Multifunctional laser processing tool bit with measuring apparatus

A technology of laser processing and measuring device, applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problem of single function of laser processing equipment, and achieve the effect of wide application range, high cost performance and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

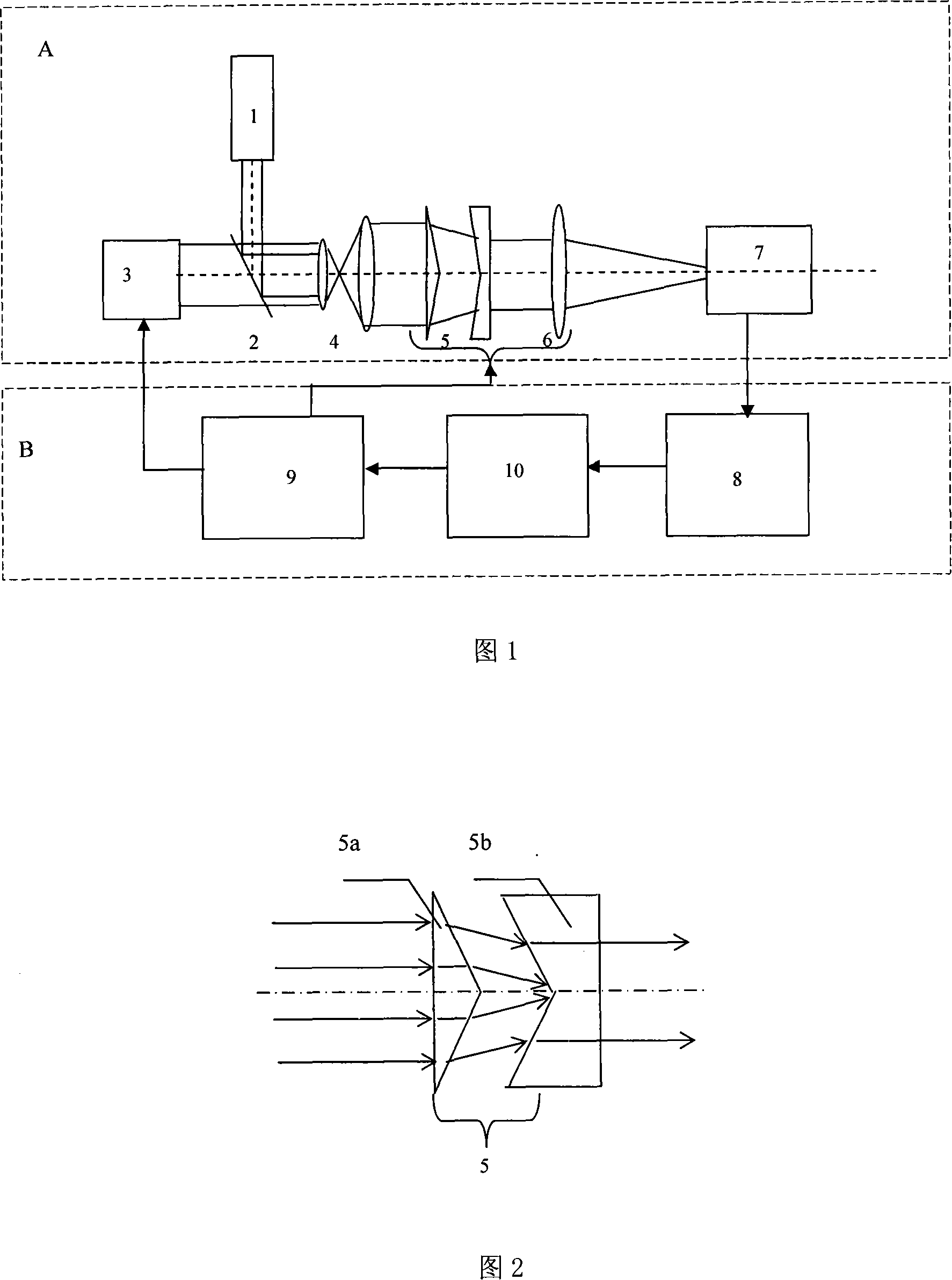

[0027] Referring to Fig. 1, the present invention includes an optical system A and an acquisition control processing device B. Optical system A is equipped with He-Ne laser 1, plane mirror 2 with both transmission and reflection functions, CO 2 Laser 3 , beam expander collimator 4 , positive rotation prism and negative rotation prism 5 and focusing lens 6 . The laser beam emitted by the He-Ne laser 1 is coupled to the beam expander collimator 4 through the plane mirror 2 which has both transmission and reflection functions, and is used as an illumination and imaging light source for the pointing system and the information collection processor 8 . CO 2 After the laser beam emitted by the laser 3 passes through the beam expander and collimator 4, the divergence angle of the beam is reduced, and a laser beam meeting a suitable aperture size is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com