Patents

Literature

234results about How to "Extend cleaning time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

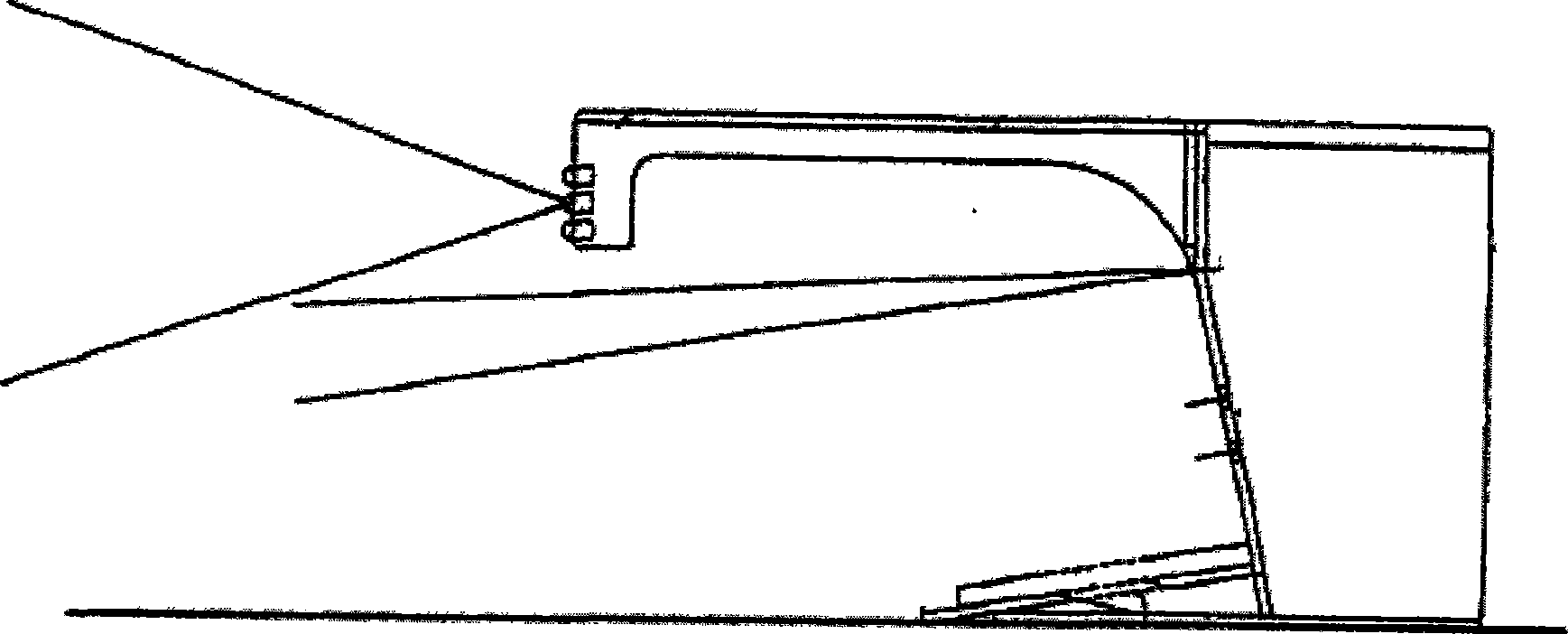

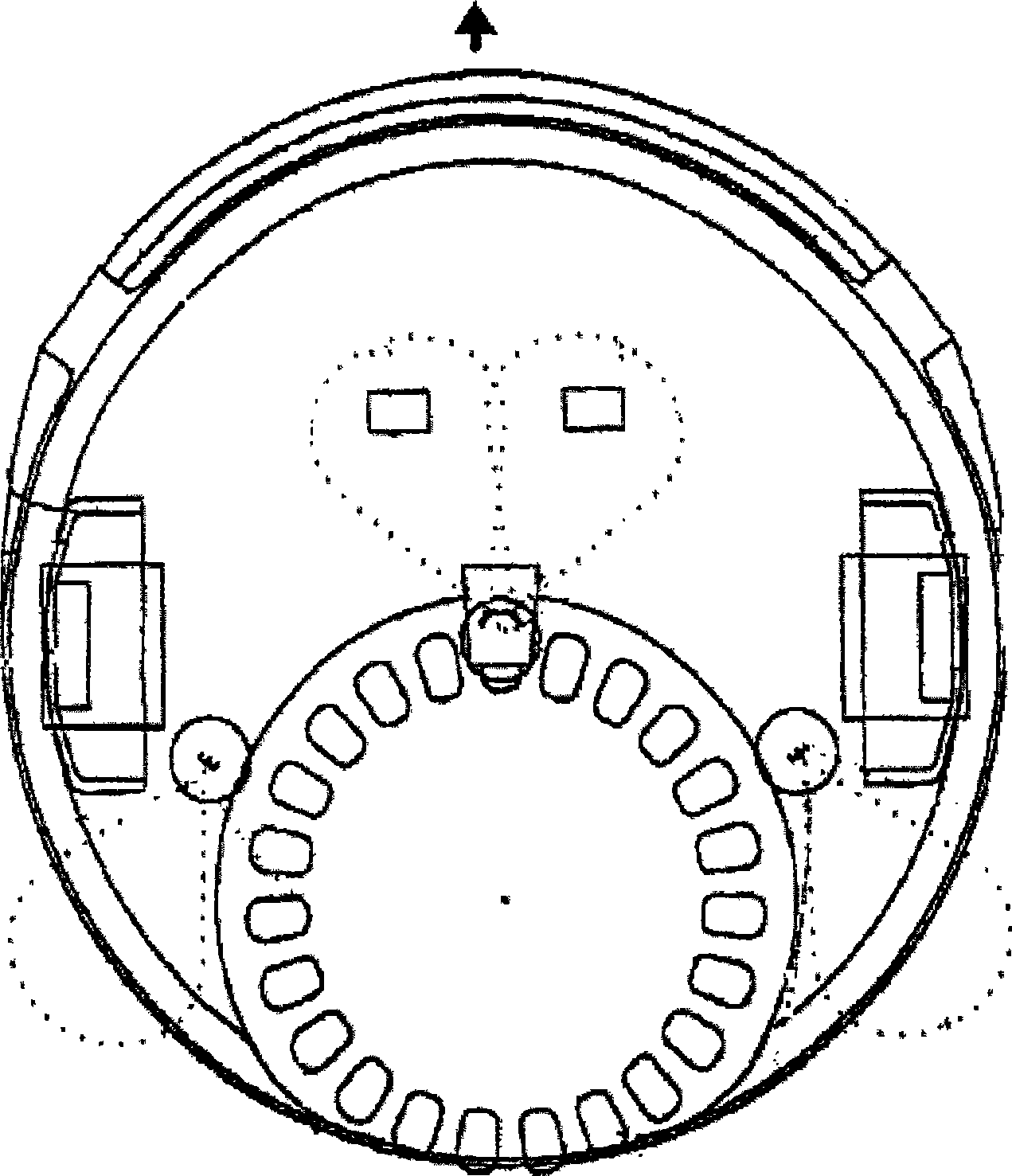

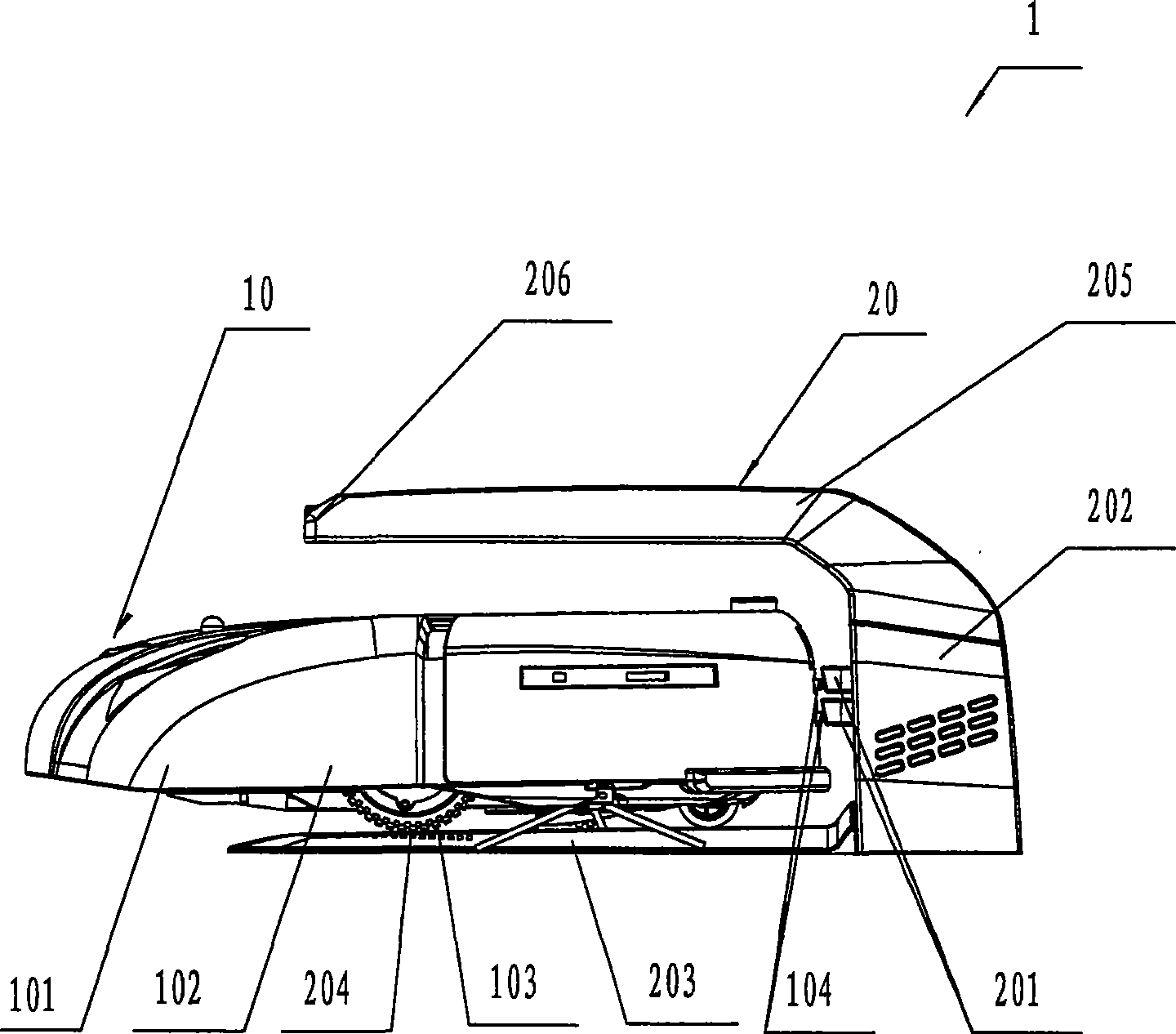

Ground processing system and method for contacting joint of ground processing equipment and charging stand

InactiveCN101375781AEasy to implement docking functionLow costCarpet cleanersFloor cleanersEnergy supplyEngineering

The invention relates to a ground handling system including an automatic moving ground handling device and a charger. The ground handling device is provided with a working mode and a charging mode and includes an energy supply unit and a control unit which can be charged repeatedly. When the electric quantity of the energy supply unit is lower than a preset value, the ground handling device is changed into the charging mode from the working mode through the control unit. The charger is used for charging the energy supply unit and is equipped with a signal emission device. A directional receiver and an omnidirectional receiver for receiving the signals emitted by the signal emission device are arranged at the front end and the top part of the ground handling device, and enable the ground handling device to automatic return to the charger for charging in the charging mode. The invention shortens the time of abutting joint and charging of the ground handling device, thereby prolong the efficient working time thereof and improving the working efficiency.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

Magnetic induction type dust-fall road barrier

ActiveCN110359391AMaintain humidityEasy to solveUsing liquid separation agentTraffic signalsWater storageInlet channel

The invention discloses a magnetic induction type dust-fall road barrier. The road barrier comprises a barrier body, wherein a counterweight base is fixedly connected to the bottom end of the barrierbody, a motion cavity, a weight reducing cavity and a water storage cavity are sequentially formed in the barrier body from top to bottom, and a partition plate is fixedly connected to the inner wallof the moving cavity in a sealed mode. The road barrier has the advantages that magnetic attraction force generated by a ferromagnet on a shell of a vehicle is converted into reciprocating rectilinearmotion of an airtight piston in the motion cavity, gas in the motion cavity is pressurized into a pressurizing cavity through a one-way pressurizing channel, outside gas is automatically supplementedto the motion cavity through a one-way air inlet channel until the gas pressure inside the pressurizing cavity reaches a preset pressure value of a pressure valve, and then the pressure valve automatically opens, water in a capillary tube is torn to form water mist by utilizing a high-pressure gas flow, so that the dust falling operation to a road is completed, in addition, the road is maintained, dust humidity on the road can be kept for a long time, the possibility that dust is lifted again after the dust is dried, and dust cleaning time is prolonged to a sanitation worker is avoided.

Owner:湖州欣盾智能机械有限公司

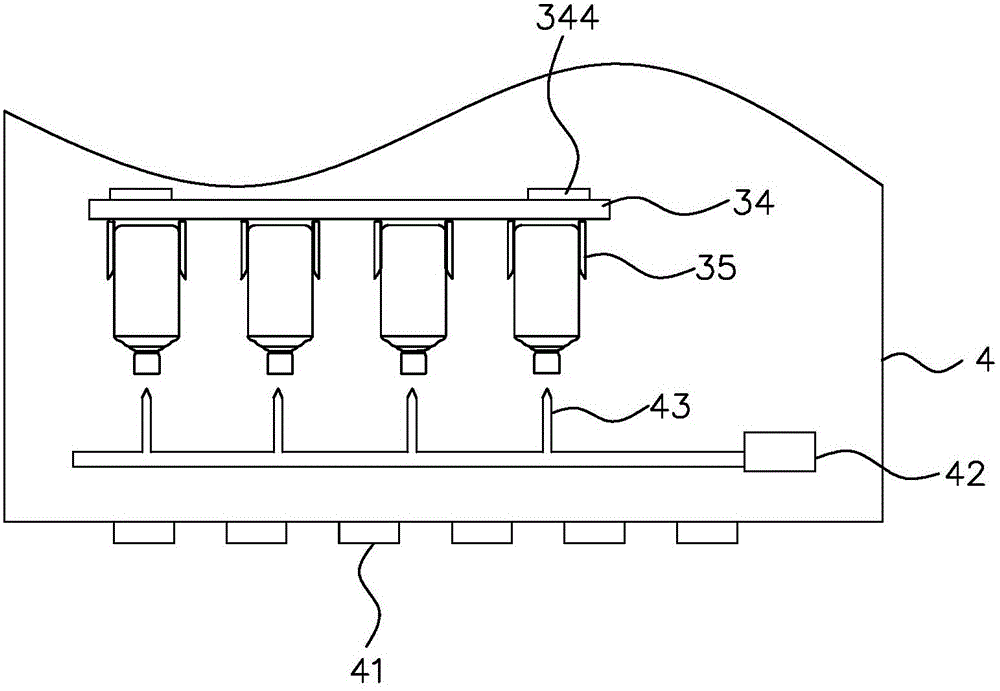

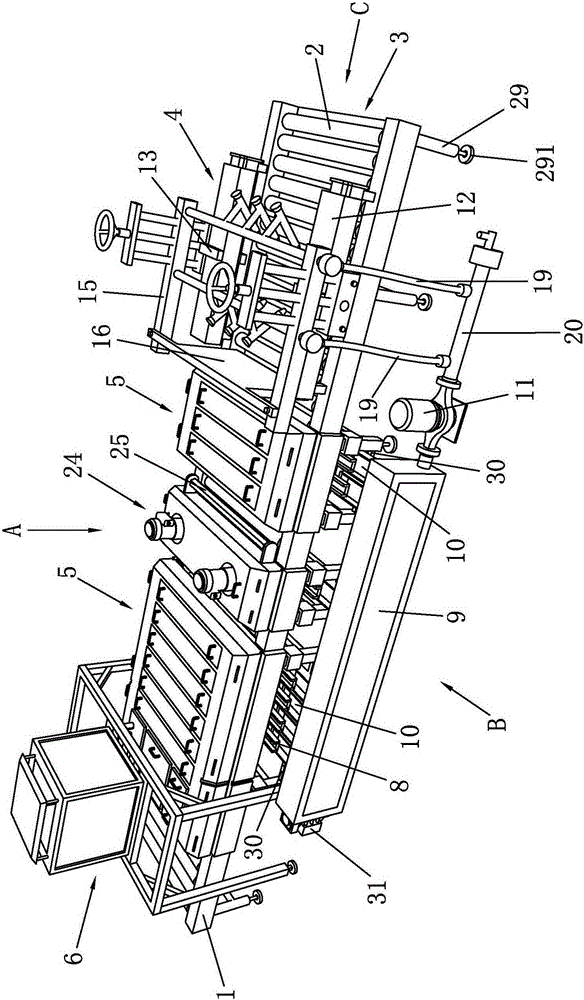

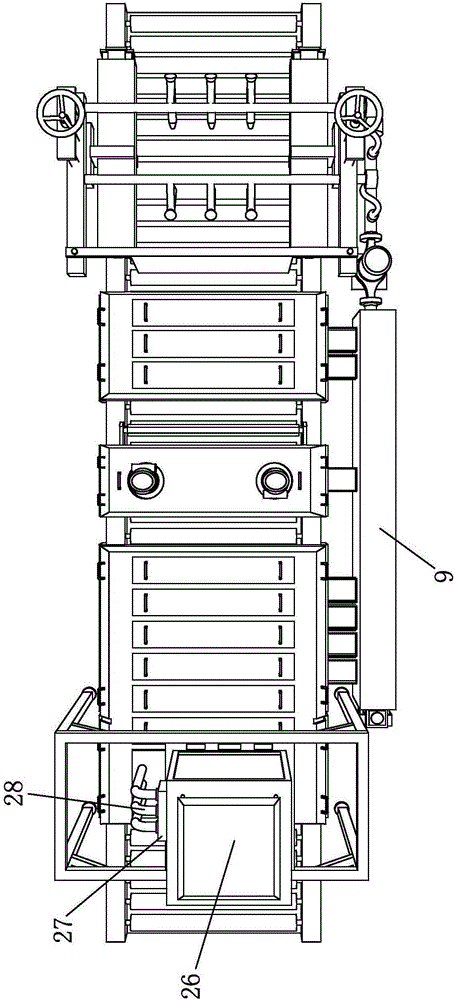

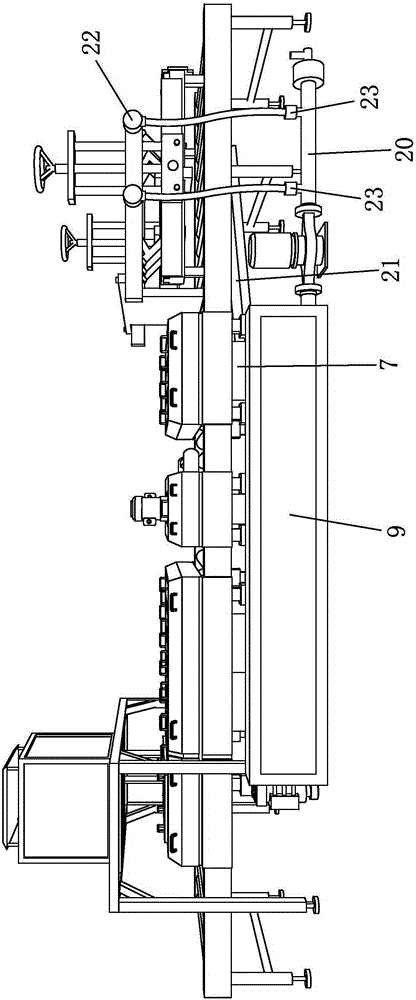

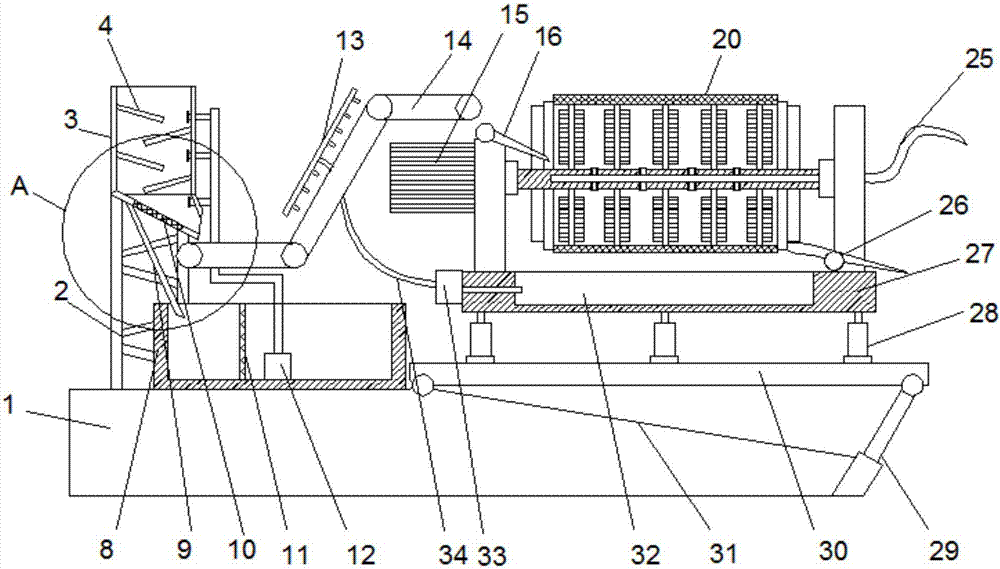

Winebottle cleaning device

ActiveCN105149307AShorten cleaning timeExtend cleaning timeHollow article cleaningCleaning using liquidsEngineeringMechanical engineering

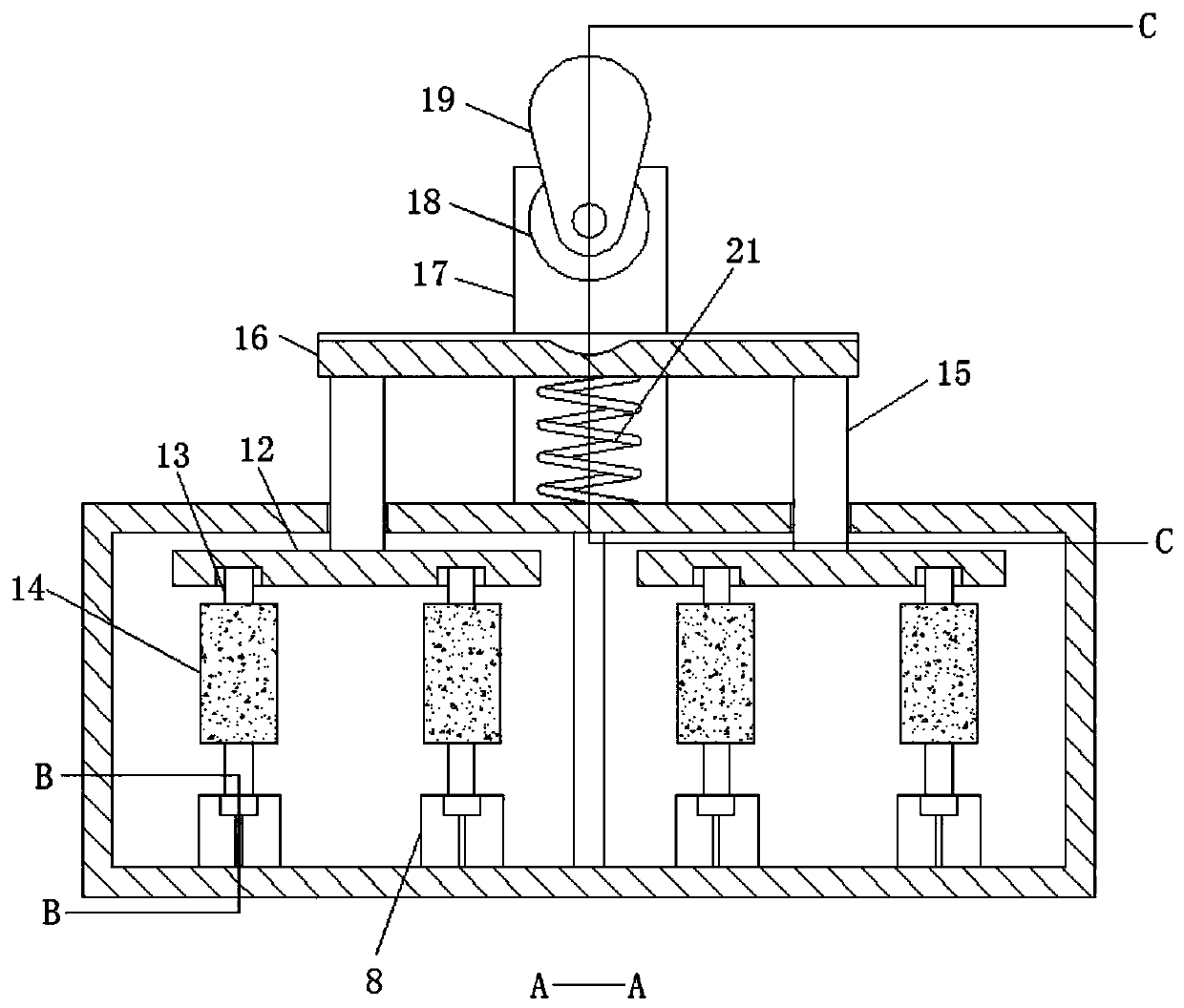

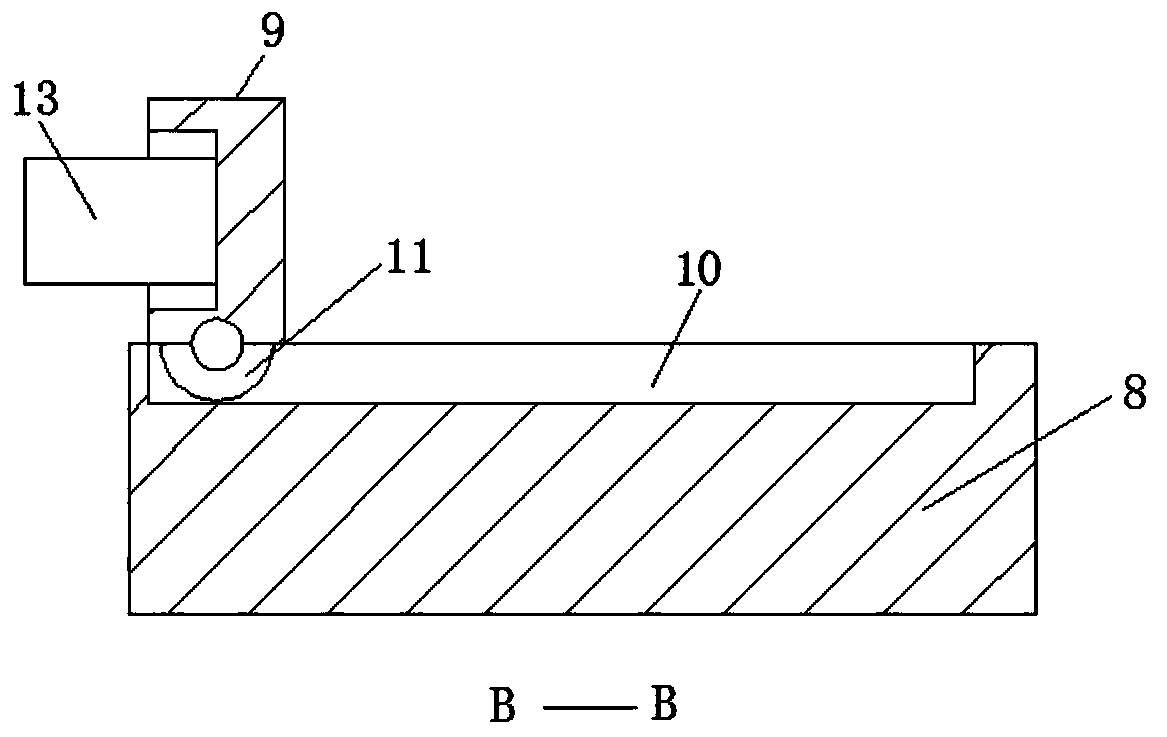

The invention provides a winebottle cleaning device. The winebottle cleaning device comprises a rack, two rotary conveying belts and a picking device, a cleaning tank, a water draining tank, an evaporating box, a drying box, a sterilizing chamber, a winebottle pushing device and a driving device which are sequentially arranged on the rack; the picking device comprises a picking air cylinder, suction cups, a vacuumizing device and multiple fixing blocks, the rear sides of all the fixing blocks are arranged on the rotary conveying belts in a pivoted mode along the two transverse ends of the fixing blocks, each fixing block is provided with three to five clamping heads used for tightly clamping winebottles, and a suction cup abdication hole is formed in the portion, corresponding to the middle of each clamping head, of the corresponding fixing block; the picking air cylinder is arranged on the rack, the suction cups of which the number corresponds to that of the clamping heads are arranged on a piston rod of the picking air cylinder side by side, the vacuumizing device is arranged on the rack, and all the suction cups are communicated with the vacuumizing device.

Owner:迁安市贯头山酒业有限公司

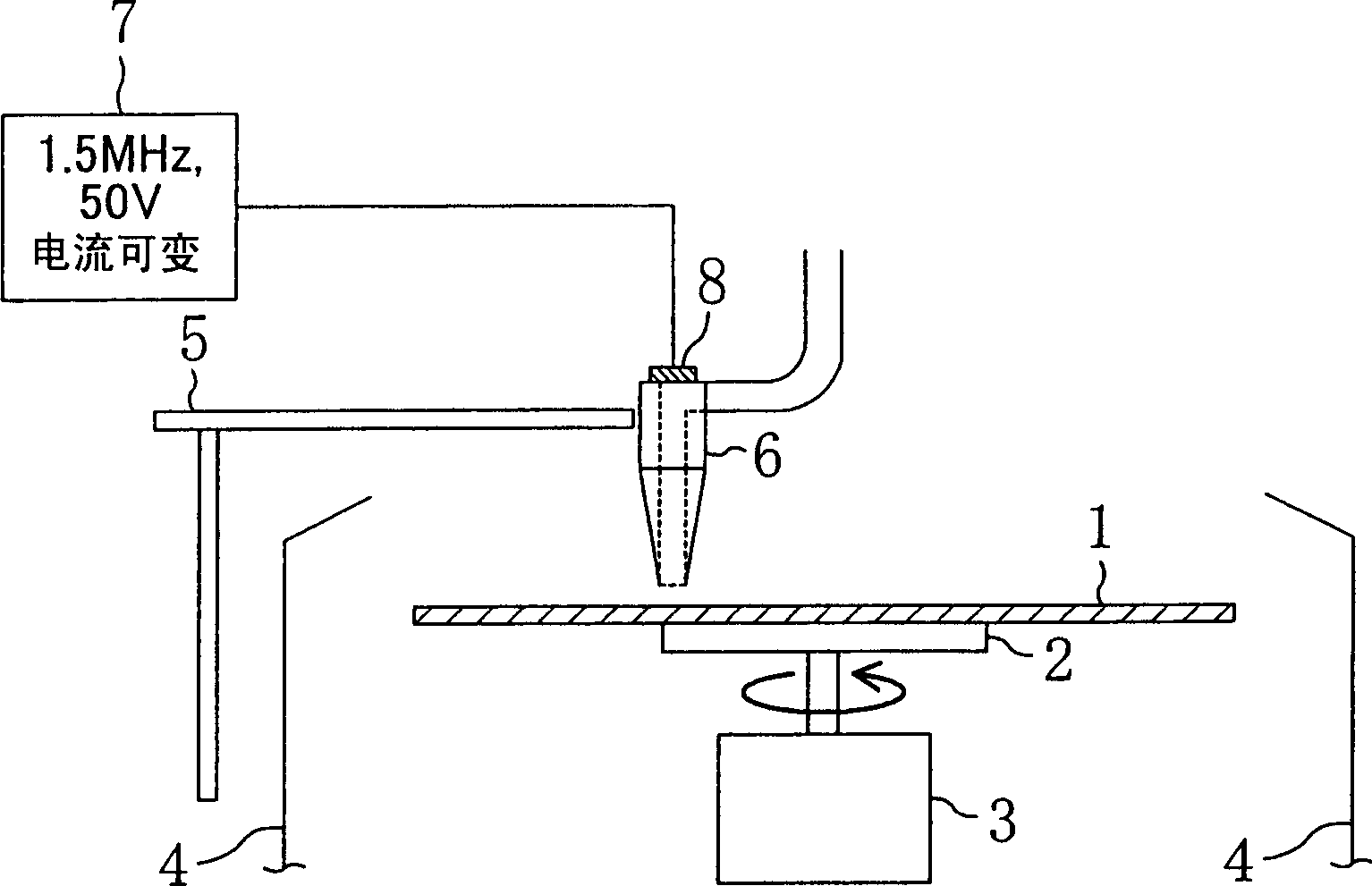

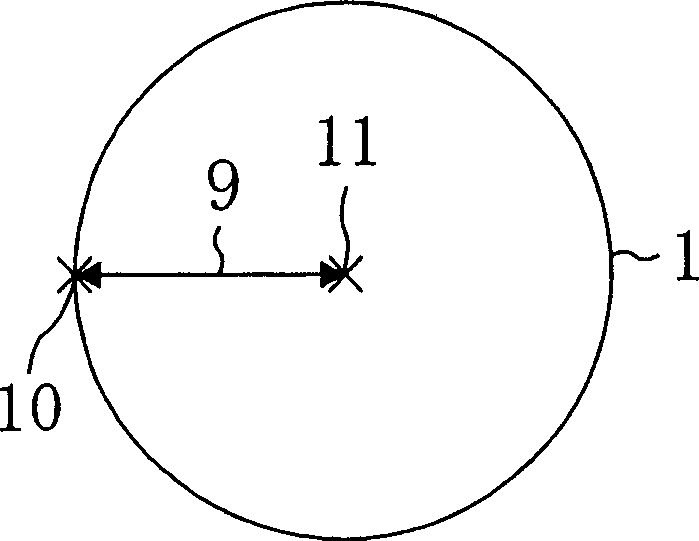

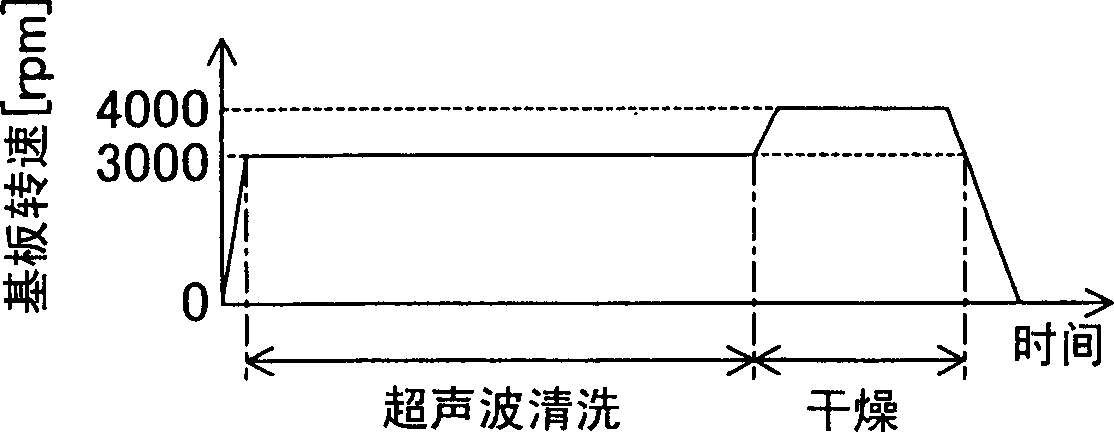

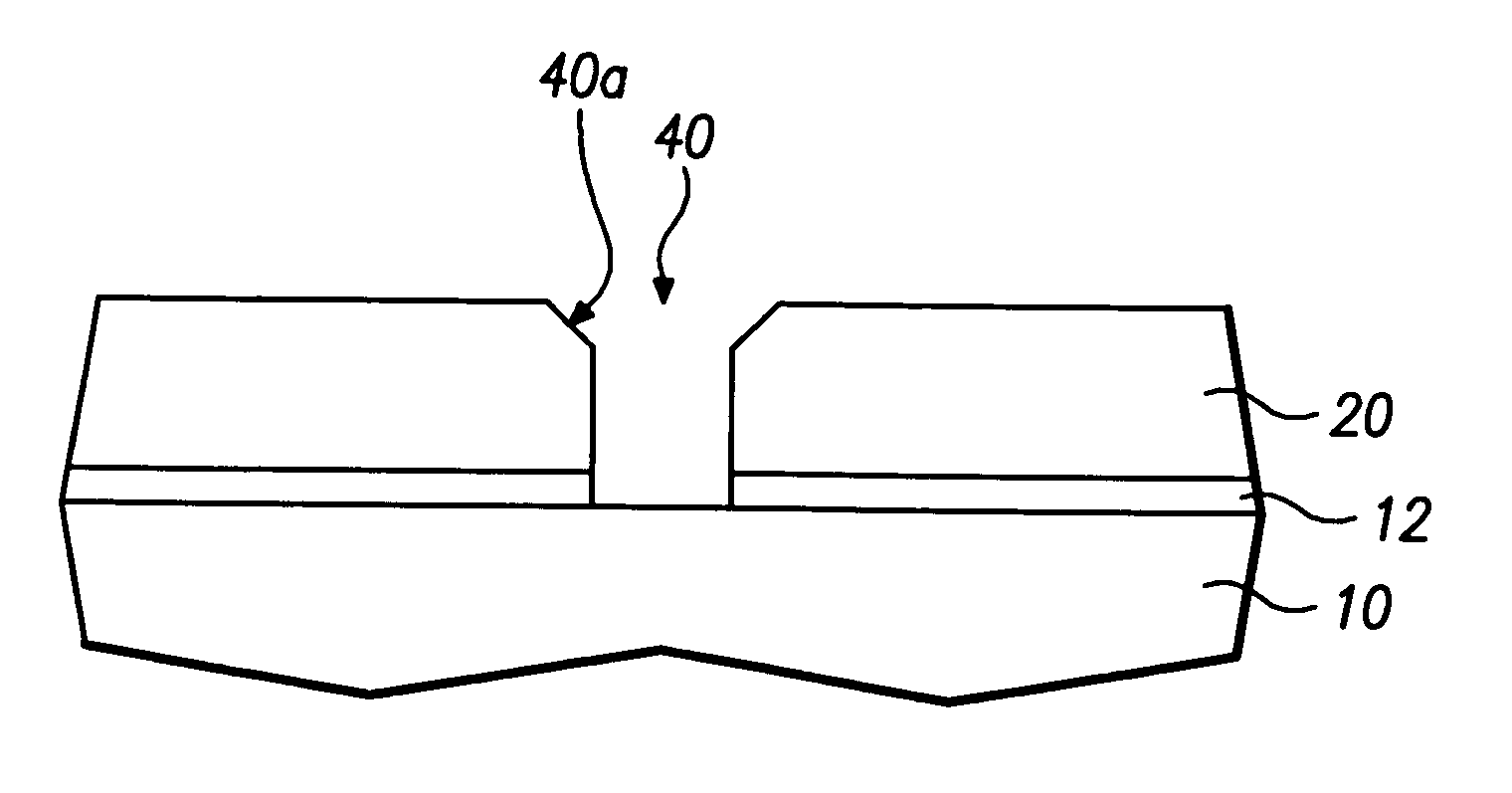

Method and device for washing base plate

InactiveCN1444256AIncrease the number of scansImprove clearanceSemiconductor/solid-state device manufacturingCleaning using liquidsForeign matterMegasonic cleaning

A substrate cleaning method and cleaning device, in which the substrate being ultrasonically cleaned is rotated at a speed of 2600 rpm or more and 3500 rpm or less. The substrate cleaning method and cleaning device can realize substrate cleaning that prevents production capacity from being reduced and device damage, and that can achieve a high foreign matter removal rate.

Owner:PANASONIC CORP

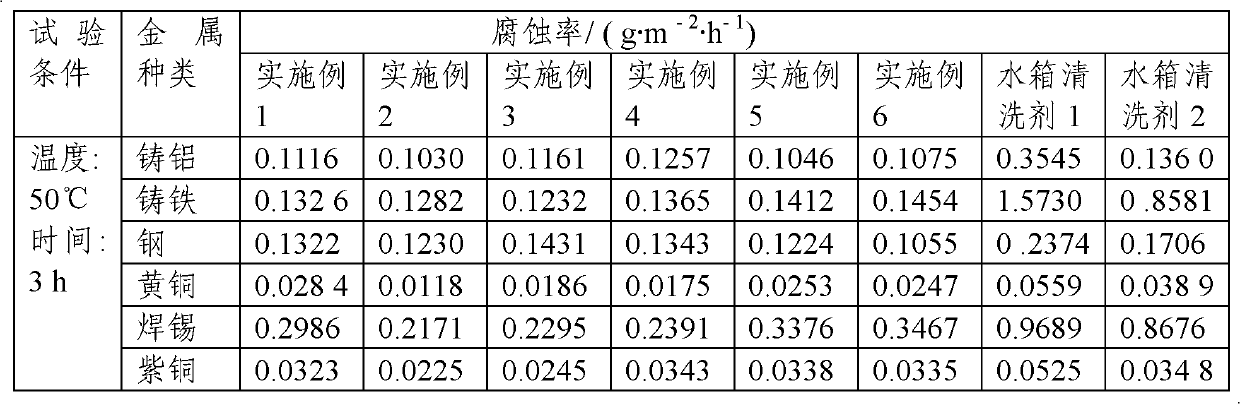

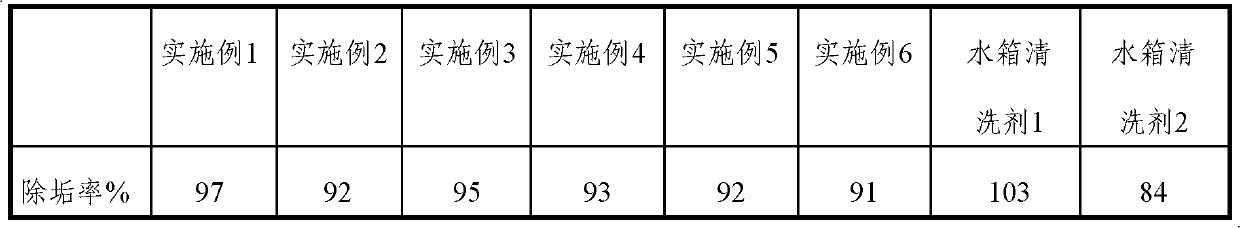

Cleaning agent for automobile cooling system

The invention provides a cleaning agent for an automobile cooling system. The cleaning agent comprises, by weight, 3 to 20% of glycolic acid, 2 to 9% of citric acid, 2 to 10% of methanesulfonic acid, 1 to 10% of ammonium citrate, 0.5 to 7% of a corrosion inhibitor and 0.01 to 2% of a surfactant, with the balance being deionized water. The cleaning agent for the automobile cooling system in the invention can effectively remove calcium scale, magnesium scale and iron rust in the cooling system, is applicable to cleaning of a variety of materials like carbon steel, iron, copper and aluminum in a cooling system of an engine and has the advantages of high efficiency, mildness and a low corrosion rate. The cleaning agent is applicable to general repair and maintenance of an automobile and is used for removing dirt generated due to usage of water as a cooling medium so as to increase the efficiency of heat transfer between the engine and the cooling medium and enable operation of the engine to be smoother.

Owner:CHINA PETROLEUM & CHEM CORP

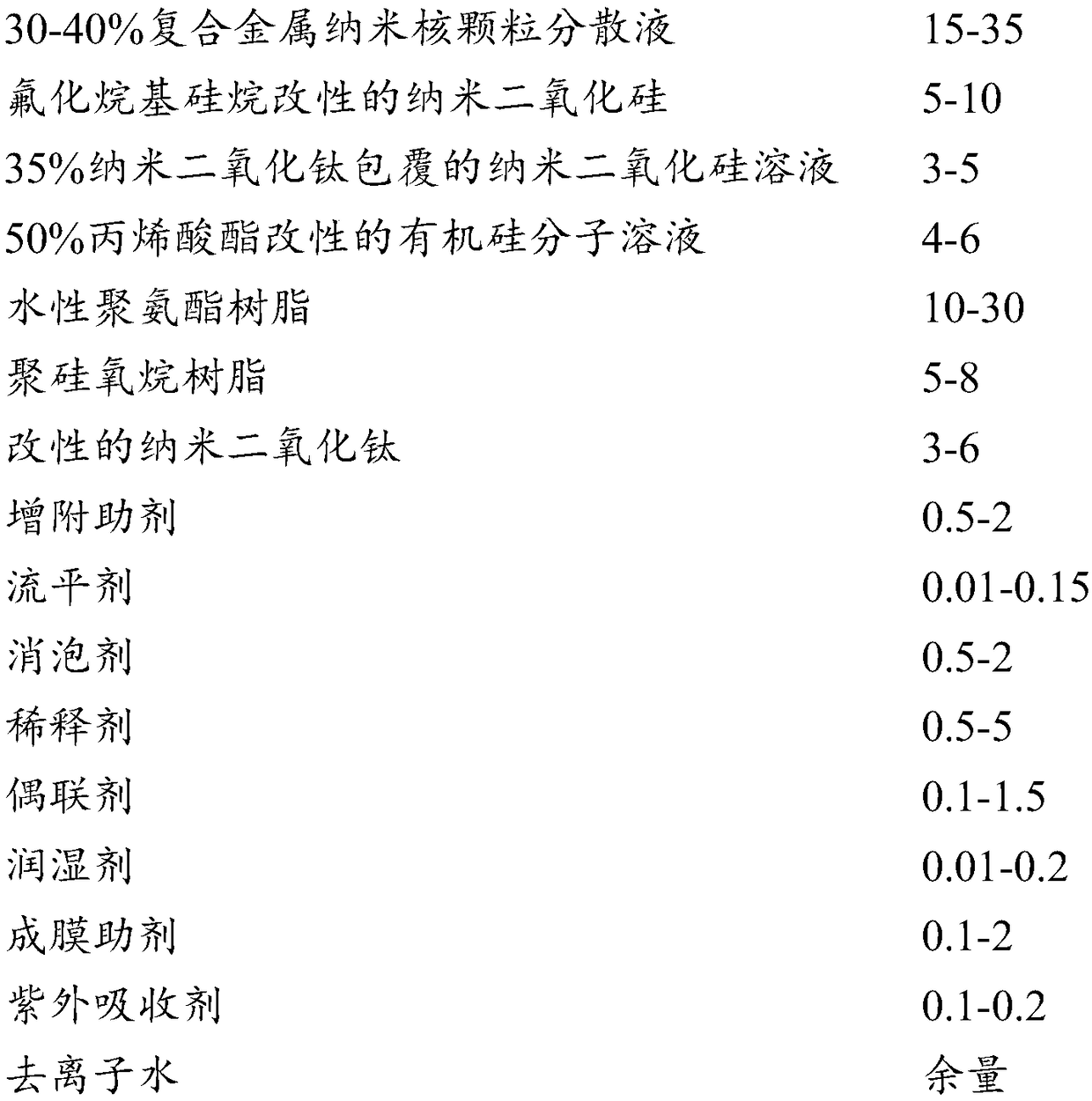

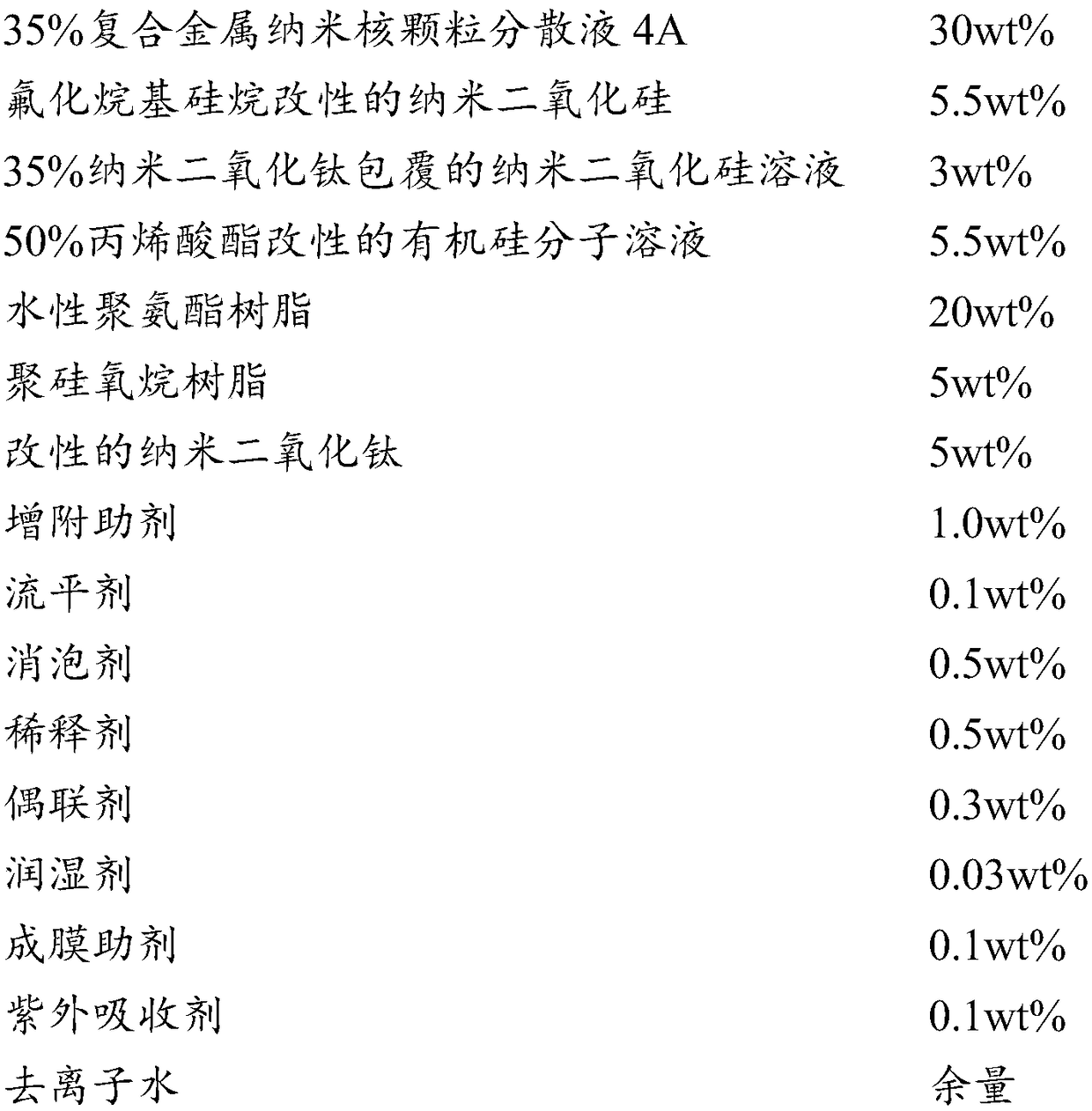

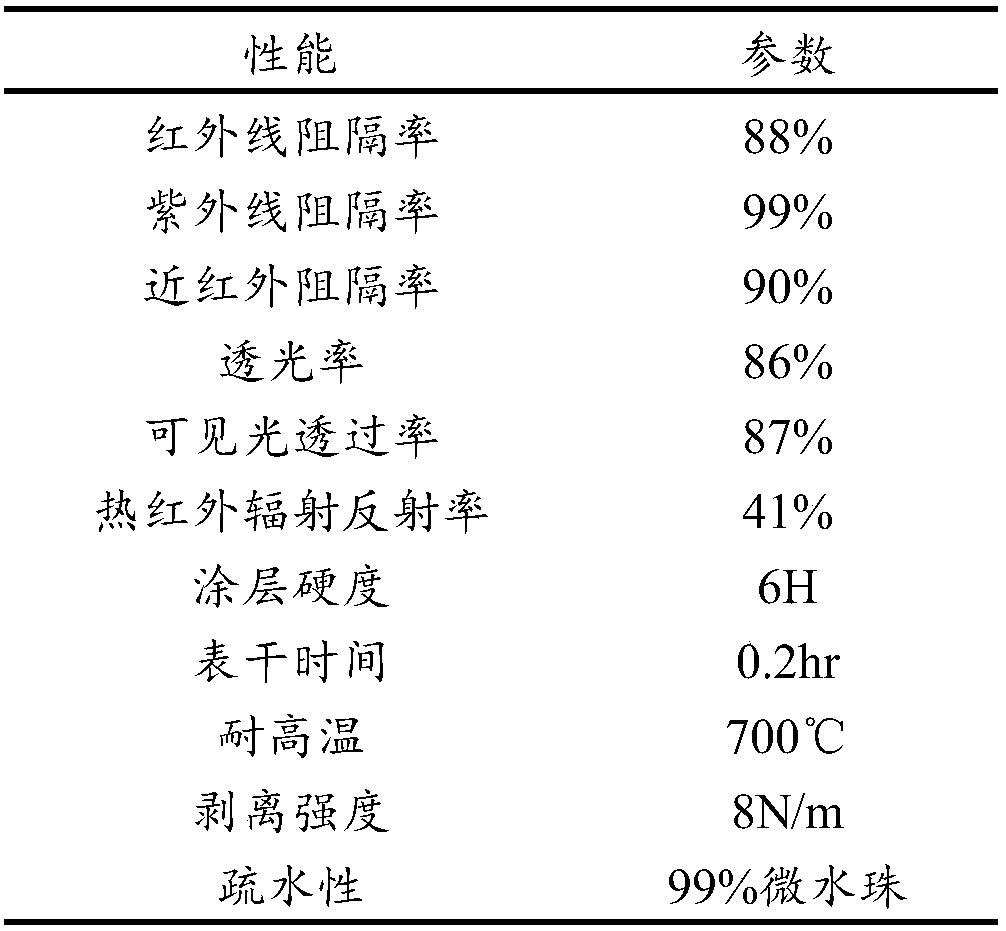

Waterborne glass nano-paint containing composite metal nanometer nuclear particles and preparation

InactiveCN108250928AImprove reflectivityGood light transmissionAntifouling/underwater paintsChemical industryAdjuvantResin composite

The invention relates to waterborne glass nano-paint containing composite nanometer nuclear particles and preparation. The paint is prepared from composite metal nanometer nuclear particles, nano-silicon dioxide modified by fluorinated alkyl silane, nano-silicon dioxide coated by nano-titania, organic silicon molecules modified by acrylic ester, modified nano-titania, waterborne polyurethane resin / polysiloxane resin composite resin, an additionally adsorbed adjuvant and other auxiliary ingredients. By certain modification and combination of composite nanometer nuclear particle ingredients andother ingredients, the performance of the paint is expanded, by mutual synergy between the ingredients, the coating material shows excellent properties, has excellent effects of high light transmitting performance, heat insulation performance, ultraviolet isolation / absorption performance, high adhesiveness, anti-aging stability, water dredging, dust prevention and self cleaning, and further has anintelligent energy-saving effect specific to environmental temperature.

Owner:深圳威耐纳米新材料科技有限公司

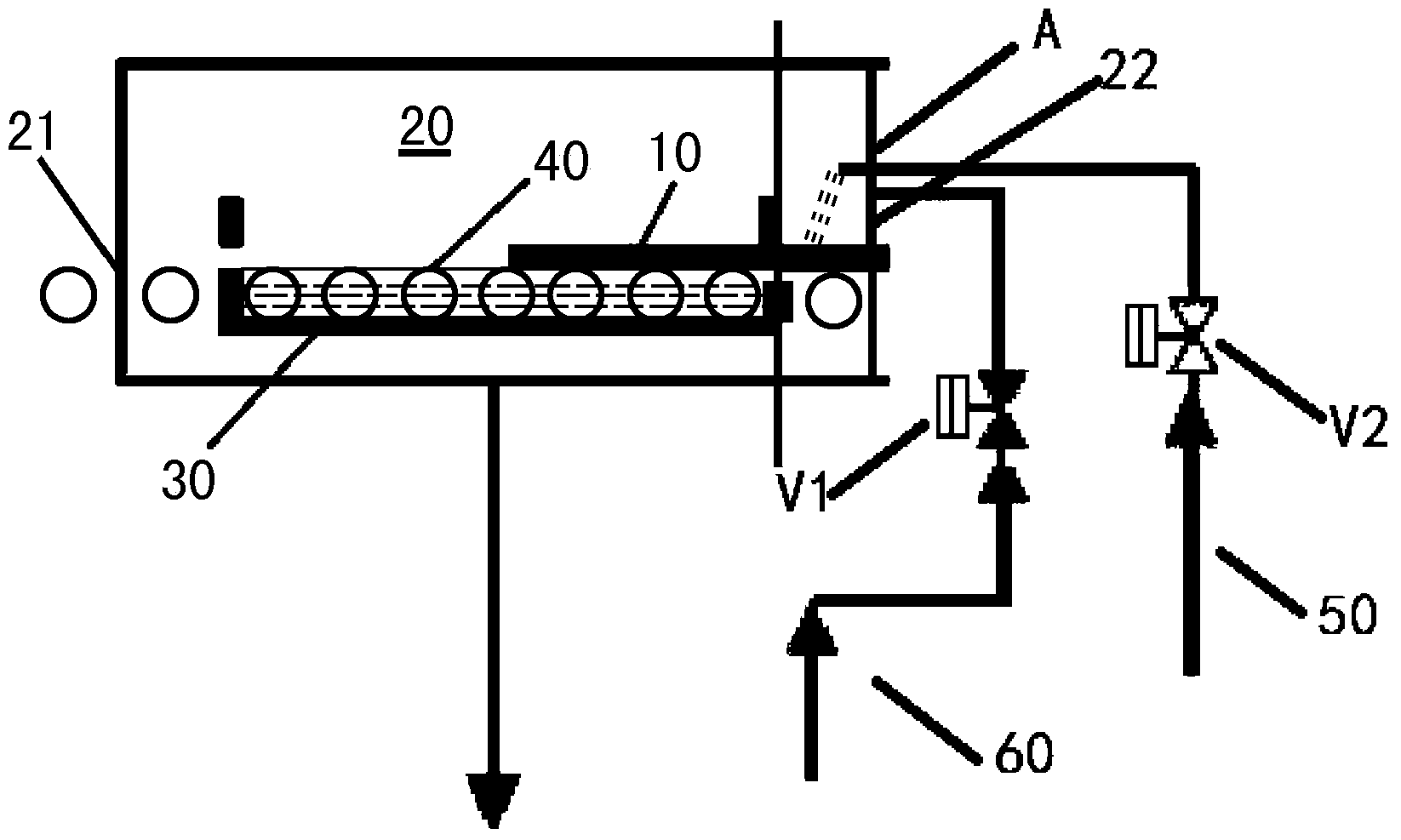

Integrated circulation glass washing device

InactiveCN105170525ACyclic stabilityPlay a purifying effectFlexible article cleaningCleaning using liquidsSpray nozzleCirculating pump

The invention discloses an integrated circulation glass washing device. The integrated circulation glass washing device comprises a base. A feeding section, a washing section, a rolling brush section and a drying section are arranged on the base. A water collector is arranged at the bottom of the rolling brush section. A liquid discharge device is arranged on the water collector. A water distribution device is arranged on one side of the base. A collection device is arranged on the water distribution device which is connected with a circulation pump. The washing section comprises a water inlet pipe and spray nozzles arranged on the water inlet pipe. The water inlet pipe is arranged on a sliding base. A hose is arranged on the water inlet pipe. One end of the circulation pump is connected with a pipeline which is connected with the hose. A filter device is arranged on the base and arranged below the washing section. The filter device is connected with the water collector in an inclined manner. The washing process is conducted by recycling cleaning fluid, and cost is reduced; meanwhile, the spraying angle and height of the spray nozzles are regulated according to glass thickness, the spray nozzles repeatedly wash glass, the glass washing time is prolonged, dirt firmly bonded is washed away, and the washing effect is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

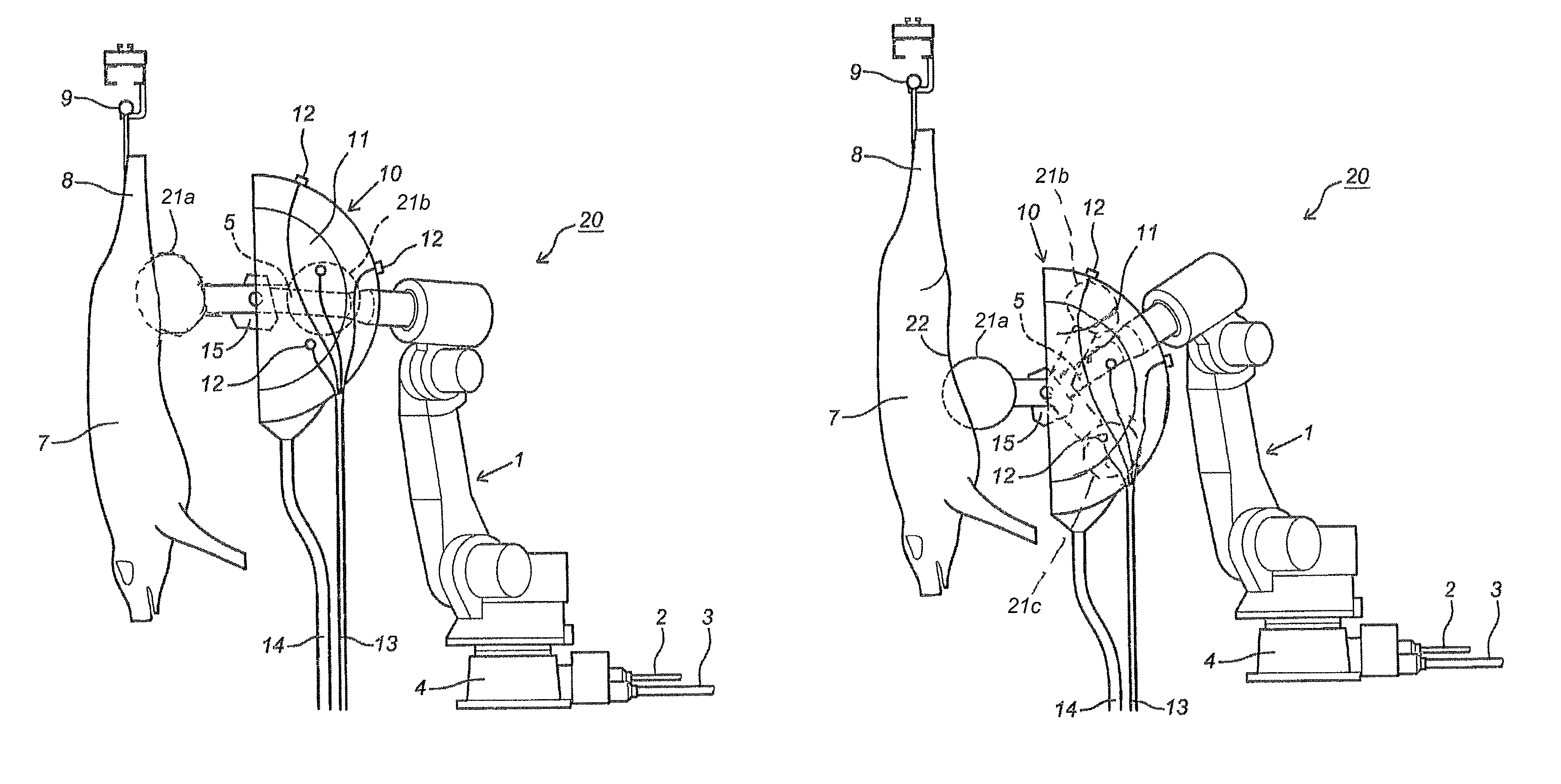

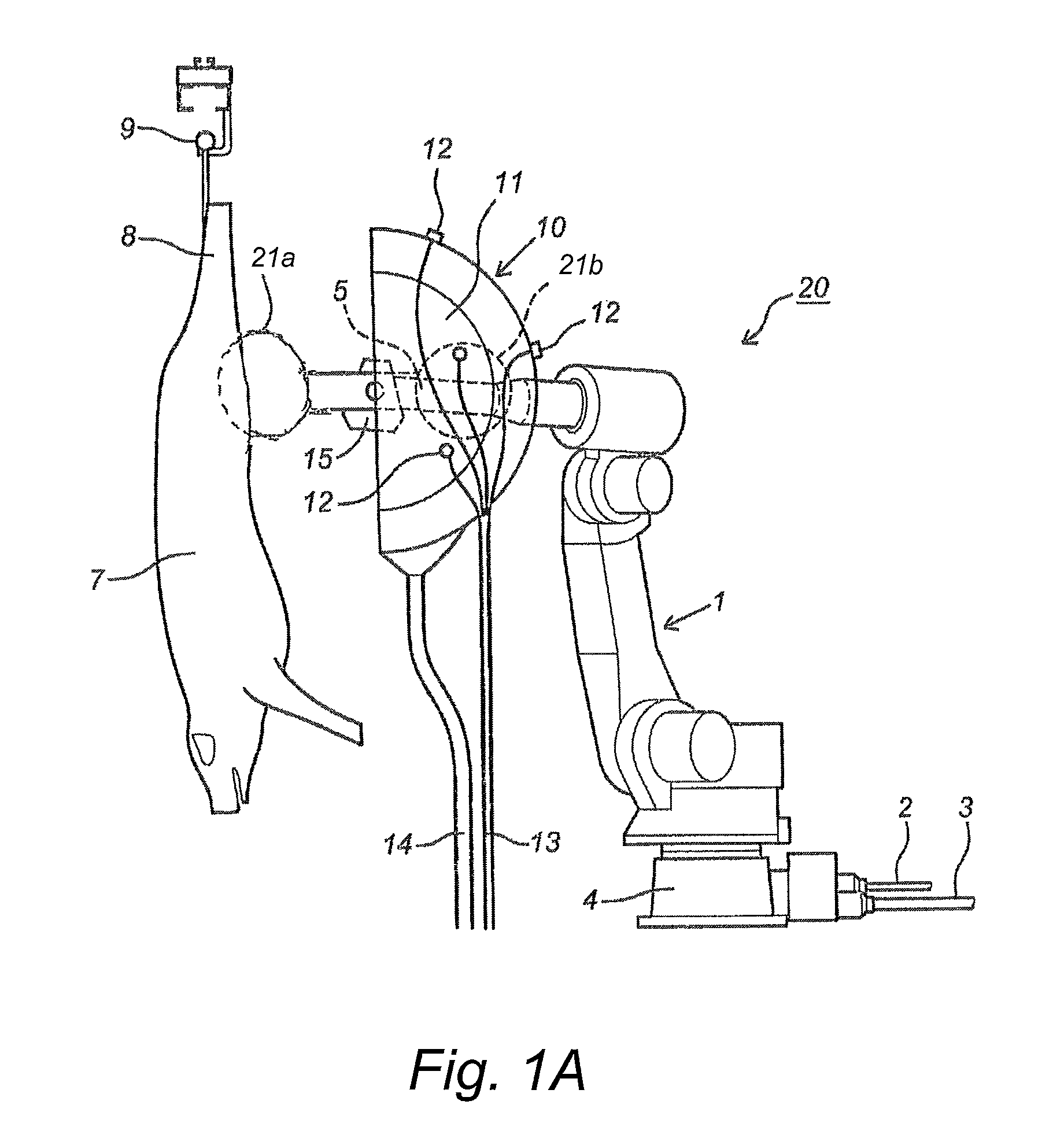

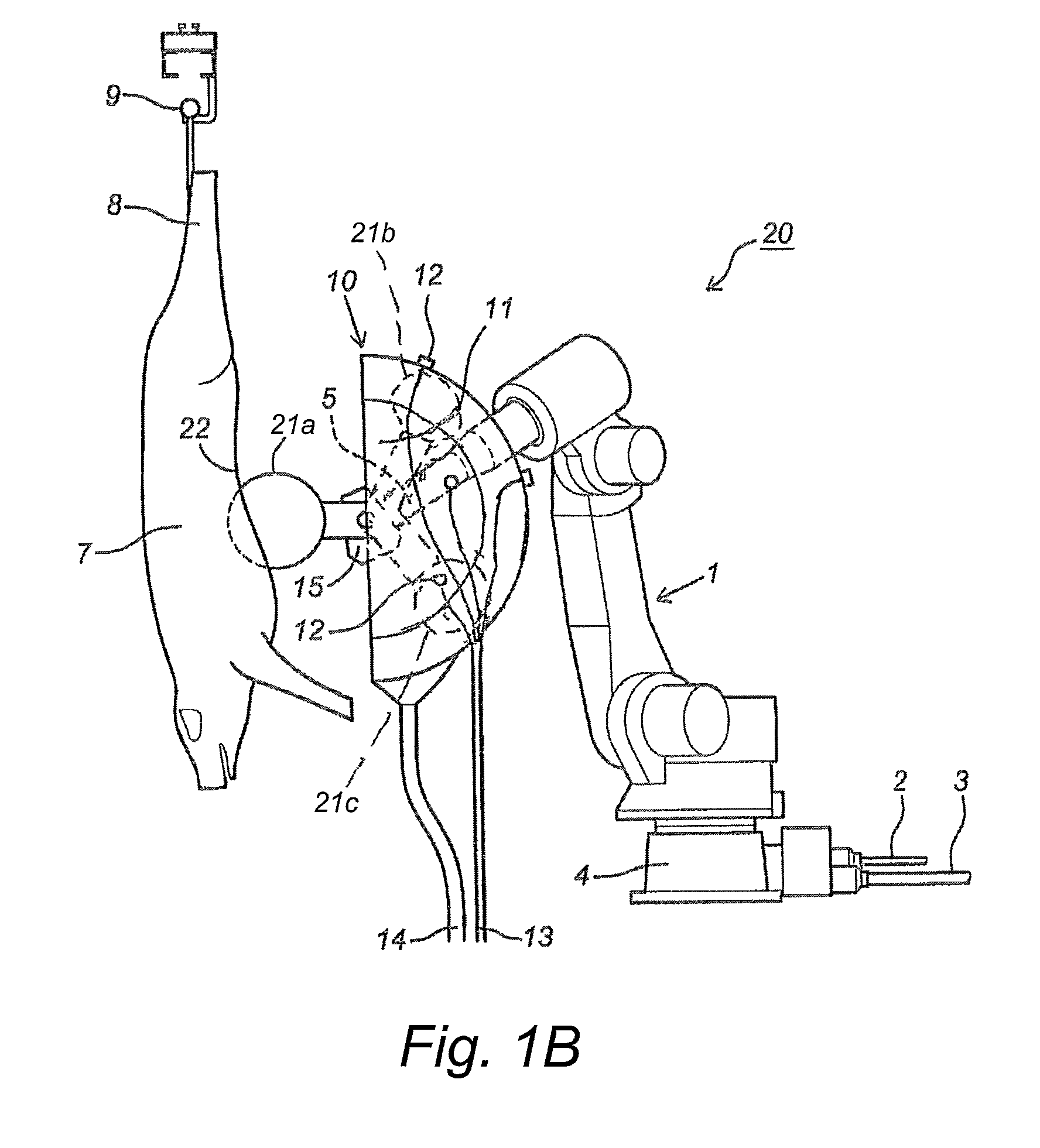

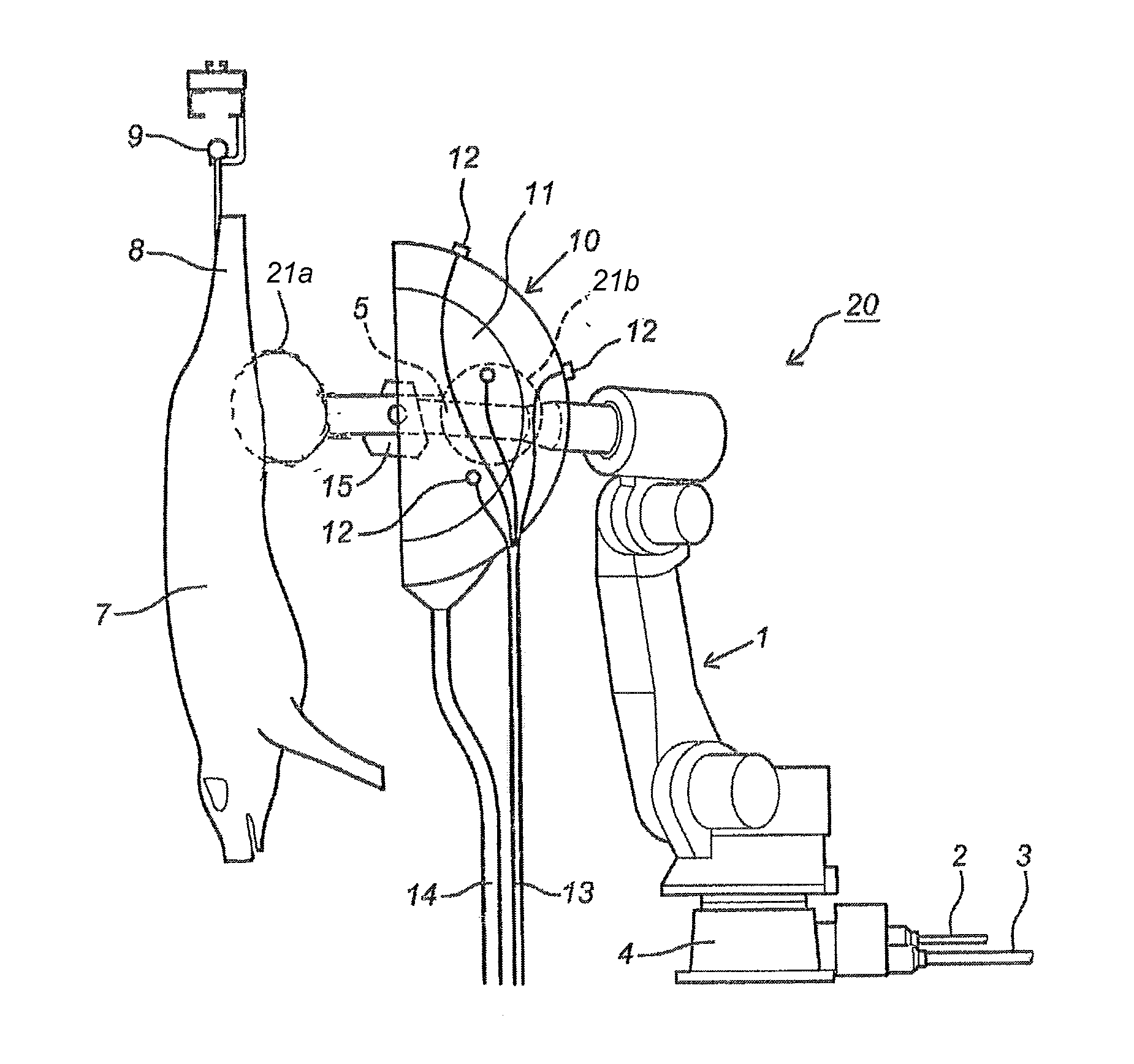

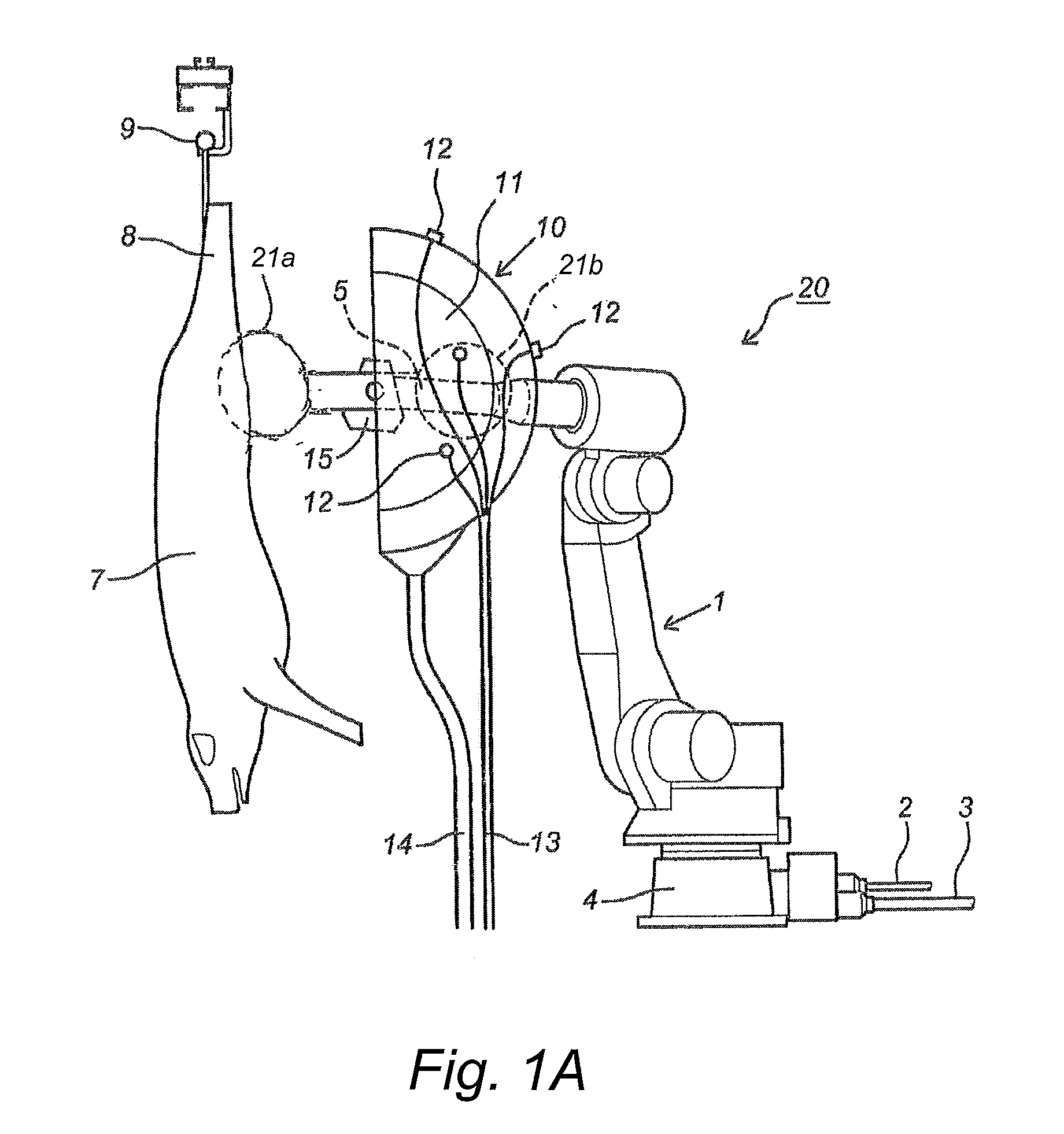

Device and method for processing carcasses of livestock

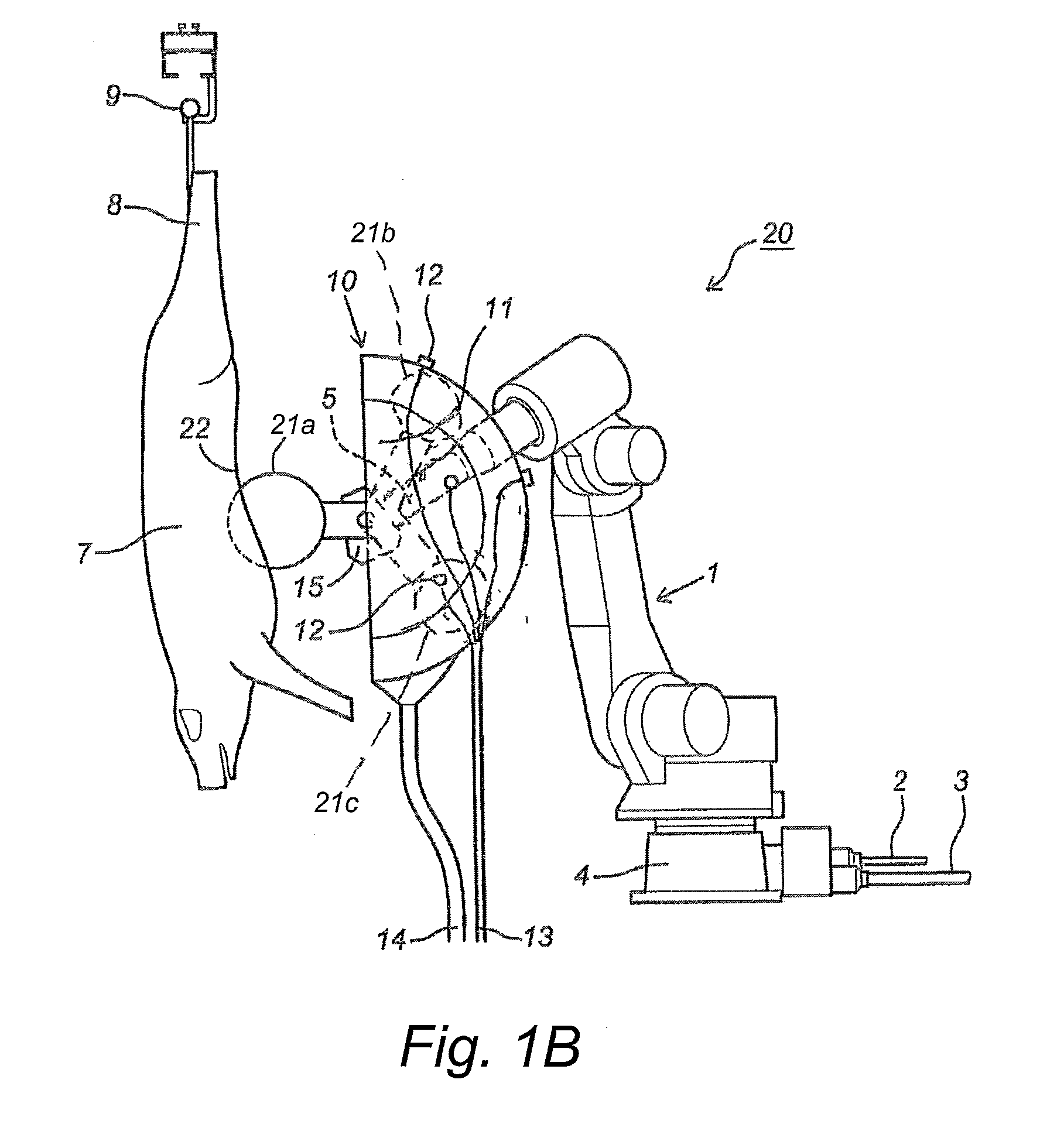

ActiveUS8986081B2Good flexibilityReduce malfunctionMeat processing plantsRobotDomestic animalComputer science

The present invention relates to a device for processing carcasses of livestock such as cattle, pigs and sheep, comprising: at least two dressing tools for performing a dressing process on livestock carcasses, and a robot arm carrying the dressing tool. The invention also relates to a method for processing carcasses of livestock using such a device.

Owner:HUMBOLDT

Fluorosilicate self-cleaning glass nanophase material and producing method thereof

The invention discloses a silicon fluoride self-cleaning glass nano-material, which is composed of solvent and active ingredients; the active ingredients are fluorinated modified silicone nano-particles, and the reaction raw materials comprise ortho-silicon ester and fluorine modified alkyl silane, with the ratio volume and dosage reaching 1.5-3:0.15-1.8. The invention also discloses a manufacturing method for the silicon fluoride self-cleaning glass nano-material, comprising two steps: synthesizing the surface modification of silica nano-particles, silica nano-particles; the ratio between volume and dosage for each added reactant is as follows: solvent: water: ortho-silicon ester: fluorine modified alkyl silane equals to 100: 1.5-3: 1.5-3: 0.15-1.8. The invention has simple production process, stable product performance, higher storage stability, excellent chemical properties, low surface energy and good tolerance against pollution, which is used for glass surface treatment; the contact angle between water and coating is greater than 110 degrees.

Owner:GUANGZHOU BAIYUN CHEM IND

Potato cleaning device

The invention discloses a potato cleaning device, which comprises a base, a bracket is arranged on the left side of the upper end of the base, a feeding cylinder is arranged on the upper end of the bracket, and material guide plates are arranged on the left and right walls of the feeding cylinder interlacedly. The inner right wall of the feeding cylinder is provided with a plurality of cleaning nozzles; the lower end of the feeding cylinder is provided with an inclined bottom surface with a high left and a low right, and a screen is provided on the inclined bottom, and a rightward inclined The muddy water deflector; the base on the right side of the support is provided with a water storage tank, the middle of the water storage tank is provided with a filter screen, and the lower end of the muddy water deflector extends into the water storage tank on the left side of the filter screen. The invention has reasonable structural design, completes quick cleaning of potatoes through three cleaning procedures, and has good cleaning effect, greatly saves water consumption, saves cost, is flexible in use, strong in practicability and long in service life.

Owner:段华勇

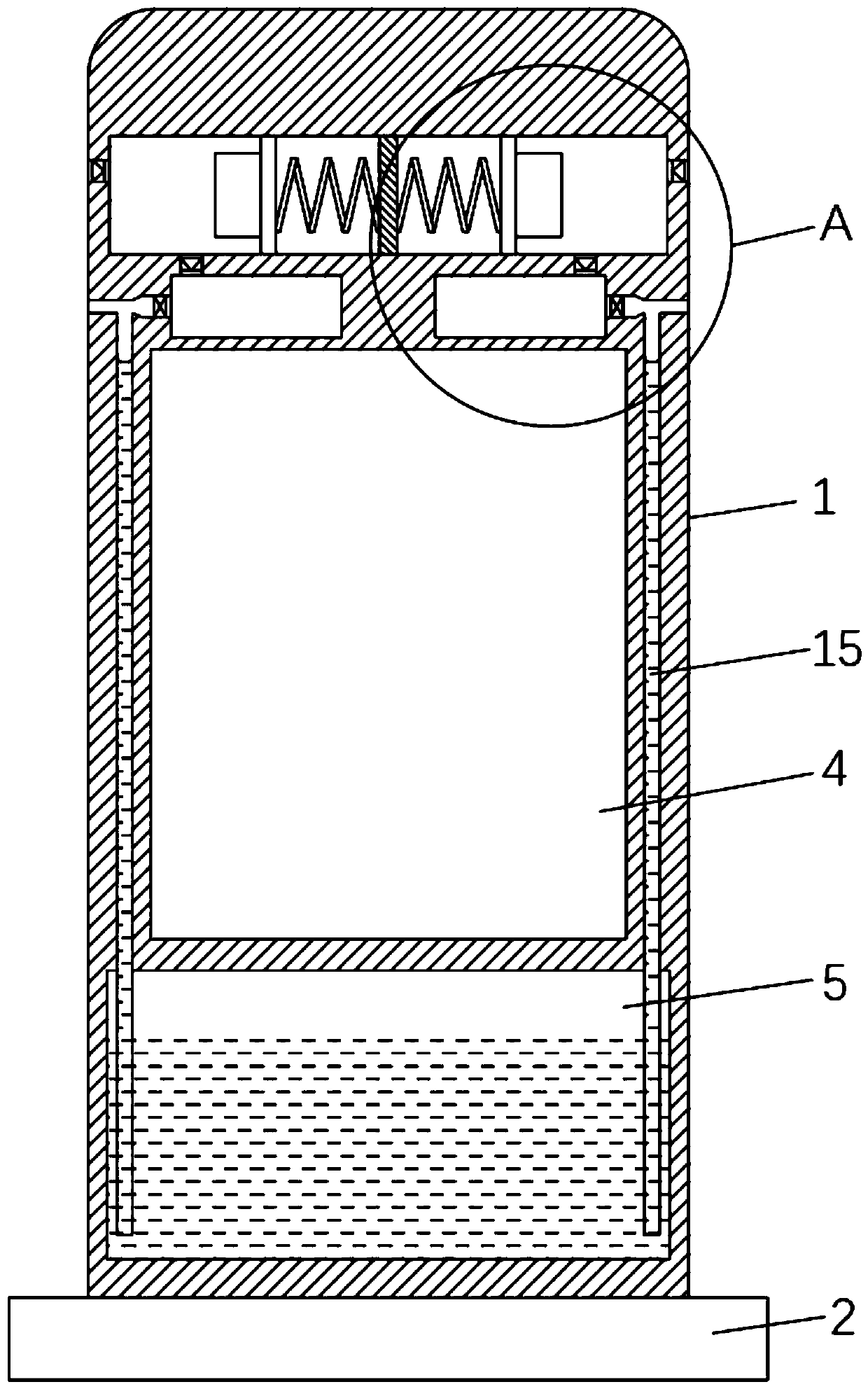

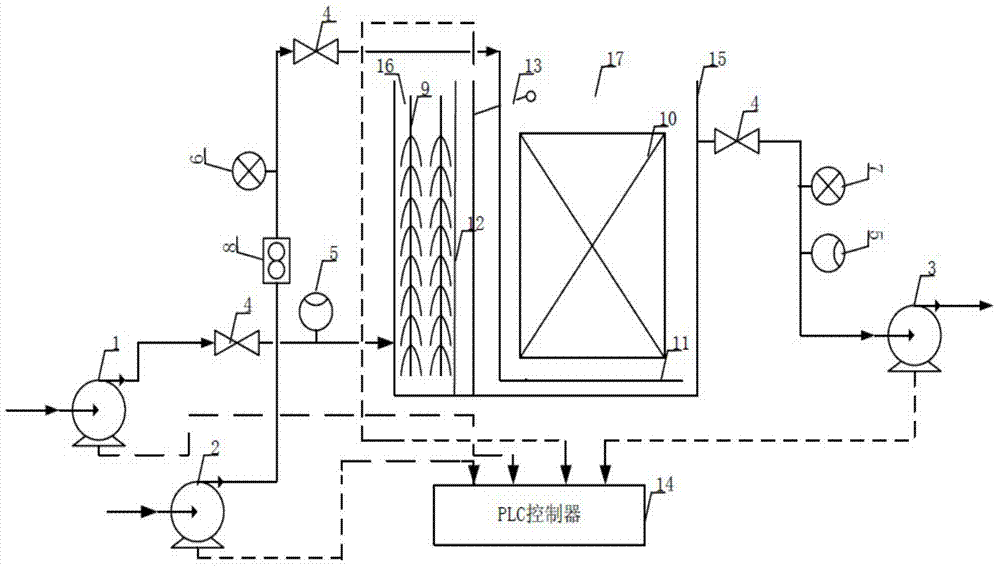

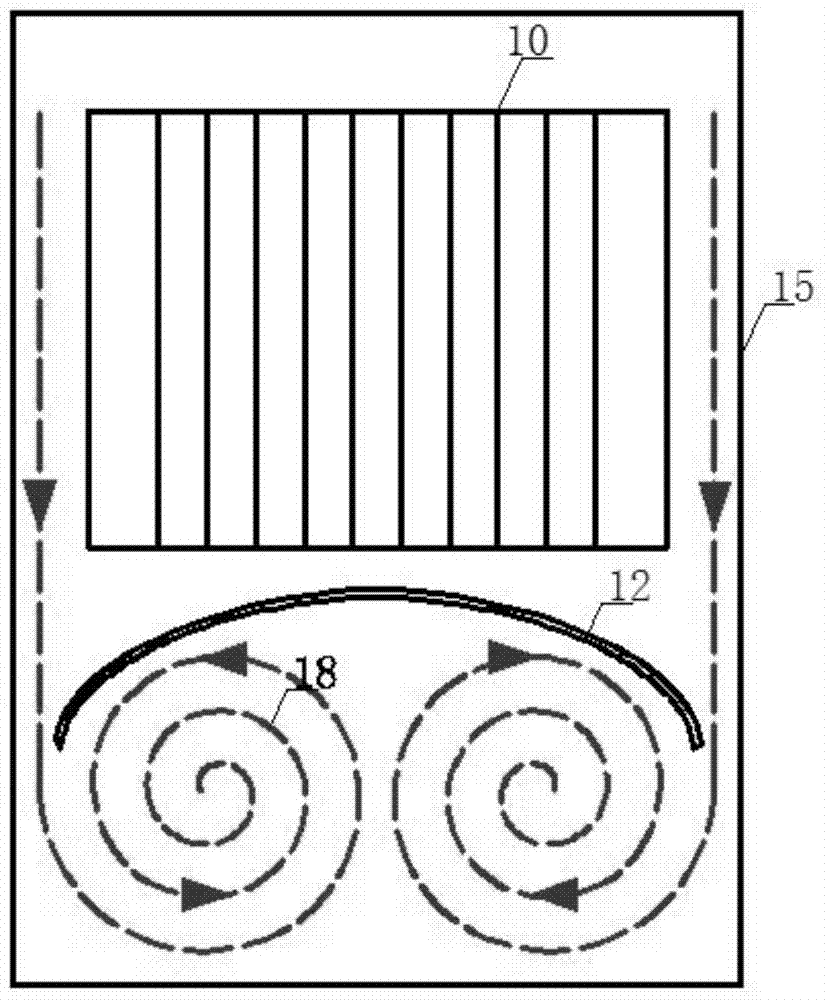

Integrated MBR (Membrane Bio-Reactor)

InactiveCN103613195AReduce pollutionImprove pollutionTreatment with aerobic and anaerobic processesFiberCarbon fibers

The invention relates to the field of sewage reuse, and particularly relates to an integrated MBR (Membrane Bio-Reactor). The integrated MBR is divided into an anoxic area and an aerobic area by using a baffle structure, carbon fiber packing is hung in the anoxic area, and an aeration device and a membrane assembly are placed in the aerobic area; the volume ratio of the anoxic area to the aerobic area is 1:3. The integrated MBR has the characteristics that due to the adoption of an integrated reaction device, the mode of multi-section processing in a single biochemical environment is solved, and the land-occupied area is saved; according to the structure characteristics, sewage circularly flows between the anoxic area and the aerobic area under the action of aeration, and shows different water flow characteristics; the device can simultaneously and effectively perform nitrification and denitrification processes, so that the sludge return is saved, thereby reducing the capital expenditure and the operation cost, and under the condition that the overall sludge concentration is not changed, the sludge concentration of the anoxic area is increased, and the sludge concentration of the aerobic area is reduced, thereby effectively reducing the membrane pollution; a carbon source required by denitrification is supplemented in a mode of feeding water from the anoxic area, thereby saving the cost.

Owner:BEIJING UNIV OF CHEM TECH

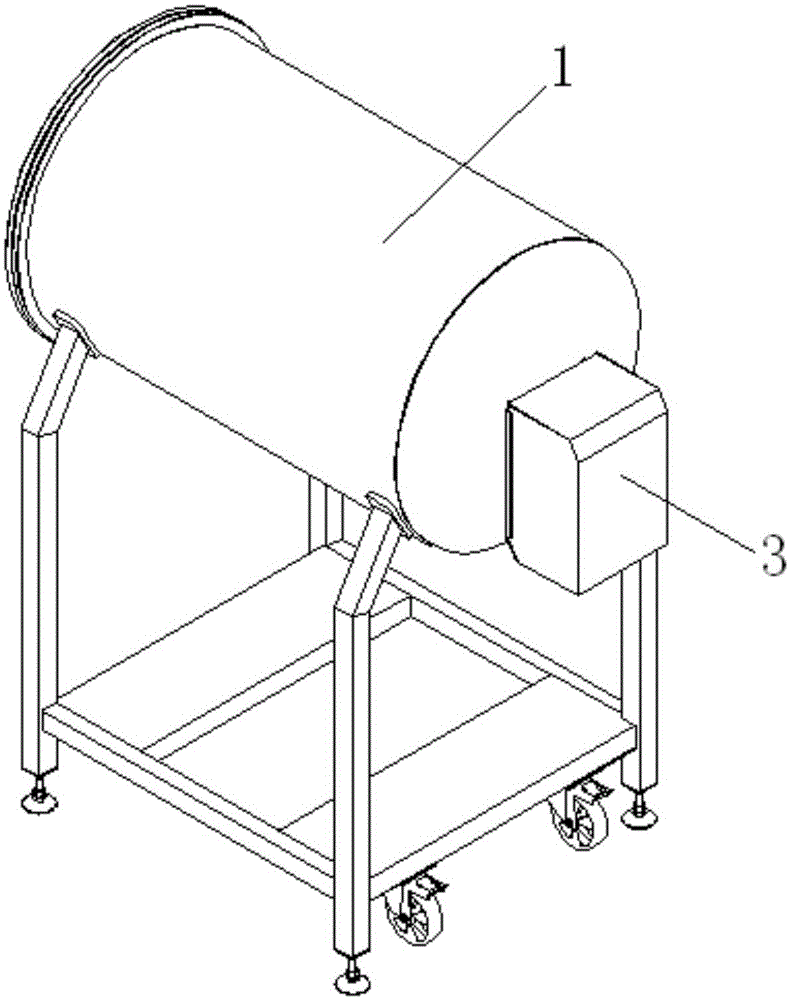

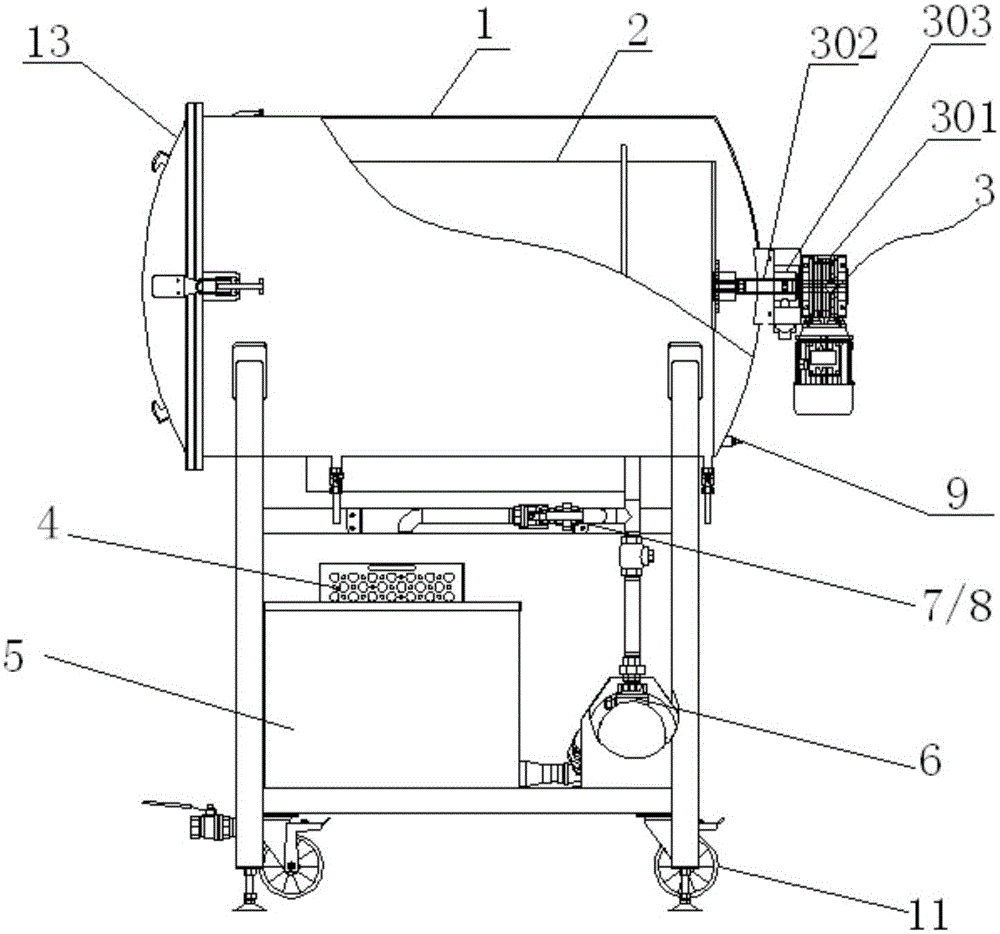

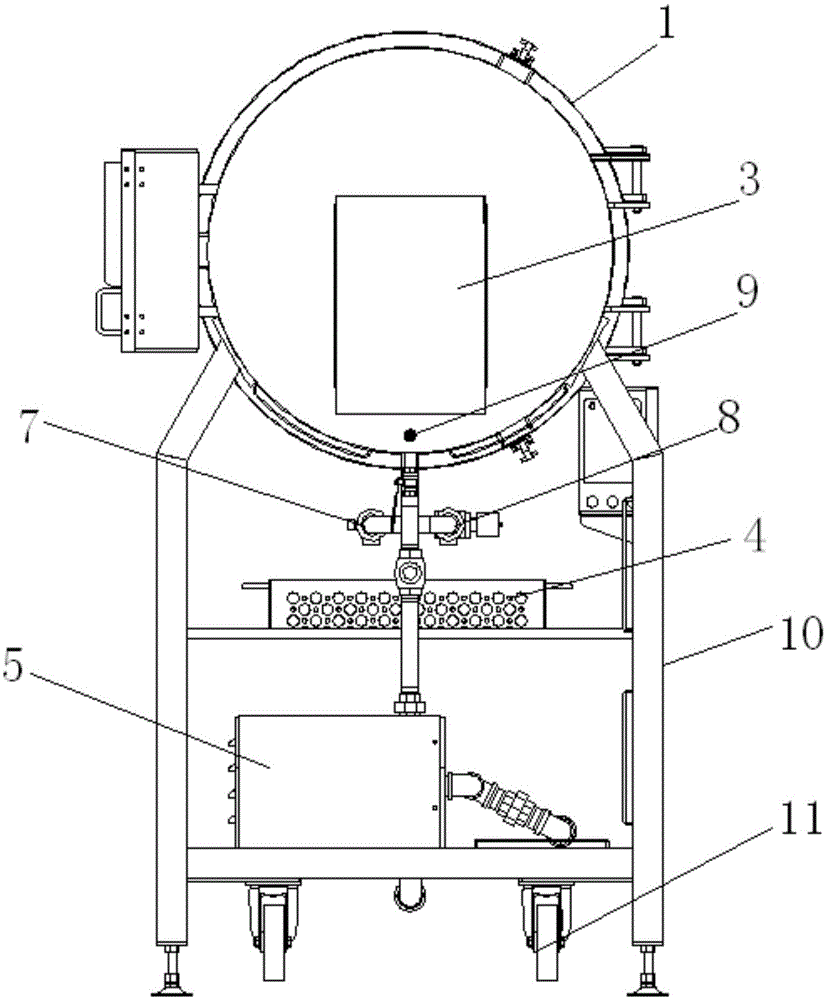

Drum-type economical washing machine

The invention discloses a drum-type economical washing machine which comprises an outer drum, a rotary drum, a power device, a filter, a water tank and a water pump. The rotary drum is rotationally arranged in the outer drum. The power device is arranged outside the outer drum. A power output shaft of the power device penetrates into the outer drum in a sealed manner and can drive the rotary drum to rotate relative to the outer drum. The water pump pumps washing water in the water tank into the outer drum. The washing water drained from the outer drum is filtered through the filter and then stored in the water tank. Therefore, the washing water drained after washing operation can be recycled, the washing effect is guaranteed, the washing water and a detergent are greatly saved, the drainage rate of sewage is decreased, the food washing time is shortened, and sanitation, durability and the economical efficiency are greatly improved. Heating steam can be injected into the outer drum as well, the washing effect is improved, and meanwhile the sterilization effect is achieved.

Owner:KUSN HAOKAOKE FOOD MACHINERY

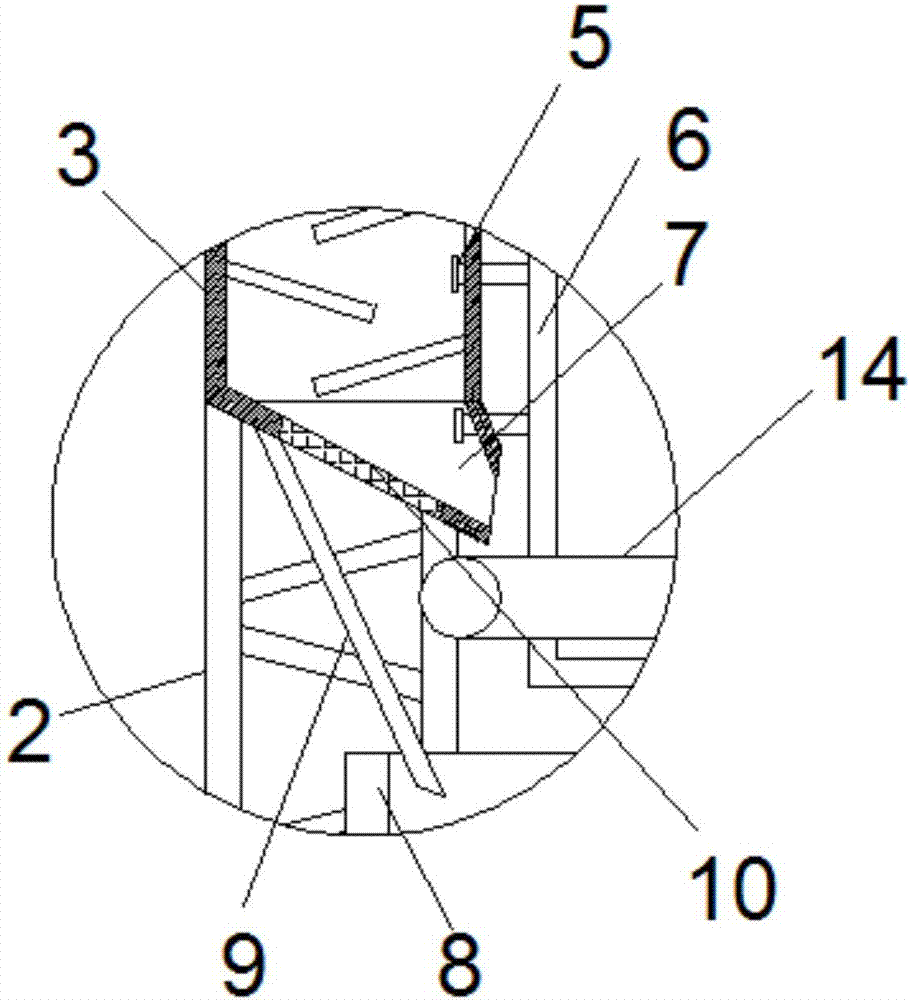

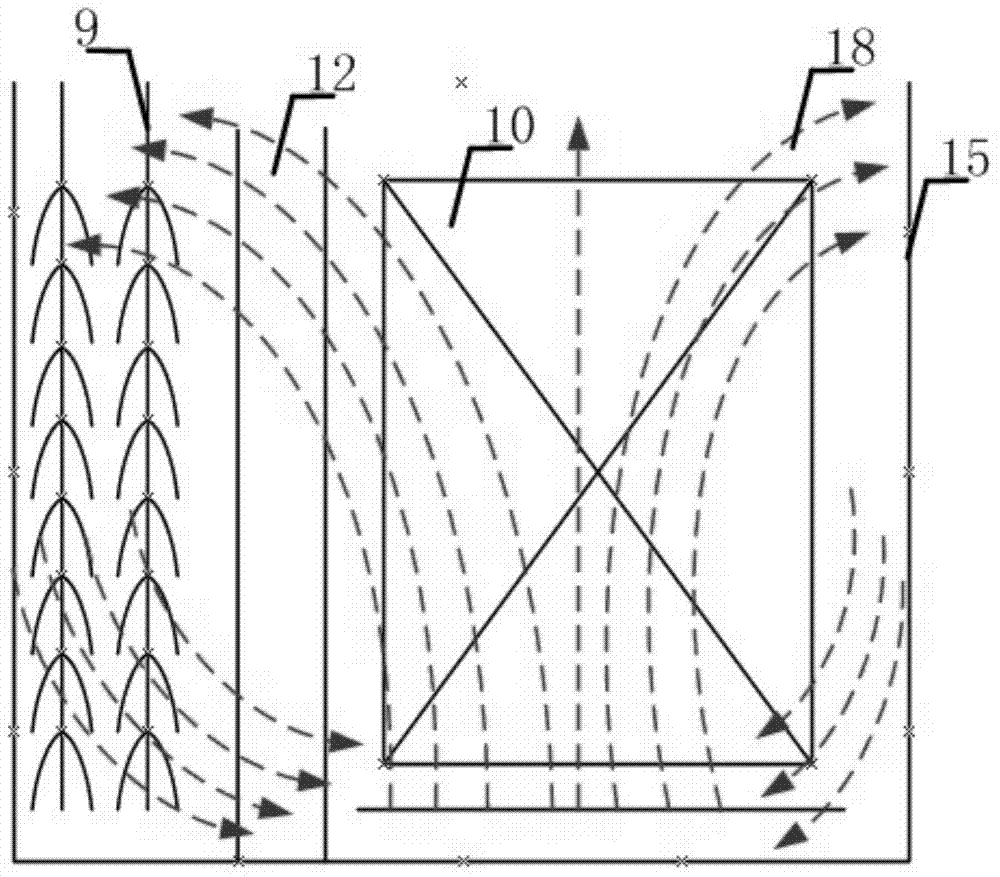

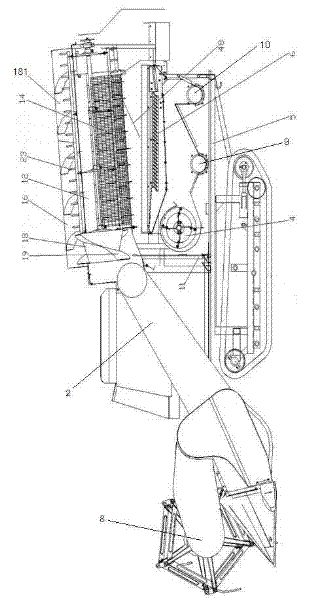

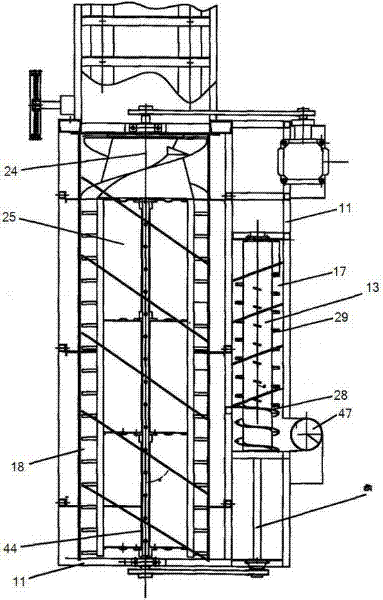

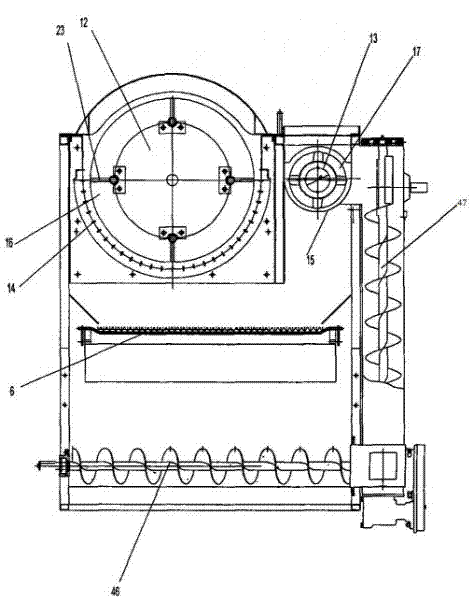

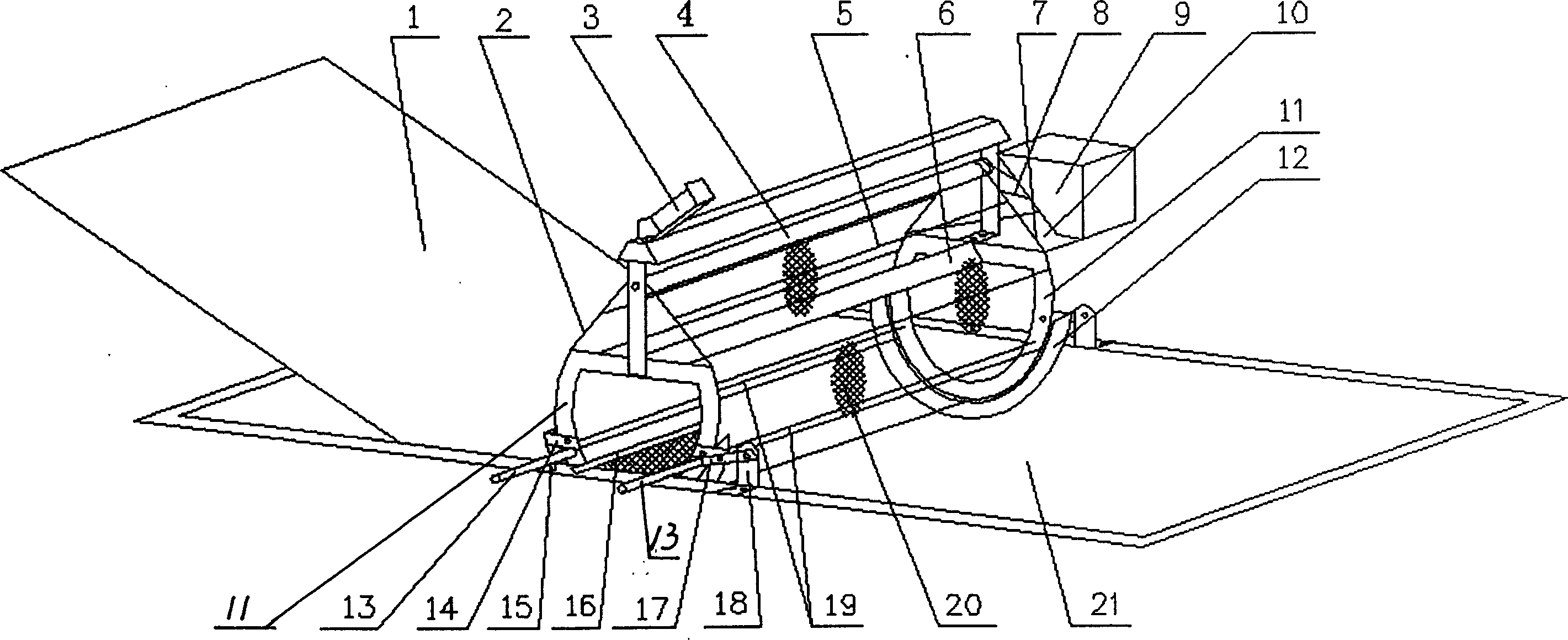

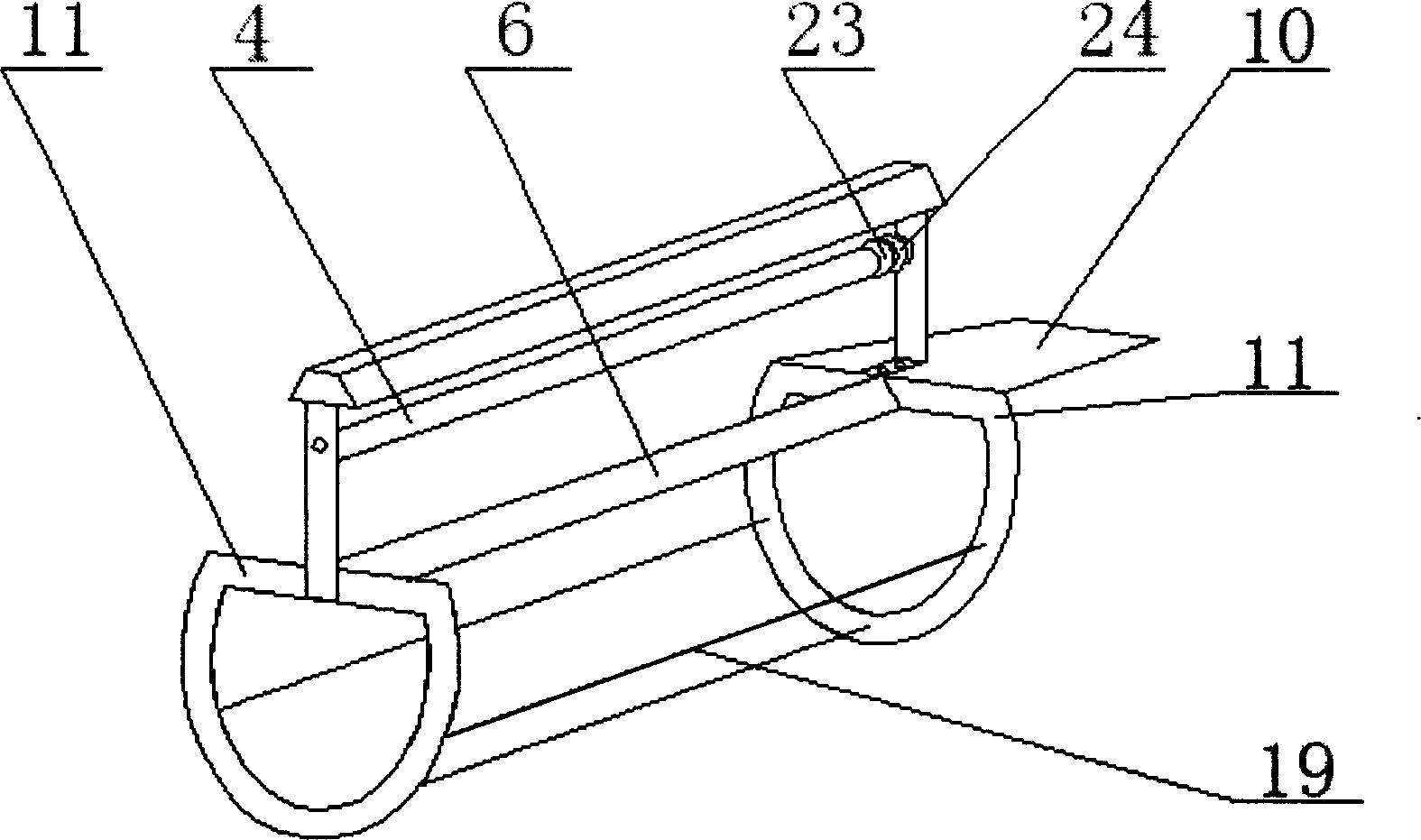

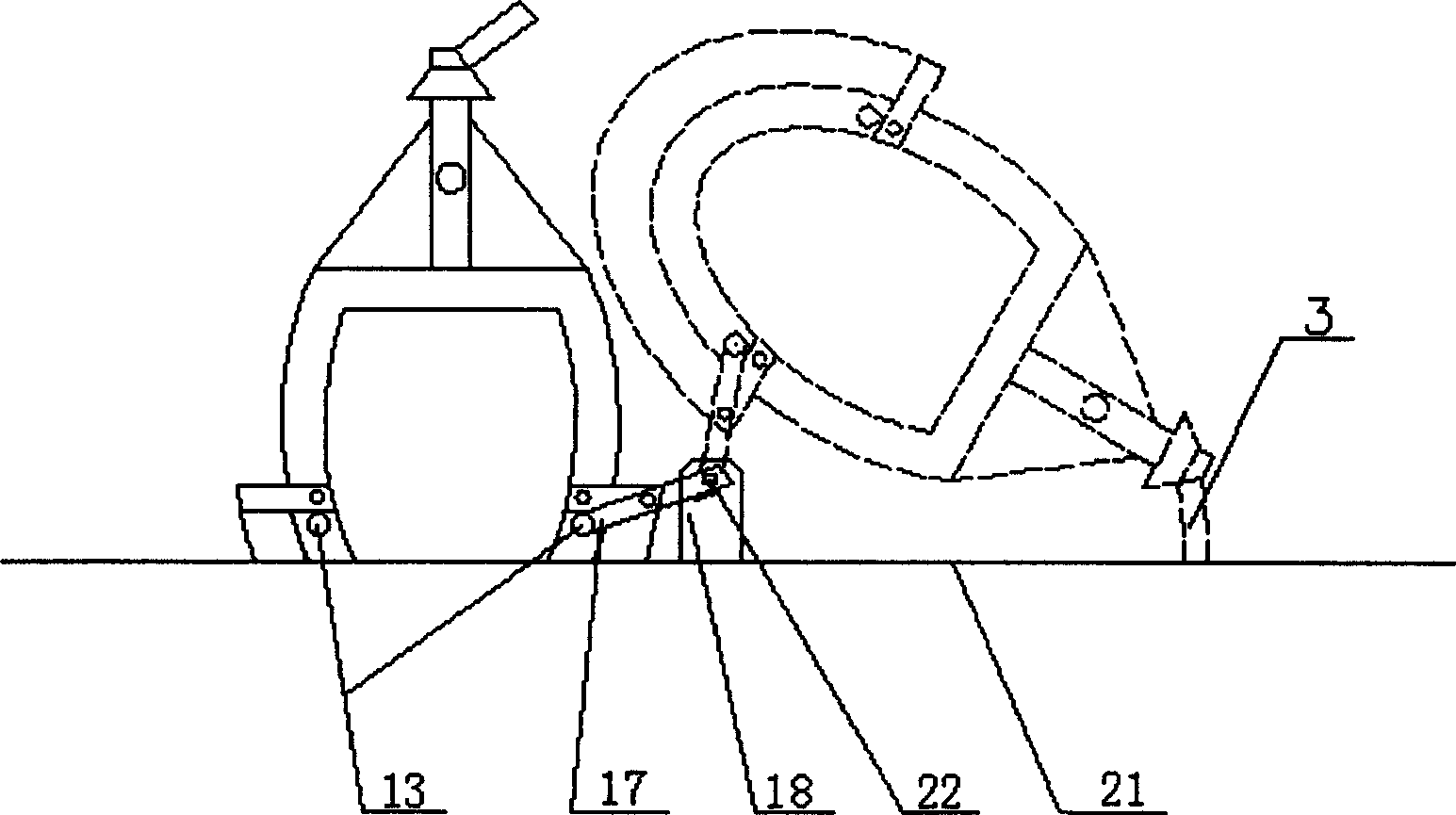

Threshing device of harvester

The invention relates to a harvester, in particular to a threshing device of a harvester. According to the technical scheme, the threshing device of the harvester comprises an underframe, a threshing frame, a main threshing mechanism, a rethreshing mechanism, a separation, cleaning and vibration screen and an impurity lifting screw, wherein the threshing frame is fixed on the underframe, both the main threshing mechanism and the rethreshing mechanism are connected to the threshing frame and disposed along the travelling direction of the harvester, the separation, cleaning and vibration screen is fixedly connected to the threshing frame and positioned between the underframe and the main threshing and rethreshing mechanisms, and the impurity lifting screw is disposed between the position below the rear end of the separation, cleaning and vibration screen and the rethreshing mechanism. The main threshing mechanism comprises a main threshing roller, a large concave screen and a main roller cover, wherein the main threshing roller is hinged to the threshing frame, the large concave screen is fixed to the threshing frame and encloses the main threshing roller, and the main roller cover covers an opening of the large concave screen. The main threshing roller is slantingly disposed along the advancing direction of the harvester. A corner between the main threshing roller and a conveying chute of the threshing device compared with the prior art is reduced, so that conveying of crops is smooth, and the shortages of the prior art are made up.

Owner:ZHONGJI SOUTHERN MACHINERY

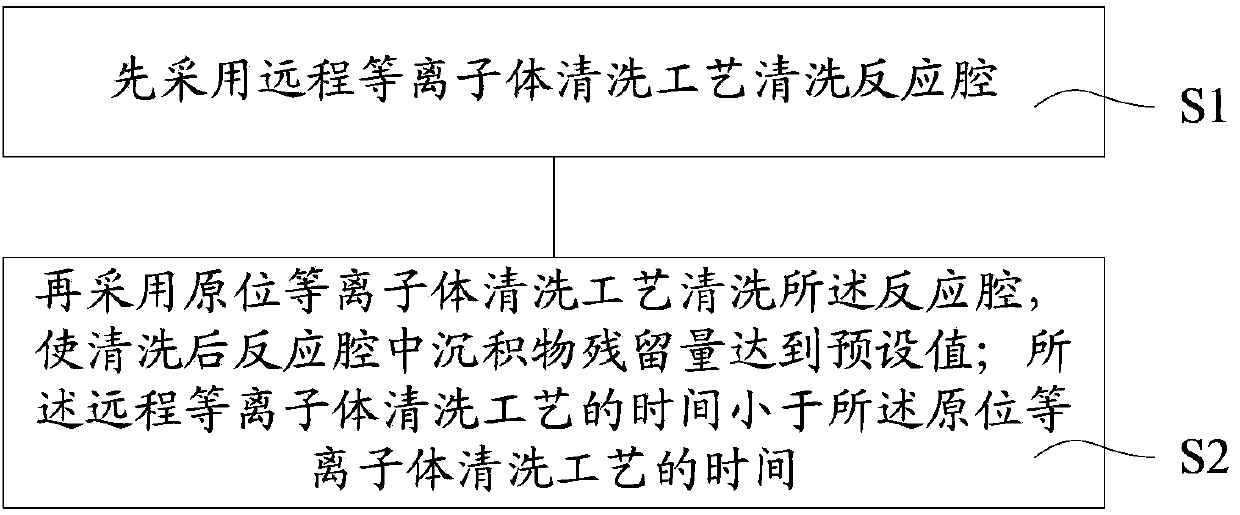

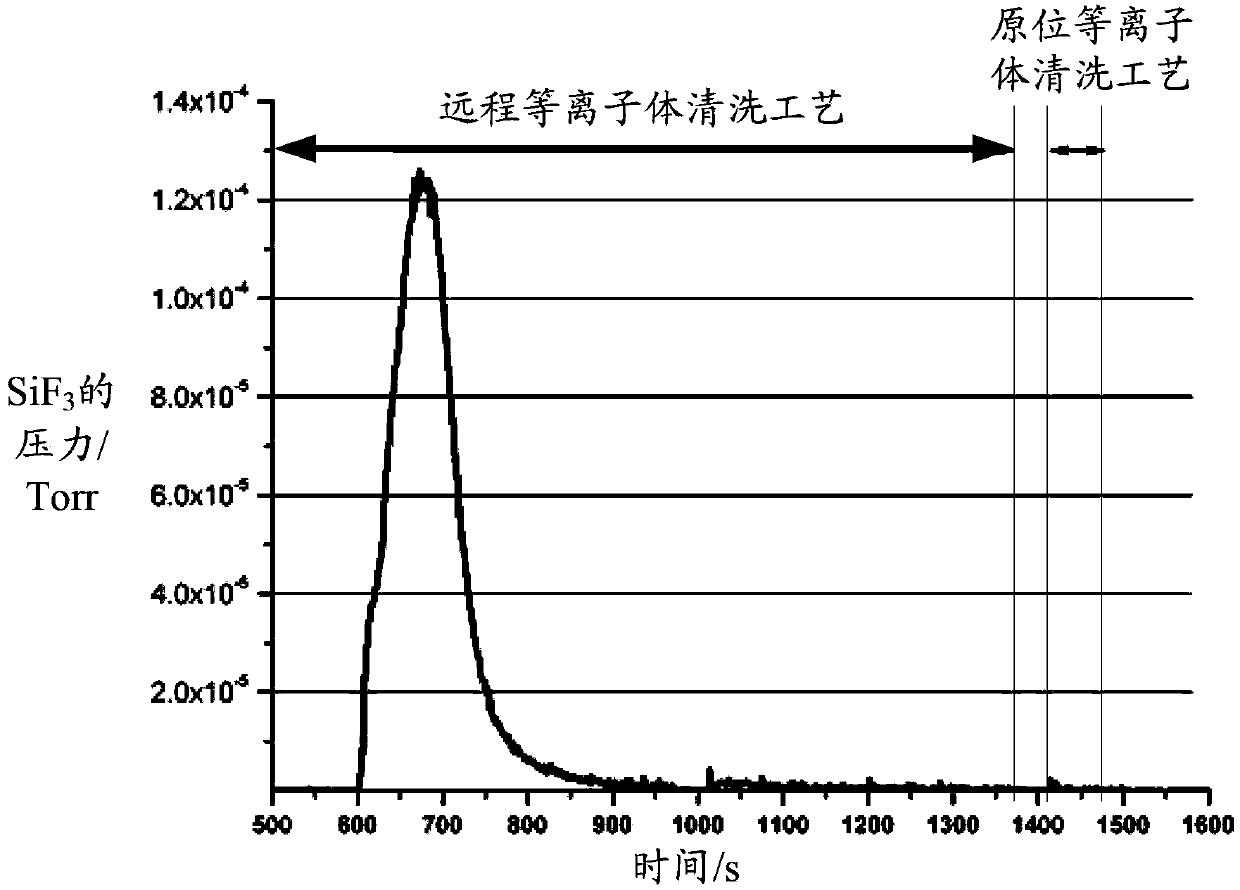

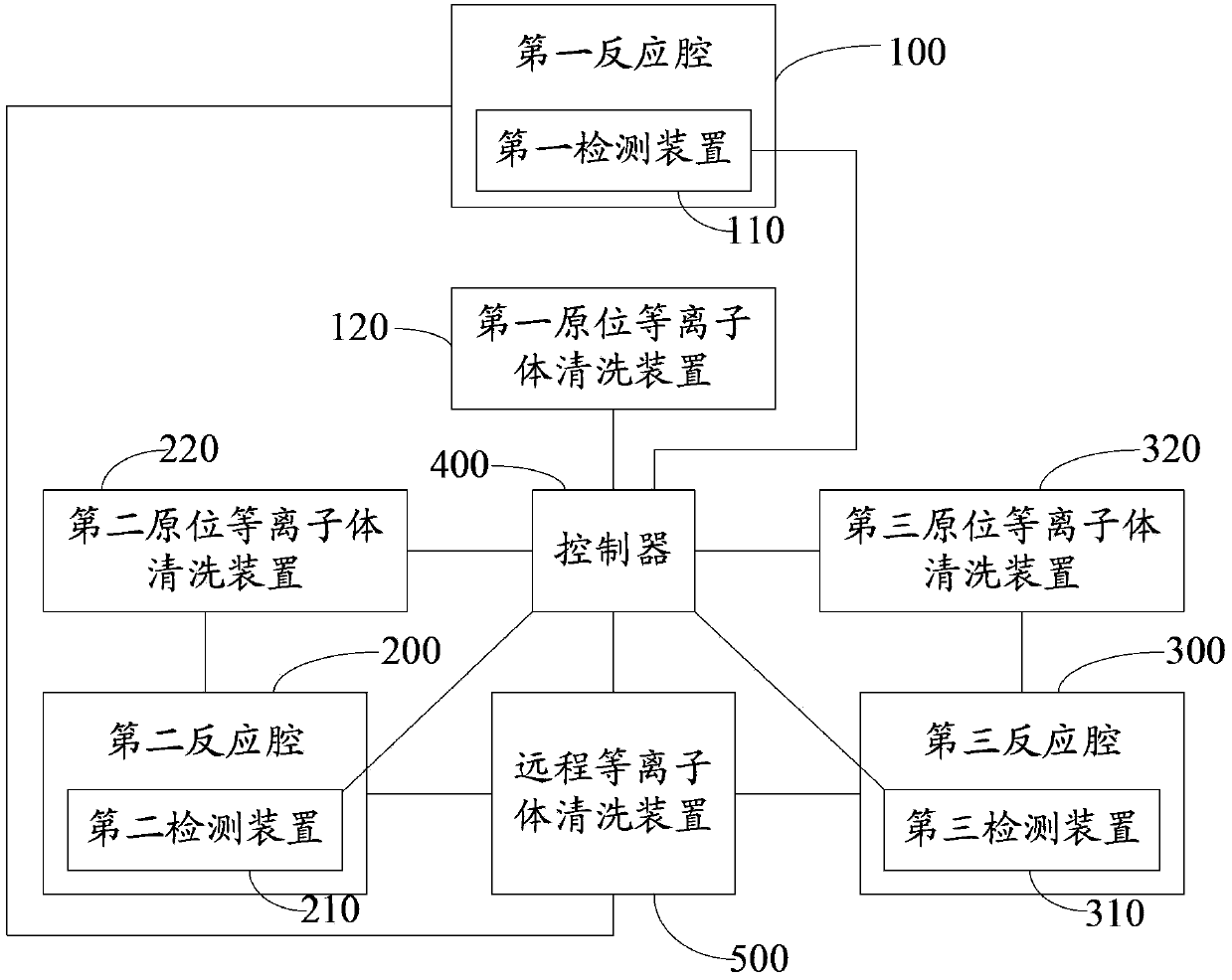

Cleaning method and cleaning system of reaction cavity

ActiveCN103374710AExtend cleaning timeShorten cleaning timeChemical vapor deposition coatingRemote plasmaOrganic chemistry

The invention discloses a cleaning method and a cleaning system of a reaction cavity. The cleaning method of the reaction cavity comprises the following steps of: firstly cleaning the reaction cavity by adopting a long-distance plasma body cleaning process, cleaning the reaction cavity by adopting a normal position plasma body cleaning process, enabling the sediment residual quantity in the reaction cavity after cleaning to achieve a preset value, wherein the time of the long-distance plasma body cleaning process is less than that of the normal position plasma body cleaning process. The cleaning method and the cleaning system provided by the invention have the advantages that the cleaning time is reduced, the cleaning uniformity is improved, and the use amount of the cleaning gas is also reduced.

Owner:理想万里晖真空装备(泰兴)有限公司

Device and Method for Processing Carcasses of Livestock

ActiveUS20130303065A1Good flexibilityReduce malfunctionMeat processing plantsRobotComputer scienceLivestock

The present invention relates to a device for processing carcasses of livestock such as cattle, pigs and sheep, comprising: at least two dressing tools for performing a dressing process on livestock carcasses, and a robot arm carrying the dressing tool. The invention also relates to a method for processing carcasses of livestock using such a device.

Owner:HUMBOLDT

Cleaning machine with twin-jet nozzle

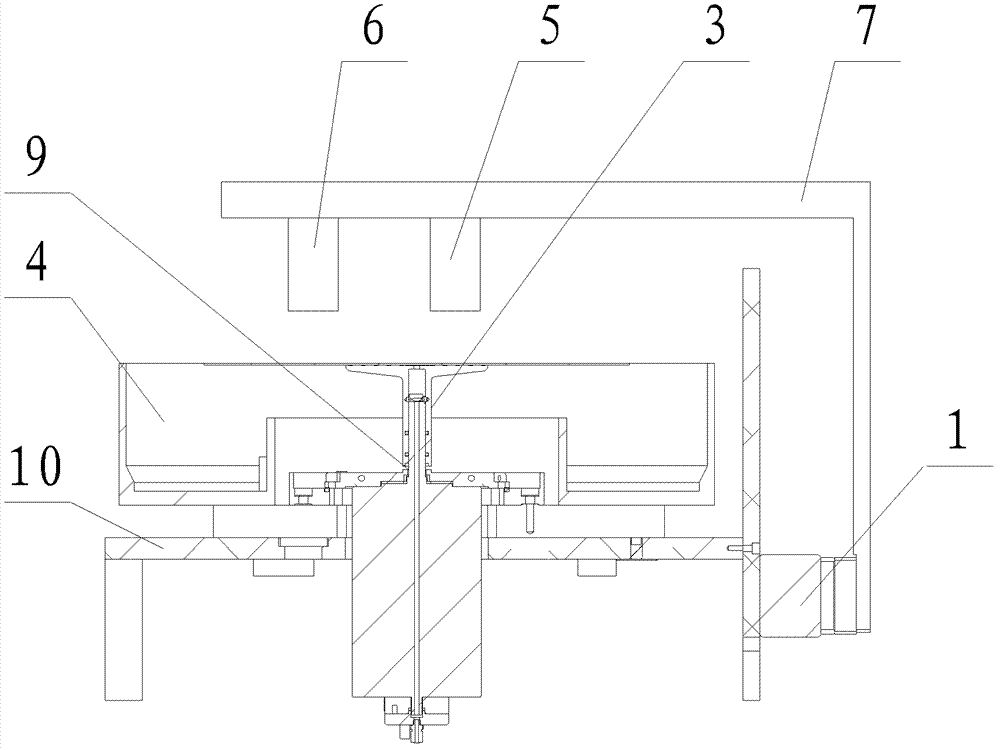

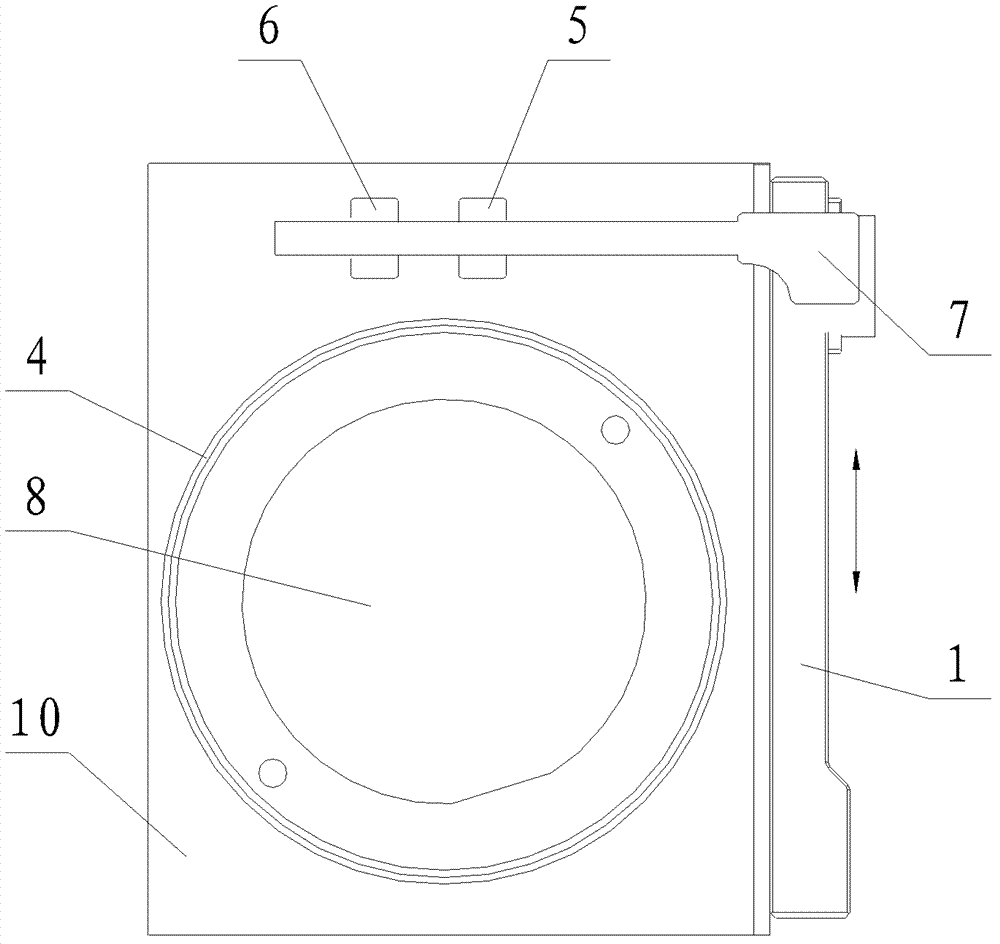

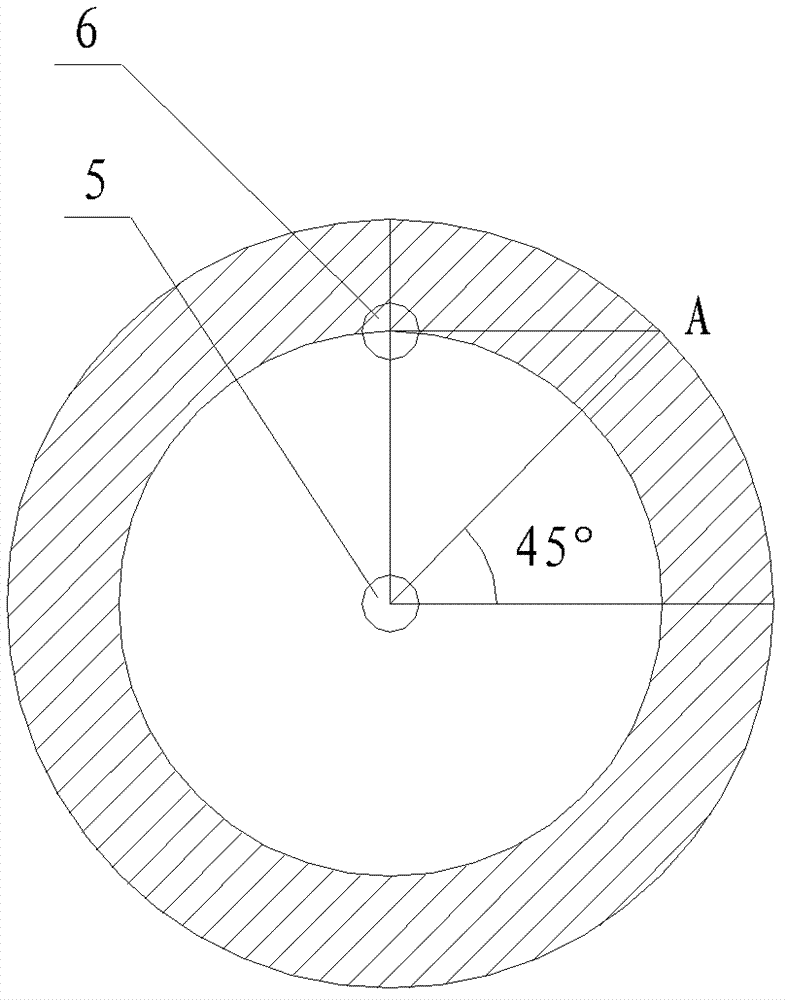

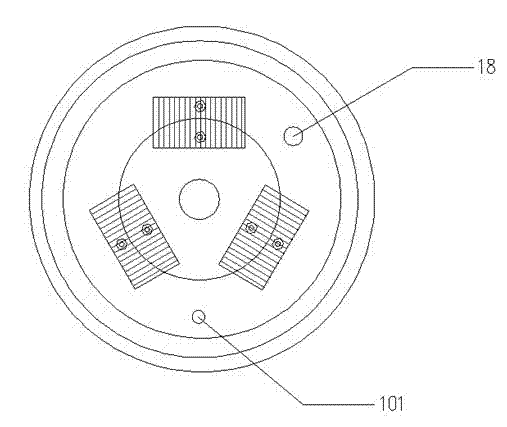

ActiveCN103094148AMeet cleaning needsTo achieve the purpose of cleaningSpraying apparatusSemiconductor/solid-state device manufacturingReciprocating motionSemiconductor chip

The invention relates to the equipment which is used for cleaning the chip in the workpiece process of semiconductor chips, in particular to a cleaning machine with a twin-jet nozzle used for optimizing the washing of the surface of the chip. The cleaning machine comprises a nozzle electric cylinder, a spindle motor, a supporting stage, a shell body, a nozzle arm, a spindle and a workbench. The spindle motor is installed on the workbench and one end of the spindle is connected with an output end of the spindle motor and the other end of the spindle motor is installed inside the shell body of the workbench. The other end of the spindle is connected with the supporting stage used for fixing and rotating the chip. The nozzle electric cylinder is installed on one side of the workbench and one end of the nozzle arm is connected with the nozzle electric cylinder and is in reciprocating motion through the drive of the nozzle electric cylinder. The other end of the nozzle arm is located above the chip and the other end of the nozzle arm is provided with the twin-jet nozzle corresponding to the chip. The cleaning machine with the twin-jet nozzle can meet the cleaning demand to the hilt through the control of the position of the nozzle and the characteristic of the rotation of the chip in the cleaning process and achieve the cleaning goal that all particles on the surface of the chip are cleared away.

Owner:SHENYANG KINGSEMI CO LTD

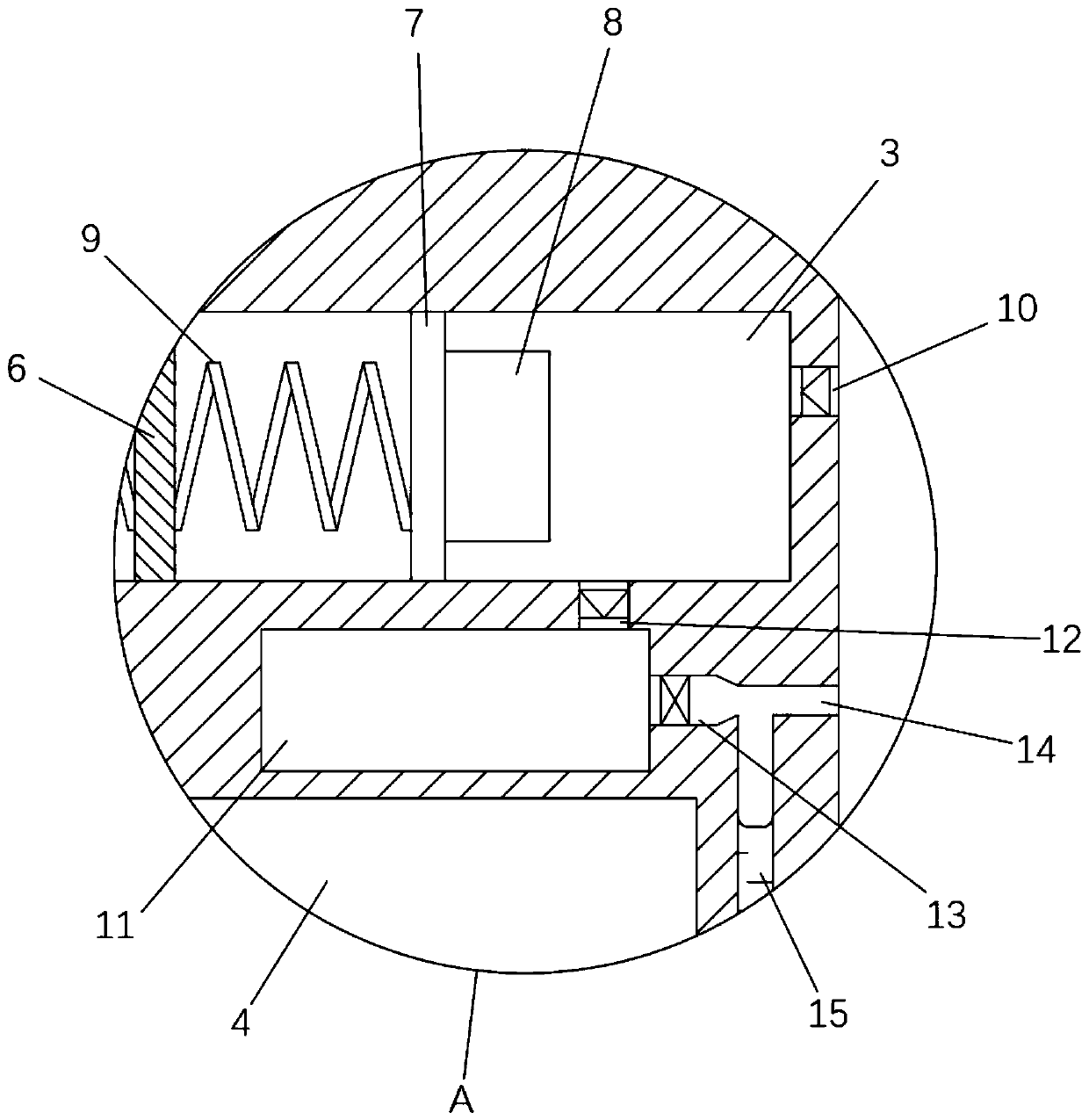

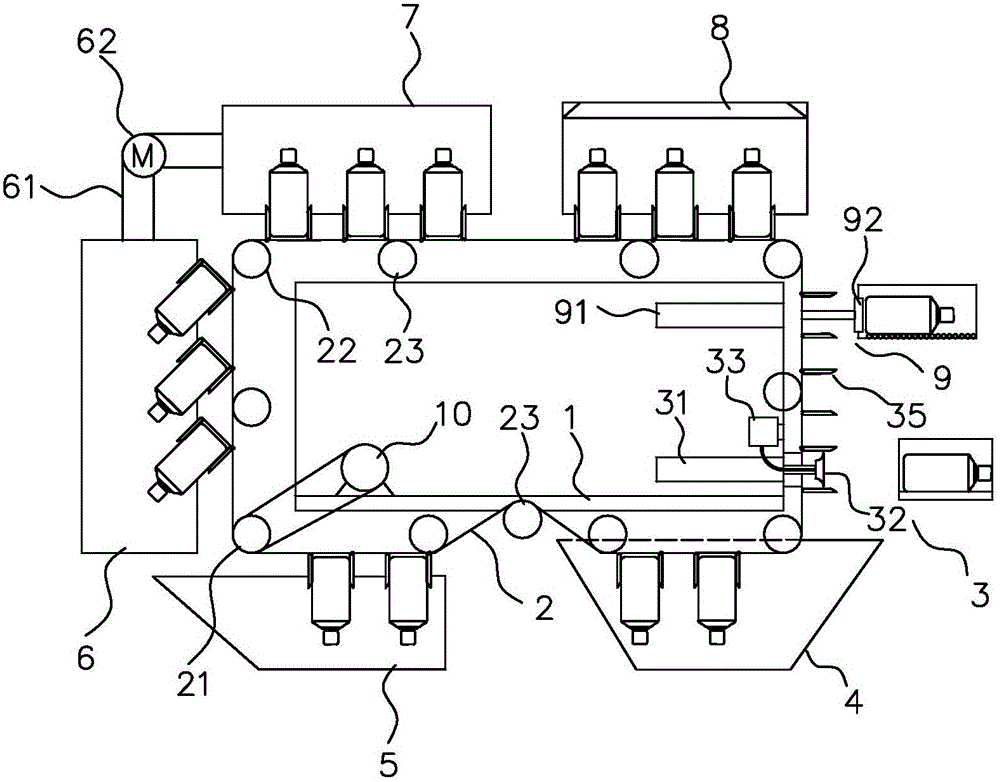

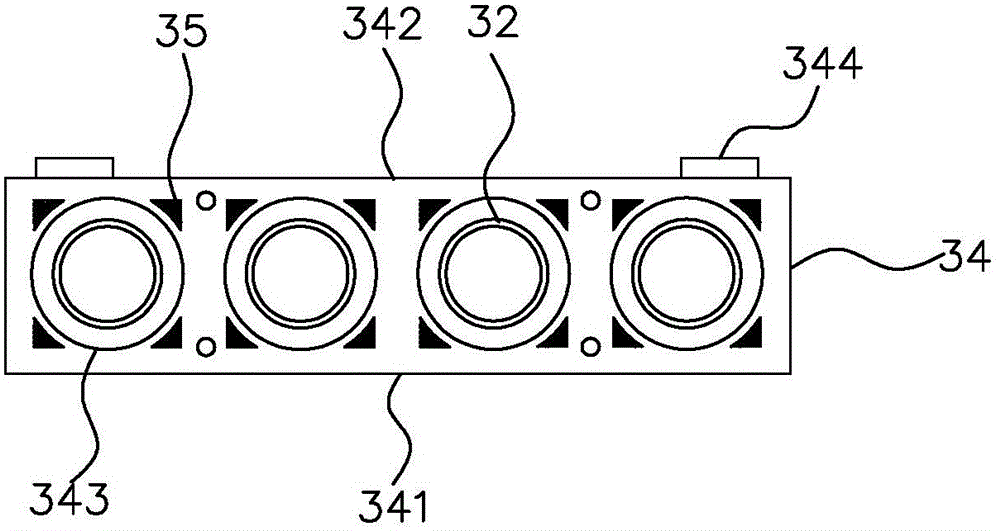

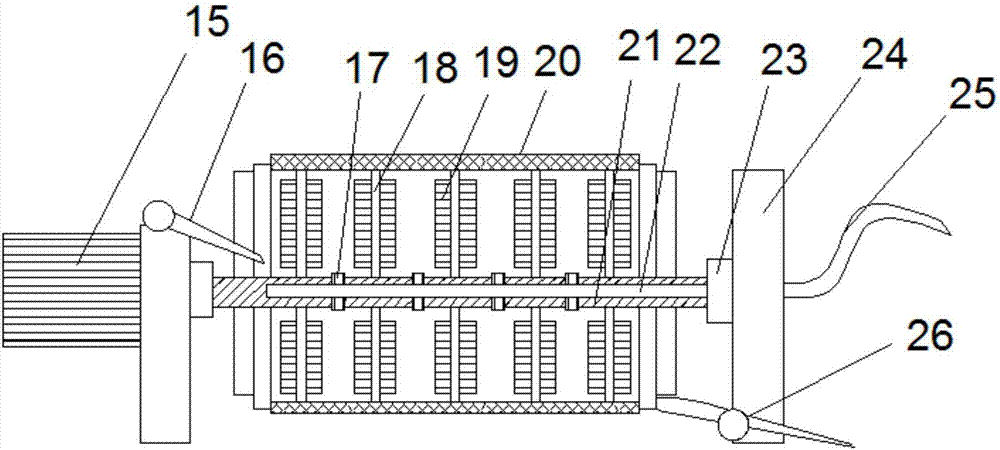

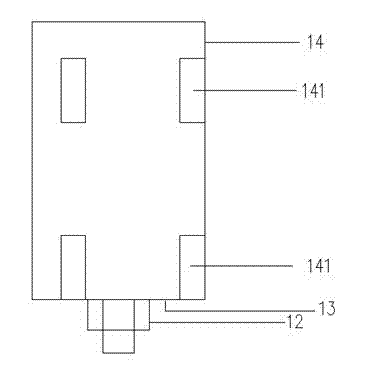

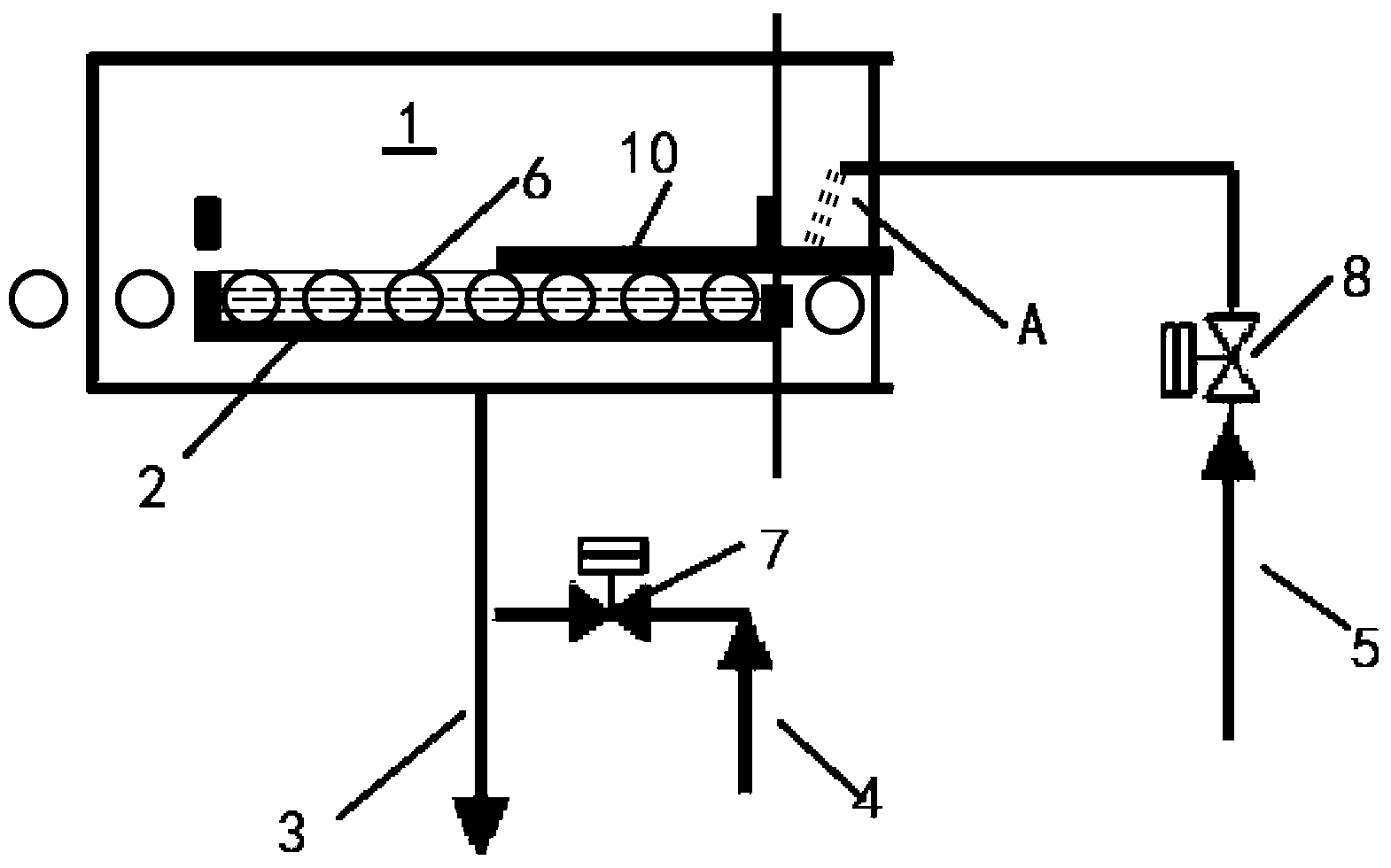

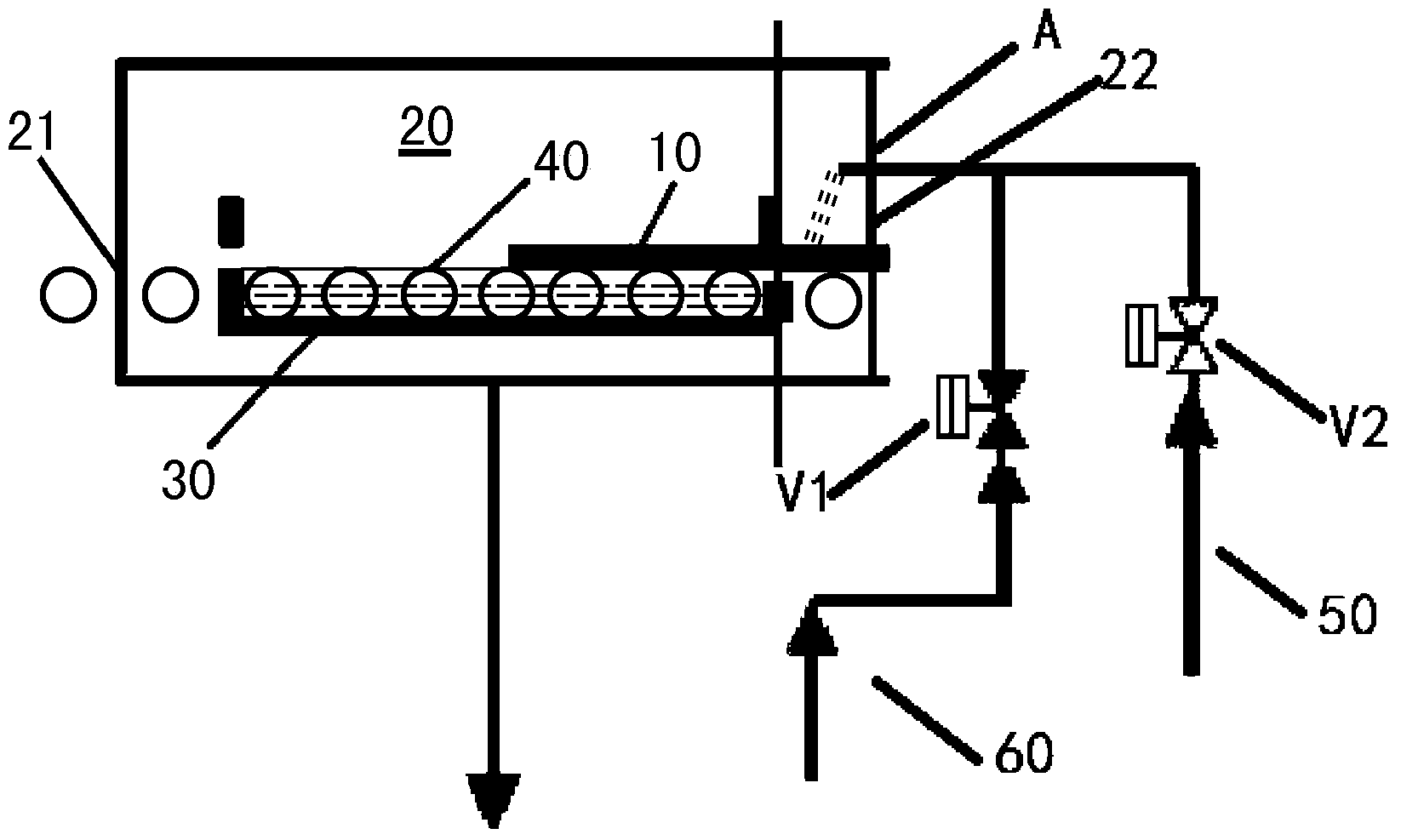

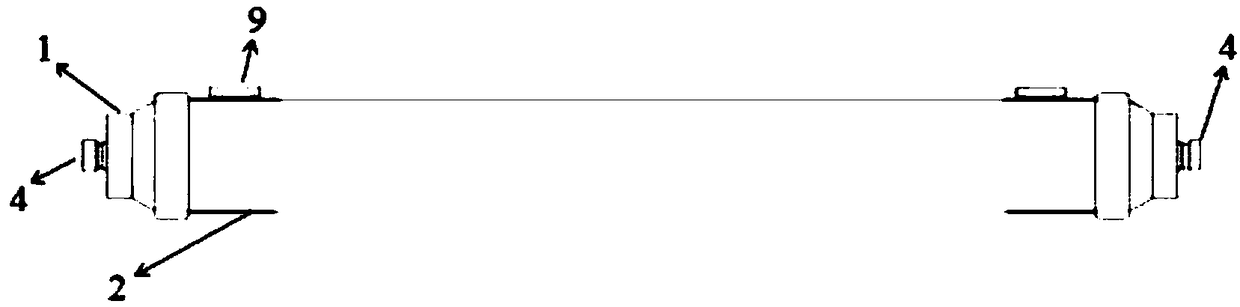

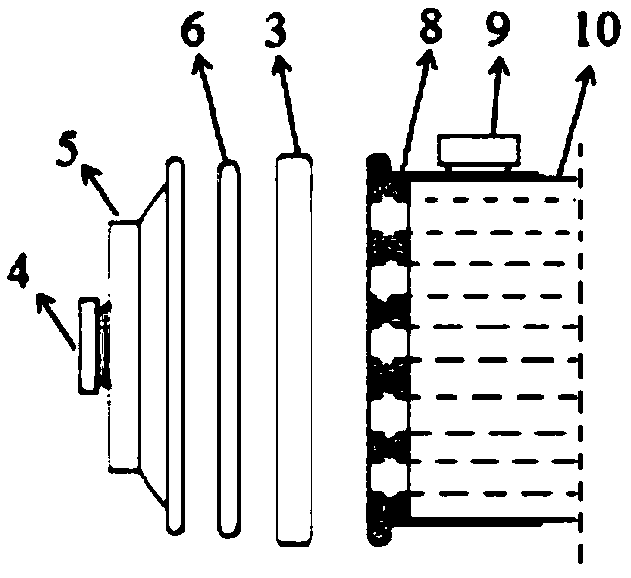

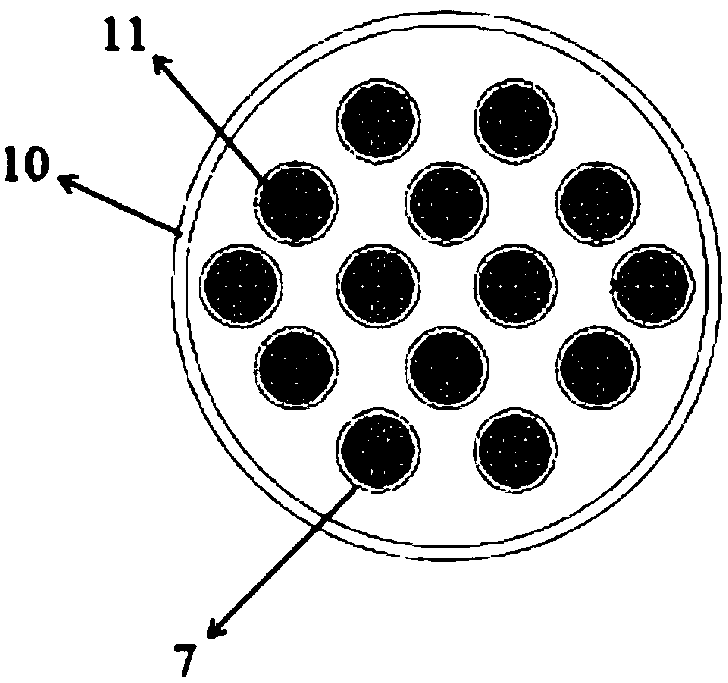

Automobile lubricating system cleaning apparatus and cleaning method

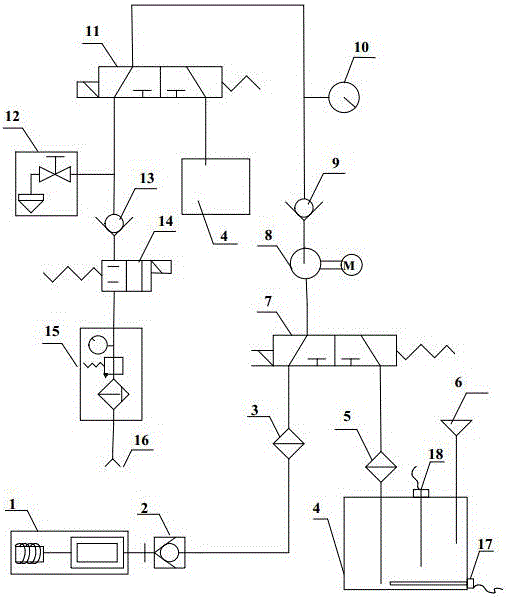

ActiveCN106321237AReduce pollutionPollution realizedMachines/enginesLubricant filling/drainingCouplingSolenoid valve

The invention discloses an automobile lubricating system cleaning apparatus and a cleaning method. The automobile lubricating system cleaning apparatus comprises a switch-over oil tube (1), a quick coupling (2), a first filter (3), an oil tank (4), a second filter (5), a cleaning oil fill port (6), a first solenoid valve (7), an electric pump (8), a first check valve (9), a second solenoid valve (11), a new oil fill connector (12), a second check valve (13), a gas source control valve (14), a pressure regulating filter (15), a gas source connector (16) and the like. The cleaning method comprises the steps of blowing the residual oil engine oil in a lubricating system out, carrying out cyclic cleaning, recovering the cleaning oil, blowing the residual cleaning oil in the lubricating system out and the like. With the automobile lubricating system cleaning apparatus and the cleaning method, the original lubricating oil can be prevented from remaining, the problem that cleaning is not thorough is solved, and meanwhile, it is realized that cleaning oil can be recycled.

Owner:MIT AUTOMOBILE SERVICE

Preparation method and applications of nanometer graphene oxide modified film

ActiveCN104826505AImprove hydrophilicityImprove pollutionSemi-permeable membranesSustainable biological treatmentCasting moldSewage

The present invention relates to the technical field of sewage treatments, particularly to a preparation process of a nanometer graphene oxide film material for a biological reactor. The specific process comprises: adding a film material and nanometer graphene oxide to a solvent, completely stirring and uniformly mixing to obtain a mold casting sol, carrying out film scrapping of the mold casting sol on a non-woven fabric, placing the non-woven fabric coated with the mold casting sol on the bottom of a polytetrafluoroethylene tank after completing the film scrapping, heating deionized water to fumigate the mold casting sol, removing the non-woven fabric after completing the fumigating so as to obtain the pre-finished product film, and carrying out cleaning and drying to obtain the nanometer graphene oxide modified film finished product having the porous structure.

Owner:波塞冬(江苏)新材料科技有限公司

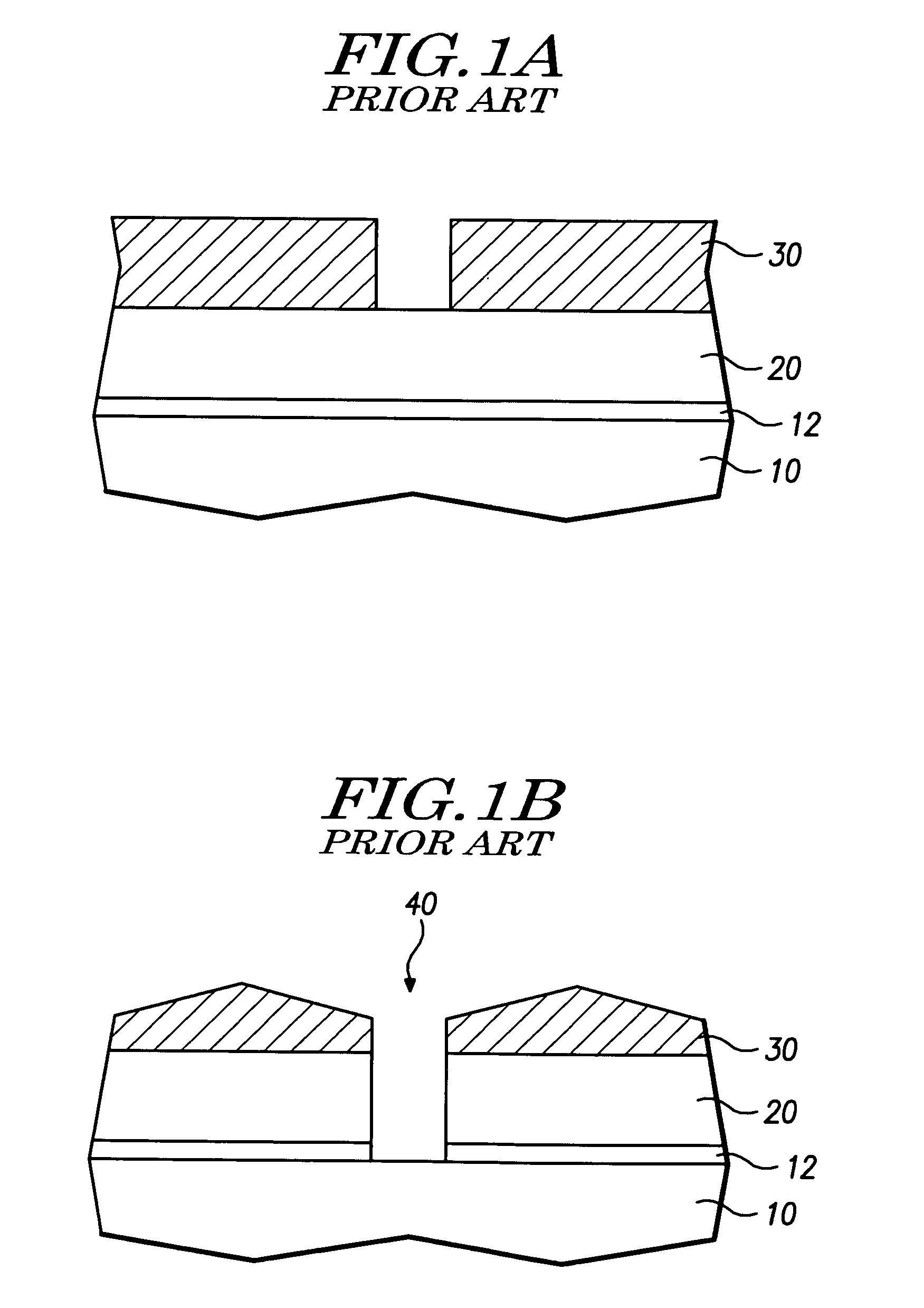

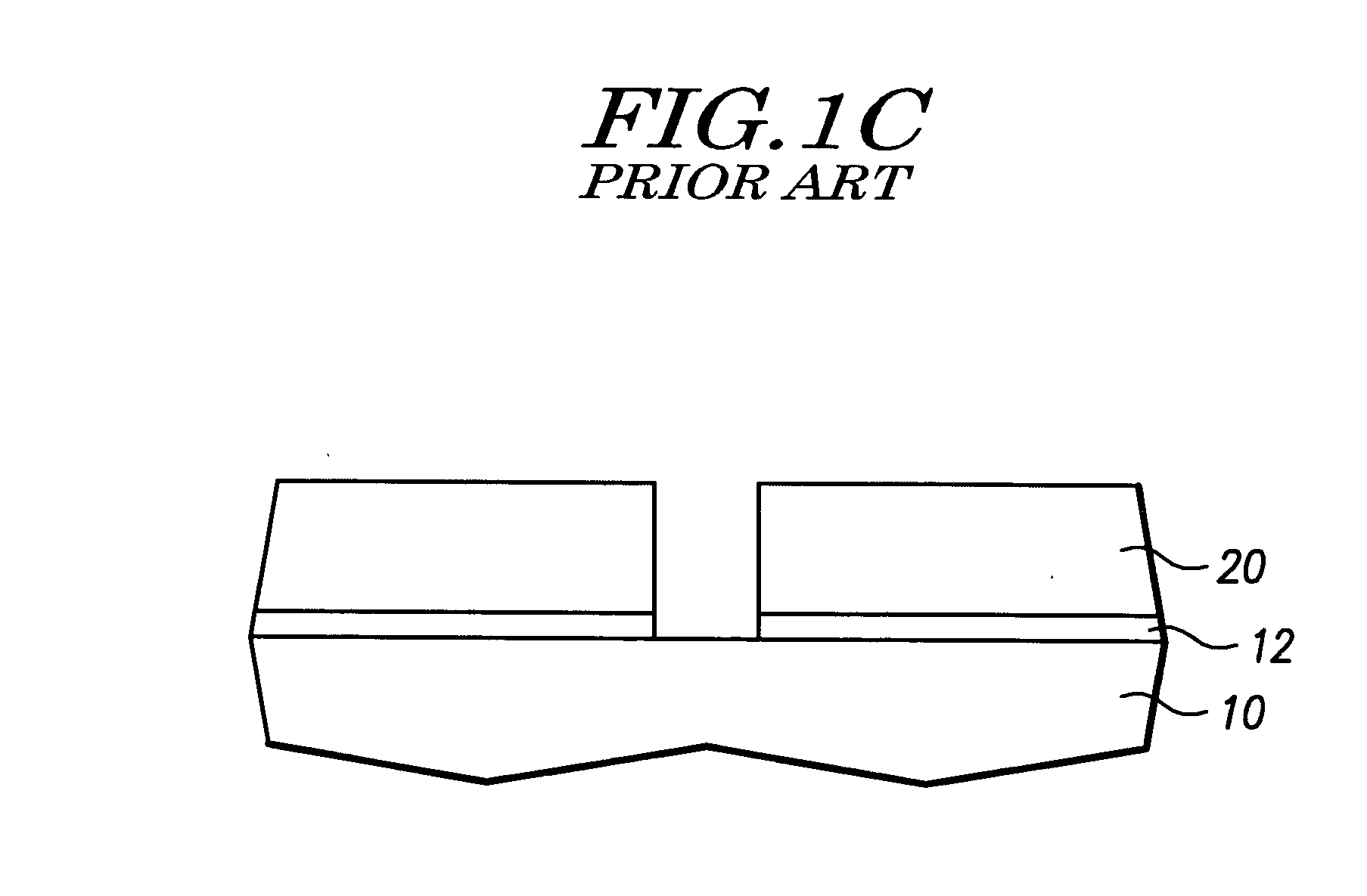

Method for forming via-hole in semiconductor device

InactiveUS20060276031A1Easy to fillReduce processing timeSemiconductor/solid-state device detailsSolid-state devicesResistPresent method

Disclosed is a method for forming a via-hole for interconnection of metallization and / or metal wires in a semiconductor device. The present method may include the steps of: (a) forming an insulating layer on a semiconductor substrate including a lower metallization and / or metal wiring; (b) forming a mask (e.g., a photo-resist pattern) on the insulating layer; (c) dry etching the insulating layer using the photo-resist pattern as a mask to form a via-hole in the insulating layer; and (d) in the same dry etching chamber, etching a top portion of the insulating layer in the vicinity of the via-hole with an etchant comprising oxygen and argon.

Owner:DONGBU ELECTRONICS CO LTD

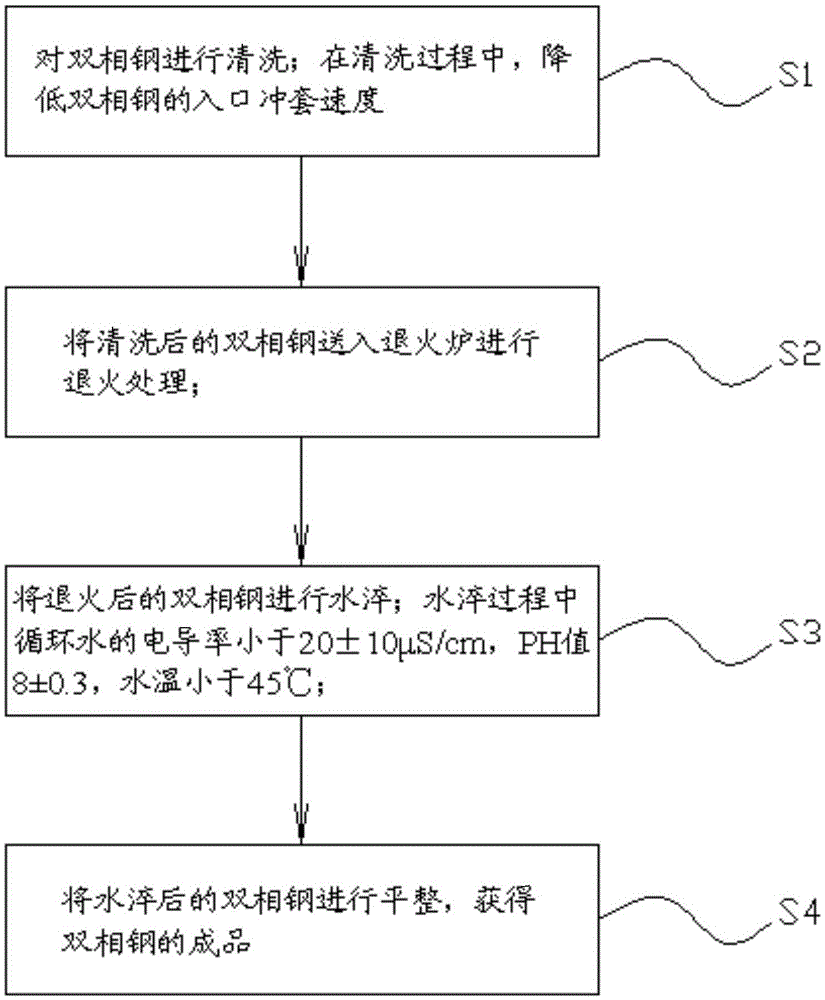

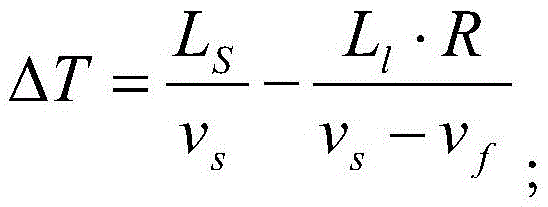

Method for controlling oxide color of dual-phase steel in cold rolling continuous annealing procedure

ActiveCN105648178AExtend cleaning timeImprovement of oxidation color defectsQuenching agentsTemperature controlPunching

The invention relates to a method for controlling the oxide color of dual-phase steel in the cold rolling continuous annealing procedure. The method comprises the following steps that the dual-phase steel is cleaned; in the cleaning process, the inlet punching speed of the dual-phase steel is reduced; the cleaned dual-phase steel is fed into an annealing furnace for annealing treatment; the annealing furnace comprises a heating segment, a soaking segment, a slow cooling segment, a quick cooling segment, an overaging segment and a final cooling segment, and the initial temperature set value of the heating segment is lower than the target value by 5 DEG C-10 DEG C; the temperature of the final cooling segment is controlled to range from 100 DEG C to 130 DEG C; the annealed dual-phase steel is subjected to water quenching; in the water quenching process, the electric conductivity of circulating water is smaller than 20+ / -10 microseconds / cm, the PH value is 8+ / -0.3, and the water temperature is smaller than 45 DEG C; and the dual-phase steel subjected to water quenching is leveled, and a finished product of the dual-phase steel is obtained. According to the method for controlling the oxide color of the dual-phase steel, the defect of the oxide color on the surface of the dual-phase steel is remarkably reduced in the continuous annealing process.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

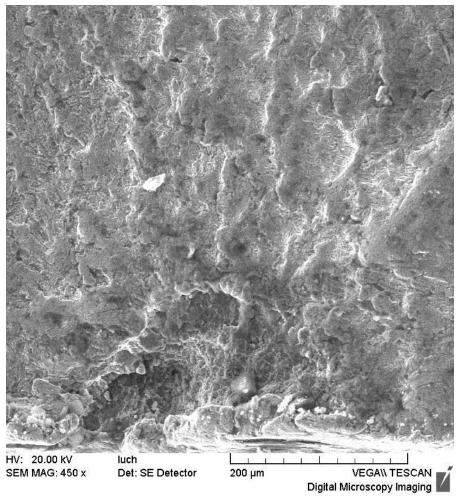

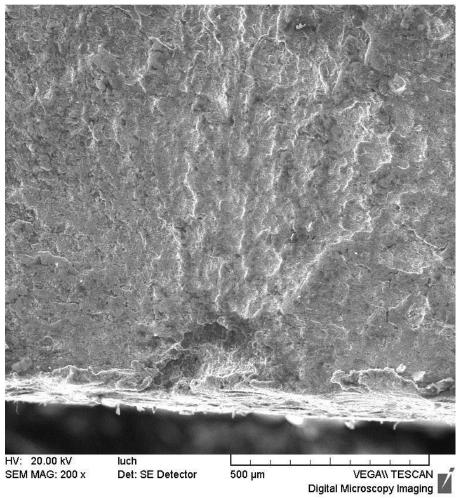

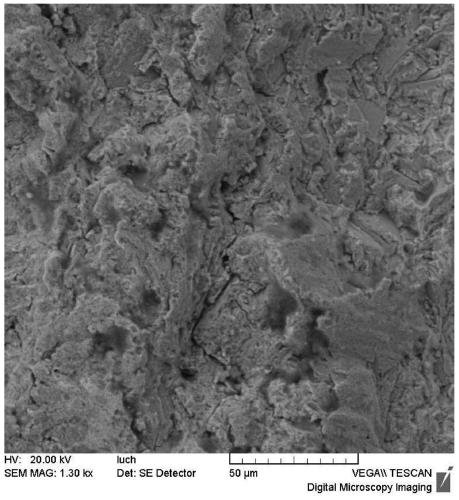

Failure fracture cleaning method and solution for cleaning

The invention discloses a failure fracture cleaning method and solution for cleaning. Sediments and loose covering matters on the surfaces of fractures are cleaned; the fractures are ultrasonically cleaned to remove the covering matters and oil stains on the surfaces of the fractures; the surfaces of the fractures are coated by colloidal solution prepared by acetone and cellulose acetate; after the coated layers are totally dried, the coated layers are stripped, and the operation is repeated by multiple times to finish cleaning of the fractures; and the fractures are cleaned by adopting cleaning solution prepared through adding of water in hydrochloric acid and urotropine. The fracture cleaning formula is simple in preparation, low in cost and mild in cleaning effect, is used by combiningwith a step-by-step cleaning method by multiple times to preferably remove corrosion products for corrosion failure of the surfaces of the fractures by carbon steel materials, and meanwhile, is lowerin damage of the fractures.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

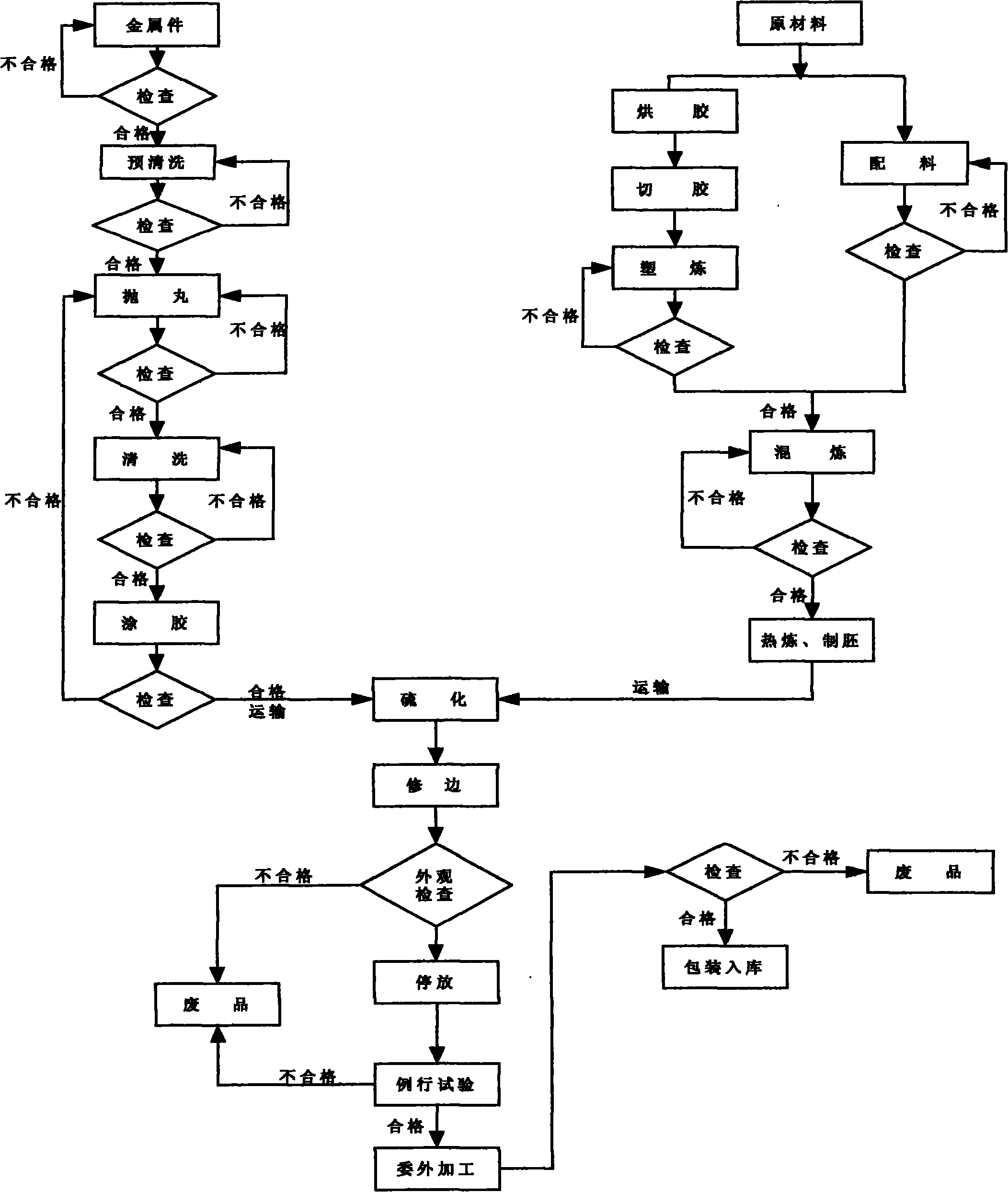

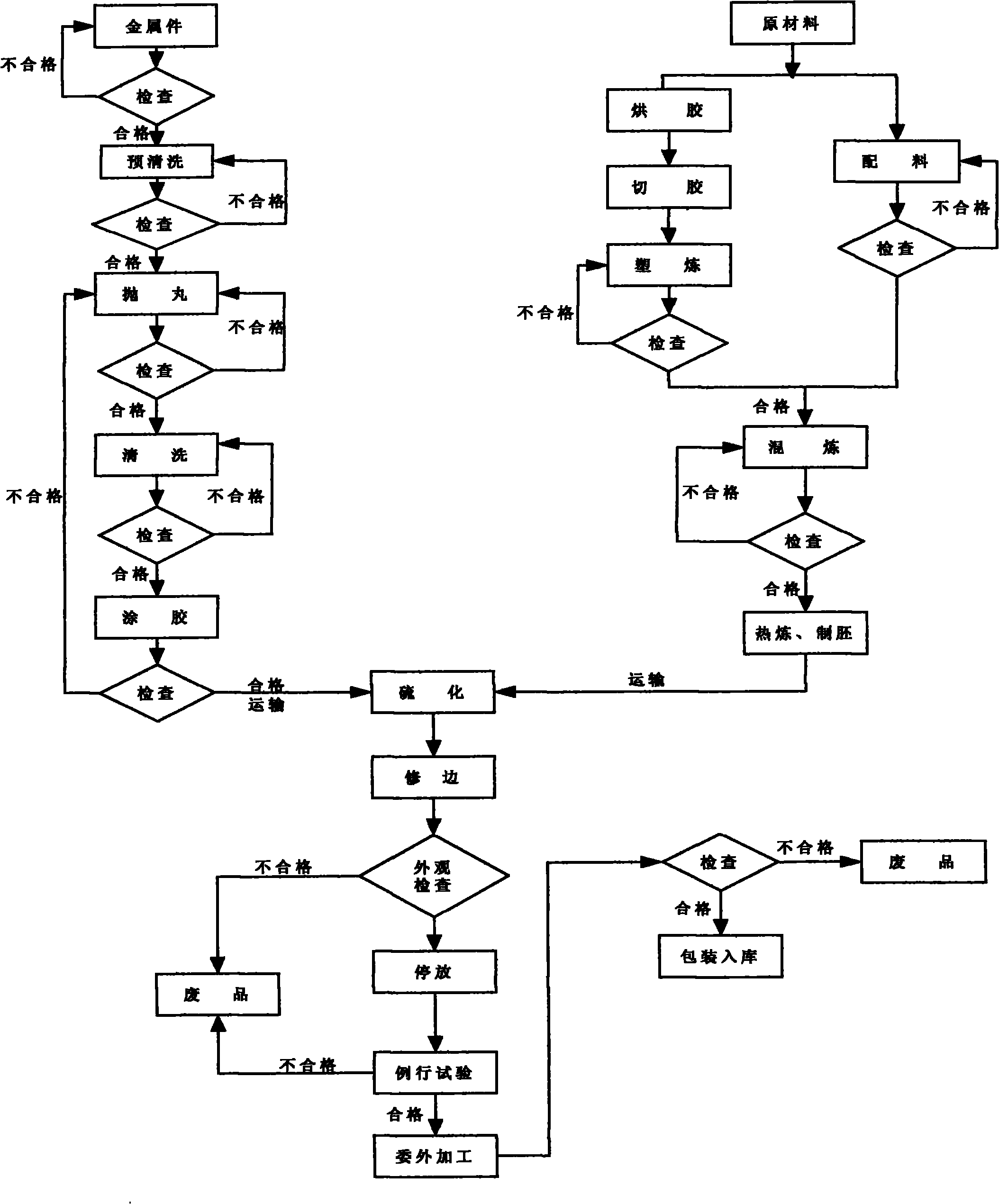

Manufacturing technology of air spring rubber stack

ActiveCN102022469AGood surface roughnessImprove adhesionSpringsGas based dampersAir suspensionMegasonic cleaning

The invention relates to a manufacturing technology of an air spring rubber stack, which comprises the pretreatment technology of a metal piece, the preparation technology of rubber material and the vulcanization technology. In the pretreatment technology of the metal piece, the pre-cleaning process step is added, so that grease on the surface of the metal piece can be removed better; the shot blasting process step can ensure better surface roughness of the metal piece, and can simultaneously improve the bonding force between an adhesive and a framework and the strength of a metal framework; the ultrasonic washing can further remove the grease on the surface of the metal framework and dust taken in during the shot blasting process, raise the temperature of ultrasonic washing liquor and prolong cleaning time appropriately, and further reach the better cleaning effect. The selection of parameters of the vulcanization technology can directly affect the matching between the adhesive and the rubber reaction speed and the formation of a cross bond between rubber and the adhesive, and products with good adhesive bonding effect can be obtained through the parameters selected by the invention.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

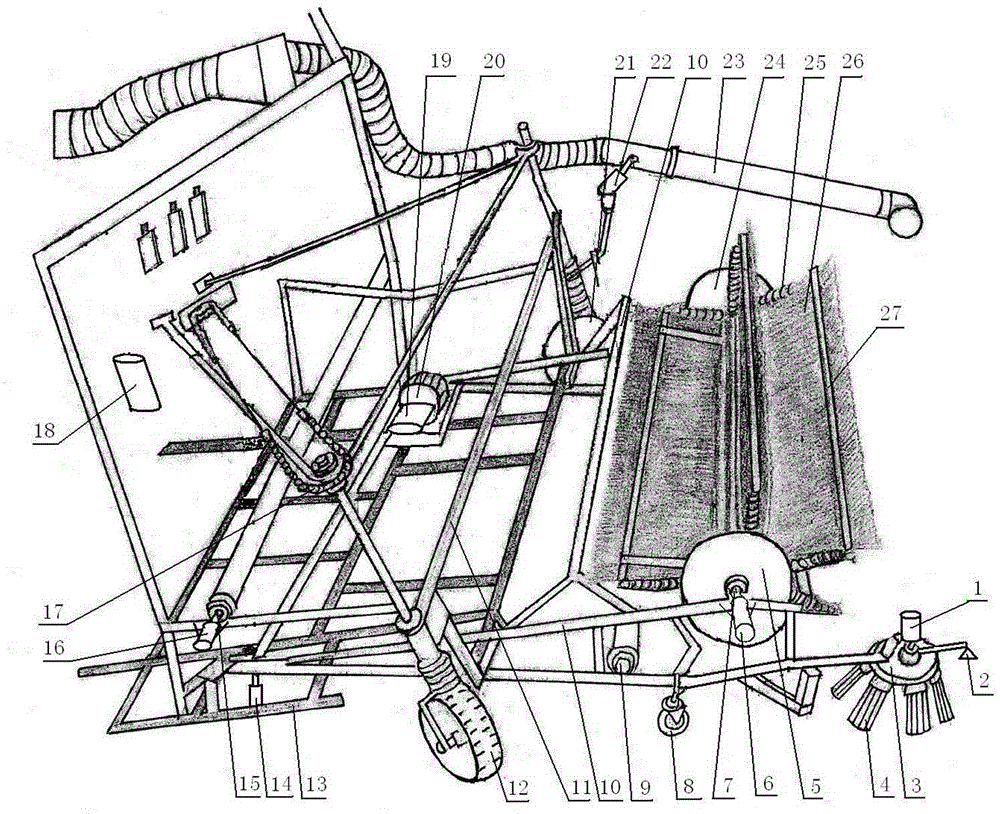

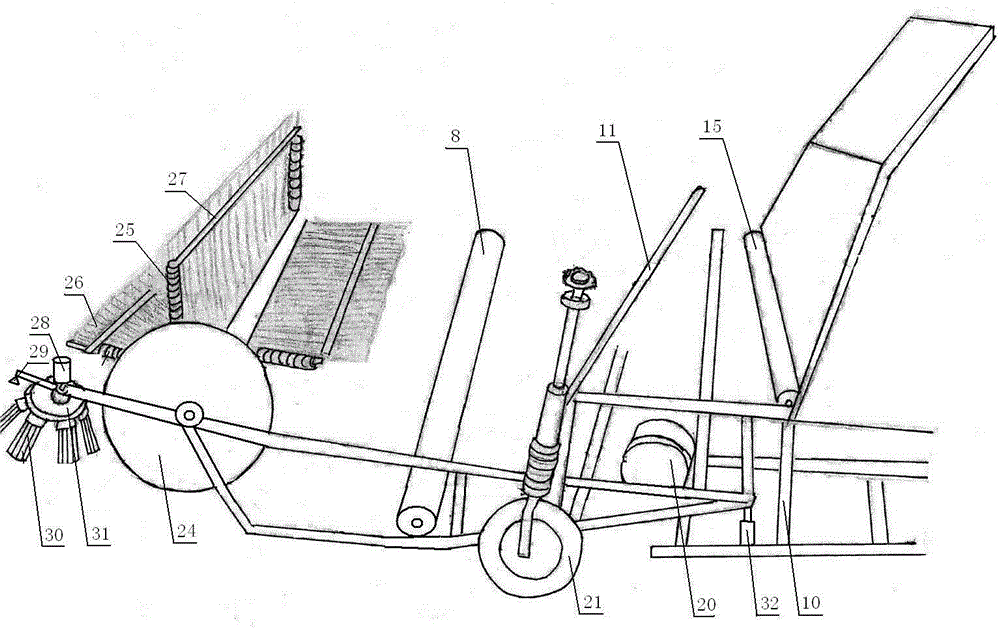

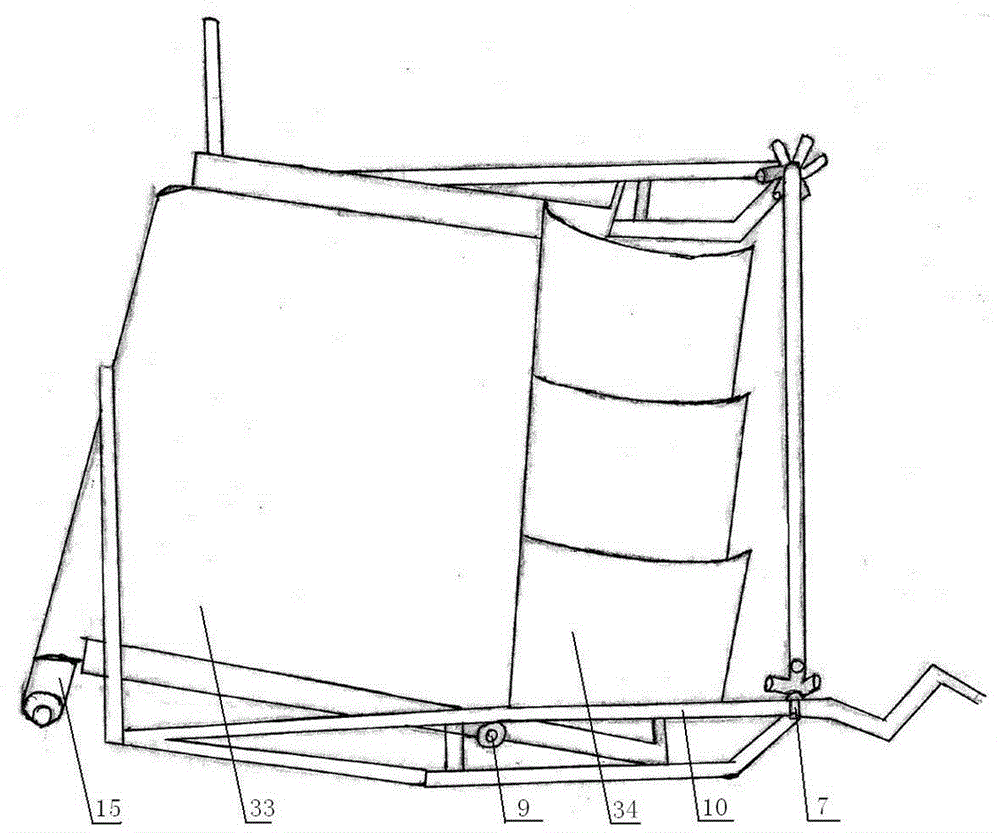

Delivery and sundries collecting device for fruit and vegetable cleaning machine

The invention discloses a propelling movement and foreign material gathering unit for fruit and vegetable cleaning machine, which mainly comprises a roller holder, a drum-type foreign matter collection tube including a hollow steel pipe and a filter screen enclosed on the outboard of the hollow steel pipe, during the use procedure, the apparatus is placed transversely on a wash tank, when washing fruits and vegetables, the garbage floating on the water surface is adhered onto the rotating drum filter screen, when the filter screen rotates to a finite altitude, the garbage falls onto the foreign matter gathering sheet positioned in the drum at the action of gravity, and can be removed from the drum manually.

Owner:ZHEJIANG UNIV

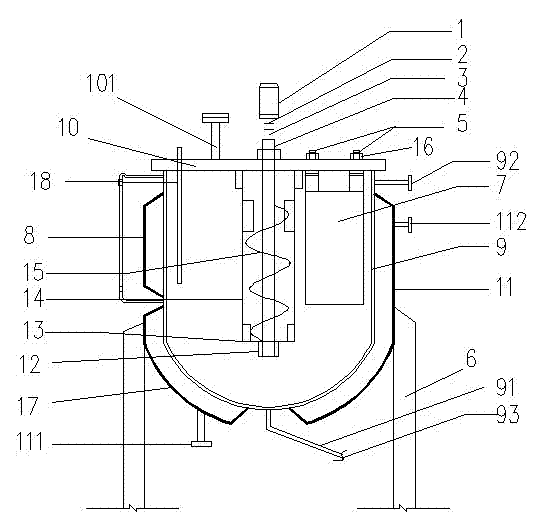

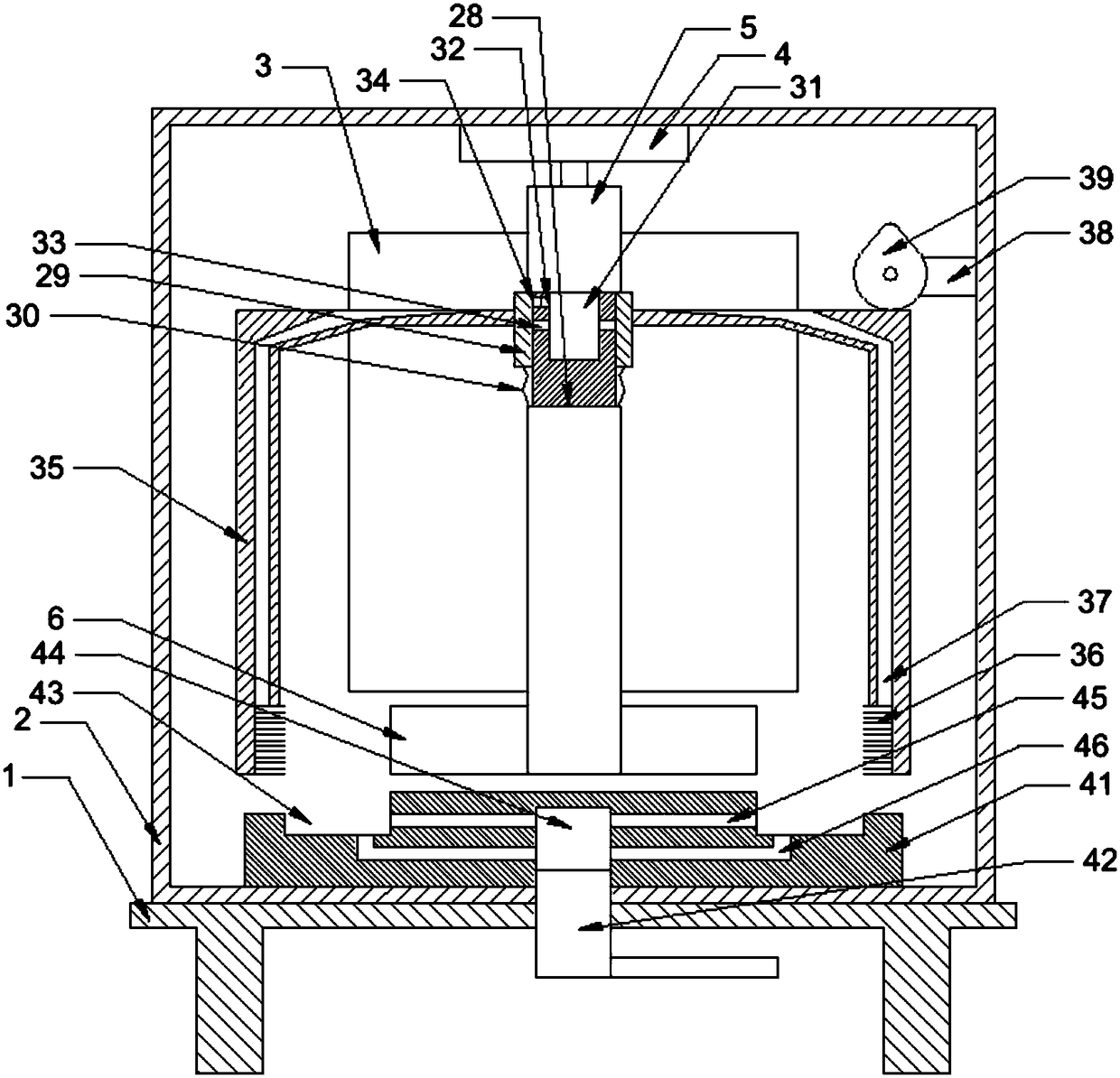

Stirring fluorination electrolytic cell

ActiveCN103243341AUniform solubilityUniform dispersionCellsElectrolytic organic productionCouplingMaterial consumption

The invention discloses a stirring fluorination electrolytic cell which comprises a motor, a coupling, a stirring shaft, a shaft seal, an electrode mast, an electrode beam, an electrolytic cell, an electrolytic cell cover plate, an electrolytic cell jacket, a sleeve pipe, a blind plate, a guide drum, a stirring paddle and an insulating gasket. According to the invention, materials are dissolved and dispersed uniformly in the whole system, fluoridation is carried out in the electrolytic cell simultaneously, the reaction induction period is reduced to one day from 3-5 days, a cell blocking phenomenon is eliminated by and large, the frequency of cleaning the cell by treating cell blocking is reduced, the cell blocking phenomenon occurs 3-4 times per year in the prior art when the stirring cell is not used while the cell blocking phenomenon is avoided when the stirring cell provided by the invention is used, the material consumption is reduced by over 20%, the capacity in unit cell is improved by 30%, polymers generated in the electrolytic cell are reduced, the cell cleaning period is prolonged by one time, and the labor intensity in manually cleaning the cell is reduced.

Owner:湖北诺邦科技股份有限公司

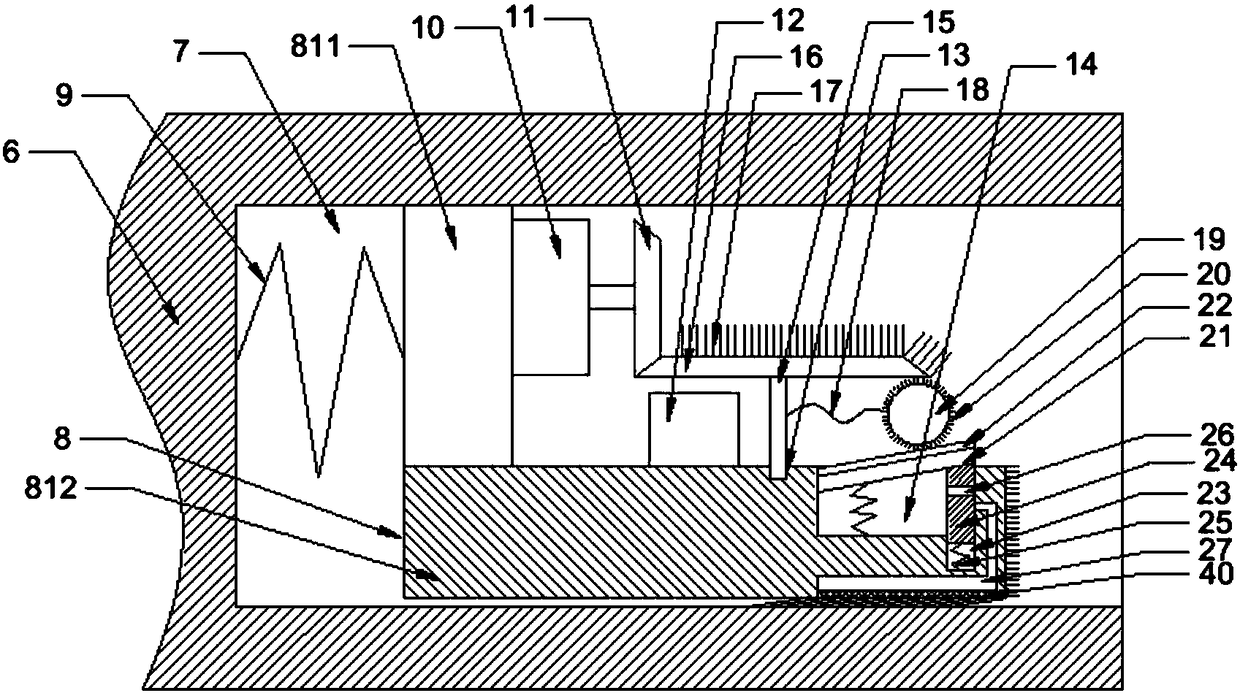

Waste tire cleaning system

ActiveCN108297305AImprove the limit effectPlay the role of storagePlastic recyclingCleaning using toolsTransverse grooveWaste tires

The invention discloses a waste tire cleaning system. The waste tire cleaning system comprises a bracket, wherein the bracket is provided with a box body. A first motor is arranged on the inner top portion of the box body, and a rotating shaft of the first motor is provided with a plurality of side rods in the circumferential direction. A transverse groove is formed in each of the side rods, an L-shaped block is slidably connected in the transverse groove, and a first spring is arranged between the L-shaped block and the transverse groove. The L-shaped block is provided with an upper cleaningmechanism for cleaning the top portion of the interior of a waste tire, and a side cleaning mechanism for cleaning the side wall of the interior of the waste tire and a lower cleaning mechanism for cleaning the bottom portion of the interior of the waste tire. A positioning mechanism for the waste tire is arranged on the inner bottom of the box body. The waste tire cleaning system mainly solves the problem of inconvenient cleaning of the interior of the waste tire.

Owner:重庆九橡化大橡胶科技有限责任公司

Mud scraping and cleaning device for well logging cable

ActiveCN110420902AGuaranteed fitClean up in timeDrying gas arrangementsCleaning using toolsWell loggingEngineering

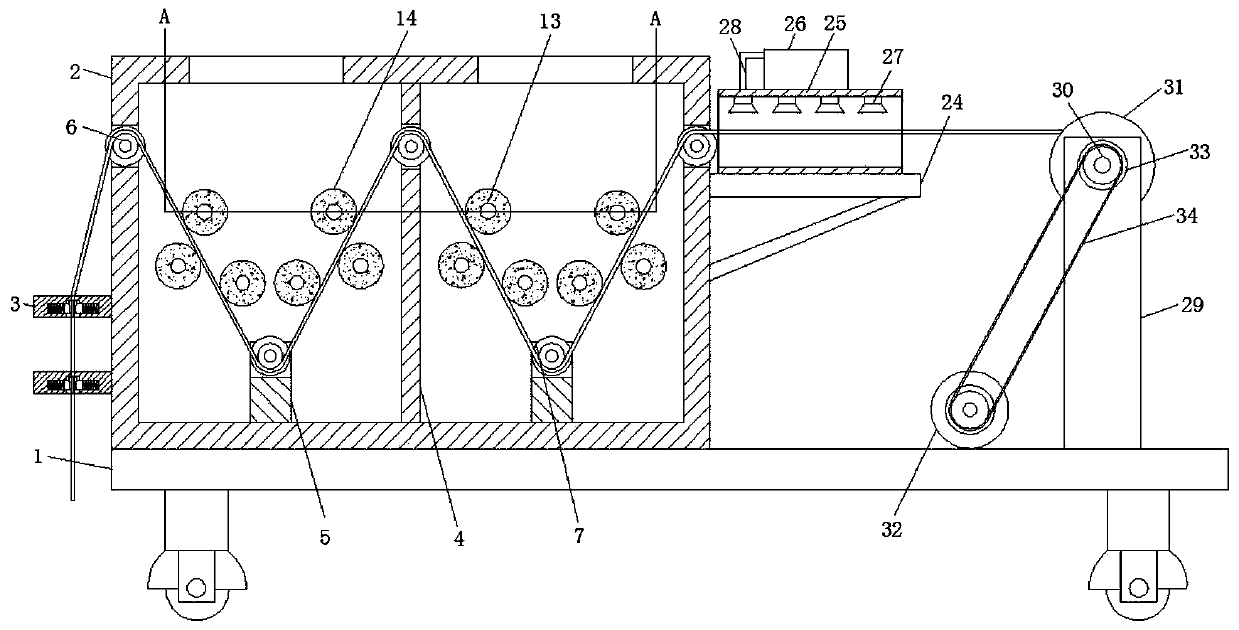

The invention discloses a mud scraping and cleaning device for a well logging cable. The device comprises a worktable, supporting legs are fixed at the four corners of the lower end surface of the worktable through screws, universal wheels are arranged at the lower ends of the supporting legs, a cleaning box body is fixed on one side of the upper end of the worktable through a screw, mud scrapingdevices are arranged on the side wall of the end, away from the worktable, of the cleaning box body, two mud scraping devices are provided, the middle part of the inner wall of the cleaning box body is fixedly provided with a sealing plate through glue, mounting plates are fixedly connected to the two sides of the inner bottom surface of the cleaning box body through screws, mounting grooves are formed in the upper ends of the mounting plates, the upper end of the sealing plate and the upper ends of the two side walls of the cleaning box body, mounting shafts are rotationally connected betweenthe front and rear end side walls of the mounting grooves through rolling bearings, guide wheels are fixedly connected to the outer walls of rod bodies of the mounting shafts through screws, fixing blocks are fixedly connected to the side walls of the front end of the cleaning box body through screws; and mounting blocks I are arranged on the upper end surfaces of the fixing blocks.

Owner:ANHUI TIANMING CABLE

Fluorine-free sodium-free ladle covering agent

InactiveCN102794419AImprove flux effectAvoid Pollution HazardsProcess efficiency improvementFluorine freeCarbon black

The invention relates to the technical fields of steel smelting and ladle metallurgy, particularly a fluorine-free sodium-free ladle covering agent. The invention aims to provide a fluorine-free sodium-free ladle covering agent which has the characteristics of strong basicity, strong reducibility, high absorption and inclusion capacity, favorable spreadability and excellent heat-insulating property; and the invention also aims to solve the problems of high melting point, low melting speed, low desulphurization capacity and poor use effect in the existing CaO ladle covering agent, and to overcome the defect of contamination hazard since the covering agent contains sodium oxide, calcium fluoride and the like. The invention is characterized in that the covering agent is prepared from the following components in percentage by weight: 40-80% of spodumene, 10-40% of lime, 2-15% of magnesite and 1-10% of carbon black.

Owner:JIANGSU UNIV

Energy-saving environmentally-friendly garbage sweeper

The invention provides an energy-saving environmentally-friendly garbage sweeper. The garbage sweeper is characterized in that a sweeping frame is arranged on a sweeper body chassis in the front of a cab, a transverse sweeping brush is arranged at the front end of the sweeping frame, edge brushes rotating inwards are arranged on the portions, on the two sides of the transverse sweeping brush, of the sweeping frame respectively, and a washboard is arranged on the portion, below the transverse sweeping brush, of the sweeping frame. A conveying belt is arranged on the portion, behind the washboard, of the sweeping frame. A motor on the sweeping frame drives a transverse shaft hydraulic motor at the transverse shaft end, edge brush hydraulic motors on the two edge brushes and a conveying belt hydraulic motor on the conveying belt through a hydraulic pump. A garbage collection box is arranged below the rear portion of the conveying belt. A dust sucking device is arranged on the rear portion of a sweeper body. Compared with a traditional vacuum sweeper, by means of the energy-saving environmentally-friendly garbage sweeper, garbage on roads can be swept thoroughly, energy is saved, the environment is protected, and the sweeper is easy to operate and low in manufacturing and use cost.

Owner:王天君

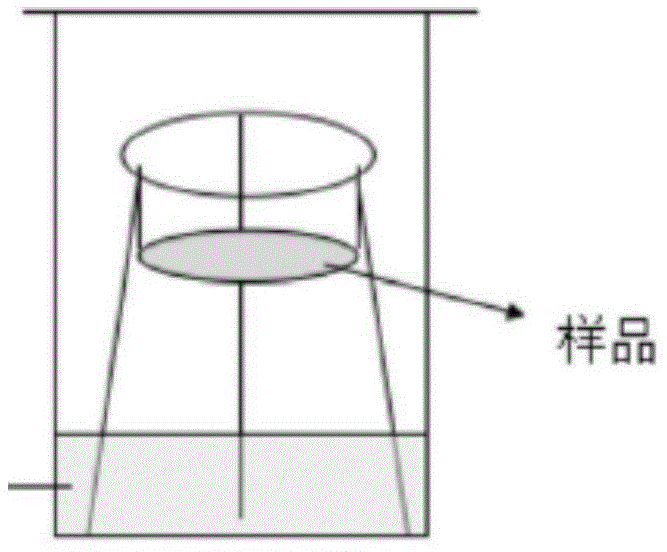

An etching machine and a method for cleaning crystals of the etching machine

InactiveCN104124147AExtend cleaning timeIncrease the number of timesSemiconductor/solid-state device manufacturingFlexible article cleaningEngineeringElectrical and Electronics engineering

The invention provides an etching machine and a method for cleaning crystals of the etching machine. The etching machine comprises an etching chamber which comprises an entrance and an exit; a liquid medicine tank which is located in the etching chamber and which contains liquid medicine; and a concentration controller which comprises a water-replenishing pipeline. A substrate is entered from the entrance of the etching chamber and is transported to the exit of the etching chamber; the substrate makes contact with liquid medicine in the liquid medicine tank in the etching chamber during the transport process; and the water-replenishing pipeline can inject water to the liquid medicine tank through the exit, and the water from the water-replenishing pipeline can adjust the concentration of the liquid medicine in the liquid medicine tank, and can clean the liquid medicine crystals at the exit. According to the etching machine and the method for cleaning the crystals of the etching machine, the easy-to-crystallize place, such as the exit, where an air curtain is formed, of the etching machine can be cleaned at the same time the water is added, thereby increasing the cleaning time and frequency of the easy-to-crystallize place, reducing the generation probability of the crystals effectively, and improving the qualified rate of the products.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

No-rinse pipe type membrane assembly for water treatment

PendingCN108579441AEasy to produceQuality is not easy to controlSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUnit massVolumetric Mass Density

The invention provides a no-rinse pipe type membrane assembly for water treatment and relates to a no-rinse pipe type membrane assembly for water treatment. The invention aims to solve the problems that the existing inlet no-rinse DF membrane has large diameter and thick wall, the membrane prepared from raw materials with unit mass has small filtering area, low membrane silk filling density, low membrane porosity and high operation pressure, and the energy consumption is increased. The no-rinse pipe type membrane assembly for water treatment consists of a sealing head, a membrane pipe and a metal hoop; the sealing head consists of a water flow port, a sealing head screw cap and a sealing ring; and the membrane pipe consists of a plurality of core pipes, a sealing head screw cylinder, a clean water port, a membrane shell cylinder and pipe type membrane silk. The DF membrane assembly at the inlet can be replaced, and application in the fields of waste water treatment and recycling as well as material separation and concentration instead of the traditional settling pool or filtering pool.

Owner:HEILONGJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com