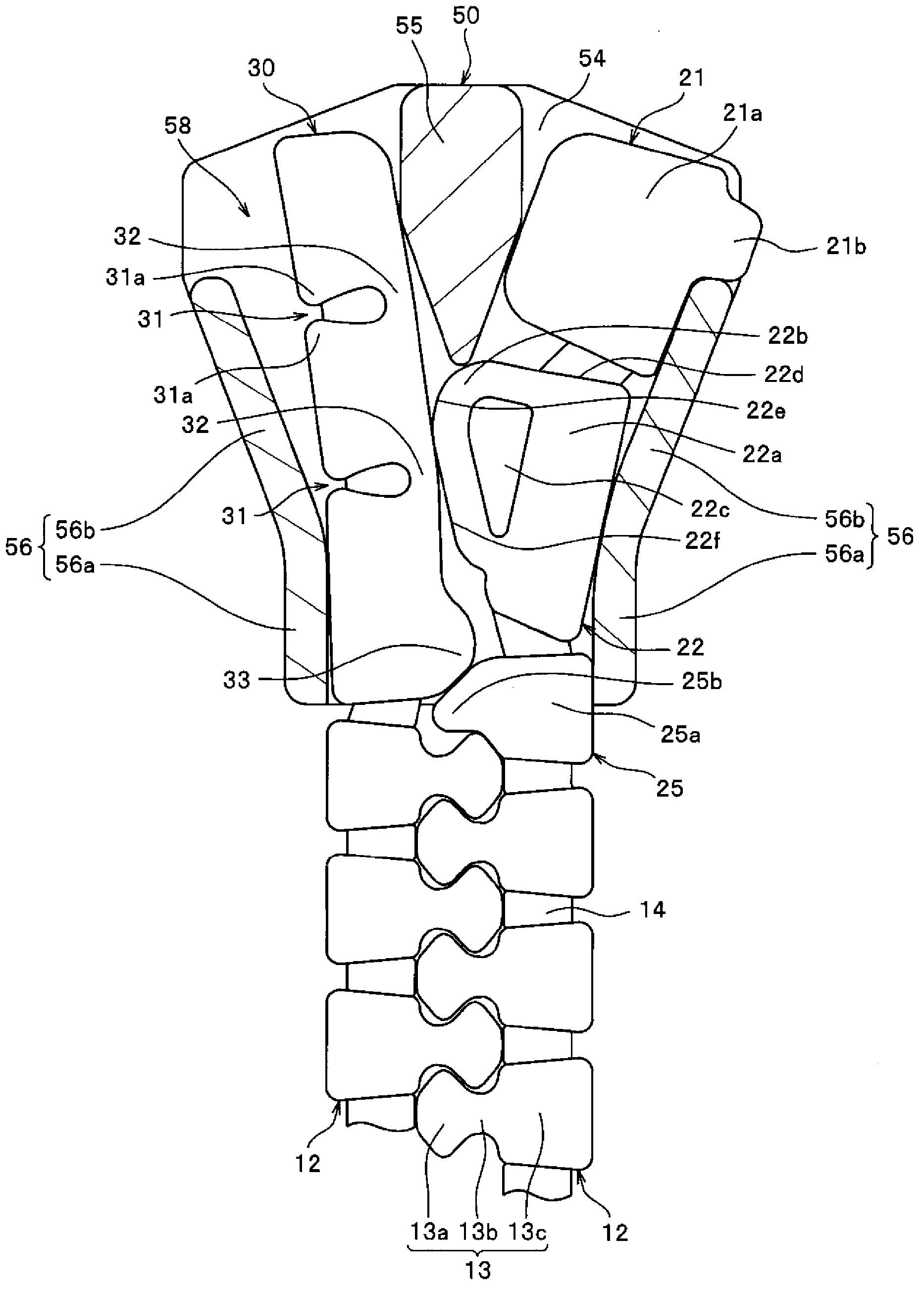

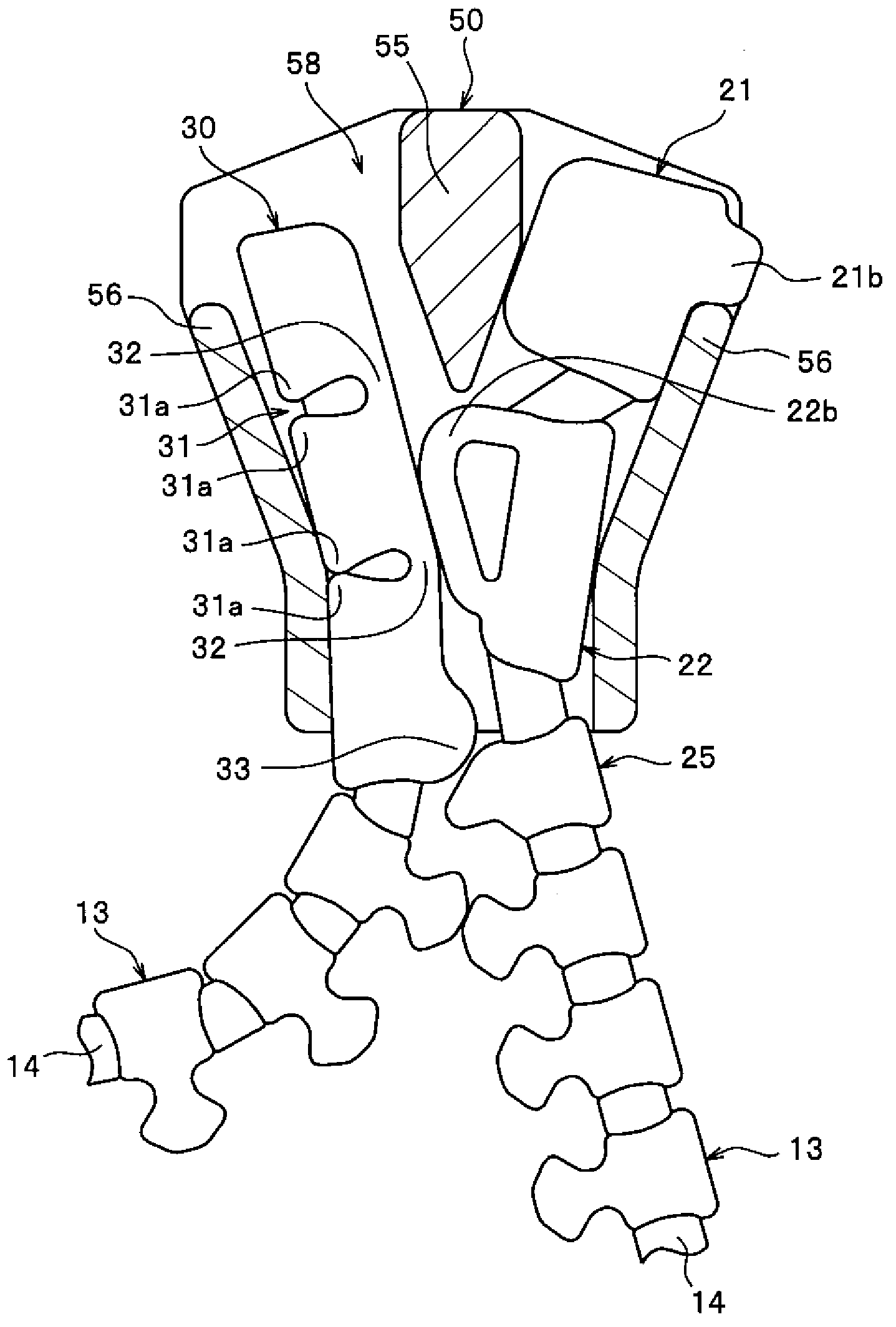

[0091] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, the present invention is not limited to the embodiment described below at all, and various changes can be made as long as it has substantially the same configuration as the present invention and can obtain the same effects as the present invention.

[0092] For example, in the following embodiments, the stopper is arranged on the fastener chain on the right side, and the lateral detachment prevention part is arranged on the left fastener chain to form a slide fastener. However, in the present invention, the fastener chain on the right side may be The fastener chain is provided with a lateral detachment preventing portion, and a stopper is provided on the left fastener chain to form a slide fastener.

[0093] In addition, in the case of the slide fastener of the present invention, the left and right element rows may be composed of a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com