A flexible scraper

A sharpening and flexible technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as affecting the service life of equipment, scratches on the surface of workpieces, and low processing accuracy, and achieve good processing results. , The effect of smooth scraping and smooth processing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

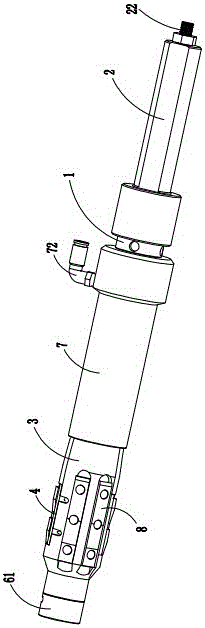

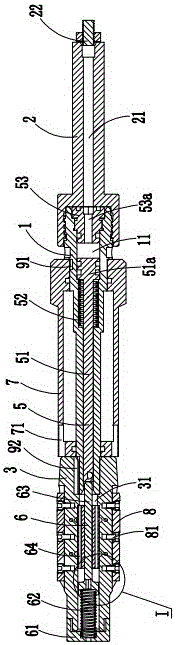

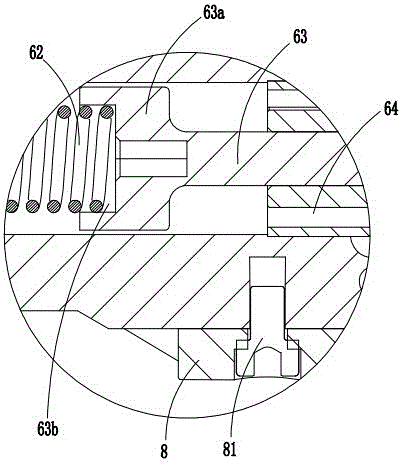

[0027] Such as Figure 1 to Figure 6 Shown is the structural representation of the present invention,

[0028] The reference signs are: main shaft 1, first through hole 11, knife handle 2, third through hole 21, hydraulic inlet 22, scraper head 3, second through hole 31, floating blade group 4, knife block 41, rough Scraper blade 42, fine scraper blade 43, cushion block 44, ejector rod mechanism 5, hydraulic ejector rod 51, stop head 51a, ejector rod spring 52, hydraulic plug 53, hydraulic hole 53a, blade adjustment mechanism 6, adjustment head 61, Adjusting spring 62, adjusting rod 63, support head 63a, groove 63b, adjusting core 64, cooling chip removal sleeve 7, punching chip hole 71, coolant pipe 72, guide bar 8, screw 81, first flat key 91, The second flat key 92.

[0029] Such as Figure 1 to Figure 6 as shown,

[0030] A flexible s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com